New ProductsJuly 16, 2024

Functional Safety Technology

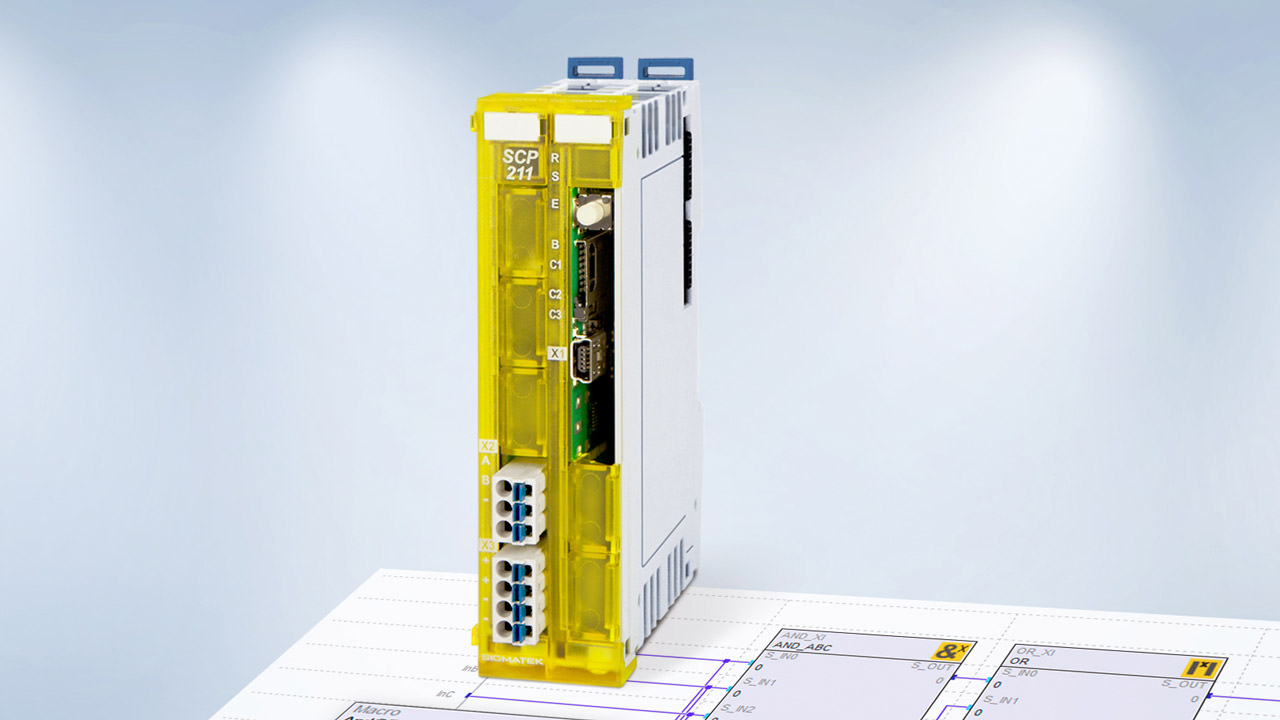

The SCP 211 safety CPU from SIGMATEK offers fast processing speeds and extensive memory.

A programmable safety system is a must-have to develop machines and systems modularly, economically and in a short time. With the SCP 211, SIGMATEK offers a very powerful safety CPU that supports new functions on the software side that simplify the creation and handling of safety applications. Safety development is carried out in the LASAL SAFETYDesigner on certified function blocks based on PLCopen.

Following the example of object-oriented programming, which has characterized SIGMATEK controllers on the application side for 25 years, it is now possible to create customer-specific macro libraries for safety applications. The special feature of the LASAL safety macros is that they can be structured in a multi-level hierarchy. Each macro is encapsulated in itself and can be tested independently as it has its own CRC test value. This significantly reduces the effort required for overall tests to obtain certifications.

The LASAL SafetyDesigner offers developers of safety-related applications the option to design them completely parameterizable and therefore very flexible. It is only necessary to create one safety application for a machine or system with numerous options, which applies to all equipment variants.

Parameter lists as engineering turbo

The parameterization, i.e. the adaptation to the often customer-specific concrete machine, takes place via a parameter list. Like the application itself, the parameter list is also protected. To ensure security, password-protected mechanisms are used when transferring the lists for setting different equipment variants.