TechnologyJuly 20, 2023

Machine connectivity and industrial edge computing

Software and IT innovation are the primary drivers for manufacturing investment. Solution architectures are expected to consolidate around specific standards, with architectural blueprints and best practices addressing end-user needs. Edge computing will also show accelerated deployment within manufacturing.

Edge computing is the next big thing for manufacturing. After providing a definition of “edge” itself, this article goes on to describe the current technological advances and market development for industrial edge computing, paying special attention to the interplay of machine connectivity and edge, as well as questions of operating models and the scalability of industrial IoT solutions.

What is edge computing?

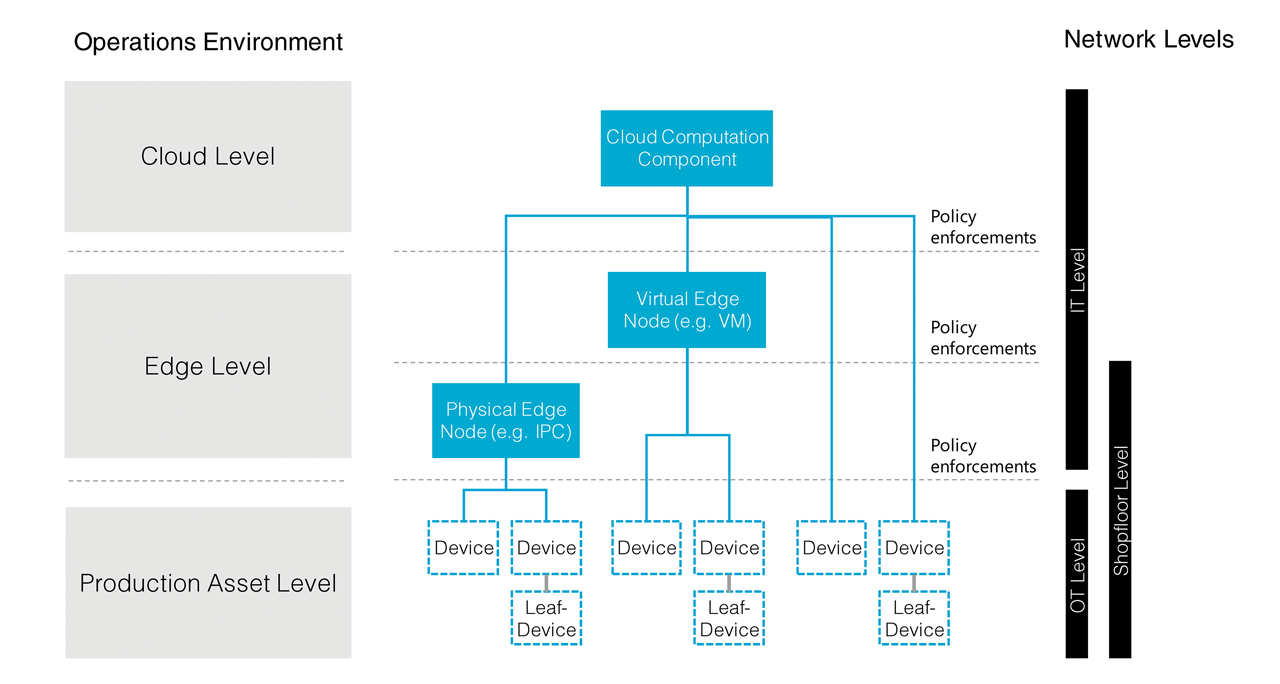

In the context of manufacturing, we propose the following definition to distinguish “edge” from “on-premises” on the one hand and, on the other, to avoid treating “edge” as if it were merely an add-on for cloud platforms: accordingly, edge computing describes a system of decentralized edge nodes that are located close to a physical data source.

These edge nodes are connected both to devices and to a central platform (such as a cloud). Unlike components on the production asset level, edge nodes can be managed centrally, with the processing of the data collected either being handled within the edge node or by the central platform.

