TechnologyJanuary 18, 2024

Snowflake technology solution from industrial edge to the cloud

By leveraging machine and production data, companies can leverage smart manufacturing solutions to optimize business operations, forecast parts usage, assess supplier quality, and adopt preventive maintenance, thereby improving efficiency and maintaining market competitiveness.

As a forward-thinking manufacturer, you’re constantly seeking ways to optimize your operations and streamline your supply chain. The challenges of maintaining efficiency, reducing downtime, and adapting to rapidly changing market demands are always at the forefront of your strategy.

By leveraging machine and production data, companies can optimize business operations, forecast parts usage, assess supplier quality, and adopt preventive maintenance, thereby improving efficiency and maintaining market competitiveness.

This is where the combined power of Snowflake’s data warehousing and Opto 22’s automation solutions comes into play. Data travels securely from groov products (edge hardware on the plant floor) up to Snowflake (data storage in the cloud). This combination gives you the tools needed to both collect and harness the power of big data, leveraging advanced analytics and machine learning to optimize plant floor operations and drive innovation.

In this article, we’ll not only explore how these technologies address immediate challenges but also delve into the technical mechanics, explaining how it all works and ties together–paving the way for a more efficient, responsive and data-driven manufacturing environment.

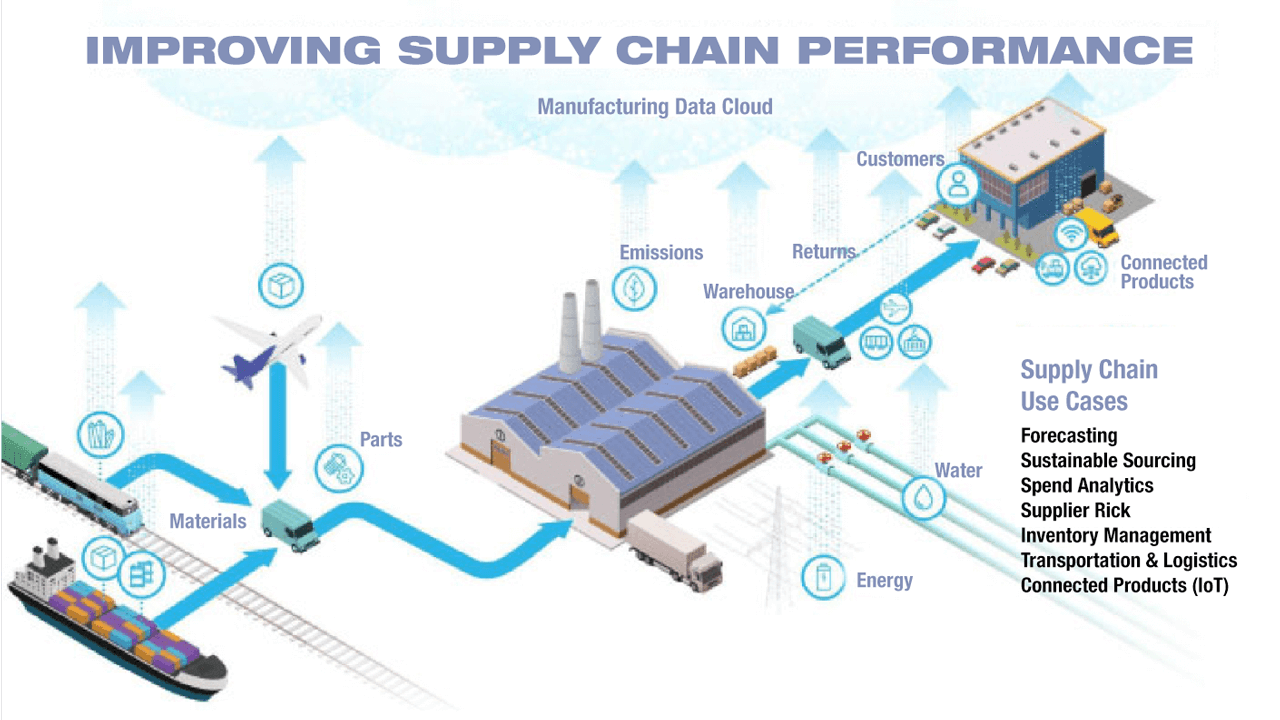

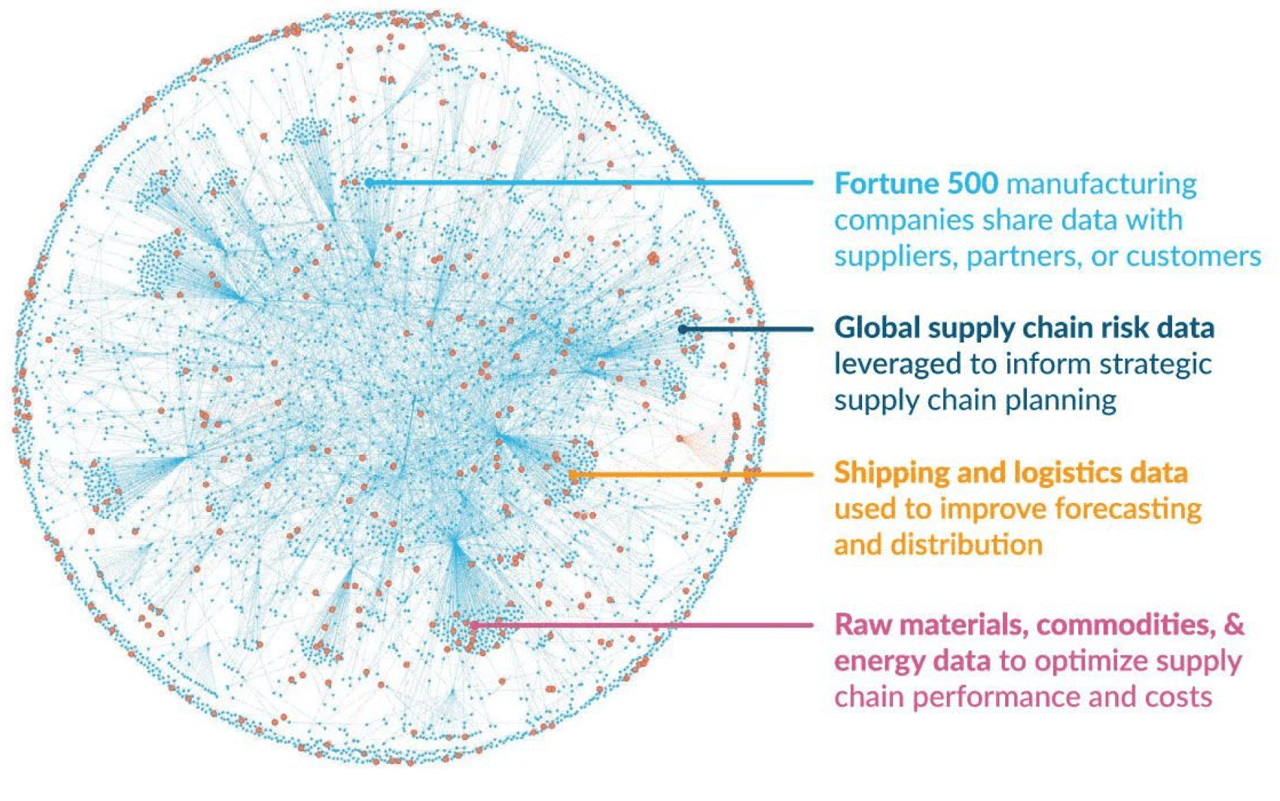

Modern supply chains require a strategy to quickly and securely share large amounts of data between manufacturing operations and suppliers, partners and customers.

