July/August 2022, Industrial Ethernet Book

The July/August 2022 issue of Industrial Ethernet Book provides coverage of Industrial Edge and Cloud Computing, and a showcase of EtherNet/IP networking solutions.

Industrial Edge computing offers a distributed computing framework that is bringing factory and enterprise applications closer to data sources such as IoT devices or local edge servers. This proximity to data at its source can deliver strong business benefits: faster insights, improved response times and better bandwidth availability.

Industrial Edge computing offers a distributed computing framework that is bringing factory and enterprise applications closer to data sources such as IoT devices or local edge servers. This proximity to data at its source can deliver strong business benefits: faster insights, improved response times and better bandwidth availability.

In our special report on Industrial Edge, the Industrial Ethernet Book reached out to industry experts to gain their insights into the rise of the Industrial Edge and particularly its impact on the IIoT.

Browse this page for a synopsis and links to the key articles in this issue of IEB.

The rising role of Industrial Edge Computing in the IIoT

In this 2022 special report, industry experts provide their perspective on the role of the Industrial Edge in the IIoT. With edge computing processing data where it’s generated, using solutions that connect the physical and digital worlds, plants are leveraging data to optimize workflows, save resources and improve quality.

Read article

EtherNet/IP focus on digitization and process industry applications

EtherNet/IP™ is a best-in-class Ethernet communication network that provides users with tools to deploy standard Ethernet technology (IEEE 802.3 combined with the TCP/IP Suite) in industrial automation applications while enabling Internet and enterprise connectivity.