The edge level can be viewed from a number of perspectives. While an application perspective describes software applications and their functions (e.g. data pre-processing, data bus, etc.), an infrastructure perspective describes the IT infrastructure deployed (including hardware and operating systems), and an operating perspective describes tools with which edge levels can be managed and administrated (e.g. monitoring tools or tools for handling multi-site software rollouts).

The three levels of the Industrial IoT solution: production assets, edge and central platform.

Arguments for why edge computing is relevant for Industrial IoT applications are well-known. Some applications require very short latencies that are unlikely to be maintained by communicating with a centralized cloud platform. Data volumes are also very high in some cases, requiring extensive pre-processing at the edge level as a minimum. Last but not least, regulatory conditions apply to some industries’ applications – and these regulations prevent data from ever leaving the company network.

Architectural trends

Customers wanting to set up and operate an Industrial IoT solution need to look at many issues, and one of the most important is the question of a suitable system architecture. As of now, there is a trend towards the consolidation of Industrial IoT architectures, which is characterized in part by the following edge level aspects and properties:

- Customers are deploying cloud platforms but want to minimize the edge level’s technological dependencies on the cloud while avoiding vendor lock-in.

- Customers are splitting the edge level into two – a factory floor level underneath plus a top level with central platform/cloud connectivity – and both managed centrally.

- Customers are deploying an MQTT broker at the edge level as a central hub for data traffic. Data are streamed with MQTT or Kafka toward the central platform while applications that are run locally can be accessed via the MQTT broker.

So how do these architectural trends and edge relate to machine connectivity?

The three levels of the Industrial IoT solution: production assets, edge and central platform.

Scalable machine connectivity

Efficient and secure access to machine or device data is a fundamental requirement for Industrial IoT applications. In terms of functionality, or the application perspective, these machine connectivity demands are virtually identical to those required by traditional shopfloor applications.

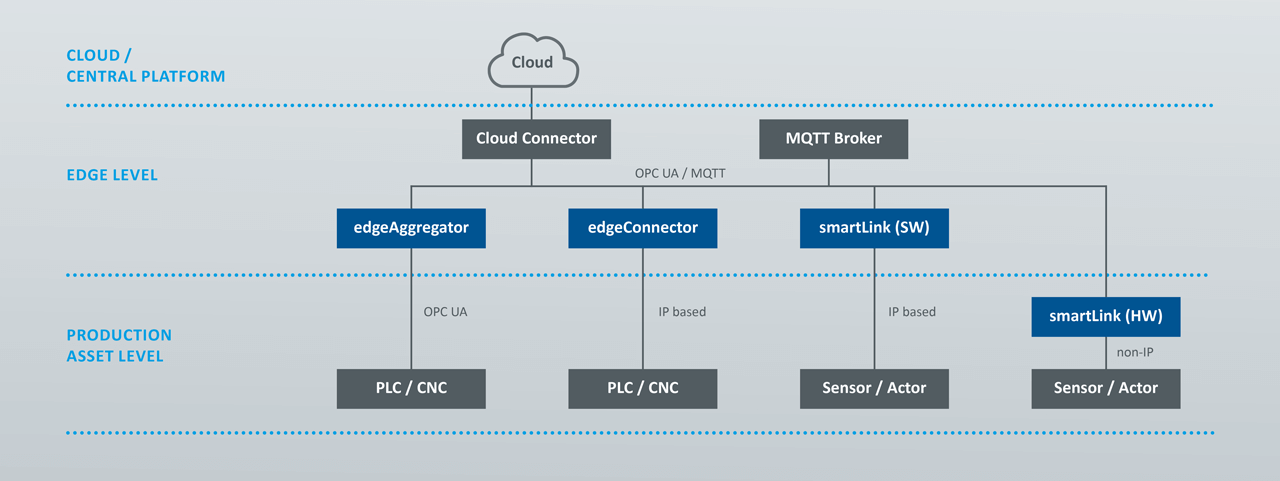

The typical devices built into plants or to be handled by brownfield projects – controls, first and foremost – need to be integrated. The collected data must be provided using standard protocols with application-side support, which usually means OPC UA or MQTT. Also important are functions that permit the efficient handling of multiple data sources, such as the consolidation of data or data sources into a single interface (server aggregation).

