TechnologyJuly 27, 2019

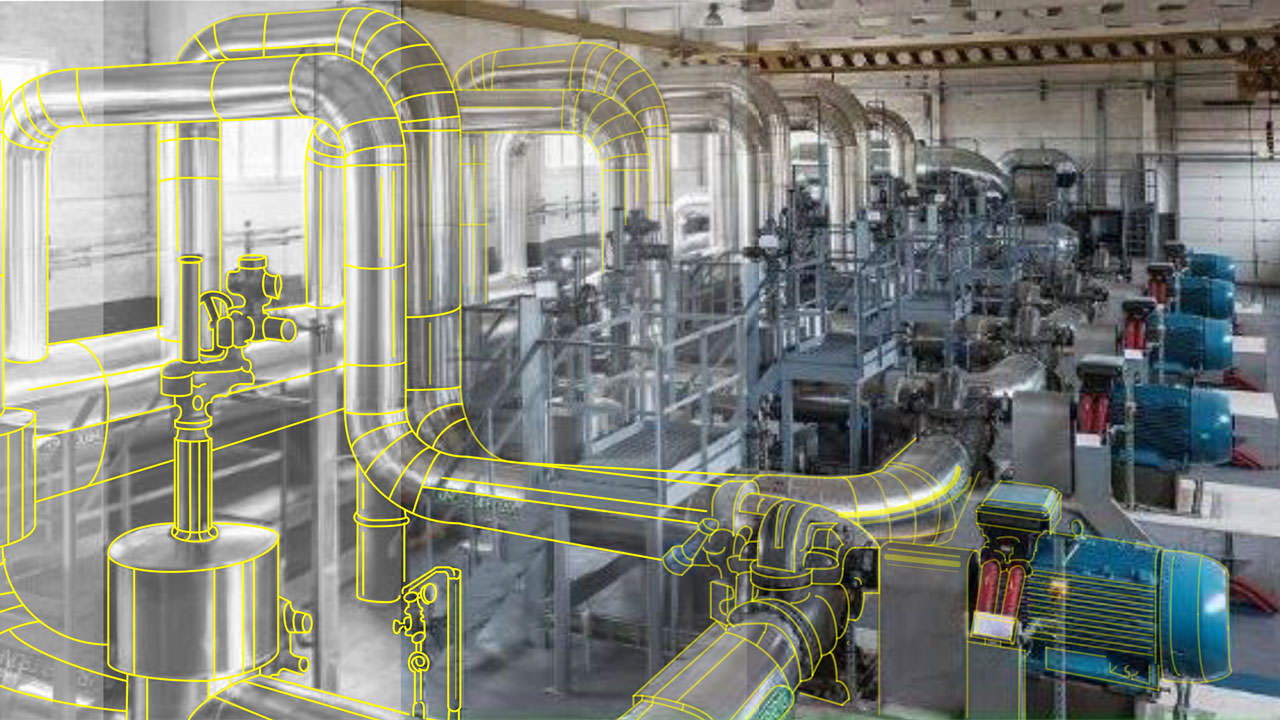

Digital twin concept as applied to industrial automation

The concept of the Digital Twin is associated with cyber physical systems and provides an innovation that will bring a new look to industrial automation. This article provides an introduction to the technology and the general structure of an industrial automation system built around the digital twin concept.

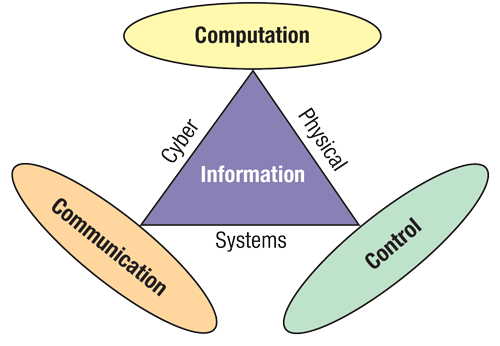

The Digital Twin, sometimes referred to as an avatar (and many other names), is a functional concept that grew out of the parent concept of a Cyber-Physical System. Dr. Helen Gill, while working for the United States National Science Foundation, coined the term Cyber-Physical System in 2006. Helen described a Cyber-Physical System as an integration of computation with physical processes where the system is the intersection of the physical and the cyber. The digital twin can be considered to be the “cyber” part of the Cyber-Physical System. It is a very powerful concept.