Read article

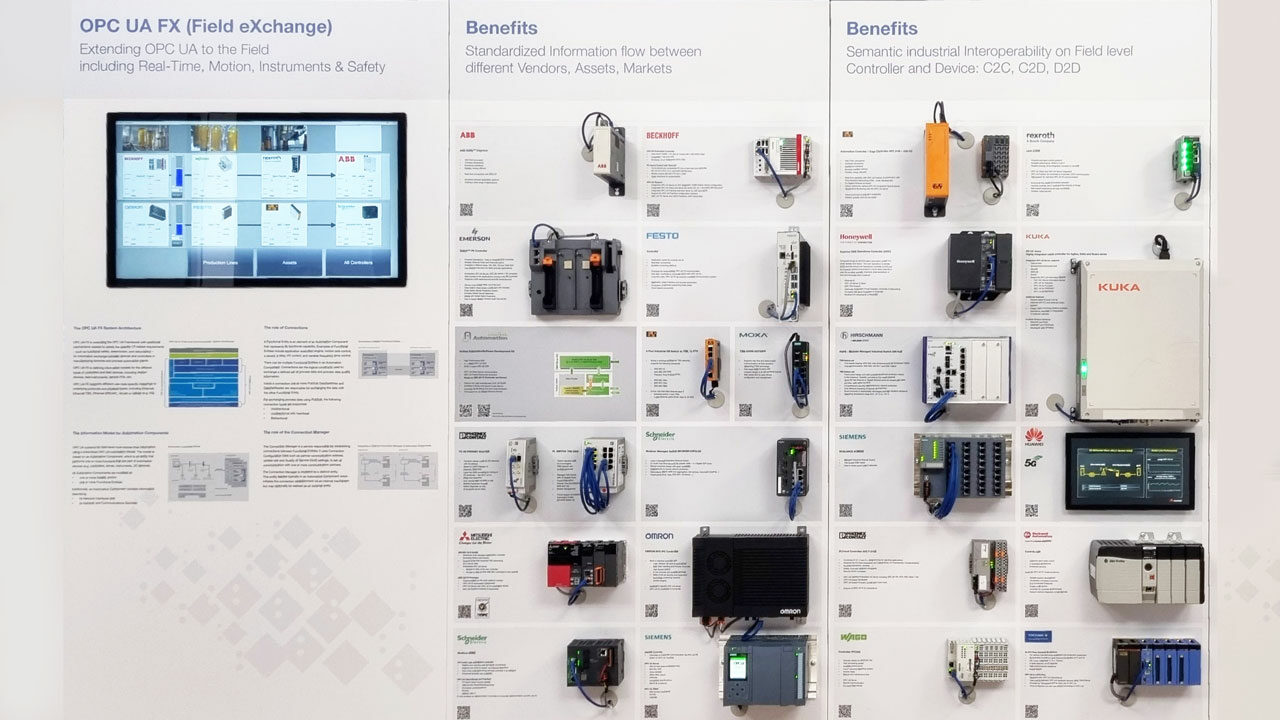

OPC UA FX (Field eXchange) for the Field Level

OPC UA is establishing itself as an industrial interoperability standard not only for the vertical integration from the control level to the edge or up to the cloud, but also as an interface for exchanging process data between controllers regardless of which protocol communicates with underlying field devices.

Read article

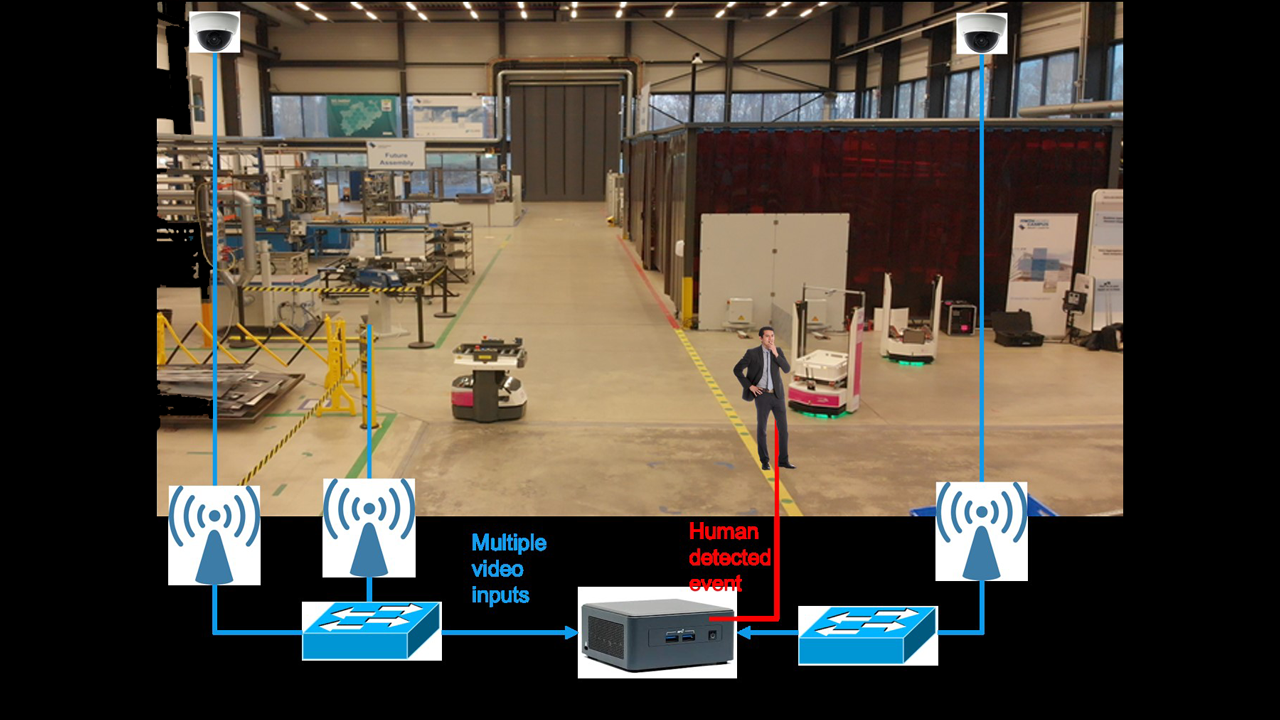

Edge computing for easily implementing IoT applications

Intelligent IoT edge solutions can close the gap between the IT and OT worlds. With preinstalled software packages as well as universal graphical user interfaces and programming environments, powerful Edge PC hardware are enabling simple development and implementation of edge applications.

