TechnologyNovember 12, 2019

Compact M8 connectors for future-proof data transmission

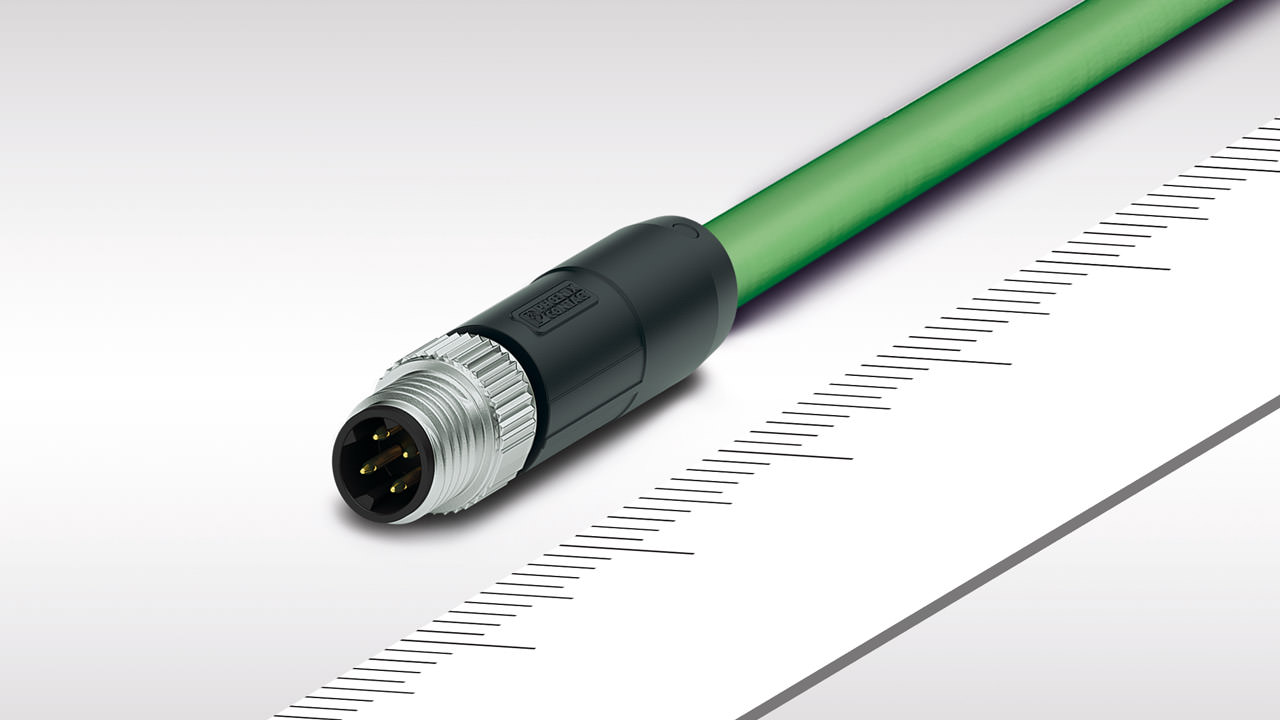

D-coded, circular M8 connectors are an excellent solution for compact and future-oriented data transmission in Industrial Ethernet environments. The symmetrical contact arrangement of its pin connector pattern prevents performance losses and allows stable real-time data transmission with bandwidths up to 100 Mbps.

The fourth industrial electronic revolution is in full swing; its pace is accelerating every day. Manufacturers of automation technology have to react to the growing demand for data, and constantly offer new, powerful solutions for continuous real-time data transmission between company, control and field level.