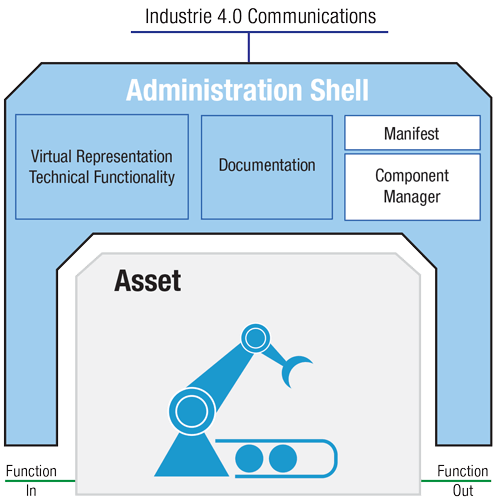

Other agencies built upon Helen’s original concept of the Cyber-Physical System to include the digital twin or at least support for the digital twin. One of the best examples is the German government program called Industrie 4.0, which includes the Administration Shell. The Administration Shell could be considered a digital twin or at least a defined interface for a digital twin. There are many other programs working on development of the digital twin.

As a concept digital twin is not entirely new to industrial automation. An “automation agent” has been part of some industrial automation segments for a long time. These agents can be thought of as the first generation of a digital twin. An agent listens for an event, verifies the condition of the event then executes an action as defined by the user. The agent automates some aspects of the control system removing some of the burden from the user. A digital twin takes this concept to higher level.

Exactly what is a digital twin is hard to say. It will be different things to people and different companies. Following will be presented one view of the concept with the features we think are needed to make an operational digital twin. In the end some standardization between usage and interoperation of a digital twin will be needed for any one company’s twin to talk to any other company’s twin and build an automation system around digital twins.

Foundational elements of a Cyber-Physical System.

Basic concept

There are a lot of different definitions for the digital twin. General Electric GE defines it as “a digital twin is a dynamic digital representation of an industrial asset that enables companies to better understand and predict the performance of their machines and find new revenue streams, and change the way their business operates”.

A more general definition of a “digital (i.e. software/hardware/communications combination of some kind) twin” is that is provides a representation of a physical entity indicating an ideal or object state of that entity, in constant comparison with its actual conditions.

Réseau de Transport d’Électricité (RTE) France (a power transmission system operator) exclaims, “the expectation for twins is to be able to do functional tests on twins in an offline system and verify prerequisite on system management before propagating the twin into the real environment, and how to manage transition phase with the quality management.”

The digital twin is a concept in flux. There are many similarities with each of these definitions. It is a digital representation. The twin is associated with a physical device. There are performance aspects. Simulation support is a need. Measurement of real-time operation metrics is a desired component. The ability to compare real-time metrics with actual operating metrics appears to be a requirement. There twin must reflect the state of the physical device but also be accessible and usable when the physical device is offline.

Rather than create yet another definition for a digital twin, we will explain the features, functions and activities needed to support the concept of a digital twin. One can create their own definition around the features and decide what the digital twin needs to be to fit into one’s own automation system.

Why digital twins?

