ApplicationsMarch 30, 2021

Dignified Motors introduces technology to mobility industry

An innovative engineer turns to edge controller technology to power an EPIC Chevy Silverado lift system. Opto 22 encourages you to think about how you can put your engineering skills to work to improve the life of someone near you.

What do you do if you own a beautiful truck but one day find yourself a wheelchair user? Chances are you’ve never considered that possibility, but answering that kind of question is what Dave Aitchison of Dignified Motors does every day. Aitchison and his team specialize in vehicle conversions and accessories that meet a variety of accessibility needs. Their work improves the quality of life of all kinds of drivers: veterans, the elderly, and families with special needs children.

The challenge

As a mechanical engineer and a wheelchair user himself, Aitchison sees the opportunity to introduce better technology to the mobility industry. For instance, typical accessible entry-exit systems like automatic ramps use limit switches that may lose their proper activation position over time and end up failing in problematic ways.

“Imagine that you aren’t able to get out of the vehicle on your own because now the door limit switch doesn’t quite make its activation position. So the ramp just doesn’t deploy,” Aitchison said. “I’ve been trapped in everything from a 1975 Chevy full-size van to a 2004 Toyota minivan.”

Driver approaches vehicle

That observation led Dignified Motors to look for technologies designed for harsher environments and extended cycle times. They reached out to Opto 22 when they were approached by a customer who needed to upgrade her Chevy Silverado’s entry system. It had been modified previously with an inventive but slow wheelchair lift.

In the Arizona heat, the slow speed wasn’t just an inconvenience: “Temperature exposure is a risk for people with spinal cord injury. Two and a half minutes sitting in 115° F weather [waiting for your lift to deploy] is dangerous.”

The solution

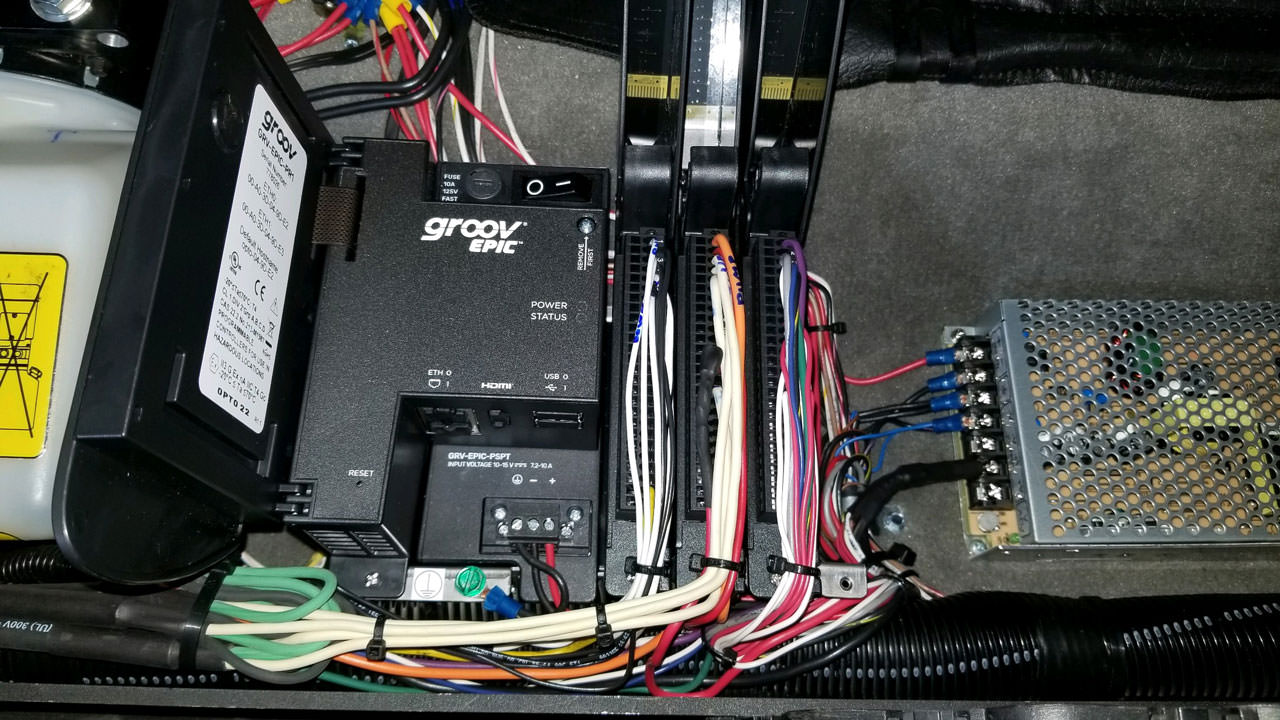

Dave replaced slow-moving DC actuators with a properly sized hydraulic system and installed a groov EPIC edge programmable industrial control system sped up the deploy time to 14 seconds. The groov EPIC controls the hydraulic valve and pump system and monitors system health and passenger safety using pressure transducer readings, door proximity sensors, and I/O checks for vehicle position and state. If the truck is not in park, EPIC will not power the lift system, preventing accidental deployment while driving.

Driver in place and seat moving into position:

Next conversion

Dignified Motors is working on a similar conversion for a quadriplegic veteran. They’ll raise the truck body and drop the floor to accommodate the additional height of the wheelchair and lift system. The truck will also be outfitted with drive-by-wire speed control, reduced effort power steering, and a tri-pin orthotic using a spinner knob bearing, giving the driver full control without requiring full grip strength or manual dexterity.

With EPIC’s embedded groov View HMI server, Dave can offer clients the option of mobile interaction with the lift system using their cell phone, which, he adds, is “a massive convenience for the mobility industry.”

When asked what else led him to choose groov EPIC, Dave is quick to mention that “Opto 22 has a history going all the way back to the SSR. That’s the kind of equipment and technology that you want to partner with when you are looking at potentially life-critical systems.”