Snowflake creates paradigm shift for data warehousing

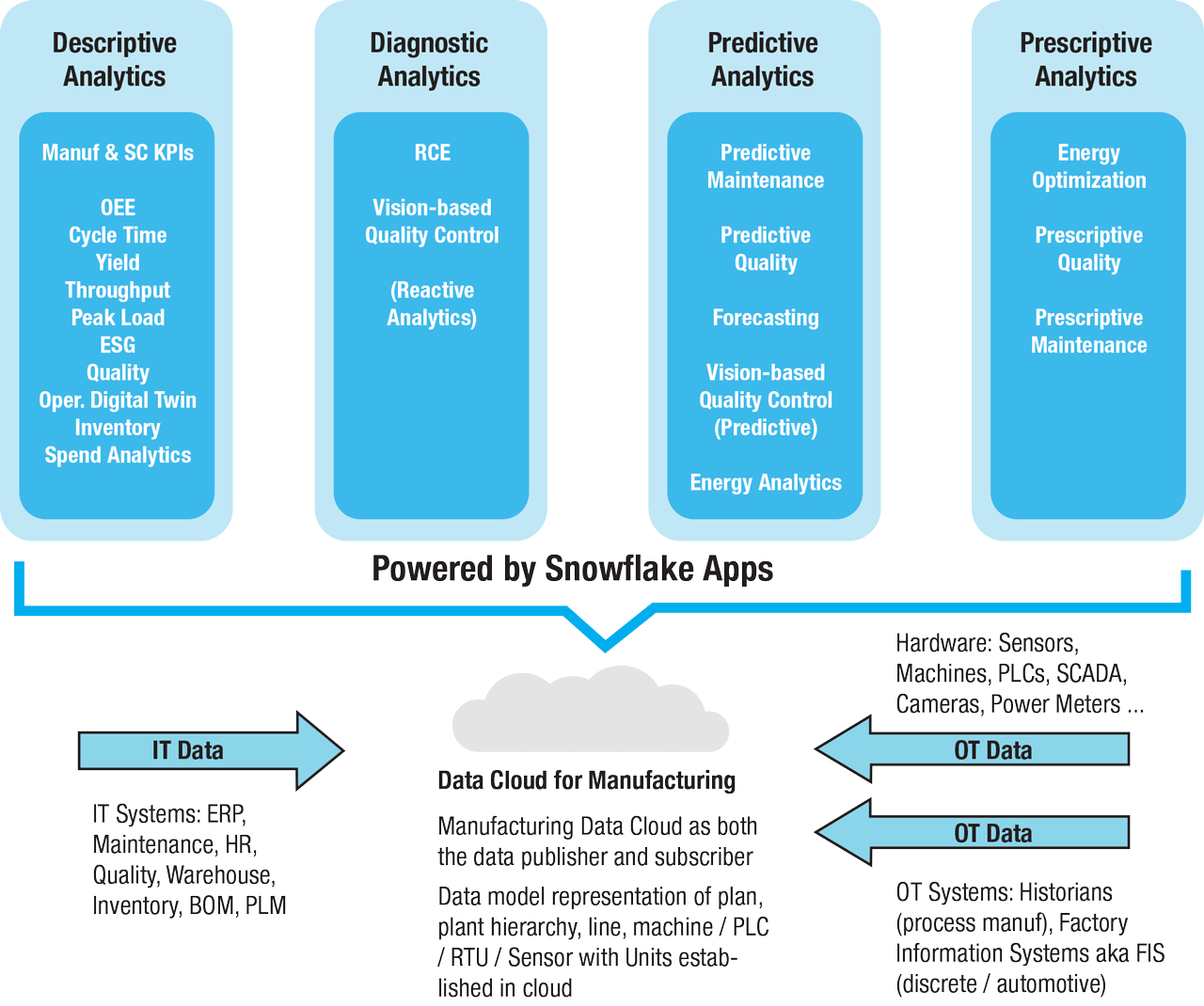

In the complex world of manufacturing, effective data management is key to optimizing operations. Snowflake’s data warehousing solution is designed with this in mind, offering a cloud-native platform that simplifies the way users can handle large volumes of data.

Snowflake is built on a unique architecture that supports the separate scaling of computing and storage resources. Inclusion of familiar technologies ensures a streamlined transition and easy adoption for users.

