TechnologyMay 14, 2022

Flexible EtherCAT control technology with fast cycle times increases efficiency

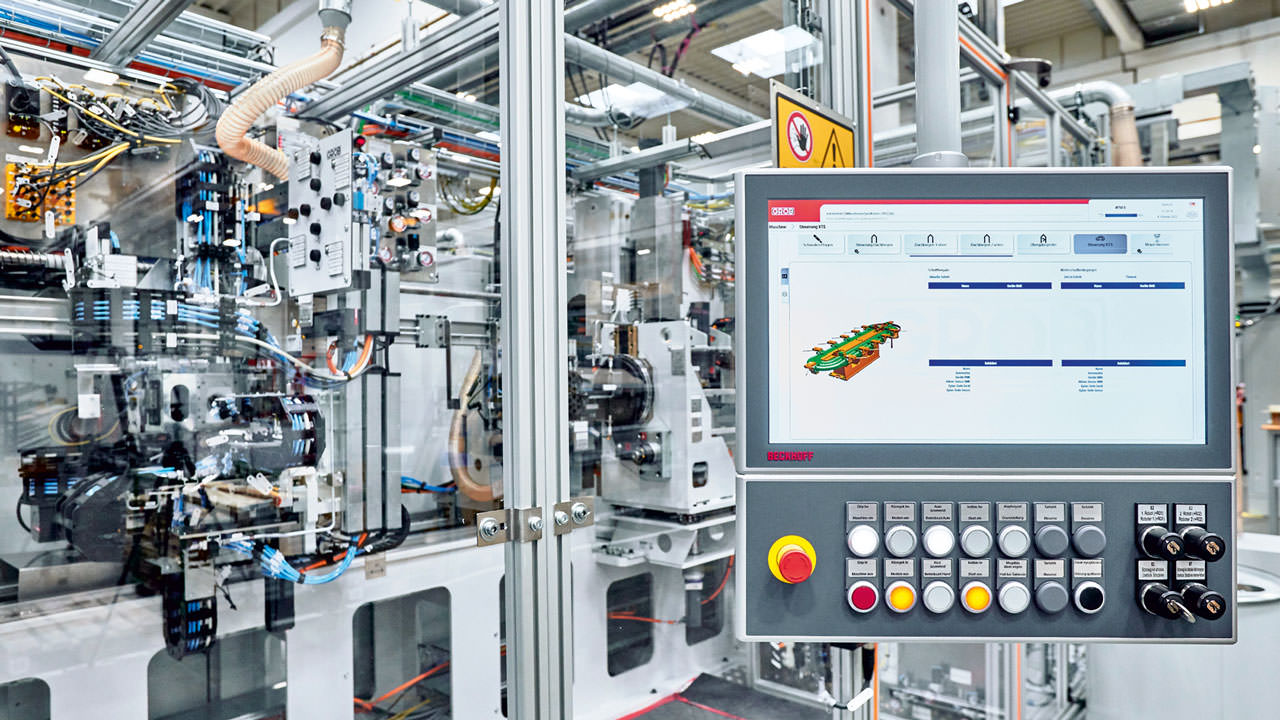

A sophisticated production machine for hairpins, from which the stator winding rims of electric motors are formed, illustrates the advantages of this optimally scalable automation solution. It leverages TwinCAT 3 on a Beckhoff C603x ultra-compact Industrial PC as the central control platform and the XTS transport system.

GROB, the machine tool manufacturer, creates high-volume manufacturing and assembly systems to meet the important, rapidly growing requirements for electromobility. The decisive factors here are minimum cycle times and corresponding fast process sequences, as enabled by PC- and EtherCAT-based control and drive technology from Beckhoff.

As a globally operating family business, GROB-Werke GmbH & Co. KG in Mindelheim, Germany, has been developing systems and machine tools for the most renowned automotive manufacturers and their suppliers, among others, for over 95 years. The portfolio ranges from universal machining centers to highly complex production systems and manual assembly stations to fully automated assembly lines. This also includes production systems for electric motors as well as production and assembly systems for battery and fuel cell technology, as Fabian Glöckler, head of the control technology department in GROB’s electromobility business unit, explains: “In this area, we cover the entire production chain and offer customer-specific systems for the entire powertrain.”

