TechnologyNovember 16, 2025

Optimize control panels and more with Single-Pair Ethernet

EtherNet/IP-based approach to connecting in-cabinet components reduces wiring, weight and installation time For producers looking for ways to do more with less, rethinking control panel connectivity with Single-Pair Ethernet (SPE) technology can be an impactful change.

One of the goals of creating smarter and more sustainable production operations today is to help industrial producers do more with less. And one area of the automation infrastructure where OEMs, system integrators and producers are realizing they can do this is in the control panel.

Today, in-cabinet components like motor starters and panel operators are typically hardwired. And because these components can require hundreds of connections, control panels can take considerable time and effort to design, build, configure, commission and maintain. Wiring in control panels also occupies valuable space; today’s manufacturers want to minimize that space to make the most of their production footprint.

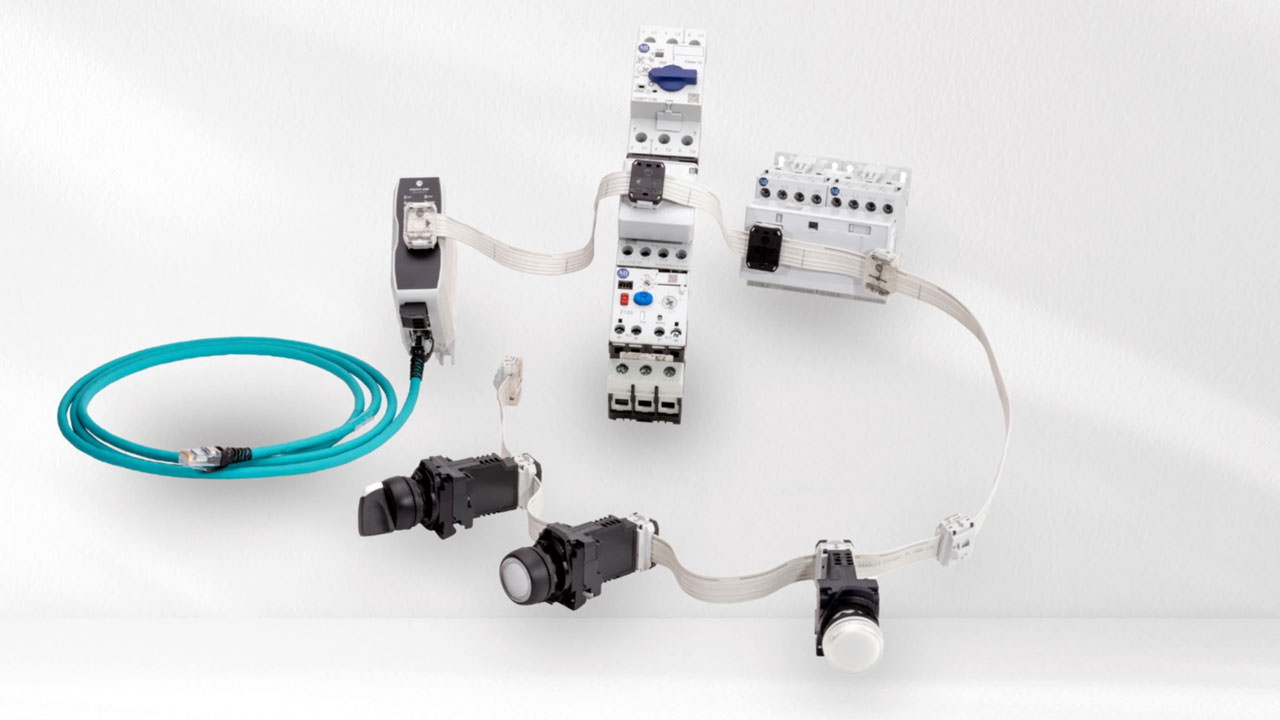

An EtherNet/IP-based alternative connection approach offers a better way forward than the use of extensive hardwiring. Specifically, the use of single-pair Ethernet (SPE) allows in-cabinet components to be connected more simply and easily via a flat media cable. This allows for cleaner, more efficient and more sustainable cabinet designs that can be installed faster and support the shift toward more data-driven decision making.

