Industry NewsJuly 1, 2020

OPC joins Advanced Physical Layer (APL) project group

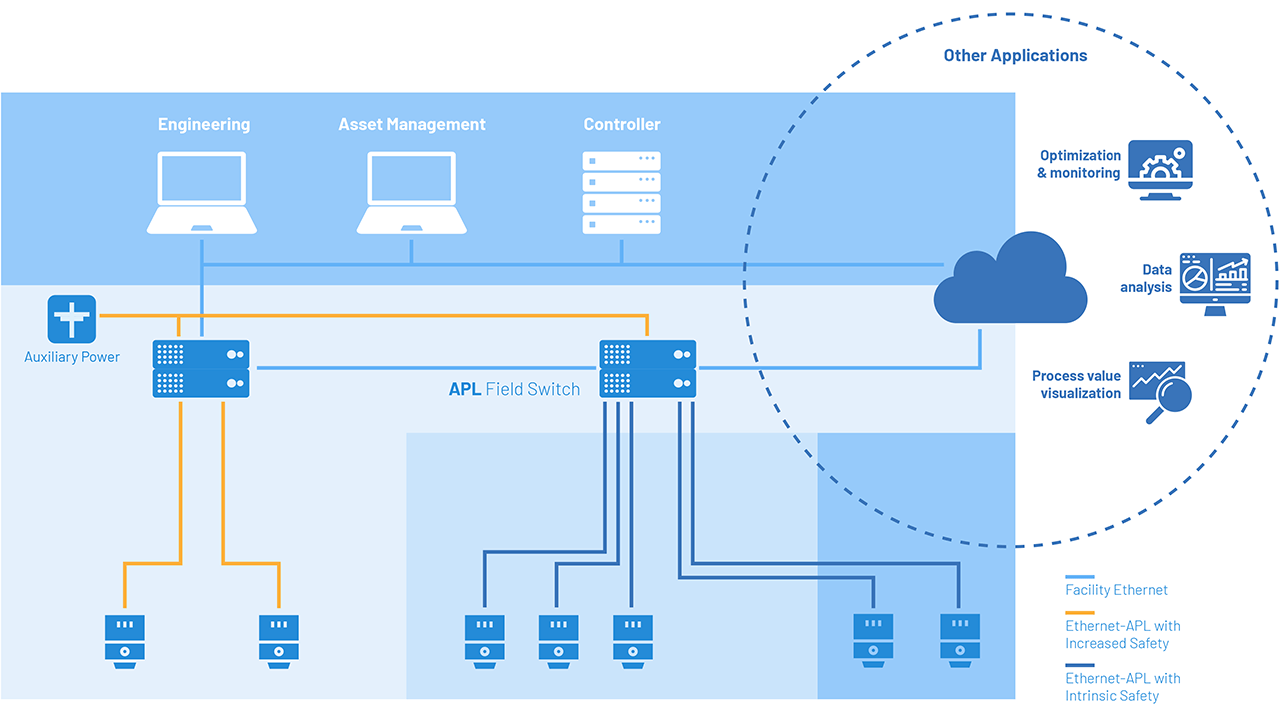

APL and its Field Level Communications (FLC) initiative is a critically important piece of technology in the strategy to expand OPC UA to all use cases and requirements in factory and process automation.

Ethernet-APL, (Advanced Physical Layer) has become critically important for the OPC UA field level strategy in process automation.

As a result, OPC Foundation announced that it has joined the APL project group in order to support the development and promotion of an advanced physical layer (APL) for Industrial Ethernet, suitable for use in demanding applications and hazardous locations in the process industry, named “Ethernet-APL”. To date, the APL Project Group has consisted of 12 industry partners and the three leading fieldbus organizations in process automation: FieldComm Group (FCG), ODVA, and Profibus & Profinet International (PI).

Jörg Hähniche, Endress+Hauser and Chairperson of APL project group said: “We welcome the OPC Foundation. While the APL project is well advanced, we are even more pleased that OPC Foundation has joined the project. Their membership completes the cooperation, as all leading organizations are now working on one Ethernet Advanced Physical Layer solution which will be integrated into their respective specifications. This has an enormous customer benefit, especially since one Ethernet Advanced Physical Layer solution now fits many applications. By jointly cooperating, we hope to benefit from the many years of experience of OPC Foundation thus benefiting a wide range of customers.”

The decision of the OPC Foundation to join the APL project group is closely related to their strategy to extend OPC UA to the field level in discrete and continuous manufacturing. For this, the OPC Foundation launched the Field Level Communications (FLC) initiative in November 2018, supported by an impressive list of major automation suppliers.

Stefan Hoppe, President OPC Foundation: “It is because of the broad acceptance, high flexibility, and vendor independence of OPC UA that various initiatives in the process industry, including NAMUR Open Architecture (NOA), the Open Process Automation Forum (OPAF), Module Type Package (MTP), and MDIS (Oil&Gas), rely heavily on OPC UA as the core technology to model devices from different vendors and exchange information between them. The extension to utilize APL as a transport layer is a logical progression – the combination of OPC UA with Ethernet-APL will be the future standard for many users in the process industry.”

Because of its versatility and manufacturer independence, OPC UA is already used today in many different industrial applications. However, OPC UA is much more than just a transport protocol in its traditional sense. Instead, OPC UA is an industrial, protocol-agnostic framework for the Industrial Internet of Things and Industrie 4.0 that contains mechanisms for secure, reliable, manufacturer and platform-independent information exchange, as well as options for semantic information modeling and self-description of devices. OPC UA scales from the sensor across all levels to MES / ERP and also into the cloud including cyber security mechanisms built from the start.

In order to meet all requirements for use cases from end users, suppliers, and integrators from process automation to factory automation, the FLC-related technical work includes the following topics:

- definition of an “Automation Component” with functions, interfaces and behaviors that are common to the different FLC-conformant devices used in various applications in process and factory automation

- definition of system behaviors and sequences for common functionalities e.g. bootstrapping, connection establishment, etc.

- harmonization and standardization of application profiles like IO, motion control, functional safety, system redundancy

- standardization of OPC UA information models for field level devices in online and offline scenarios e.g. device description and diagnostics

- mapping to subordinate communication protocols and transmission physics, such as TCP, UDP, Ethernet APL / SPE, deterministic Ethernet (TSN) with future mapping to 5G and Wi-Fi 6

- guarantee the best integration of OPC UA companion specifications like FDI, FDT, PA-DIM, ADI (Analyzer Device Integration), Module Type Package (MTP), and MDIS (Oil&Gas), VDMA pumps, UMATI, Spectaris, and so forth

Peter Lutz, Director OPC Foundation FLC Initiative said: “APL is recognized by the OPC Foundation and particularly its Field Level Communications (FLC) initiative to be a critical important piece in the strategy to expand OPC UA to all use cases and requirements in Factory and Process Automation, supporting the vision of a fully scalable, industrial interoperability solution, from sensor to cloud.”

About Advanced Physical Layer

Ethernet-APL describes a physical layer for Ethernet communication technology developed for the requirements of process industries. The development of Ethernet-APL was determined by the need for communication at high speeds over long distances; the supply of power and communication signals via common single, twisted-pair (2-wire) cable; and protective measures for the safe use within hazardous areas.