ApplicationsNovember 24, 2024

From no PLC experience to custom data acquisition and monitoring

Tucker Energy Services set out on a development program to replace an aging data acquisition system, improve their limited visibility and data sharing, reduce their dependence on third-party solutions and eliminate inaccurate/nonexistent level sensing in fluid tanks.

Tucker Energy Services (TES), based in the twin island nation Trinidad and Tobago, provides specialty services for the Oil and Gas industry. With a focus on enhancing oil well integrity and efficiency, they offer customers:

- Well cementing, which involves sealing wellbores and securing casings in oil and gas wells—prevents the migration of fluids between underground formations and supports the well casing, ensuring the structural integrity and isolation of the wellbore.

- Coiled tubing, a continuous length of flexible steel tubing that can be wound onto a large reel—helps speed up processes like pumping services and well cleanouts.

- High pressure pumping, using pumps to inject fluids at high pressures into oil wells—helps to stimulate production.

TES also offers wireline and mud logging services as well as operates their own Liquid Mud Plant, a specialized facility designed for the preparation, storage, and maintenance of drilling mud—a crucial component in drilling operations. The facility helps TES ensure a consistent supply of customized drilling fluids while their comprehensive services support the operational success of oil and gas customers in the region.

Outdated equipment & visibility voids

In 2019, TES found their operations hindered by outdated equipment and an insufficient ability to manage data. The company identified four critical areas needing improvement:

Aging data acquisition system: The existing setup was over a decade old and could not be adapted to new technologies or integrated with modern data management practices.

Limited visibility and data sharing: The legacy system’s lack of Ethernet connectivity restricted data access to local operators only, preventing efficient remote monitoring and decision making.

Dependence on third-party solutions: Previously implemented systems from external providers offered little room for customization or expansion without incurring exorbitant costs.

Inaccurate/nonexistent level sensing in fluid tanks: Only 8 of the 150 tanks had level sensing capabilities, and those in place used mechanical level switches, which were prone to failures that led to unreliable readings and potential costly spills.

Costs, controls and learning curves

Navin Singh, Electrical & Instrumentation Supervisor at Tucker Energy Services, knew that a technology upgrade would increase reliability and improve visibility, so he began researching. The investigation led Singh into quite the dilemma.

Ready-made systems for tank monitoring and data acquisition came with steep price tags, significantly inflating the budget. Furthermore, maintenance and updates for these systems would require TES to rely on third-party integrators, which limited control over their system and further added to their costs—necessitating ongoing expenses for external engineering support.

The other option was for Singh to select commercially available controls equipment to develop a homegrown system. But the team at TES had minimal exposure to Programmable Logic Controllers (PLCs), so adopting new technology would be a steep learning curve. To pull this off, Singh would need a user-friendly product with learning tools that wouldn’t break the bank.

The move to groov

“We had a supplier who used Opto 22 systems with PAC Control programming software, and we heard they were able to develop their own data acquisition system,” Singh recalled. “We wanted to have full control of the hardware and software development.”

“I heard about this new groov EPIC system, and the information on YouTube excited me—showing what it could potentially do. It was quite reassuring that when I initially made contact, I was able to speak directly to an engineer [Opto 22 Application Engineering Specialist, Selam Shimelash],” said Singh.

Other data acquisition systems that Singh was exploring— from both the U.S. and the UK—didn’t quite fit the mold he was looking for. The groov EPIC system, an Edge Programmable Industrial Controller from Opto 22, however, provided real-time control, connectivity, and data visualization all in one platform.

“For making future improvements, with groov, we are in full control. And with no software development fees or annual licensing fees, we can keep adding and improving while keeping costs down,” Singh said.

Practical steps and solutions

Winmate® monitor displaying groov View visualizations.

TES started by integrating seven groov EPIC systems—processor, power supply, chassis, and I/O— to monitor tank levels for their 150 tanks. Each groov EPIC is placed in a strategic location near a group of tanks to avoid long cable runs.

An eighth groov EPIC system is installed in their main office and displays an aggregated view of all 150 tanks on a single heads-up display.

Using the EPIC’s native HDMI output, Singh paired each EPIC with a cost-effective Winmate® monitor to provide local views for operators. The monitor displays the free groov View™ visualization software that is preloaded on every EPIC system.

For help building his screens, Singh utilized Opto 22’s free SVG Image Library.

For additional data acquisition, TES uses a variety of groov input modules, from traditional analog to specialized frequency input modules, part number GRV-IDCIFQ-12, for measuring pumping rates and calculating the volume of fluid being moved.

Later in the project, Singh implemented digital output modules to sound the alarm and prevent potential overflows and spillage—a huge savings since drilling mud and other related fluids are expensive, cleanup costs are high, and the environmental impact of spills can be devastating.

Taking the tech up a notch

Winmate® monitor displaying groov View visualizations.

With Singh’s newfound proficiency in PAC Control, he took advantage of the file creation and writing tools to log tank level and production data to a .CSV file that could be opened and manipulated as a spreadsheet.

Soon thereafter, he discovered something new on Opto 22’s YouTube channel—Node-RED opened the door to a more sophisticated possibility: SQL data logging. “All the data is now recorded and sent to a MSSQL database,” he noted.