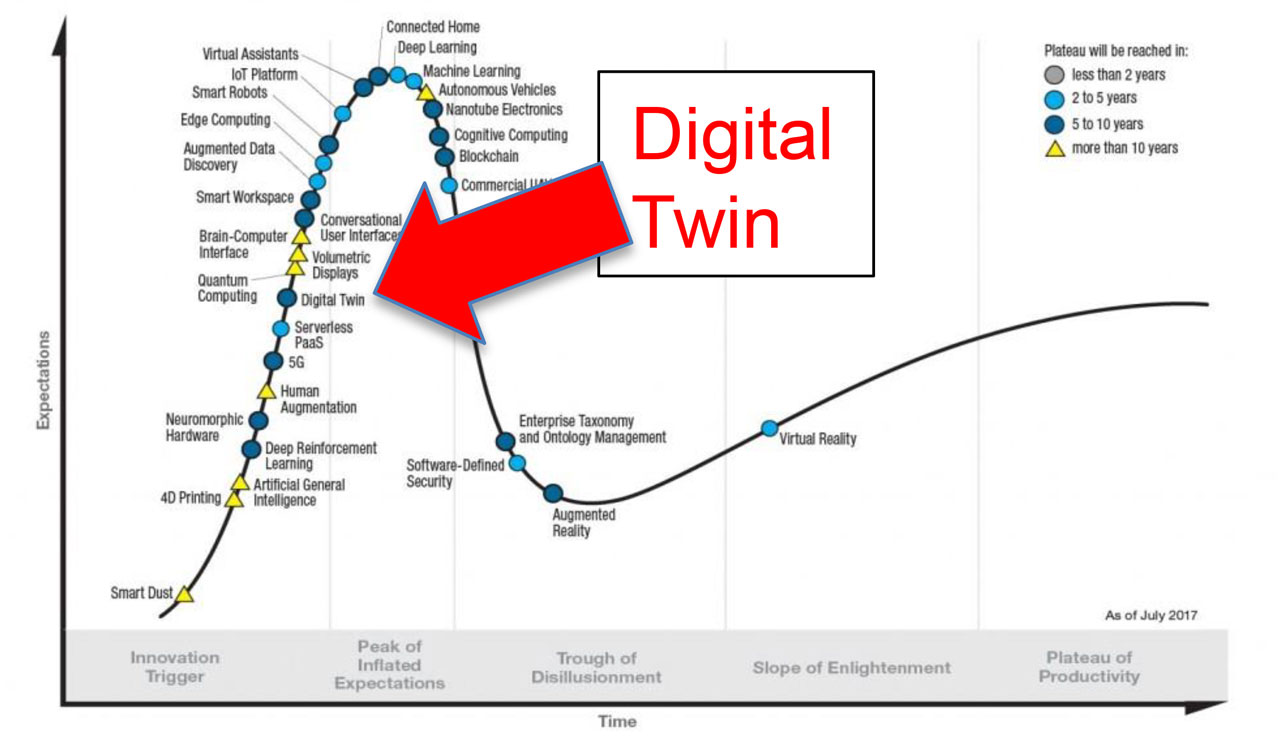

It is expected digital twin technology will make an automation system at least 10% more efficient. Further the technology is being widely developed. As stated by Gartner, “Gartner predicts that by 2021, half of large industrial companies will use digital twins, resulting in those organizations gaining a 10% improvement in effectiveness”.

The digital twin is one of Gartner’s top ten strategic technology trends for 2017 and 2018. Other analysts such as Deloitte also sees a growth in the technology. Deloitte states the global market for digital twins is expected to grow 38% annually to reach $16 billion by 2023.

Deloitte does warn that not every automation system requires digital twin technology and could add unneeded complexity to simple automation systems. ARC with General Electric thinks that digital twin technology is “one of the top five key technology trends that will have a major impact on both process and discrete automation”.

Most thought leaders in the industrial automation space think digital twin technology will bring large improvements to automation systems and will provide new and expanding services as well. Companies that embrace digital twin technology development will benefit with new revenue streams and greater profitability from their automation solutions. The real issue is deciding what a digital twin is for your company and defining the new services and revenue streams you want to derive from this technology.

Diagram of the I4.0 Administration Shell.

Functional elements

This article will not design a digital twin that will be left to the developer. We will discuss the major elements needed in a digital twin to make it useful to the operator of the automation system in order to use that system more efficiently and to provide new services to the operator.

