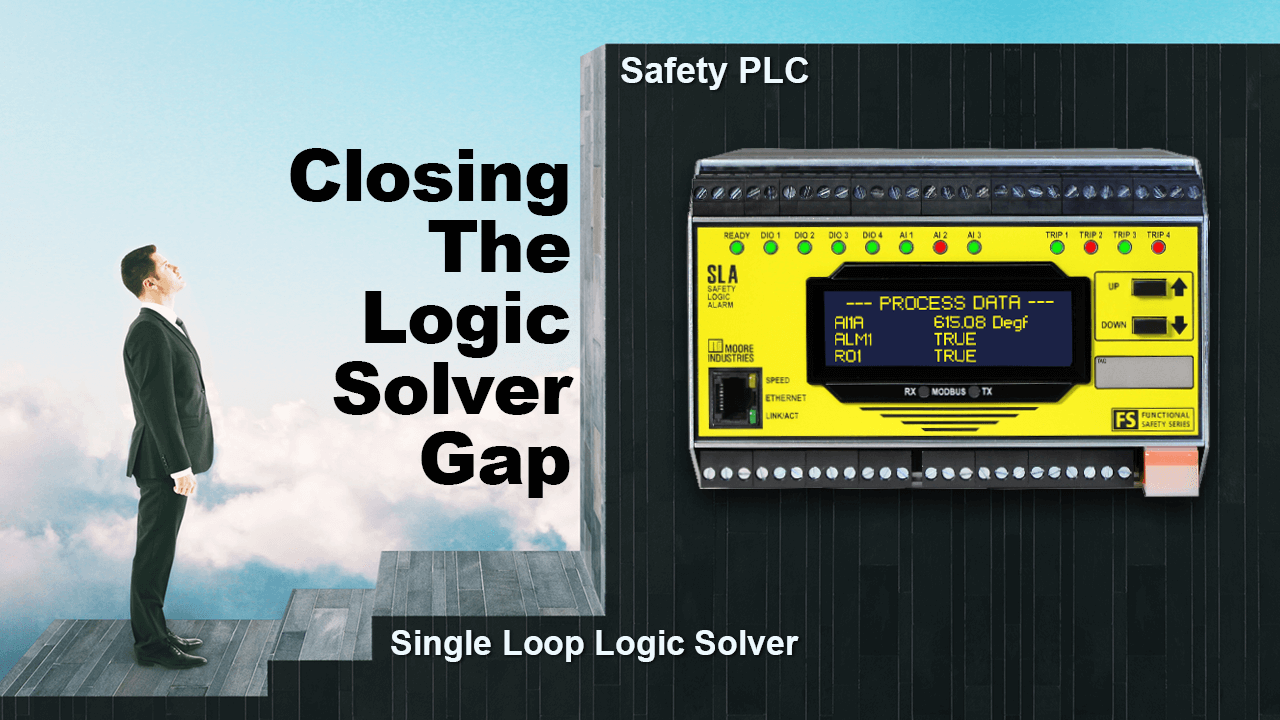

NEW PRODUCT

Cost Effective Logic Solving with Secure Programming and Industrial Ethernet

The SLA Multiloop and Multifunction Safety Logic Solver and Alarm fills the logic solver gap between single-loop logic solvers and costly Safety Programmable Logic Controllers (PLC).