As Node-RED proficiency ramped up, Singh was tasked with another challenge: establishing outbound communication from his groov EPIC systems using WITS Level 0—a standard for real-time data exchange in the Oil and Gas sector. Despite modern advances in Ethernet, WITS Level 0 still uses serial communication to exchange ASCII data between drilling equipment and monitoring systems.

Using Opto 22’s GRV-EPIC-CSERI-4 module for serial data transmission, Singh found a Node-RED flow in the open-source community that supported the specialized protocol, and in a short amount of time, he was able to deliver the serial data to their customer, a local oil company, in the specialized format they required.

Tank levels home screen in groov View.

Tangible benefits and forward-looking strategies

Tucker Energy Services has realized significant operational improvements since implementing their new tank monitoring and data acquisition systems. In fact, future enhancements are already in discussion:

Tank monitoring, with radar level sensors and alarms, has drastically reduced spillage risks associated with expensive drilling mud and related fluids. TES is already beginning the next phase of this project, which will include automatic shutdown of pumps to prevent overflow and automated emails with existing tank levels every 12 hours.

Winmate® monitor displaying groov View .visualizations.

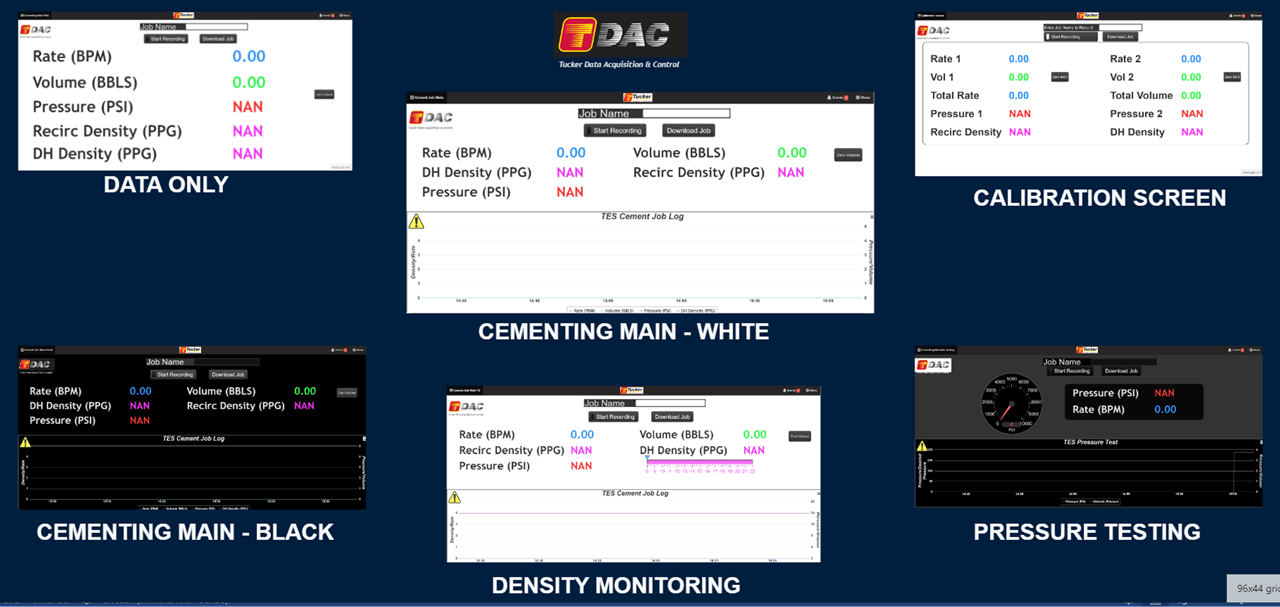

groov View HMIs have improved visibility and empowered operators, who are now able to choose among different specialized screens depending on the type of job. For example, a cementing operator is more interested in fluid density and pumping rates while high-pressure pumping operators are interested in real-time pressure readings. Having the right information at their fingertips empowers operators to make better decisions and prevent mistakes.

Data acquisition with groov EPIC systems using Node-RED writing data to MSSQL is in its early stages.

Singh estimates the cost of this system is about one third of what a turnkey solution would have been. And as full, rich data begins to fill their database, TES will gain more valuable insights into their daily operations.

Upper management has been delighted that without a PLC programmer on staff, Singh and his team have been able to build a custom system at a fraction of the cost for a turnkey solution. “We have upcoming meetings with management, and we expect all future applications to be based on Opto 22 groov devices,” Singh affirms.

And the cherry on top? In a recent audit, a large oil and gas conglomerate visited TES to view their fluid, which is stored on TES’ site in some of the newly instrumented tanks. The customer was quite pleased with the significant improvement in their monitoring and data acquisition systems.

Singh’s final comments for others considering this type of project, “Troubleshooting is a different mindset from programming. Watch some of the YouTube videos and do some of the online training, especially if you are new to programming.” When asked to describe his experience working with engineers at Opto 22 he remarked, “Very refreshing and great!”

Case study by Opto 22