Capabilities, features, and characteristics of the digital twin will be defined by the physical device and be represented by the twin. The twin must represent the physical, communication aspects, and operational aspects of the physical device precisely. If the device can do something then the twin must that same thing in the same way. There could be a type of digital twin that resides entirely offline and does not participate in the actual automation system.

The offline twin could provide simulation of the physical device, mimicking the exact characteristics of physical device. In the offline digital twin there could be no deviation from the actions, features and capabilities of the physical device.

Is this true for any other version of a digital twin? Well maybe not. For a digital twin that can be used offline and online it may be useful to have some differences between the twin and physical device. If the physical device in a certain configuration would flood the automation system with traffic should the digital twin also flood the system with traffic given the twin is also in the same configuration? (In the “Automation System” section following some more thought will be given to this scenario.)

When the system is operating normally with the digital twin, many digital twins actually, one for nearly every device, then the digital twin could prevent the physical device from creating the flooding traffic. By not allowing the system to place the physical device into an unacceptable configuration, the twin would prevent the flood.

The twin could inform the system and system operator that the configuration is not proper for the device and even suggest a configuration for the device that achieves the goals of the original system configuration but can be safely applied to the physical device. When the digital twin is not available, the automation system would be free to place the physical device into an improper configuration and the device would then flood the system with traffic.

This raises the question of what is the role of the digital twin and how much responsibility does the digital twin take on within the automation system. It has been said that “a person has as much authority and responsibility as that persons chooses to take until someone else takes it away”. With this in mind, the digital twin should be designed to take and use as much authority within the automation system to insure the best operation of the physical device within the operational guidelines of the automation system.

The digital twin needs to be designed in such a way that the system operator can take away as much authority as desired by the operator from the digital twin for use within that specific automation system. The digital twin should assume full authority over the associated physical device and let the system operator remove/block/disable any authority the twin has over device as decided by the operator.

Configuration could be done in the offline digital twin and verified through simulation. If the simulation is satisfactory and the configuration has the desired results then the configuration files can be exported to the physical system and loaded onto the physical devices in the field.

The digital twin can know more about the physical device than the physical device knows about itself. The digital twin can be connected to the documentation of the physical device allowing for greater knowledge of the capabilities and limitations of the device. It is possible to store critical information about the device directly or locally stored in the digital twin for immediate access. For example, the twin can be aware of the type of material of which the physical device housing is made and the twin can be aware of the operating environment in which the physical device resides.

Gartner Hype Cycle 2017 with Digital Twin technology reference.

If the operating environment is detrimental to the physical device in some way; outside the operating temperature of the device or too caustic for the integrity of the housing, then the twin can inform the operator and the automation system that the physical could fail or operate improperly since the device is in an inappropriate environment. The digital twin can be aware of the history of the physical device, revision history, usage history, etc. Further, it can contain maintenance information about the device and use that information to build a predictive maintenance profile.

Even when the device is offline, the digital twin can be available to the system. The cache of information about the physical device is available in the twin as long as the digital twin is online. In effect, the digital twin is a single entry point to the device. The system communicates with the twin and not necessarily with the physical device. The digital twin can accept the configuration from the system, regardless of the state of the physical device.

Once the physical device is online the twin can transfer the device configuration to the physical device. Checking can be performed by the digital twin to insure the configuration being sent to the device is valid for that device. Warnings can be sent back to the system to inform the operator when a configuration is not valid or would be detrimental to the operation of the system or the device. Depending on the level of trust the system has with the digital twin, the twin could prevent the physical device from being placed in a detrimental configuration.

Established device configuration standards, like FDI, FDT and others, should be used for device configuration. There is no need to create new standards for the digital twin. However, the same mechanism should be used for offline and online configuration without regard for the configuration standard being employed.

Deloitte warned us about making simple systems too complex with digital twin technology. For simple devices one need only produce a text based description file such as the xDS file to function as a digital twin. There is no point to raise complexity in systems where it is not needed.

