ApplicationsJuly 1, 2020

Scalable automation solution for heat exchanger manufacturing

PC-based automation, drive networking and Ethernet I/O reduces control technology cost and cycle times for OEM machinery builder. Use of EtherCAT technology improved PLC cycle times by 30% and reduced control system costs by approximately 30% when compared with equipment from previous vendors.

For its customer Core Energy Recovery Solutions, specialty machine manufacturer RAMP based in Waterloo, Ontario, Canada, has developed a solution for manufacturing heat exchangers, or energy recovery ventilators, which increase energy efficiency in buildings. By automating the production machinery with powerful and scalable Beckhoff automation products, RAMP was able to reduce control technology costs, improve PLC cycle times and complete the demanding project on schedule.

For its customers across North America and Europe, RAMP leverages its extensive experience in numerous industries with particular strengths in energy recovery and automotive projects.

The projects range from the design of new manufacturing systems to modernizing existing plants, always by combining custom-tailored solutions with standard components – to deliver maximum efficiency. Jeff Kerr, manager of mechanical design at RAMP, explains: “We cross-functionally examine all requirements and break them down into individual conceptual designs. This way, we ensure that all mechanical and control components are fully compatible, resulting in the best possible solutions for customers.”

Recently, RAMP developed a machine for Vancouver-based Core Energy Recovery Solutions. The system, which was installed in 2018, manufactures heat exchangers or energy recovery ventilators (ERVs) that increase the energy efficiency of ventilation systems in residential and commercial buildings. The heat exchange is achieved by conducting cold and warm airflows past each other through internal channels.

The machine takes base materials, including a patented polymer membrane and corrugated aluminum foil, and laminates them in layers of various heights and pitches based on the customer’s unique recipe. The second half of the machine takes the laminated materials through a high-precision vacuum conveyor that was designed and built by RAMP. This custom sheet layer then has separating materials placed on it using a unique pick-and-place process with standard pick positions but recipe-driven place positions varying from 250 mm to 1 m.

Finally, the layers are stacked across multiple dimensions and heights according to the last customer specifications and discharged via a conveyor belt.

RAMP selected a C6930 control cabinet IPC (left) with an Intel Core i5 processor as its control platform as well as compact EL7211 drive technology (center) and AX5000 series servo drives.

Powerful open control technology

For the Core project, RAMP relied on PC-based control technology from Beckhoff to implement the scalable drive technology, efficient controls and integrated I/O system.

The programming of PLC and motion control components with TwinCAT 3 in various IEC 61131-3 languages extends the company’s standards-based approach to software engineering. TwinCAT also helps RAMP leverage open, vendor-neutral technologies like the OPC UA standard for secure connectivity to higher level databases such as Amazon Web Services (AWS) and SAP.

For Core Energy Recovery Solutions, RAMP required a powerful Industrial PC (IPC) to handle the company’s recipe and data acquisition solutions in addition to the automation software.

“Since we needed an IPC that could run our applications with a one millisecond update rate to have maximum control over the process, we picked the high-power, cabinet-mounted C6930 IPC from Beckhoff,” says Steve Slothouber, project control lead, RAMP. The IPC also featured sufficient performance reserves to accommodate the rising requirements from repeatedly adding I/O components during the one-year development phase, and to complete the project within the tight deadline.

RAMP connects the C6930 to advanced CP2916 multi-touch Control Panels from Beckhoff to display dashboards that provide operators with an overview of current production data and overall equipment efficiency (OEE) information.