Electromobility requires powerful control technology

According to Martin Ellenrieder, Group Manager of Function Development in GROB’s electromobility business unit, the trend toward electromobility also places new demands on control technology: “Compared to systems for internal combustion engines, the systems are characterized by more sophisticated stations, reduced PLC cycle times, a higher proportion of drive technology in assembly and sophisticated coupled movements.” This is also evident in the hairpin machine (second generation), which is fully equipped with Beckhoff control and drive technology. In addition to four GROB spindles, a total of 57 NC axes are implemented – 40 real and five virtual axes as well as 12 movers of the eXtended Transport System (XTS) that are operated as individual servo axes. In addition, there is an extensive I/O level consisting of EtherCAT and TwinSAFE Terminals or Box modules, with 270 digital inputs and 150 digital outputs.

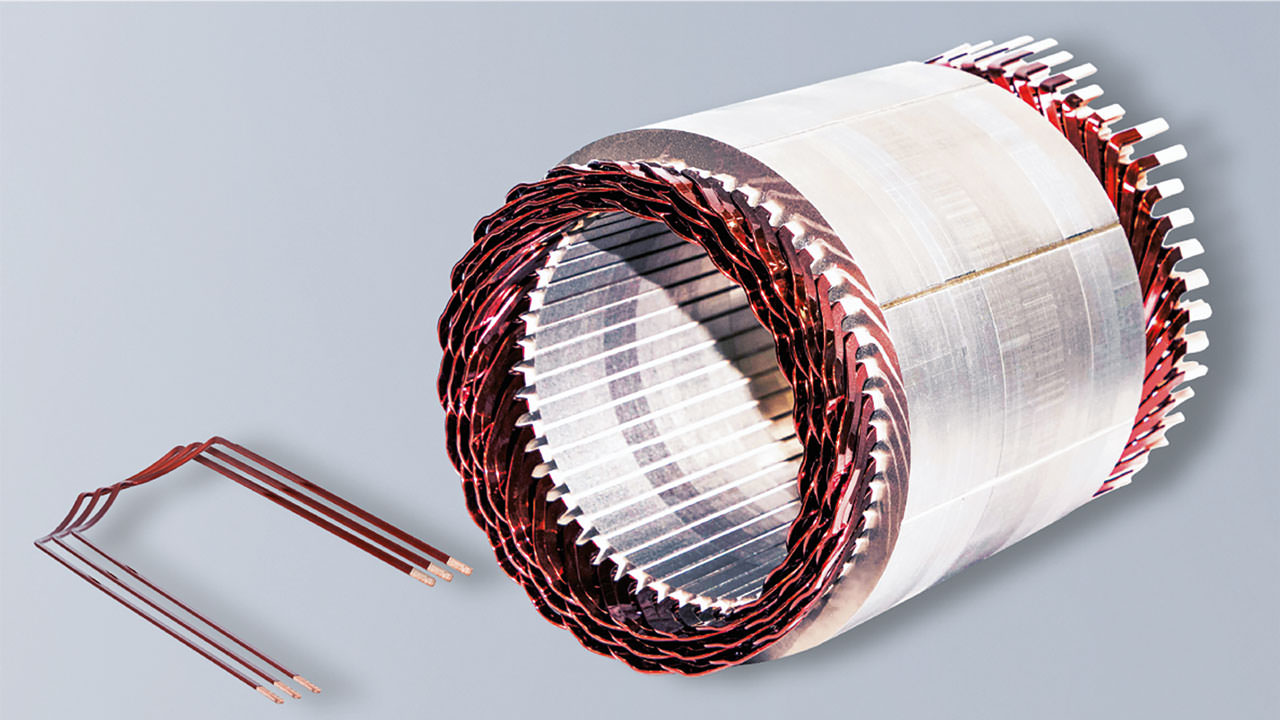

GROB’s electric motor stators (right) contain several winding rims made of individual hairpins (left).

Using a C6030 or C6032 ultra-compact Industrial PC and TwinCAT software as the control core, the machine achieves an extremely high output rate based on a cycle time of just 2.3 s per hairpin. Around 200 individual hairpins require separate production for each stator. This is all the more impressive due to the complexity of the machining process and the wide range of control tasks involved, which extend from the infeed of the copper tube wire through its straight alignment, complex bending and stripping, to exact positioning in a pre-insertion nest:

- Wire supply (from coil to straight copper wire, with or without electrical testing of wire insulation): PC-based control for dancer control