Looking at suitable operating models reveals more significant differences between traditional shopfloor applications and Industrial IoT solutions.

Deployed and operated locally at a production facility, traditional applications plus machine connectivity will feature an HMI or SCADA system, for example, MES solutions, or a database link with the aim of ensuring data backups. Machine connectivity users are typically non-specialists and therefore require IT interfaces that are as simple to use as possible. Low-maintenance solutions are required, which usually remain unchanged after initial commissioning.

In contrast, Industrial IoT solutions characteristically involve applications or an IoT/cloud platform being deployed across multiple production sites. Not only does the platform run several applications rather than just the one, but these applications evolve over the solution lifetime, with one key driver of this change being the short innovation cycles in software and IT. Dedicated teams are deployed to run the solution: these employees are assigned multi-site responsibilities and have extensive IT know-how. Customers are looking to utilize IT-driven operating models and their associated benefits in terms of solution efficiency and scalability (in other words: the platform + edge level of the solution as outlined above).

As with other solution components, machine connectivity needs to meet the same requirements for flexibility, operating efficiency and scalability. Increasingly, customers are no longer viewing machine connectivity in the context of the Industrial IoT solution as a production asset, but as an edge level component, with all of its associated advantages in terms of efficiency and scalability.

Machine connectivity part of edge

So if machine connectivity is to be deployed as part of the edge level, which requirements then need to be met? The following are some of the key aspects here:

- Machine connectivity is provided with software modules that are deployed on standard hardware and managed by end customers in exactly the same way as for other edge-level software components. Docker containers are now a common choice here.

- Machine connectivity can be managed by standard IT tools. Often, this will involve popular Kubernetes-based platforms like RedHat OpenShift or Suse Rancher, but leaner alternatives such as Portainer may also be used.

- Machine connectivity supplies relevant data to popular IT monitoring tools such as Prometheus and Grafana.

- Machine connectivity provides documented, stable interfaces for configuration that make use of standard protocols – whether remote, automated, or both (e.g. http REST).

Alongside these technical requirements, customers also have an increasing interest in utilizing machine connectivity as a service, looking for flexible fee schedules that reflect actual need (and benefits) without requiring capital expenditure or investment in equipment.

Solutions from Softing

As a specialist for industrial communication and automation, products for machine and device connectivity have been part of the Softing Industrial Automation GmbH portfolio for many years. Softing Industrial has been tracking the trend toward software virtualization and edge computing for a while now, and used SPS 2018 as the occasion to launch the first commercially available Docker container for machine connectivity, with its software module for connecting to Siemens controls – the edgeConnector Siemens.

Since then, the company’s portfolio has grown to include eight Docker containers for machine connectivity, including two variants specially designed for Siemens Industrial Edge, with other products now in development or on the roadmap.

These products meet typical requirements for PLC connectivity in brownfield projects. In addition, the company’s edgeAggregator product offers OPC UA-based server aggregation plus additional IT security functions, making it especially suited to deployment in innovative industrial IoT solutions.

Also in relation to server aggregation, the use of OPC UA information models for interface abstraction is now an increasingly important topic in this field. These information models can either be deployed at the shopfloor level, for one or a few controls, or can be integrated at a higher, facility-based level to present different sites as a homogeneous entity from the perspective of a central platform.

Softing Industrial now offers initial functionality for implementing these requirements and scenarios, with other functions in the pipeline.

Outlook

For the foreseeable future, software and IT innovation will remain the primary driver for manufacturing investment. Solution architectures are expected to show further consolidation around specific standards, with architectural blueprints and best practices offering simpler approaches to addressing end-user needs. Edge computing will also show accelerated deployment within manufacturing.

For Softing Industrial it is interesting to see that customers are starting to show look into IT-driven operating models for machine connectivity, even though the solution context is still conventional and does not feature Industrial IoT aspects. Over the medium to long term, however, this trend will strengthen, with IT standards and tools then finding increased acceptance at the shopfloor level and within OT. In time, this will render obsolete the distinction made in this article between conventional and Industrial IoT solutions – at least in terms of machine connectivity.

Dr. Christopher Anhalt, Vice President Product Marketing, Softing Industrial Automation GmbH