EtherCAT I/O system

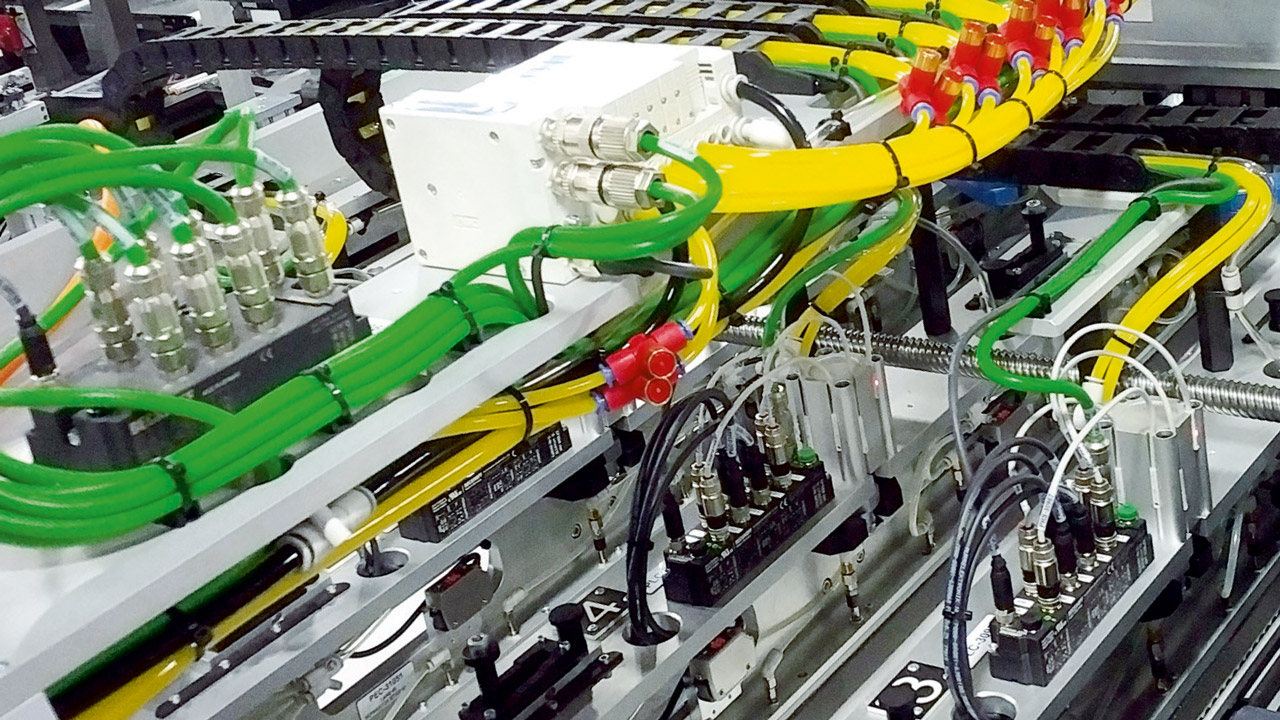

RAMP uses analog and digital I/O components from Beckhoff to cover all data acquisition and machine safety requirements. Space-saving EtherCAT terminals permit a free mix of safe and non-safe I/O in the same segment. High-density (HD) EtherCAT terminals, which offer as many as 16 I/O channels in a 12 mm wide housing, deliver even greater space savings.

“The EtherCAT I/O system provided the high-speed networking and fast scan times we needed while ensuring flexible network topologies,” says Matt Buchwald, electrical design lead at RAMP. “The Core application required high-end control technology that can react to production changes and adjust output controls in under 10 milliseconds.” The application also had to integrate with various third-party field devices such as EtherNet/IP components for web handling equipment, vision system hardware, automatic power tensioning controls and dispensing units.

RAMP also used EtherCAT Box modules with IP 67 protection throughout the system. “This allows us to place our field inputs and outputs closer to the application and reduce overall cable length and cable track requirements,” explains Matt Buchwald. “Integrating all safety systems on the same EtherCAT network via TwinSAFE I/O further reduces the overall cabling costs and installation time.”