- Stripping copper wires on the fly: axis positioning, cam plates and flying saw

- Wire feed: coupling of axes to a second encoder system, switchover of the encoder system depending on the operating status of the system, as well as switching of the axes used via interfaces for special operating modes (travel with or without wire)

- Wire inspection: transport and positioning

- Press-fitting/cutting: cam plates as well as compensation of material displacement during the pressing/cutting process via dynamic coupling factors of the virtual gear functionalities

- 2D bending: dynamic cam plates generated by hairpin parameters which are coupled using dynamic coupling factors of the virtual gear functionalities

- 3D bending: dynamic cam plates generated by hairpin parameters which are coupled to the XTS movers by dynamic coupling factors of the virtual gear functionalities

- Pre-insertion of the hairpins: cam plates or coordinated motion

- Variety of infeed variants/positioning movements of the pre-insertion nest and clamping finger: coupling of virtual and real axes

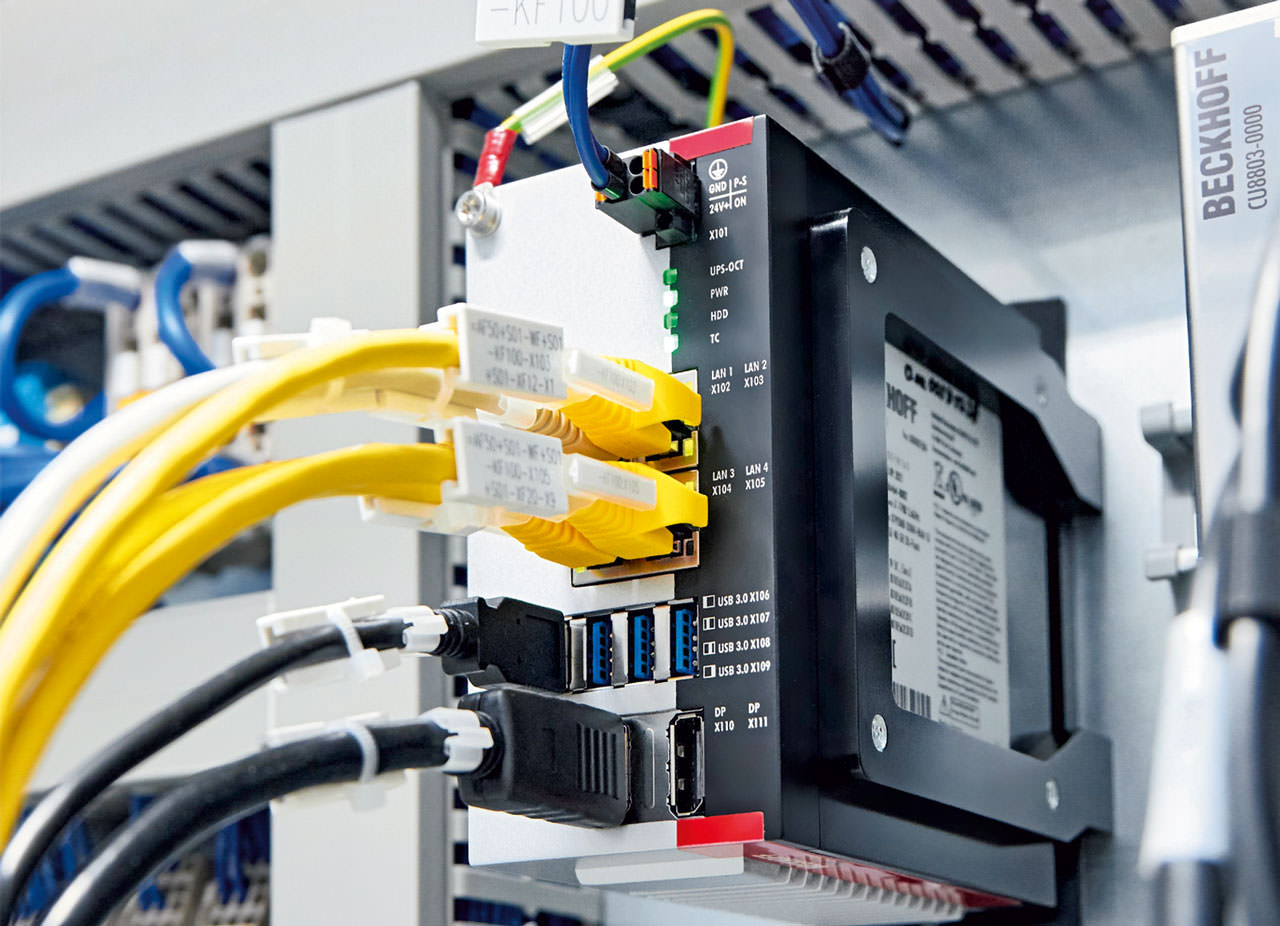

A C6030 ultra-compact Industrial PC provides optimal computing power for central control of all process sequences.

