ApplicationsSeptember 10, 2018

Ricola leverages Proficloud to satisfy strict FDA requirements

Everyone knows the "Who invented it?" slogan from TV and radio ads that made the Swiss company Ricola famous. Now, the firm is proving that its traditional cough drops can go hand in hand with modern technology by turning to Proficloud as a solution to meet strict FDA requirements cost-effectively.

Cloud computing is an integral part of the development of new candies at Ricola, and opening up new markets that often involves additional certifications. To be sold in the USA, for example, they must meet the stringent requirements of the FDA (Food & Drug Administration). Storage and production processes have to be documented from end to end as part of such certifications, and so Ricola is turning to cloud computing and all it has to offer. Many companies struggle to grasp what this technology is all about.

The idea is that, as intelligent devices with Internet capability are networked more and more, the data they provide will improve productivity and competitiveness; but how this will actually be realized in practice and the specific benefits are still unclear. One example of what a cost-effective solution could look like is this combination of tried-and-tested automation technology and Proficloud.

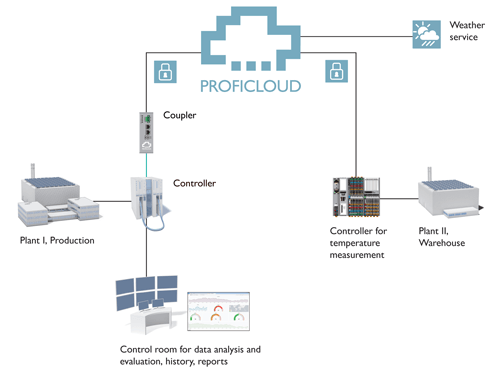

Topology of the Proficloud application at Ricola.

Transmit status data across sites

The PROFINET Industrial Ethernet standard can be used to realize a huge range of automation concepts from machine building and production technology, through process and building automation, right through to drive technology. The real-time-capable transmission protocol uses the TCP/IP channel and IT standards, and is able to incorporate both fieldbus and cloud-based systems. Proficloud technology now enables PROFINET automation networks to be connected to the Internet, opening up the limitless opportunities presented by the Internet of Things (IoT) to the user.

But what does IoT have to do with making speciality herbal candy? The Ricola herbs are grown by approximately 100 herb farmers in five regions in the Swiss mountains. A total of 1400 tonnes of herbs are processed annually; these herbs must be stored and processed under optimum conditions. Therefore, both the administration offices and the storage and production facilities are located in Laufen, albeit in different districts.

The decentralised arrangement of buildings means that relevant information must be exchanged as cost-effectively as possible between the various facilities. Furthermore, the solution must be integrated into the existing automation technology. Daniel Bhend, Senior Director Technology/Engineering at Ricola, has therefore worked together with the integrator Kundert Automation AG and the experts from Phoenix Contact to develop an efficient solution. A combination of standardized communication protocols for automation technology and the Internet is used to exchange data over long distances.

Ricola leverages Proficloud to satisfy strict FDA requirements

Connecting automatically to cloud

At Ricola, information on the condition of the storage rooms, which are located some 15 kilometers from the production facility, must be transmitted to the central distributed control system (DCS). To achieve this, recorded measured values are transmitted via PROFINET protocol to the process control system. The relevant PLC also assumes the function of a PROFINET controller, which is why the Proficloud was an option. A standard Proficloud application is normally made up of at least one Proficloud coupler, one Proficloud device, and one PROFINET controller.

The Proficloud coupler connects the local PROFINET network to the Proficloud via two Ethernet interfaces. While one interface is used to establish a connection to the local PROFINET system in the production facility, a second Ethernet interface is used to establish a connection to the Internet. The coupler then initializes a connection with the Proficloud automatically, and is ready for use after a short amount of time. The same applies to Proficloud devices that are likewise simply connected to the Internet and that connect automatically to the Proficloud.

At Ricola, the decentralised AXC Cloud-Pro Proficloud controllers acquire the data from the many temperature sensors distributed throughout the storage rooms via alignable I/O modules of the Axioline F product range, and transmit this via Internet to the Proficloud coupler. “By using the Proficloud, we do not have to develop a complex network infrastructure,” Bhend said.

The system integrator commissioned by Ricola, Kundert Automation AG, simply had to register the Proficloud devices in the Proficloud using their UUIDs (Universal Unique Identifiers) and assign them to the central Proficloud coupler. UUIDs are used for the clear identification of information in decentral systems and ensure secure communication via the Proficloud. Upon registration, the PROFINET system records the TLS-secured data transmission via the Proficloud.

Ricola leverages Proficloud to satisfy strict FDA requirements

Weather information from Internet

At Ricola, along with the capture and transmission of measured values from the storage rooms, the latest weather information is also communicated to the DCS in order that this can be added to the FDA inspection documents. Ricola could have installed a weather station for this, which would have had to be set and connected to the PLC. It is easier to use the Proficloud Weather cloud service, so relevant information can be retrieved from the weather service via the Internet. This can then be used by the controller directly as PROFINET data. The Proficloud service is treated as a virtual Proficloud device in the Proficloud system. With the input process data, the user determines for which location the weather information is to be retrieved, in this case by entering the warehouse coordinates.

How does the data from the Proficloud devices now find its way to the PLC and how is the process of exchanging data protected? As soon as a connection has been established to the Internet and, therefore, the cloud, the PROFINET device sends its process data to the Proficloud. Restricting communication to an outbound connection ensures that no Internet subscribers can communicate with the Proficloud devices unsolicited in order to manipulate temperature data, for example.

Once the connection to the Proficloud has been established via the Internet, a PROFINET instance is created in the Proficloud coupler for each connected Proficloud device. The station in the warehouse and the weather device thus receive a separate IP and MAC address that is represented in the local PROFINET network. After that, each Proficloud device can be programmed as a local PROFINET device.

Unauthorized access protection

Due to the fact that the data transmission of Proficloud couplers and devices is protected with TLS1.2 encryption and the connection can only ever be established by the Proficloud devices, two fundamental aspects are taken into account with regard to data security of the Proficloud. Even the web application for configuring the Proficloud is securely transmitted to the user with HTTPS and is thereby protected against unauthorized access; this has already been certified by independent agencies.

In conclusion, the combination of tried-and-tested automation standards and innovative cloud technology has long been a reality. The Proficloud has been available as a live cloud platform for over two years, is being used in more and more operations applications all the time. For example, in addition to the cloud-based PROFINET communication utilized by Ricola, time-series database solutions have also been realized and company-specific concepts have been developed that are based on the Proficloud.

Flexible use of Internet

The Proficloud is a cloud-based, open IoT platform which connects hardware and software components found in an enormous variety of systems and machines. This enables automation systems to benefit from the limitless possibilities offered by the Internet. Being dependent on one single automation manufacturer is detrimental here and also contradicts the open approach of Proficloud.

The technology links real objects to the digital world in order to realize powerful industry applications and provide digital services. This improves competitiveness and opens up new business models. As an open IoT platform, the Proficloud allows innovative solutions to be developed and provided in a versatile ecosystem without having to obtain a costly developer license.