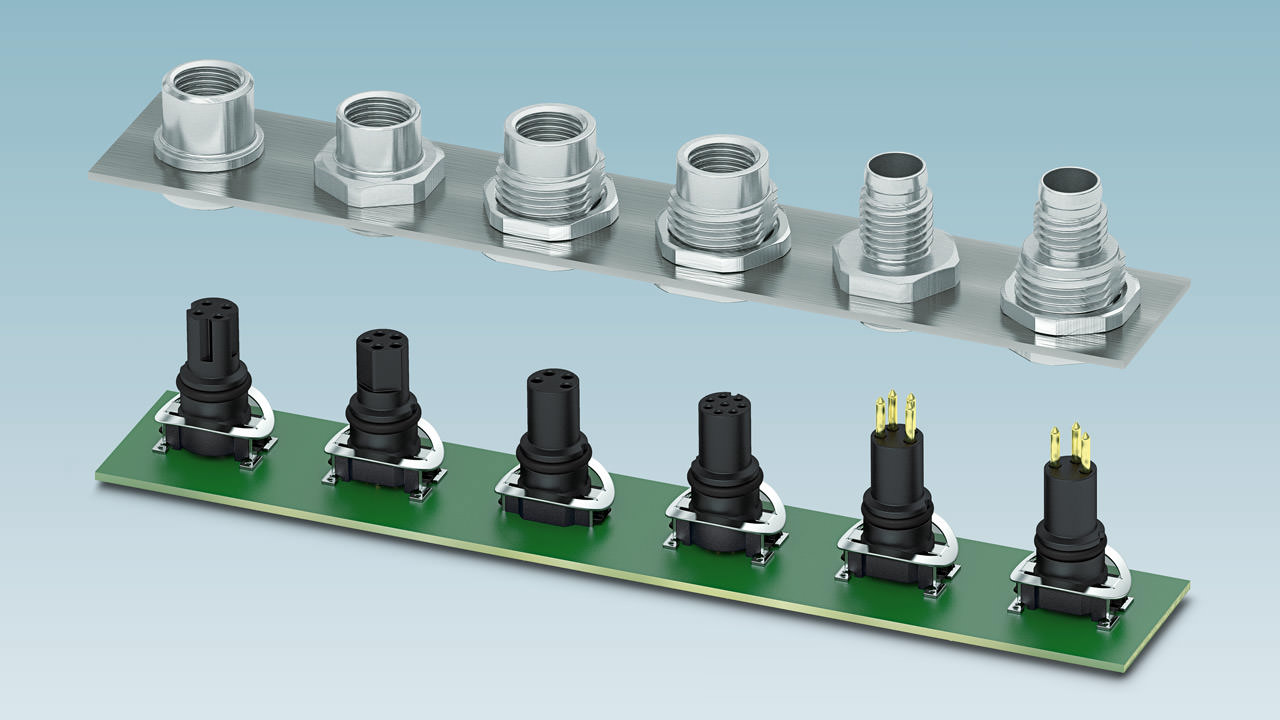

New 4-pin D-coding in the design of space-saving M8 built-in device connectors supplements the proven reflow product range with an important component, and thus future-oriented and standardized solutions for compact data transmission.

With the increasing automation of production plants, buildings and infrastructure facilities, the classic automation pyramid is being turned upside down. More and more “intelligent” devices are processing and transmitting signals and data directly in the field. At the same time, these devices such as industrial PCs, I/Os or sensors and actuators are becoming increasingly powerful and compact.

This in turn increases the demands on the installed interfaces. Device and cable connectors must fit into compact device fronts and control cabinets and simultaneously transmit a large number of signals, high data rates, as well as power. In addition, they must be able to be efficiently integrated into the production process – in order to enable high unit numbers and thus economies of scale – and at the same time offer a high degree of robustness and flexibility. Sounds like an all-in-one device? The M8 standard already offers many of these features today.