The digital twin must be able to be made up of other digital twins, a nesting sub-system digital twins. In other words a digital twin can be system of many digital twins that appear as a single entity to the automation systems. Dr. Peter Martin of Schneider Electric would refer to this system of systems for a digital twin as “system-ness”. Should any sub-system digital twin fail or enter a faulted stated or be taken offline, the full system digital twin should continue to operate and work around the troubled sub-twin.

Again, this may be result in the system twin operating in a degraded manner. If the failed sub-twin is critical to the operation of the full system twin then if it is possible the full system twin should gracefully remove itself (assuming the twin has permission to do so) from the automation system.

Failures within a digital twin that is built of many sub-system digital twins must be handled gracefully and if needed removal of the complete twin from an automation system must be equally graceful.

Use in automation systems

The automation system would communicate directly to the digital twin and treat the digital twin as the primary resource for interaction. The digital twin would handle the actual communication to the physical device. In a proper operating the automation system the digital twin would appear to the system as the actual device. In a sense the digital twin is part of the critical infrastructure of the automation system. The operator could be unaware if the system is talking to the physical device, the digital twin, or a gateway to the twin and device. To the operator, this could all be the same thing.

In the event that the digital twin is not available or offline for any reason, the automation system must be able to communicate, directly, with the physical device. The system must be able to operate even if there is an issue (planned or unplanned) with the digital twin. It is expected that the operation of the system could be degraded or less capable when communicating directly to the physical device. The services that are created by the digital twin within the automation system will not be available to the operator when the twin is not available.

The location of the digital twin inside the automation system would be anywhere it makes sense to place it. This could be in “cloud” technology where the automation system owner prefers to place the twin. Whether the cloud is local (“fog”) or somewhere else on premise or off is up to the automation system owner. Depending on the location of the digital twin, that information will dictate the type of communication needed between the automation system and the twin and between the digital twin and the physical device. The location of the digital twin be more critical in high-speed systems where real-time is a very short duration.

An automation system can be comprised of a very large number of digital twins and associated physical devices. A system could consist of 100,000 devices or more. Think of a process plant for oil & gas for example. It would not be practical to manually configure each device. For a system build around the digital twin concept to be functionally useful a means for bulk online and offline configuration will be needed.

As a device level asset the digital twin can translate between the vernacular of the plant control and the vernacular of the device asset. The digital twin talks to the asset in the vernacular of the asset. The digital twin can be used as a translator between the control functions and the operation functions for a device. This will allow the user of digital twin to use an asset not necessarily designed for that specific system to operate seamlessly in any automation system. The digital twin could be a means to allow devices to be used in nearly any automation system without change to the physical device or asset.

Support in CIP

In order for digital twin technology to be useful with CIP, features within CIP must be used. Further, changes in CIP need to be considered to support the new technology as well as to allow one company’s digital twin to work with another company’s digital twin. This is by no means an exhaustive list.

It is an educated guess to highlight some of the features in CIP to support digital twin technology and the new features needed to get the most out of the operation of a digital twin. Once digital twins become common in automation systems using CIP the changes and additional support needed will be understood and developed.

Redundant owner for I/O will be important in any system that supports redundant digital twins for any reason such as safety, fast failover, or other higher functions. In a system where there are primary twin and redundant backup twin redundant owner could be needed keep both twins in the same state and access to the same I/O especially when to the redundant twin.

Multicast functionality of EtherNet/IP will be needed to write to multiple digital twin that need similar information. There may be scenarios where you are writing to the twin and the device at the same time and remove any latency issues between the digital twin and the physical device. However the digital twin could contain additional rule sets to warn and/or prevent out of bound states for I/O data. The twin could tell the system that an I/O cannot be ramped at the rate prescribed by the system. There will need to be updates to the exception handling for redundant owner operations. Multicast would allow the physical device to continue to function even when the digital twin is not available.

New objects, assemblies and possibly profiles will be required for the digital twin. Association objects to tie the digital to the physical device will be needed. Normalizing attributes will need to be applied to device, such as configuration of additional features that are not supported by the physical device that could be virtually supported by the digital.

