TechnologyNovember 16, 2025

Advancing Physical AI safety systems in manufacturing

New virtual safety fence and real-time quality inspection systems use industrial-grade network infrastructure. Accenture, NVIDIA, and Belden are creating safer, smarter, and more connected industrial operations where the physical and digital worlds converge.

Belden. has collaborated with Accenture to help develop and deploy physical AI systems for worker safety in factories and warehouses. The systems demonstrate how time-sensitive network infrastructure enables advanced AI applications that enhance worker safety, improve quality control and modernize existing factory operations as modern manufacturing increasingly integrates autonomous systems alongside human operators.

“By providing the full stack of technology from sensor to edge, we’re enabling manufacturers to implement advanced AI safety systems using existing factory infrastructure.”

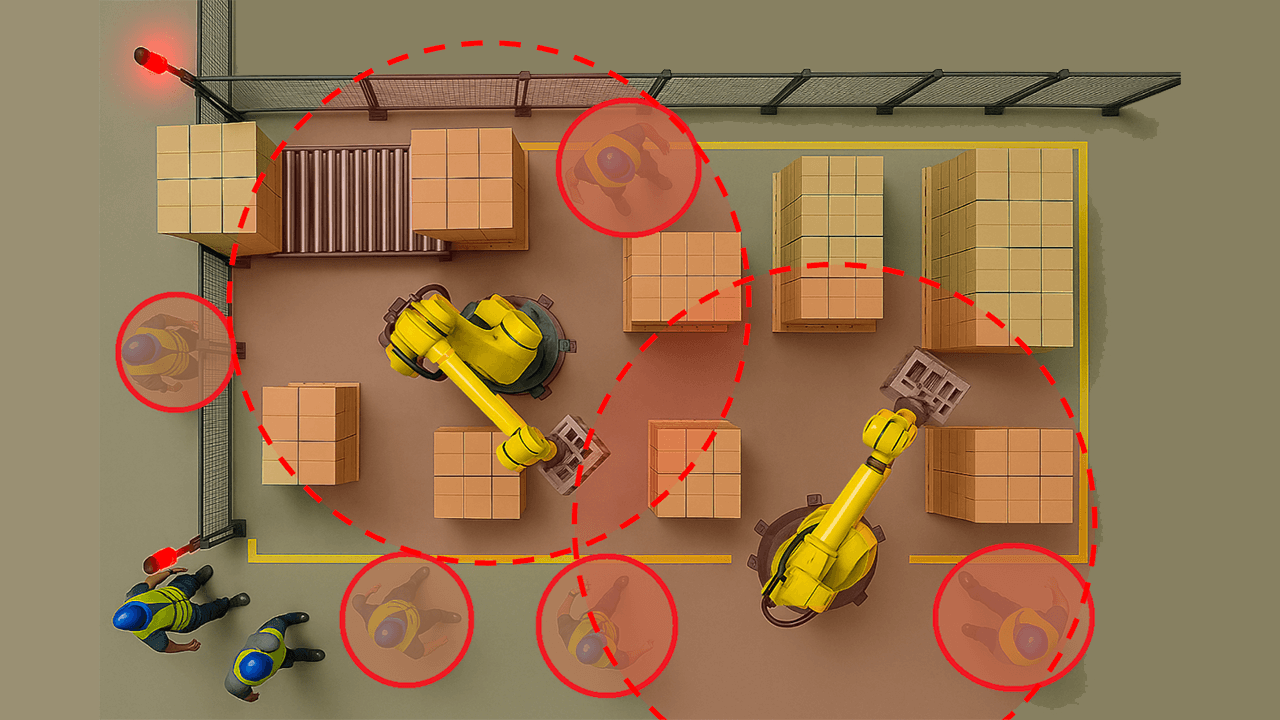

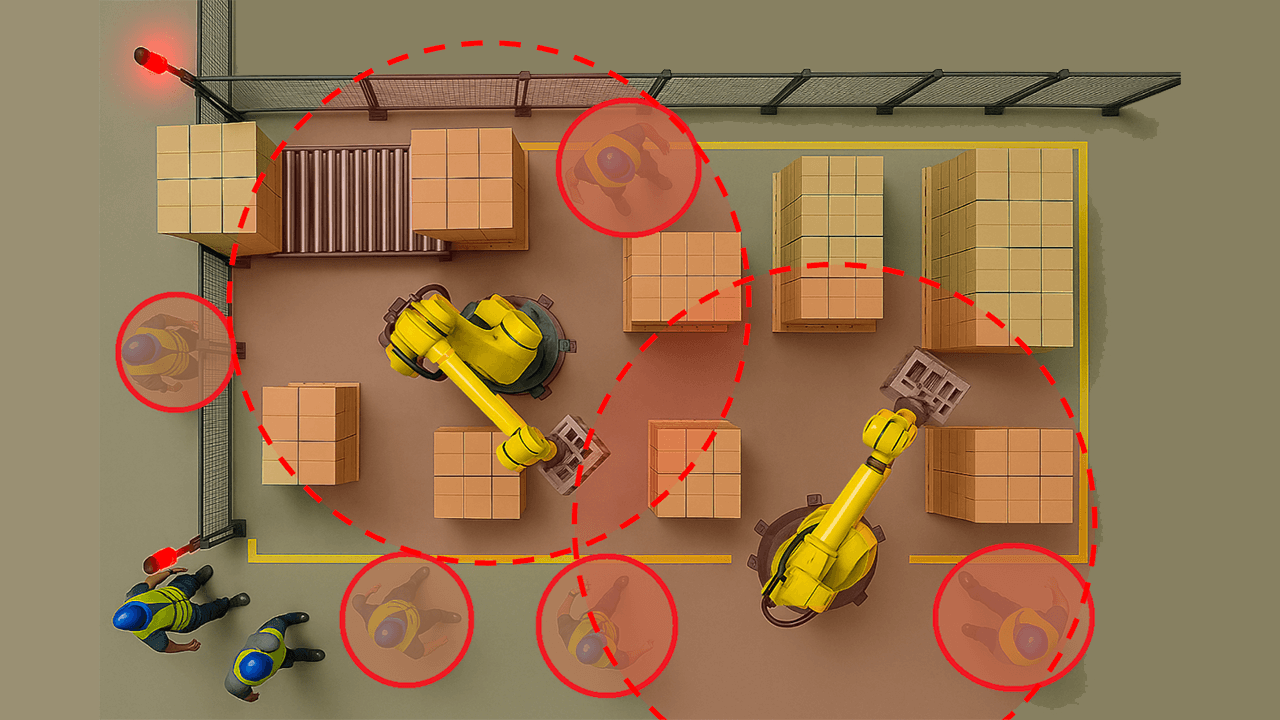

Belden’s virtual safety fence solution was developed with Accenture’s “Physical AI Orchestrator,” which uses NVIDIA Omniverse, NVIDIA Metropolis libraries for digital twins and agentic AI from Accenture. It applies computer vision and closed-loop control to monitor worker movements and automatically pause robotic operations when humans enter hazardous zones.

Following the pilot project completed in September, the virtual safety fence solution is now expected to be commercially deployed at an automotive manufacturer for pedestrian safety in warehouse environments later this year. “The physical AI safety systems we are building represent our evolution from connectivity products to comprehensive industrial solutions,” said German Fernandez, VP of Ecosystem Partner Programs at Belden. “By providing the full stack of technology from sensor to edge, we’re enabling manufacturers to implement advanced AI safety systems using existing factory infrastructure.”

Accenture’s Physical AI Orchestrator, powered by NVIDIA Omniverse and NVIDIA Metropolis libraries and integrated with Belden’s Time-Sensitive Network, enables real-time monitoring and orchestration.

Enabling synchronized precision for safety-critical applications

The technical breakthrough centers on Belden’s Time Sensitive Networking (TSN) capabilities, which enable microsecond-precise synchronization of video streams from multiple cameras across factory floors. This synchronization is essential for accurate tracking of people and equipment movement in real-time safety applications.

“The physical AI systems we help Belden build on Accenture’s Physical AI Orchestrator platform address the critical need to protect workers while maintaining the operational flexibility that modern manufacturing demands,” said Ramalingam Hariharan, a managing director at Accenture.

“Industrial-grade networking protocols are critical for safety applications that require precise timing,” said Fernandez. “Our TSN technology enables real-time, closed-loop control between AI systems and production equipment, which is fundamental for both safety and quality applications.”

Belden’s physical AI systems also demonstrate real-time quality inspection capabilities. During another pilot project with pharmaceutical blister packs, AI-powered vision systems successfully identified incomplete or damaged packages and automatically triggered robotic removal systems while maintaining full production speed.