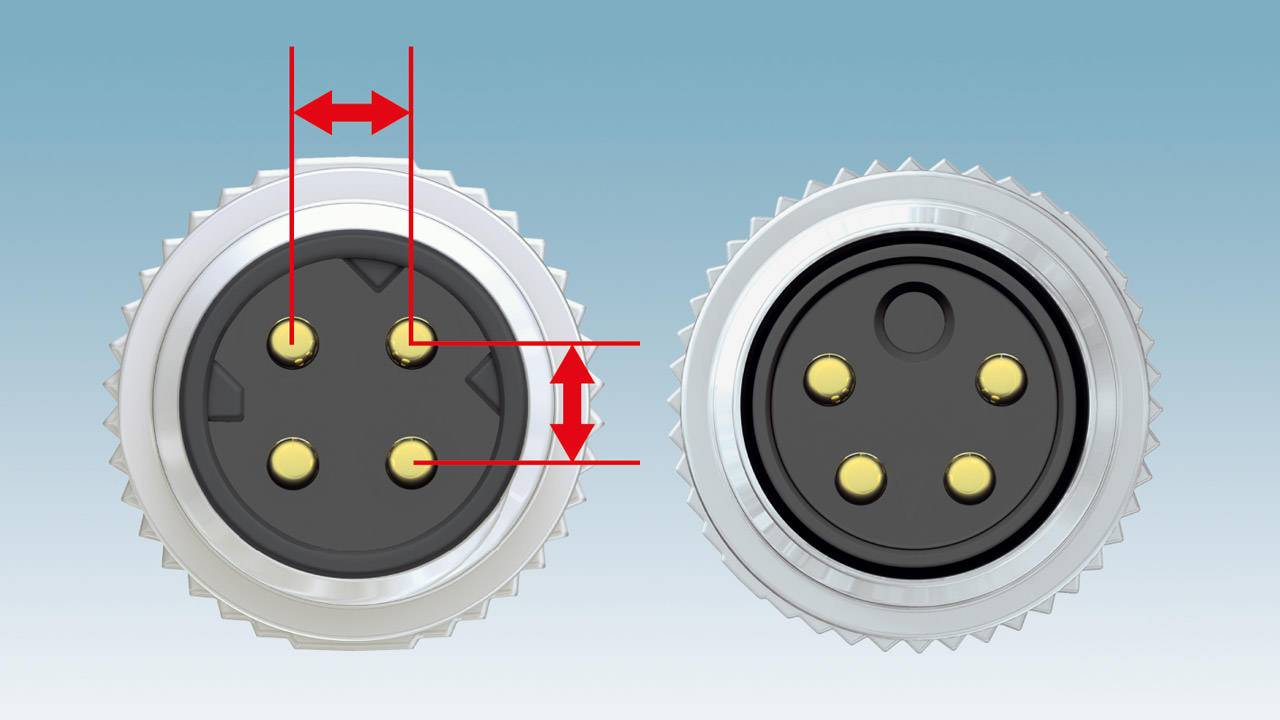

The symmetrical contact arrangement permits stable bandwidths of up to 100 Mbps.

A question of coding

Thanks to its standardized metric thread, its compact design and its industrial and robust design, the M8 circular connector has already established itself in many areas of industrial cabling. With the spread of Industrial Ethernet, however, this circular connector is increasingly conquering new areas of application in decentralized data transmission. By now, it is not only the overarching elements such as controllers and production control computers that communicate with each other via protocols such as Ethernet/IP or Profinet, but also sensors and actuators at the lowest field level.

The M8 standard is ideal for these compact applications. However, the contact arrangement of the A-coded pin connector pattern limits the application in the field. Thanks to the asymmetrical arrangement of the four contacts, the pin connector pattern is protected against mis-mating, but the electromagnetic fields of the contacts located closer to each other also have a stronger influence. The result: stronger Near End Cross Talk (NEXT).

In practice, the A-coded M8 connectors for Ethernet and Profinet allow bandwidths of up to 100 Mbps. However, they do not meet the requirements of the CAT5/Class D transmission category, as the connection may not have sufficient reserves to compensate for additional influences such as long cable lengths, EMC interference or other couplings. This can cause the bandwidth to drop below a stable 100 Mbps, causing data packets to be lost and resent. The connection thus becomes unreliable.

Phoenix Contact offers D-coded M8 connectors specifically for data transmission in Ethernet/IP and Profinet environments. The standardized, symmetrical arrangement of the four contacts also enables transmission rates of up to 100 Mbps, according to IEEE 802.3, and also meets the requirements of CAT5.

The contacts positioned opposite each other form pairs to which either two opposite wires of a star quad cable or wire pairs of a twisted pair cable are connected. Since the electromagnetic fields cancel each other out due to the symmetrical contact arrangement, data losses due to near-end crosstalk are avoided. This makes the pin connector pattern ideal for secure data transmission in demanding environments such as welding cells.

Two-piece device connectors offer multiple options for efficient integration into the SMT/THR process.

Efficient process integration

In addition to the reliability and speed of data transmission, device manufacturers are increasingly focusing on their own production processes. Worldwide markets and the high variance of application areas require device designs that can be implemented cost-efficiently and easily adapted if necessary.

As the central component of every industrial electronic device, the printed-circuit board and its components are of great importance. In order to reduce production time, enable higher quantities and thus reduce unit costs, manufacturers rely on partially or fully automated assembly processes. Phoenix Contact therefore supplies all device connectors for SMT or THR mounting in tape-on-reel packaging. The applicable standard DIN EN 60286-3 ensures that the two-piece connectors can be inserted into the feeders of all common assembly machines, fed without interruption and picked up by nozzles or grippers and placed on the printed-circuit board.

The SMD design has one major advantage. The connectors assembled on one side require less space on the printed-circuit board and therefore allow a higher packing density than conventional components for wave soldering. With a co-planarity of less than 0.1 mm between armature plates and contacts, the SMD versions still contact safely and reliably.

The new D-coded M8 connectors are also design-compatible with the already established two-piece M8 and M12 circular connectors. Electronics suppliers and device manufacturers can thus install all M8 and M12 codings on an identical printed-circuit board and housing level. Even for different applications such as power transmission via M12 and data transmission via M8, the printed-circuit board and device design remains the same. The finished device can therefore be developed without adaptation for different markets and applications; complex individualized housing contours are not necessary.

