TechnologyMay 12, 2022

Digital solutions in production by integrating OT and IT

The Porsche plants in Stuttgart-Zuffenhausen and Leipzig implemented a common data infrastructure and universal cloud connectivity based on Connectware technology. A neutral technical framework provides a wide variety of digital solutions along the production chain that can be implemented efficiently and in a compatible manner.

A common data infrastructure and universal cloud connectivity based on Cybus Connectware technology was implemented at the Porsche plants in Stuttgart-Zuffenhausen and Leipzig. The Industrial Cloud Community Partner Cybus provides a neutral technical framework with which a wide variety of digital solutions along the production chain can be implemented efficiently and in a compatible manner.

The digitization of production and logistics in the automotive industry takes place through many small solutions that are developed along the entire production chain. For a fast and effective development of compatible use cases, factory modernization requires a neutral technical framework that connects the shop floor and operational technology (OT) with the factory IT. Porsche has taken up this challenge and developed an overarching data strategy together with the Industrial Cloud Community Partner Cybus. The plants in Stuttgart-Zuffenhausen and Leipzig are pilot plants for the development of a solution that could be scaled to other locations in the Volkswagen Group in the future.

The neutral technical framework for factory modernization

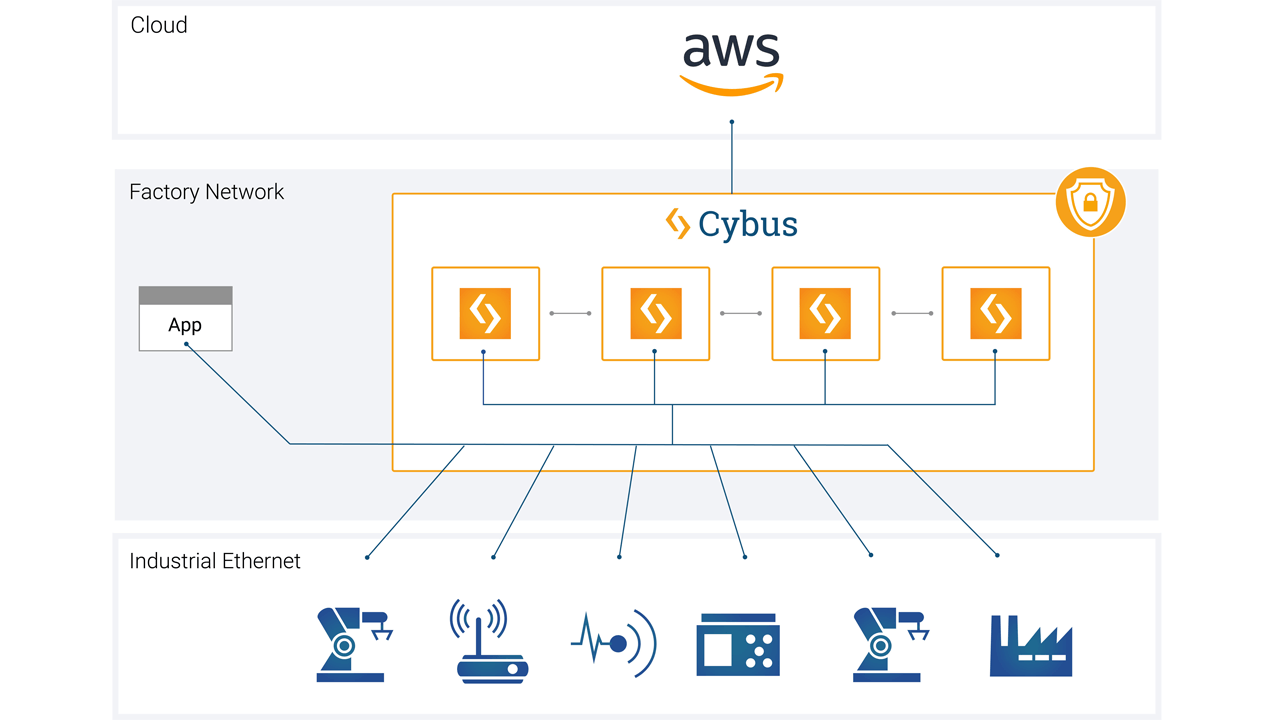

With more than 1000 machines from different manufacturers in a single hall, the complexity of digitizing production sites becomes clear. Until now, almost every machine required a special digital solution or individual integration into the cloud in order to enable cross-plant analyzes and optimization measures. In addition, the demands on an infrastructure are high: It must be high-performance, avoid downtime, allow flexibility and be able to handle a high data load. The sports car manufacturer is successfully meeting these challenges with a comprehensive data strategy. As a key component, the Manufacturing Data Platform from Industrial Cloud Community Partner Cybus creates a technology-neutral layer that seamlessly integrates OT and IT.

The Manufacturing Data Platform is a breakthrough in manufacturing IT

Cybus’ on-premises Industrial IoT solution collects operational data, which is then harmonized and transmitted to the cloud. The central data infrastructure creates autonomy for applications, systems and environments and covers overarching security and specific data protocol requirements. As high-performance and easy-to-maintain software, Connectware runs 24 hours a day without downtime in the three-shift system of the production facilities. This is achieved through the use of Kubernetes clusters running Cybus Connectware – a breakthrough in production IT.

For high-tech car factories, OT and IT are seamlessly connected

The implementation of Cybus’ Industrial IoT Edge Layer enables the holistic management of data streams across OT and IT borders and realizes the high demands on IT infrastructure and security. As a pioneer in the Volkswagen Group, Porsche thus achieves full flexibility and scalability for its digital projects as well as a flexible transformation from petrol to hybrid to fully electric automobile production – and thus sets the course for the future of automobile production.

The first use cases in the areas of logistics, maintenance and production have already been implemented with the Manufacturing Data Platform from Cybus. Examples include the Industrial Computer Vision applications, which enable guided installation, documentation and quality control of signs and labels in production, and the Call Rocker Solution, which automates replenishment in SAP logistics systems.

“The use case is an example of how the Volkswagen Group is making great strides towards a scalable and future-proof production IT landscape. As a partner of the Industrial Cloud Community, Cybus is proud to support this,” said Peter Sorowka, CEO of Cybus.