SQL-based query language

Snowflake uses a variant of SQL for its query language. So if a user is familiar with SQL, they will find Snowflake’s query language quite intuitive. It supports most of the standard SQL commands and functions, allowing users to perform complex data manipulations and analyses–helping to make informed decisions quickly.

The coordinated flow of IT and OT is vital to achieving digital transformation in modern manufacturing systems.

Relational data

Snowflake’s architecture lets you store, process, and analyze relational data, so you can run complex queries and transactions. Inclusion of relational data modeling means you can create tables, set primary and foreign keys, and establish relationships between different tables on various data types.

AI integration

With AI, ML, and anomaly detection (AD)–plus the integration of large language models (LLMs)–Snowflake helps you unearth patterns and insights from your data. Given the scale of data storage available in the cloud, a single human would be hard pressed to make sense of it all. But think of using simple language prompts like, “When was my peak energy consumption last quarter?” or “How many widgets did I produce between 11AM and 3PM on November 8, 2023?” This. Is. Powerful.

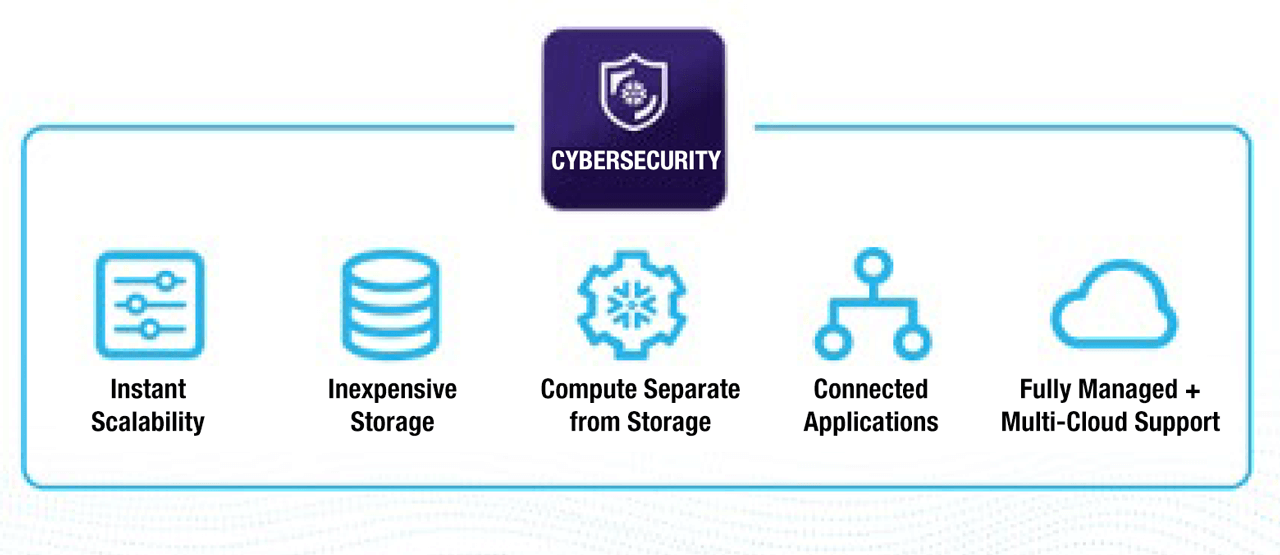

Effective cybersecurity strategies must address a wide range of technical issues.

Security and compliance

Knowing that data is secure and compliant is vital. Snowflake’s encryption and access control measures ensure that sensitive information is protected, both when stored and transferred. Users can trust in robust authentication, network policies, and comprehensive audit logs for secure and transparent data management. Sensitive information is protected at all times.

Opto 22’s groov products

Data comes in many forms, from the tiniest building block, a single bit, all the way up to UDTs and complex data models. But even before that, it starts as a real-world signal—an output from a sensor in your facility that could be measuring voltage, current, temperature, pressure, vibration, fluid level, proximity switches—and the list goes on.

