ApplicationsNovember 12, 2019

More than 30 solar sites on one SCADA platform

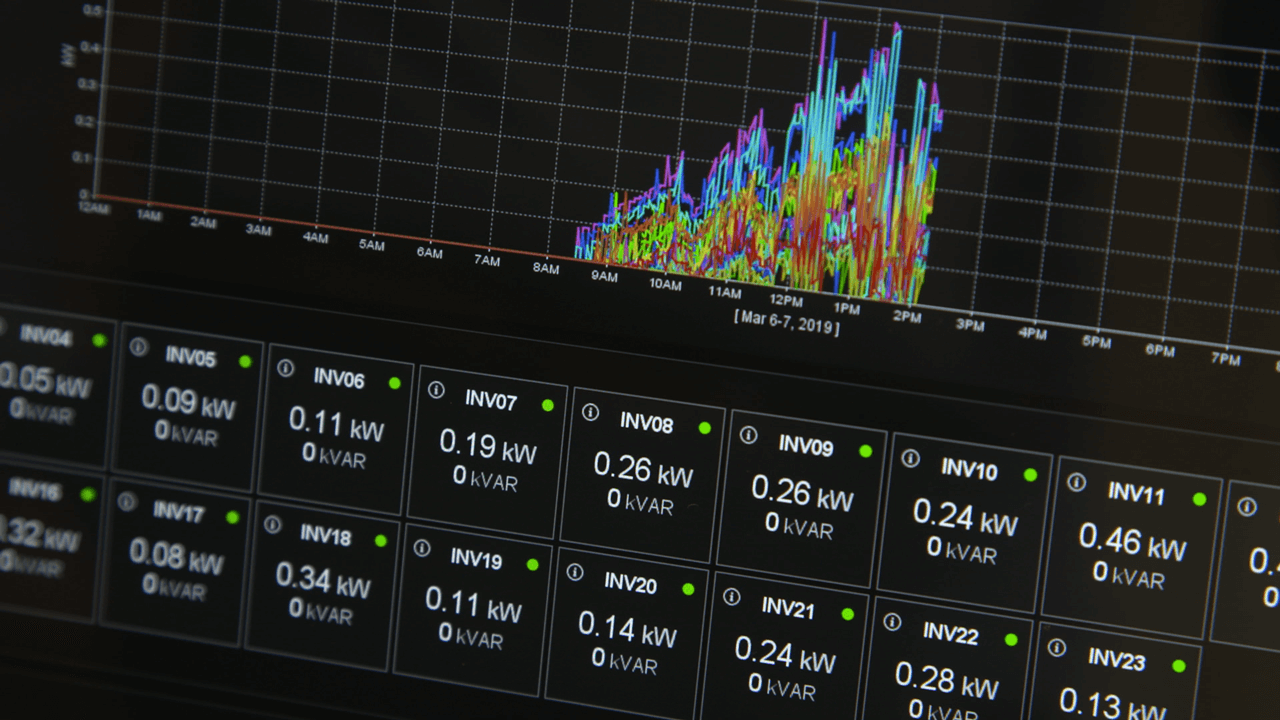

New SCADA system developed at Ecoplexus provides better data access, improved efficiency, and lower costs. The company also now has a consistent "look and feel" for all its solar sites—in addition to lower costs, greater efficiency, more data, and improved data analysis.

Solar power is great for our planet. But it’s not always as simple as one might think. For example, what if you’re trying to manage more than 30 solar sites, all with different control systems and equipment? Ecoplexus, a leader in renewable energy, was in just that situation. But the company was committed to getting all its systems onto one platform. With the help of system integrator NLS Engineering, Ecoplexus was able to accomplish its goal. Now, the company has a consistent look and feel for all its sites—in addition to lower costs, greater efficiency, more data, and improved data analysis.

Ecoplexus provides a range of professional services for all stages from development to ownership. It has offices in the United States, Mexico, Japan, South Korea, and Vietnam, and its sites produce 365 MW of power. Another 420 MW are in construction or backlogged. Projects in development could add another 3,600 MW.

NLS Engineering has completed more than 1.5 GW of utility solar SCADA design, programming, and commissioning in the United States and Canada. The company focuses on supervisory control and data acquisition (SCADA) for renewable energy.

Ecoplexus needed a standardized, customizable SCADA system that could handle large solar and energy projects while also providing deep data acquisition and analysis. The company had a fairly tight timeline for bringing existing sites onto the single system, and it also needed the kind of data access that would appeal to potential buyers of its sites.