Objects to tie twins together to make a hierarchical association for an overlying digital twin made sub-systems twins will be needed. This is especially applicable to asset management operations. The hierarchical association must mimic the physical world and to system control function should appear as a single device. This leads to a need for CIP

Object hierarchy support.

xDS file development happening inside ODVA will assist and compliment the digital twin development. Since the xDS file will have access to a large portion of the information and documentation for the physical device to which it is attached it is logical to use the xDS file with the digital twin in as large a capacity as practical.

Most if not all of the configuration information needed for the twin will be contained in the xDS file therefore using the xDS file as the basis to configure the digital twin.

Beneficially, the xDS file can be updated without need to update the physical device and stay very current, this update feature of the xDS file will improve the accuracy of the digital twin. Since the xDS file is a conformance tested and certified document it will insure that the digital twin remains current within an automation system. The digital twin can assure the authentication of the information of the xDS by checking the certification of the file through ODVA. Since the xDS file can be sourced externally in whatever repository being used by the device vendor, the xDS file should be able to improve and simplify the method used apply bulk digital twin configuration across the automation system for all the digital twins.

Energy and power management of the digital twin, especially when you consider a digital twin built up of many sub-system digital twins, will be a key advantage of this technology. The energy and power management objects existing inside CIP will be used to provide this advantage. Some updates and modifications may be needed for the associated energy and power objects.

There are changes needed or perhaps a better operational understanding on how to best use the FWD/Open features in CIP. This is especially true for twins made up of sub-system twins. The FWD/Open features in CIP will need to work effortlessly for any digital twin and the associated asset. This is especially true for digital twins that are made up of other digital twins.

Objects and attributes must be defined to support a common ontology and semantics. This is essentially the language and vocabulary used by and between the digital twins within the automation system. In order for the digital twins from different companies to work together in the same automation system the twins must speak the same language and use a common vocabulary. Whether the ontology and semantics adopted in CIP is developed by ODVA or is adopted from another standards group is a decision that can be made in the near future. However it is essential that all the digital twins supporting CIP technology speak a common language and use a common vocabulary.

Benefits of a digital twin

Reasons the market analysts are so bullish on digital twin technology are the system operational efficiency that can be obtained, the increased services that will be created, the simplification of automation system updates and many others. Listed below are just a few of the obvious benefits of the digital twin within automation systems. There are too many to list and companies will find benefits that will be part of their differentiation when providing digital twin technology.

A very valuable service that can be provided by digital twin technology is simulation. This simulation service can be used in multiple ways. The twin technology can be a standalone simulation environment and if the twin is a perfect (near-perfect) representation of the actual physical device then the simulation built on these twins will reflect the physical system precisely.

Configurations could be tested in a safe cyber environment and, once verified with the desired operation, the verified system configuration can be copied to the physical devices. The physical system should operate in a well-known manner with after this simulation. Essentially, the system configuration would happen and be verified offline before being safely ported to physical devices bring the configuration online. This was touched on in the discussion above.

The simulation services can be more beneficial when not bounded by time. Running the simulation environment at a much higher rate than the real-time operation of the actual automation system can reveal the effect of changes in the far distance future. These effects can be known to the operator and allow the operator to understand long-term implications of any changes made to the system. It may identify situations where there was a negative effect in a system and the root cause was not found since the causal event happened so far in the past. This scenario can be avoided.

Related to simulation is system commissioning. System commissioning becomes a complex simulation event that leads to a better process for the actual build out of the automation system. It will be an iterative process that focuses on the function or purpose of the automation system and not build around the networking components and topology used inside the system.

Most modern automation systems are designed around the networking components and the process for which the automation system is needed is forced to fit into the automation network. The commissioning simulation would focus on the desired process and mix and match the devices needed to complete the process.

Since all the devices are represented by their digital twin, adding, removing, and replacing devices in the system would be relatively easy since they are all cyber devices. A complete redesign of an automation system would only require clever programming and simulation compute cycles in cyberspace.