That’s where Opto 22’s groov family comes into play, comprising groov EPIC, groov RIO, and the new groov RIO Energy Monitoring Unit (EMU). The robust hardware platform and comprehensive suite of software solutions has current users describing groov as a “Swiss Army Knife” for IIoT applications. More than a PLC platform, groov products combine the standard functionality of a PLC with a myriad of cybersecure, IIoT enabling technologies.

Communications

Planning to connect a variety of disparate devices and systems across greenfield and/or brownfield applications? Perhaps each device uses a different protocol?

The groov family offers extensive communication protocols, including MQTT (Sparkplug B or string payloads) for lightweight and efficient messaging, OPC UA for interoperability between different industrial equipment, and support for legacy protocols like Ethernet/IP, ProfiNet, OptoMMP, and Modbus/TCP.

Cybersecurity

Opto 22 ensures robust protection for your industrial network with groov products, incorporating an onboard firewall, port conduits for secure traffic management, and an OpenVPN client for protected remote access. SSL/TLS certificate management enhances communication security, while LDAP integration streamlines user management, ensuring that only authorized individuals have access to your critical systems and data.

Physical I/O

Need flexibility to connect to various sensors, actuators, and other industrial devices across your plant? The groov family supports a versatile range of physical I/O options, including AC/DC inputs and outputs, digital and analog signal support, serial communication (RS232/422/485), and CAN bus connectivity.

User-friendly programming and configuration

The groov family offers an accessible programming experience with intuitive interfaces, catering to both novice and experienced automation users.

Integration with popular third-party software like Ignition Edge, CODESYS, and Node-Red enhance versatility and application development. These features collectively ensure a hassle-free setup and efficient management of industrial automation and IIoT solutions.

Technical mechanics: how it works

Understanding how Snowflake and Opto 22 work together to improve manufacturing processes is key. The big question: How does it work?

Step 1: Data begins its journey on the plant floor with devices such as Opto 22’s groov EPIC, RIO, or EMU, collecting real-time data from various industrial processes. Tag data can originate from real world signals—voltages, currents, resistances, etc.–or from other 3rd party devices–PLCs, VFDs, meters, or from any device with a serial or Ethernet connection, including web sites, services, and databases. The data is transmitted as individual tags or packaged up as data models or user defined types (UDTs).

Step 2: Data is then published using MQTT Sparkplug B, a lightweight pub/sub messaging protocol designed to be efficient and reliable in challenging network conditions. The data flows upstream to an MQTT broker, serving as a central hub for data communication. This can be any broker of your choosing and can reside either on premises or in the cloud.

Step 3: From the MQTT broker, data is subscribed to by the IoT Bridge for Snowflake, a software package developed by Cirrus Link Solutions. The bridge plays a crucial role in the integration—translating MQTT Sparkplug B data into a format easily digestible by Snowflake using their native API. IoT Bridge for Snowflake can be deployed on various cloud platforms, including AWS, Azure, and Google Cloud.

Step 4: Once IIoT data is in Snowflake, leverage its advanced analytics and machine learning capabilities for predictive maintenance and anomaly detection. Utilize AI-driven insights and large language models to streamline operations and enhance decision-making, ensuring optimal performance and efficiency in manufacturing processes.

Streamlining operations with targeted solutions

The integration of Snowflake’s data warehousing and Opto 22’s automation technology can provide tangible benefits to your production process.

With Snowflake, cloud based management of industrial data enables improved decision-making and operational insight. SQL derived tool sets you already know combined with a new wave of artificial intelligence tools will help you optimize processes and take swift action when required.

And with Opto 22, you’ve got an automation solution that paves the way to the cloud. Integration of various software suites on top of plentiful native protocol support ensures your valuable data doesn’t get trapped on the plant floor, but rather, makes its way into a secure, data centric ecosystem.

The bottom line is that this is not just about keeping pace with industry trends; it’s about directly enhancing your operational capabilities, reducing downtime, and improving overall efficiency.