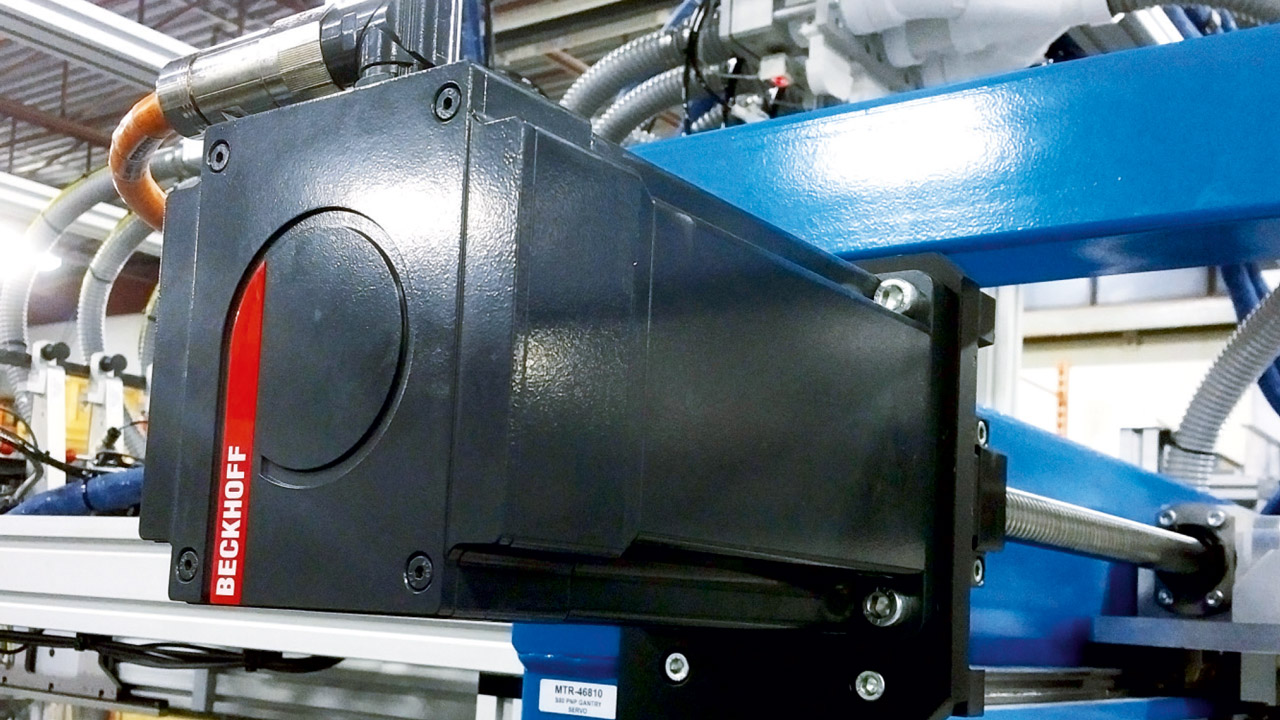

The AM8000 series servomotors with OCT handle conveyance, pick and place, web lamination, tension control and height adjustments.

Highly scalable drive technology

For ultra-compact drive technology, RAMP applied Beckhoff EL7211 servomotor terminals. “The 24 mm wide EL7211 terminals further reduce our cabinet space,” explains control systems manager Stephen Gugeler. “We can use one low-cost 48-volt power supply for the EL7211 drives, significantly reducing space and cost requirements for servo drives.” In addition, the application features inexpensive AS1020 series stepper motors driven by EP7041 stepper motor modules (50 V DC, 5 A) with built-in incremental encoders for resonance-critical applications.

For higher power and load requirements, the RAMP machine also incorporates AX5000 series servo drives for high-end position control, electronic gearing, velocity control and superimposed position control. The drives are connected to AM8000 servomotors with One Cable Technology (OCT) to handle conveyance, pick and place, web lamination, tension control and height adjustments for the production line.

PC-based control technology

Since RAMP first transitioned to PC-based control and EtherCAT technology, the company has had ample time to compare metrics with older-generation PLC- and PAC-based systems. Stephen Gugeler summarizes the findings: “Specifically, we improved PLC cycle times by 30% and reduced control system costs by approximately 30% when compared with equipment from previous vendors. Leading-edge control and networking technology with competitive pricing from Beckhoff helps RAMP increase production throughput and exceed customer requirements every time.”