Daniel Gugenberger, group leader of electrical design at GROB’s electromobility business unit, explains the difference between this and the production of internal combustion engines as follows: “The classic assembly processes, such as bolting, press-fitting and manual assembly operations, have been automated to a large extent and would not be able to be performed by a machine operator with the required quality, precision and speed.” This is where PC-based control from Beckhoff has proven its worth, he says, because detailed machine and process data are of crucial importance due to the very high system throughput: “When a complete manufacturing process runs in two seconds, production monitoring and error analysis are possible only with appropriate analysis tools and high-speed cameras. We very often use the TwinCAT Scope View software oscilloscope for this.”

Around 200 hairpins in approximately 50 different designs are required to build a stator winding. These are produced one after the other in the order required for placement in the pre-insertion nest. Inline error detection is therefore important. Fabian Glöckler explains: “In the event of a material or geometry error, the corresponding hairpin must be produced once again and inserted into the system using automated feed so that it can be inserted at the correct position. With the large number of motion axes and hairpin variants, this means an enormous management task for the control technology, as a wide variety of parameters, bending angles and cam plates need to be calculated just in time.”

Proven automation system and innovative HMI

As early as 2004, the first GROB process machine was equipped with Beckhoff technology, Martin Ellenrieder recalls: “Initially, test stands and additional magazines followed, until 2017, when the first assembly line was also automated with PC-based control. The main reasons for the respective use were the short control cycle times as well as the high system flexibility with respect to future applications and requirements. These include numerous interfaces to different bus systems, the extensive motion functions and a high diagnostic depth. TwinCAT offers as an advantage, a special openness – e.g. with the integration of MATLAB® which helped especially in the development process for the systems. Process engineers could thus easily integrate simulations into test facilities. Further aspects include automatic code generation from the E-CAD system through to the HMI, the simple integration of motion control blocks developed in-house, as well as the integration of version control, bug tracking and software testing. In addition, the flexibility of TwinCAT makes standardization in software development much easier for us.”