Read article

How Wi-Fi 6/6E enables Industry 4.0

A Wireless Broadband Alliance (WBA) report explores how autonomous Mobile Robots, Automatic Guided Vehicles, Augmented and Virtual Reality use cases can be addressed with Industrial Internet of Things deployment guidelines.

Read article

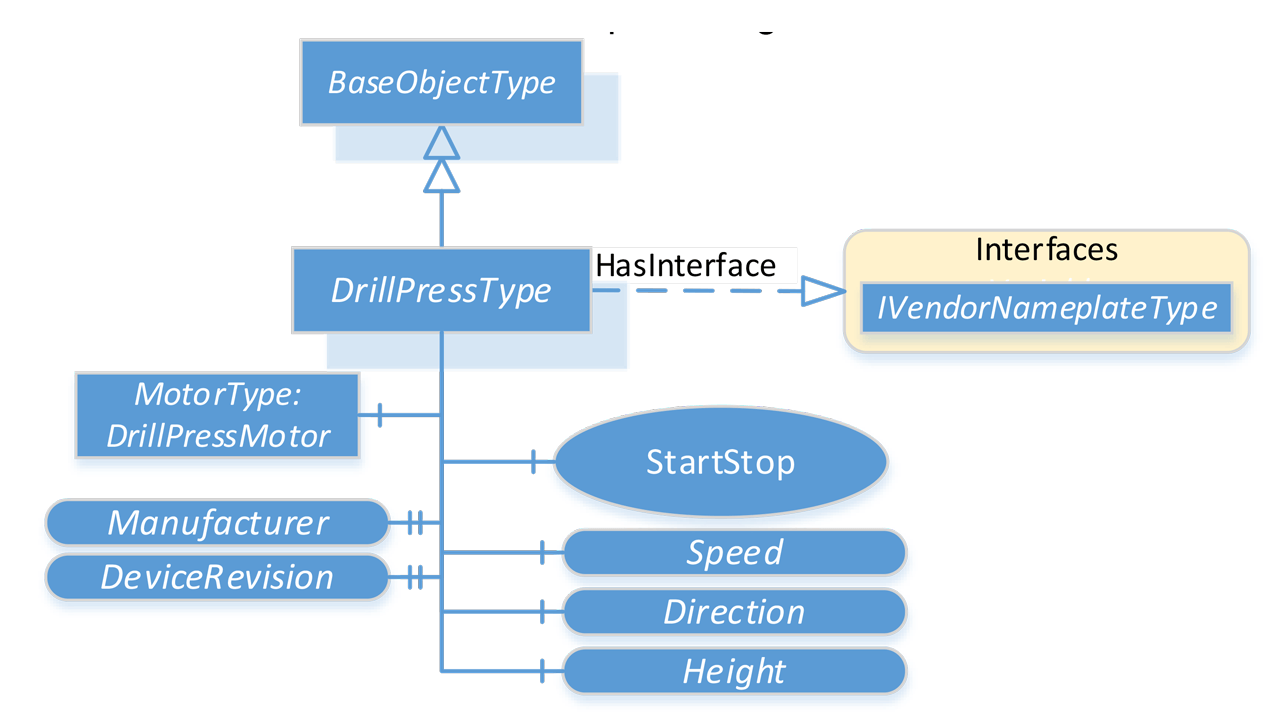

Mapping CIP to OPC UA: companion specification update

The world is abuzz with talk of the next industrial revolution, Industry 4.0. Digitization, smart technologies, machine-to-machine communications, Internet of Things deployments, the list goes on, and on. All these innovative concepts will benefit from the standardized exchange of information between all levels of an industrial system.

Read article

Intelligence at the Edge: boost productivity and improve costs

As factories strive to boost productivity and improve operational costs, the demand to deliver new technology that empowers intelligence at the Edge is increasing. ”What does the edge mean?” The Edge is where the machine meets or interacts with the real world.