The opportunity

An in-cabinet connection system that uses SPE allows industrial producers to take EtherNet/IP deeper than it’s gone before – down to the simplest cabinet components – based on the IEEE 802.3.cg Ethernet standard and ODVA’s EtherNet/IP specification.

An SPE gateway translates a user’s full Ethernet stack to SPE when connecting to in-cabinet components. And multi-drop topology allows up to 39 in-cabinet components to be connected in a simple and clean panel design.

This approach replaces traditional point-to-point hardwiring with network-based connections. And by eliminating this dense wiring and the need for extra wire trays, producers can either get more room in their cabinets for value-added features or reduce the size of their cabinets to save floor space.

A simplified wiring approach can also provide other benefits, including:

Reduced wiring time: With traditional point-to-point hardwiring, each wire must be cut, stripped, labeled, and terminated. This process can take up to six minutes per connection, creating significant time and labor demands for panels that have hundreds of connections.

With SPE, in-cabinet components can be quickly snapped into place on a simple piece of media, without the need for special tools. This can deliver big time savings. In fact, with one recently launched product, field testing sites reported up to an 80% reduction in wiring time and as much as a 50% decrease in testing time. It can also help reduce dependence on hard-to-find skilled labor, such as electricians, during machine setup and deployment.

Enhanced visibility: With SPE, in-cabinet components no longer need to exist in silos, isolated from the rest of the automation infrastructure. Instead, their data can be accessed, and they can be added to dashboards with minimal effort.

This can give manufacturers a more detailed view of what’s happening in their operations to help them stay productive. For example, they can identify when a starter is drawing more current unrelated to the load, which could be an early indicator of a mechanical failure. Or if an unplanned downtime event occurs, they can review fault logs of in-cabinet components to more quickly determine what happened.

Improved sustainability: Smaller panels with less wiring create more sustainable machines. They can significantly reduce material usage and waste, including copper, wiring, and plastic, and reduce weight to make machines less costly to ship.

In one case, SPE technology eliminated more than 500 feet of wiring from a panel, resulting in a 20% reduction in size and a one-third reduction in weight.

Volga reduces control panel wiring time by 66% with Rockwell Automation’s EtherNet/IP In-cabinet solution.

System integrator simplifies panel design

Brazilian system integrator Volga set out to explore how SPE could enhance its panel design and assembly process – and discovered the technology offered dramatic improvements.

To evaluate the potential of the technology, Volga performed a time study of the two different wiring methods at its on-site test area.

First, the team at Volga assembled a hardwired panel with six direct online motor starters, PLC and I/O modules, and operators, all interfaced with terminal blocks. Prior to the test, the team had already routed the cables using CAD software, cut the cables and stripped the ends, and inserted the marking system on the panel. This kept the test focused on wiring the control circuits.

The team then assembled a second panel of the same composition using an in-cabinet SPE system. During the time test for this panel, the team installed the flat cable and connectors, the remaining control circuit wiring, pre-wiring, and detailing.

The time study revealed a stark difference between the two methods. For the first panel, hardwiring the control circuits took just over 20 hours. For the second panel that used the SPE connection technology, completing the control circuits took a little more than six and a half hours – or one-third the time of the first panel.

“When you extend this concept to a large motor control center or panels with a lot of cables, it will have a huge impact in the assembly process,” said Carlos Leopoldo, commercial director at Volga.

The SPE technology also helped Volga achieve a 36% reduction in panel size and 32% reduction on weight compared to traditional hardwiring. And it allowed the team to use substantially less wire and copper.

“For some of our customers, the first point for them is sustainability,” Leopoldo said. “We’ll be talking with our customers about this technology that reduces cabling and copper and reduces the impact on the environment.”

Modernization reaches control panel

SPE allows EtherNet/IP to be easily extended to the smallest and simplest components in the control cabinet. In doing so, it enables simpler, cleaner and smaller control panels and in-cabinet components to finally join the rest of a manufacturer’s operations in a smart and connected environment.

For producers looking for ways to do more with less, rethinking control panel connectivity with SPE technology can be an impactful change.