Belden’s new physical AI systems are the result of each company’s core capabilities: Belden provides industrial networking infrastructure and protocol integration with embedded security; NVIDIA provides simulation, agentic AI and accelerated computing platforms; and Accenture brings expertise and capabilities in physical AI, manufacturing automation, systems integration, industry and reference architectures.

Accenture, NVIDIA, and Belden are creating safer, smarter, and more connected industrial operations where the physical and digital worlds converge.

Supporting manufacturing transformation

Belden’s new physical AI systems address two key manufacturing challenges: labor shortages and enabling rapid facility modernization. As manufacturers struggle to find experienced workers, AI-enhanced safety systems help protect newer personnel by providing intelligent hazard detection and automated safety responses.

The integrated approach reduces both infrastructure costs and complexity while improving overall equipment effectiveness. The same network infrastructure that handles safety monitoring can simultaneously manage quality inspection and other industrial applications, demonstrating the multi-service network capabilities that distinguish the breadth of Belden’s automation solutions.

Making Safer Spaces: NVIDIA and Partners Bring Physical AI to Industrial Infrastructure

Advanced blueprints, vision language models and synthetic data generation extensions accelerated by NVIDIA RTX PRO 6000 Blackwell GPUs enhance productivity and improve safety across environments.

Physical AI is becoming the foundation of smart cities, facilities and industrial processes across the globe. NVIDIA is working with companies including Accenture, Avathon, Belden, DeepHow, Milestone Systems and Telit Cinterion to enhance operations across the globe with physical AI-based perception and reasoning.

The continuous loop of simulating, training and deploying physical AI offers sophisticated industrial automation capabilities, making cities and infrastructure safer, smarter and more efficient. For example, physical AI applications can automate potentially dangerous tasks for workers, such as working with heavy machinery. Physical AI can also improve transportation services and public safety, detect defective products in factories and more.

Advancing Physical AI

Making Safer Spaces: NVIDIA and Partners Bring Physical AI to Industrial Infrastructure

Accenture is collaborating with Belden, a leading provider of complete connection solutions, to enhance worker safety by creating smart virtual fences that factories can place around large robots to prevent accidents with human operators.

The smart virtual fence is a physical AI safety system that uses an OpenUSD-based digital twin and physics-grounded simulation to model complex industrial environments. Using computer vision-based mapping and 3D spatial intelligence, the system is adaptive to increased variability in the dynamic human-robot interactions that occur in a modern shopfloor environment.

Accenture taps into the NVIDIA Omniverse platform and Metropolis to build and simulate these smart fences. With Omniverse, Accenture created a digital twin of a robot arm and workers moving in a space. And with Metropolis, the company trained its AI models and deployed them at the edge with video ingestion and the NVIDIA DeepStream software development kit (SDK)’s real-time inference capabilities.