NLS provided all this and more with Ignition by Inductive Automation. Ignition is an industrial application platform with tools for building solutions in SCADA, human-machine interface (HMI), and the Industrial Internet of Things (IIoT).

“We have around 35 systems around the country,” said John Morrison, senior vice president for U.S. operations for Ecoplexus. “We needed a way to monitor and operate those sites remotely, and Ignition is the tool that we use to do that. We just have to have data that other systems don’t provide. We’ve had previous data acquisition systems, but they didn’t give us the visibility we needed with the richness and robustness of the data necessary to really operate these farms well.”

Ecoplexus has 35 systems in operation, and needed a way to monitor and operate those sites remotely.

Unlimited licensing saves money

NLS Engineering brought in Ignition in part because of the software’s unlimited licensing model; there are no extra costs for additional sites, tags, users, devices, or projects. And the software was easy to integrate with numerous disconnected sites.

“Before the project, Ecoplexus had various data systems from a wide variety of vendors,” said Michael Crawford, vice president of operations at NLS Engineering. “There was no consistency or standardization from an operations platform, and their ability to produce financial and performance metrics for prospective asset buyers was limited. Ignition was a perfect fit for this project in every way. The unlimited licensing model removed all the cost barriers, and the underlying technology platform made it really easy for us to customize the system to their exact needs.”

The Ecoplexus portfolio had included an assortment of data acquisition system (DAS) providers. Standardization had not been possible, and the systems were not designed for a large-scale solar enterprise. The systems didn’t have control capabilities and didn’t provide the kind of deep-dive data analysis that Ecoplexus was seeking. For potential buyers, more site-performance data was needed. Financial analysis was also a must. With previous providers, costs for adding control capabilities and greater access to data were prohibitive. Ignition’s unlimited licensing and open architecture proved to be a big improvement on all fronts.

“There are quite a few benefits we’ve recognized since moving over to Ignition,” said Christopher Thomas, solar operations monitoring manager for Ecoplexus. “It allows us to bring all our sites under one solution and provides a level of consistency that is conducive to our performance analytics — and even to our monitoring applications because there is consistency across the sites. So, operators know exactly where to look for items, or for tags, or for analysis.”

“This software seamlessly lends itself to templating and driving consistency and standardization across all assets,” said NLS’ Crawford. However, the software also allowed customization where needed. For example, HMIs were changed to better identify issues that Exoplexus wanted to call out. Also, the team created Investor View, which presents data in a manner more suited to a non-technical public.

Bringing all the sites under one solution provides a level of consistency conducive to performance analytics.

More data = more opportunities

NLS used the software to collect and present data once every second, allowing for a level of analysis that was impossible with the previous system, which only presented data every 15 minutes. And the unlimited licensing means Ecoplexus owns the data from its sites, as opposed to paying recurring monitoring fees for a proprietary system.

“Ecoplexus needs to do financial analysis of all their sites, which is heavily reliant on data,” said McKenzie Santin, associate director of energy at NLS. “In a lot of cases that’s not data they were getting adequately from their previous systems, so we’ve allowed them, through the software, to receive much more data. And they can store it in much higher frequency and store many more data points. And Ignition actually costs far less than their previous solutions. Even though it stores more data, faster — and has more tags — it costs them less than their other solutions.”

The software also presents greater opportunities for new connections. “We’ve been able to integrate artificial intelligence into Ignition much more easily than other systems,” said Santin. “Since the code is much more open, we’re able to pull in data from many different sources. We’re able to use MQTT and a lot more IoT-focused technology.”

Ecoplexus consolidated systems and reduced long-term operating and maintenance costs by a significant amount.

The end result is greater efficiency and lower costs. “This project has been really good for Ecoplexus,” said Santin. “It’s allowed them to consolidate their many different systems and it’s actually reduced their long-term O&M costs by a very significant amount.”

NLS was just as pleased with the results as Ecoplexus. In fact, NLS used this project as a springboard for the creation of a new product, nextDAS, which it can provide to other customers. NextDAS is a powerful O&M platform for projects in solar, wind, and battery storage. It provides key metrics, site dashboards, live and historical data, alarm summaries, device status, weather data, and more. The web-based interface can be accessed from anywhere in the world, with both desktop computers and mobile devices. NextDAS is available from NLS Energy, a U.S.-based subsidiary of NLS Engineering.

“NLS was a really great partner in our implementation of Ignition,” said Morrison. “We had close to 30 existing sites that needed to be converted and needed to be converted fairly quickly. They were able to bring the software up to speed, and then help us get those retrofit sites in place. And as we continue to build sites, we’ll be bringing those new systems in too.”