A further advantage of the two-piece design: printed-circuit board and housing can be manufactured at different locations, and only be married later during final assembly. This allows for greater flexibility in the selection of electronics suppliers and at locally, regionally and internationally distributed production sites.

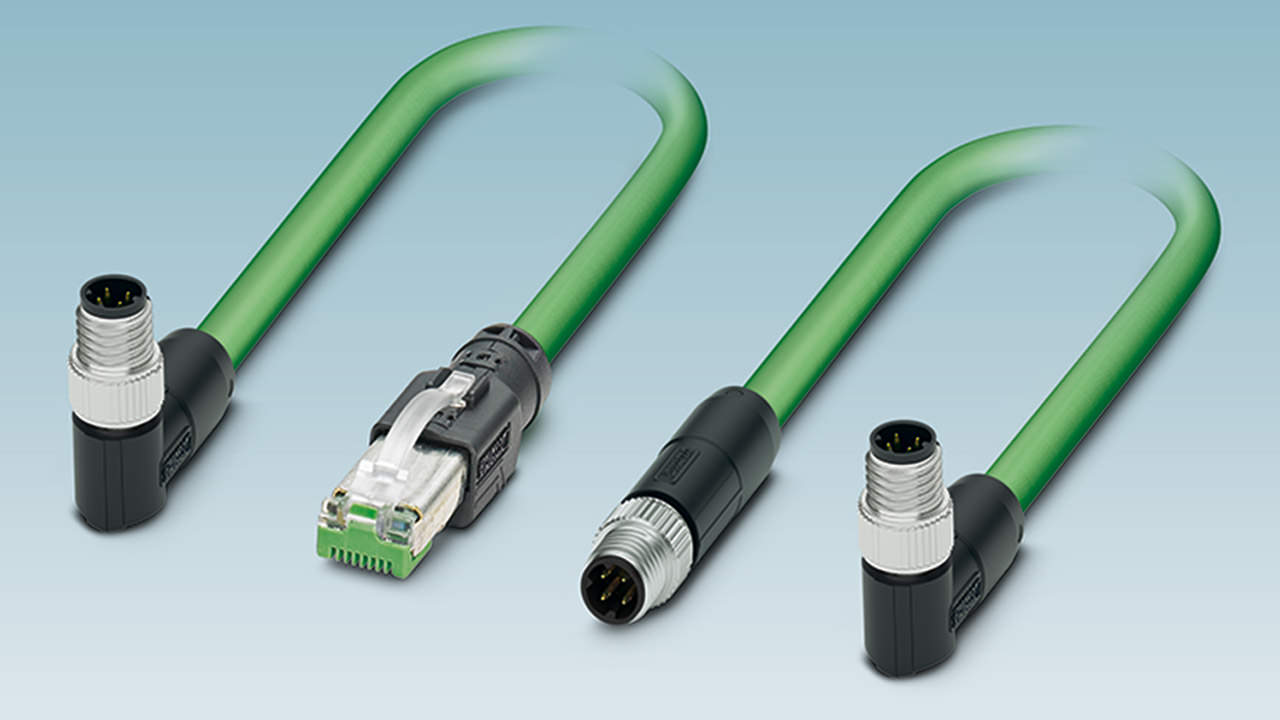

Pre-assembled cables or cables with free cable ends permit integrated cabling solutions.

Complete flexibility

Different mounting types are offered for front or rear mounting. Even a press-fit variant or direct integration into the customer housing are possible. Thanks to this variety of options, it is even possible to install different printed-circuit board versions in one and the same housing. The user not only saves development time, but also tool and storage costs.

In order to ensure safe operation even under harsh industrial conditions, the new M8 connectors are designed in protection class IP67 (according to IEC 61076-2-114). Physical environmental influences such as dirt, dust or water therefore do not affect the real-time data transmission between cable and device connectors.

In addition to the two-part device connectors, the product range also includes the matching D-coded cable connectors. Whether with open cable end, double-sided M8 connector or in combination with an RJ45 connector, Phoenix Contact technology offers standardized or customized solutions for different cable lengths.

Summary

D-coded circular M8 connectors are an excellent solution for compact and future-oriented data transmission in Ethernet environments. The symmetrical contact arrangement of the pin connector pattern prevents performance losses and allows stable real-time data transmission with a bandwidth of up to 100 Mbps. The two-piece device connectors are suitable for fully automated SMT and THR processes and offer different options for front and rear mounting.

Device manufacturers and electronics suppliers can thus efficiently integrate the connectors into their own production and develop uniform printed-circuit board and device designs for different application areas and markets. Thanks to their standardized pin connector pattern, the connectors fit perfectly into the wide range of circular connectors. The combination of different suppliers for device and field cabling is also possible without any problems, creating a symmetry that sticks.