Read article

Secure and smart: Edge computing with SCALANCE LPE

Data is a treasure for every company; the question is how to lift this treasure safely and efficiently? For ROBUR Automation, an industry and application-suitable data preprocessing is key. For this task, ROBUR relies on a local processing engine to provide a new parking experience in the German city of Miltenberg.

Read article

CC-Link IE Network Keeps Power on Track at Euston Station

To ensure reliable and fast inter-substation data transfer, a proven high-bandwidth open network technology was needed for the High Speed Two (HS2) railway line at London’s Euston station.

Read article

Effective Control Systems Key to Launching a Nationwide Equipment Network

ALTA Refrigeration uses automation control technology to achieve faster, easier product development and servicing with groov EPIC and MQTT technologies.

Read article

Process Applications Framework using CIP Technologies

Advanced Physical Layer (Ethernet-APL) is gaining attention due to the opportunity it presents to extend the reach of EtherNet/IP into areas in which Ethernet has not been deployed. However, this is just one of several areas where development is taking place to facilitate the use of EtherNet/IP in process applications.

Read article

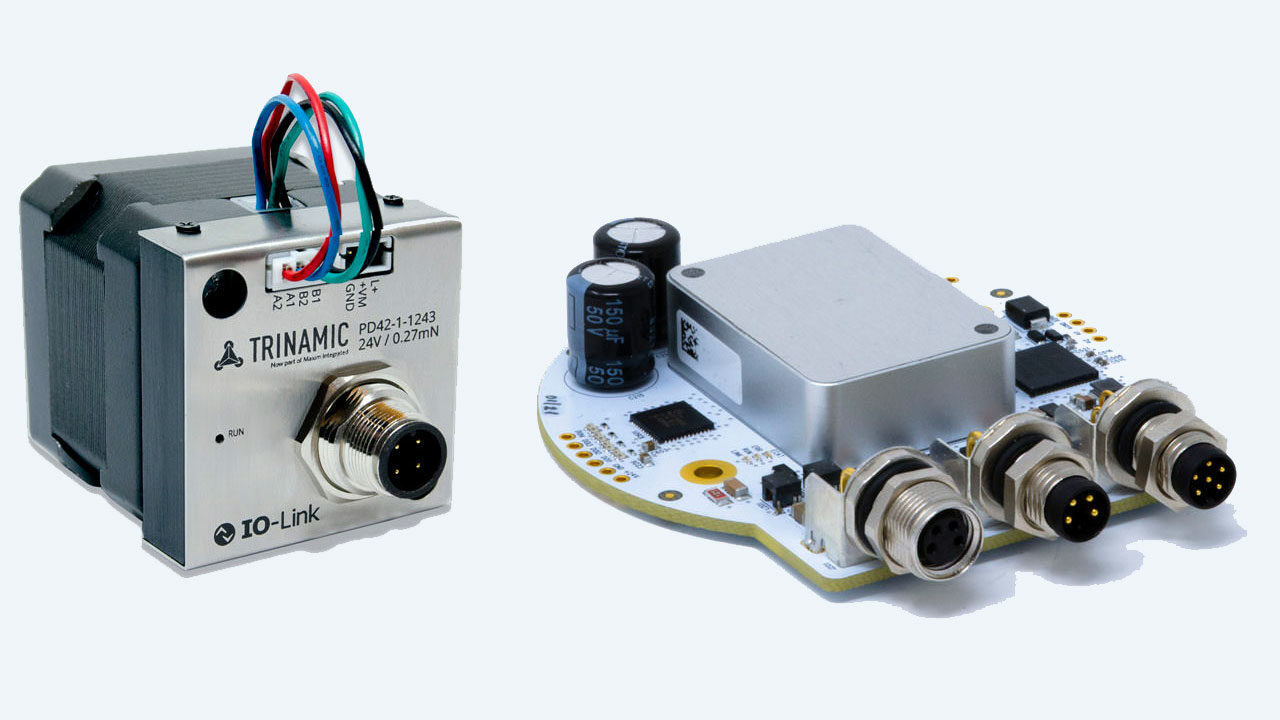

Open control automation technology for “Baumkuchen 4.0” bakery

Ultra-compact Industrial PC and TwinCAT solutions power robot-based cake production, providing flexible EtherCAT technology for the Theo robot which bakes high-quality Baumkuchen.

