Industry NewsSeptember 10, 2018

VDMA releases OPC UA specs for robotics and machine vision

In the smart factory of the future, machines must speak the same language. A decisive factor for robotics and machine vision applications is the standardization of the communication interfaces.

The OPC UA machine vision & robotics working groups have released the first versions of their companion specifications.

“Interoperability is the key for distinguishing our products in a connected world of Industrie 4.0. OPC UA is the designated standard to make machines talk the same language in the smart factory of the future. With the release of the companion specifications, we have reached a major milestone on this way,” Dr. Horst Heinol-Heikkinen, Chairman of the VDMA OPC Vision Initiative said.

“The VDMA recognized the potential of OPC UA at an early stage and promoted the standardization of data and interfaces of devices and machines in its sectors in an exemplary and consistent manner with its members,” added Stefan Hoppe, Global Vice President of the OPC Foundation.

Robots describing themselves

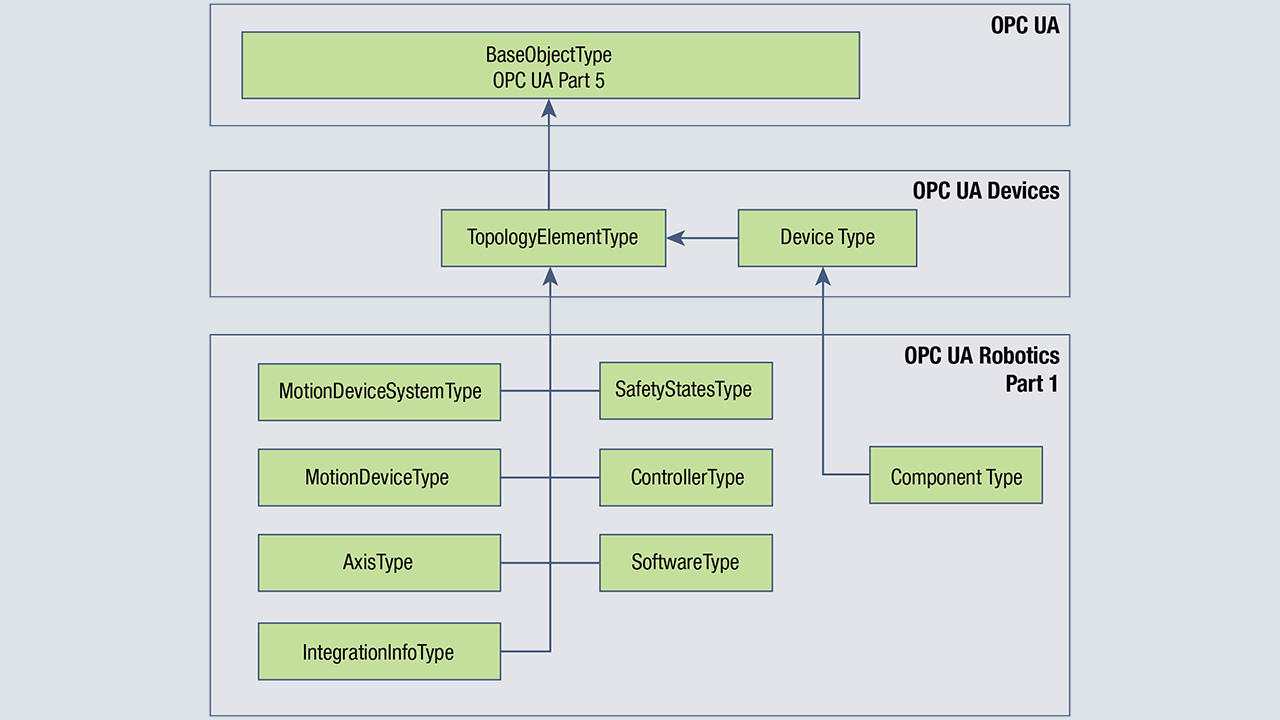

The OPC UA Companion Specification for Robotics (in short, OPC UA Robotics) provides a standardized information model which is capable of presenting all robot related data regardless of manufacturer or location in a uniform manner. Part 1 released as a draft version permits asset management, condition monitoring, preventive maintenance and vertical integration at any time, anywhere in the world and independent of the robot brand or type. It provides the basis for data analytics and for boosting OEE.

Simpler machine vision integration

The OPC UA Companion Specification for Machine Vision (in short, OPC UA Vision) provides a generic model for all machine vision systems – from simple vision sensors to complex inspection systems. Put simply, it defines the essence of a machine vision system. Part 1 published as release candidate version describes the infrastructure layer which is an abstraction of the generic machine vision system. It allows the control of a machine vision system in a generalized way, abstracting the necessary behavior via a state machine concept. It handles the management of recipes, configurations and results in a standardized way, whereas the contents stay vendor-specific and are treated as black boxes.

Skill-based control

Beside the release of the two new companion specifications, a demonstrator for skill-based control with OPC UA was presented for the first time. The demonstrator is a fully-fledged assembly cell producing fidget spinners and integrating systems and components from over 20 manufactures speaking one language: OPC UA.

Robotics condition monitoring

A further use case presented at automatica demonstrates the OPC UA Companion Specification for Robotics in action. Major robot manufacturers show how condition monitoring can be implemented independently of manufacturer and robot type in the cloud. All relevant status data are clearly visible on a dashboard. Applications of the demonstrator are asset management, condition monitoring, preventive maintenance and vertical integration.

First OPC UA testbed

VDMA is co-founder of the pre-competitive and non-profit association Labs Network Industry 4.0 (LNI) that neutrally operates testbeds and use cases focusing on SME requirements and standardization validation. The University of Applied Sciences Ravensburg-Weingarten, Germany, plans to host in their lab the first testbed together with industry partners. “The practical validation by users, including SMEs, is a key to success for the international standardization activities to follow”, Dr. Christian Mosch from VDMA Forum Industrie 4.0 emphasizes. The testbed is open to new partners without obstacles.

OPC UA Companion specifications

The OPC UA Vision companion specification is available free of charge as VDMA Specification number 40100 (as release candidate version). The OPC UA Robotics companion specification is now available free of charge as VDMA Specification number 40010 (as draft version). Both specifications can be requested at [email protected].

For more information about the VDMA please visit http://www.vdma.org/r+a