The entire design of the automation system including layout can be done in simulation with a high degree of confidence that the physical system built from the cyber system will run and produce in the same manner as the cyber system. The trail operational phase of the physical system will be much shorter. The construction and connection errors common in commissioning will be reduced and much easier to identify.

This leads to improved training for an automation system. The operators, maintenance personnel, management, etc. can use the digital twin simulation environment to learn the system operation prior to the system being built. Operational issues can be identified and fixed in simulation. These fixes can be placed into the commissioning simulation before any money is spent on building the physical system. Even once the physical system is built, this training simulation can be used to instruct new personnel on the operation and up keep of the automation system.

Operational expenses are always a major concern for the customer when deciding on an automation system. Maintenance costs and needs are a big factor in the operational expenses. Digital twin technology will improve the maintenance of an automation system in several ways.

Better trained maintenance personnel, can simulate failures to help find root causes faster reducing cost, be better at predicting cost of maintenance during planning, and overall improve the effectiveness of the maintenance process. The digital twin will be a key factor in bringing real predictive maintenance capability to an automation system. This will allow for greater up time in a system and sustained production cycles. The digital twin will allow the predicted failure device to be removed and its replacement installed seamlessly.

Automation systems, especially in the Industrial Automation space, have not been an attractive employment space for young professionals. The vision of the old sweat shop and dirty operations comes to most young professionals minds when discussing industrial automation systems. If automation and production is going to be an active part of any community’s economy, new professionals must become active in this space. The digital and connected atmosphere in which they live their lives gives them a certain perspective as to what is an attractive job. Technology such as the digital twin will transform automation systems bringing the industry back into relevance with the “Millennial” generation.

Conclusions

Digital twins will be a major feature of all automation systems in the near future. It is a matter of what one puts in the digital twin not IF one wants to design a digital twin. The digital twin will be a common part of the system. Companies that ignore this technology will be left behind.

In order for digital twin technology to be adopted it must improve the Operating Expenses (OpEx) or the Capital Expenses (CapEx) for the customer. From the simulation aspects alone it is easy to see how this technology will reduce both of these expenses. The customer will have confidence they are buying the best automation system available to them and have a very accurate estimation of the capital expense. The customer will further understand the operating cost of that system over the life of the system. An assurance can be made that the system will have value over the life of the system. The decision making process for the customer is improved. The confidence that the customer is getting the value from the system purchased will be much higher than with the current sales cycle.

We are in this together. Companies that wish to remain relevant in industrial automation will develop digital twin technology. Most modern automation systems built today use multiple vendors’ devices. It is critical that every company’s digital twin technology can communicate and interoperate with many other companies’ digital twin technology. Therefore there must be some commonalty between digital twins from differing companies that want to interoperate.

Consortia such as ODVA will be critical in defining this commonality. A common ontology and set of semantics will be needed and may need to be developed in ODVA. There will be differentiation between vendors, every company will have their own value-add, but there must be enough in common for vendors to interoperate seamlessly.

For ODVA, digital twin development will impact all aspects of CIP and the associated protocols. Digital twin technology will impact any new technology and protocols being developed in association with ODVA. All the current and new technology will have to be retrofitted or design from the beginning with incorporation of digital twin technology in mind. The xDS Concept in ODVA is a perfect example of the need to be designed around or at least with digital twin technology as a core feature.

This is not the idea of a mad scientist. It is common knowledge with the support of many knowledgeable people and companies. Market analysts agree that digital twin technology will have a significant impact on automation systems in the near future. The analysts do not agree on specific numbers and percentages but all have the technology as critical to the growth of the industrial automation segments. For most, it is a top 10 or top 5 key technology trend that will have a major impact on both process and discrete automation in the years ahead.

Perhaps digital twin technology will bring the fun back into working in the industrial automation segments and lure the “Millennial” generation to want to build the next generation self-configuring, self-adapting industrial automation systems.