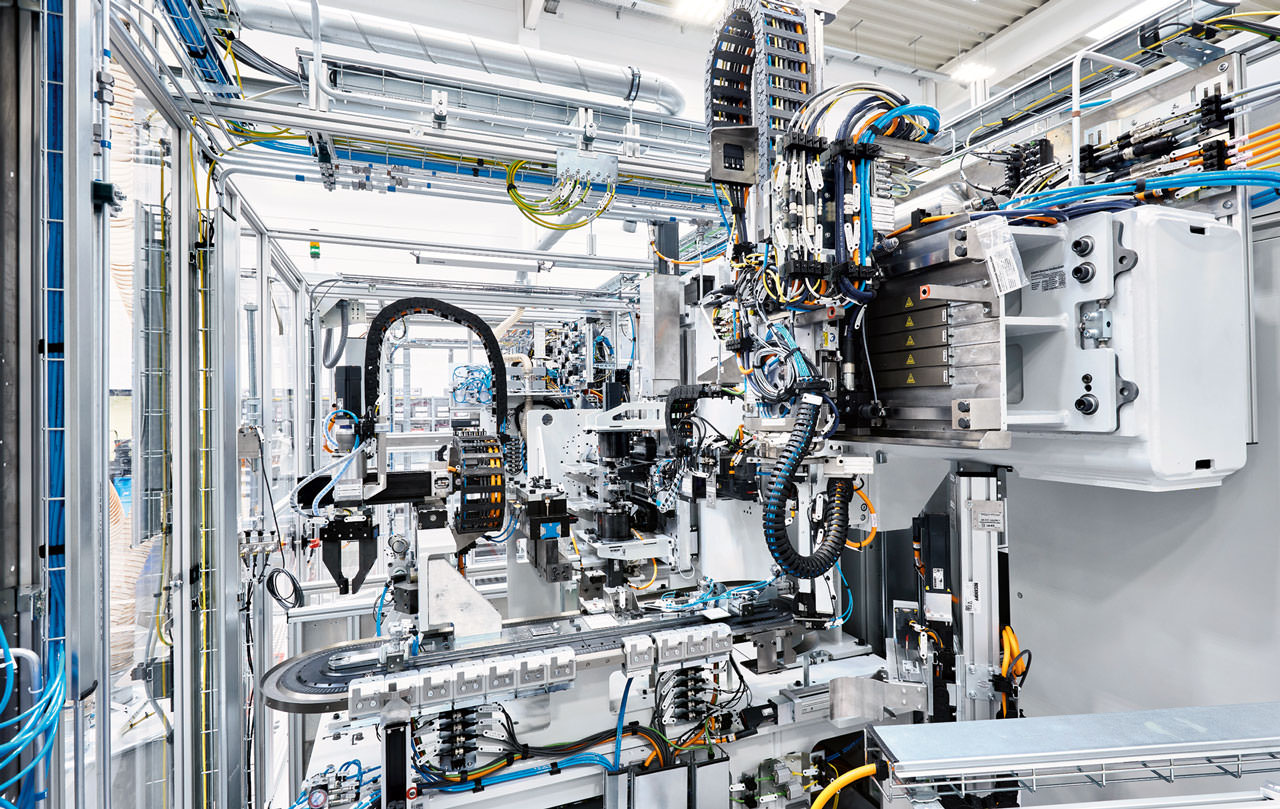

A look inside the machine gives an idea of the complexity and variety of the motion sequences, right up to the XTS system (foreground).

The ultra-compact Industrial PC, C6030 or C6032 (if more interfaces are required), is used in connection with a CP3918 multi-touch Control Panel with customer-specific push-button extensions. “The IPC provides sufficient computing power to reliably achieve our target of a 4 ms PLC cycle time. Added to this are its very compact design and variable mounting options,” says Fabian Glöckler. In the case of the human-machine interface, the focus is on convenient and error-free machine operation, and the company has been relying on TwinCAT HMI from a very early stage: “Accordingly, close cooperation with Beckhoff, especially with the Munich subsidiary, was important at the beginning in order to be able to implement such a large HMI project. This worked very well – e.g. with the automatic coupling between HMI and PLC and the implementation of multiple languages – and resulted in an HMI tailored to our requirements with a focus on intuitive usability, clear parameter display and very high diagnostic depth. The result is a uniform and innovative operating concept for all of our systems.”

Sophisticated motion via servo axes and XTS

The numerous rotary axes are implemented with AX5000 Servo Drives and in part with EL72xx and EP72xx compact drive technology and AM8000 servomotors. In this context, Martin Ellenrieder sees a particular advantage in the One Cable Technology: “OCT results in a significantly reduced cabling effort and minimizes the sources of errors. Other important factors when using the AX5000 are the additionally covered encoder interfaces and the safe motion functions of the AX5805 TwinSAFE option card.” Added to this is the rich set of functions within TwinCAT, such as TwinCAT NC PTP, NC Camming or NC Flying Saw, and above all the combination of these functions, he says.

In addition to the compact drive technology from Beckhoff, AX5000 Servo Drives are primarily used to control the AM8000 servomotors – with One Cable Technology (OCT) for minimization of installation space and cabling effort.

The rotary motion axes are supplemented by XTS from Beckhoff. An oval, 3-meter-long track system with 12 movers transfers the individual hairpins to a linear portal for the final insertion process. According to Daniel Gugenberger, the XTS offers application advantages with the increased flexibility of the system and the ease with which new functions can be added. And further: “In addition to classic transport tasks, we use XTS for flexible positioning at different processing positions – the bending and camera stations. We benefit from the system’s compact design as well as from its modularity, which makes it easy to integrate different stations. The transport system yields further advantages through flexible distance control according to the component status (no component, first bend, second bend), the reduction of cycle times, and the decoupling of individual processes so that, for example, varying process times do not directly affect the machine as a whole.”

According to Martin Ellenrieder, TwinSAFE has proven itself overall as a system-integrated safety functionality and offers a high degree of flexibility in the safety application. In addition to the drive-based safety technology, the EL6910 TwinSAFE Logic module is also used as a dedicated safety controller. In complete production lines, the distributed safety applications of the individual machines and systems communicate with each other via the EtherCAT Automation Protocol (EAP).

“This safety communication across control system boundaries is a very important aspect of machine safety, as our customers generally use a large number of systems that are also interlinked,” sums up Martin Ellenrieder.