Read article

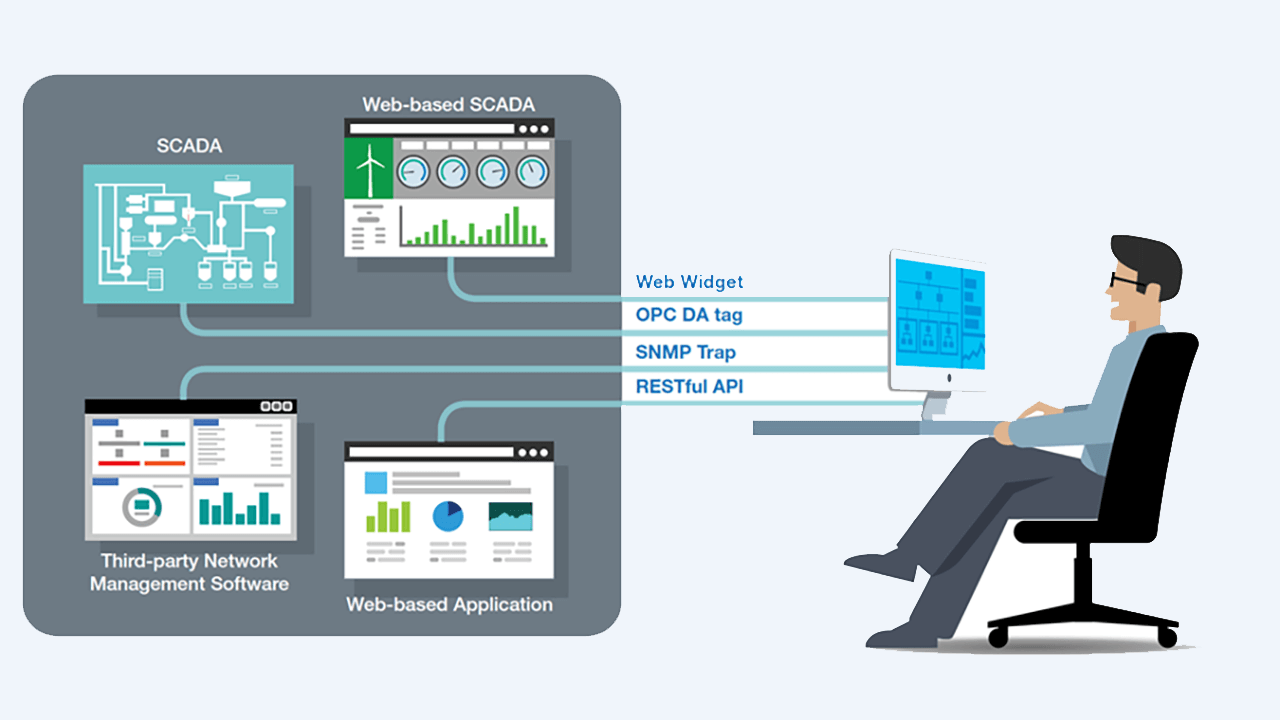

Getting IIoT networks ready for the future

Three keys help create more effective, future-proof IIoT networks. Achieve a greater level of integration by using an unified infrastructure. Create an ability to access remote machines anywhere with hassle-free cloud services. Implement tools for visualizing network status by both OT and IT professionals.

Read article

Standardising data collection in breweries

As the beer industry continues to expand globally, brewing companies that operate across multiple international sites face issues with data management. There is often little consistency in how these sites track data, making it impossible to optimise performance across the brewer’s entire production landscape.

Read article

5 Ways Smart Factory Analytics Bridge Data and Communication Silos

Manufacturing companies across the world are trying to figure out a way to integrate data and simulate it for meaningful decision-making. Complete deployment of smart manufacturing with IIoT and cloud technology has brought the industry to the doorstep of this end-to-end connectivity.

Read article