TechnologyMay 20, 2023

Ethernet celebrates 50 years with 2023 roadmap and demo

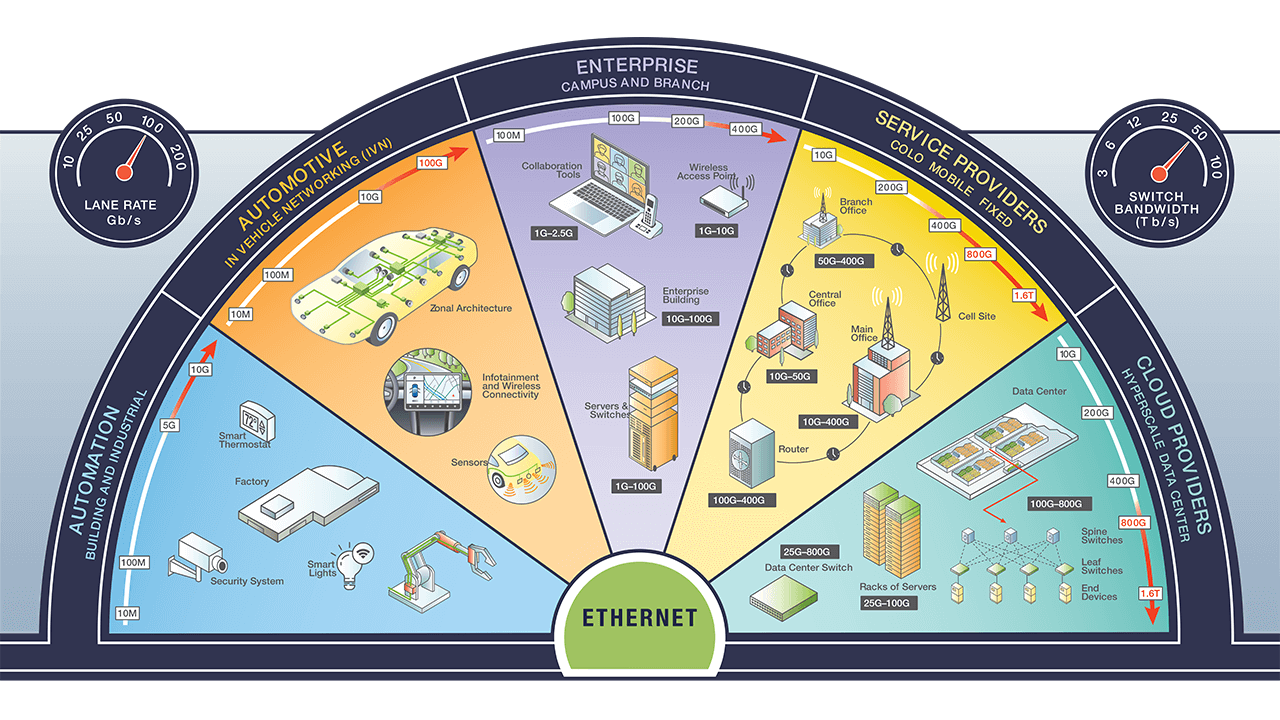

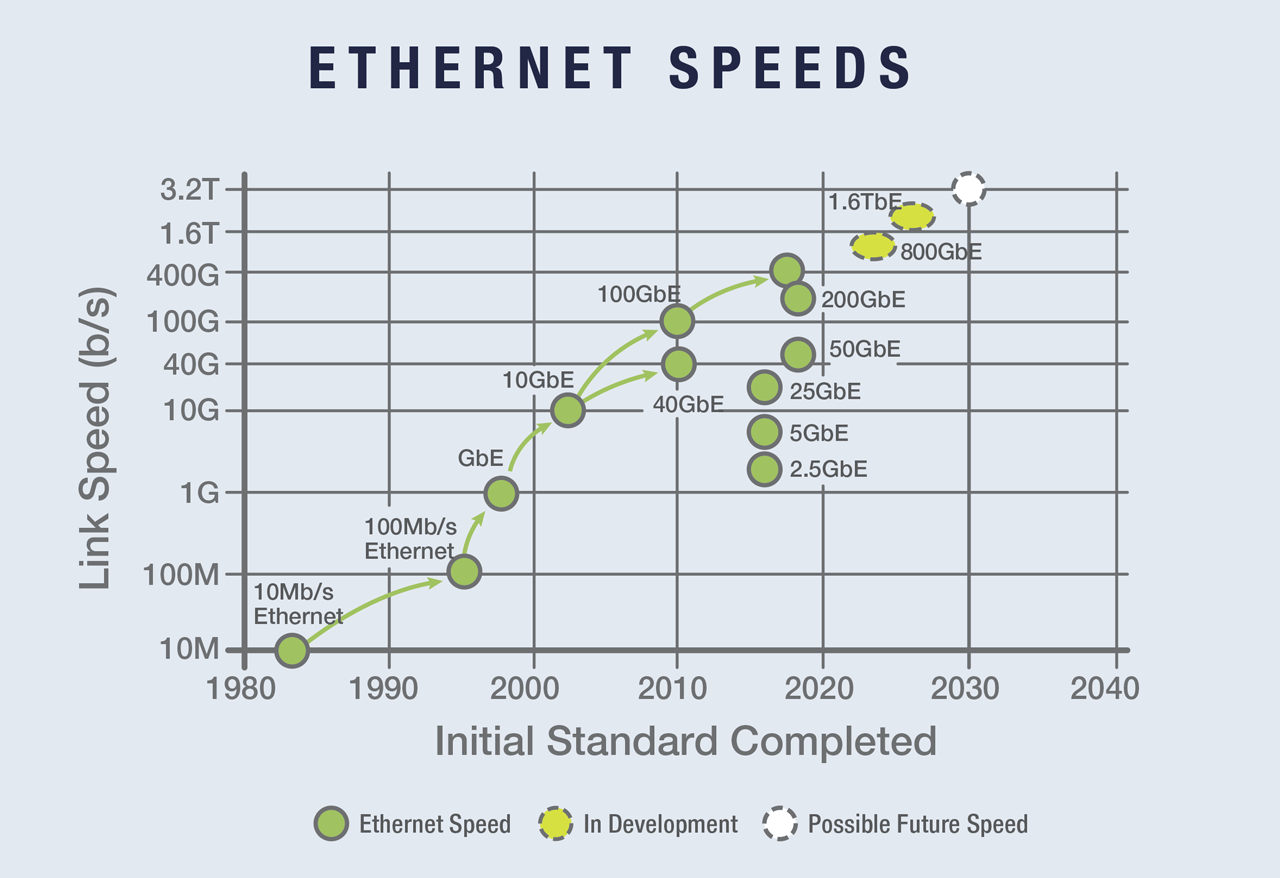

It’s a big year for Ethernet as it celebrates its 50th anniversary. And the Ethernet Alliance has released its new 2023 Ethernet Roadmap showcasing Ethernet’s bright future as it continues to expand into new speeds and applications. We’re now at the half-century mark, but Ethernet’s star continues to rise.

Ethernet’s Past, Present, and Future is converging with the Ethernet Alliance’s release of a new 2023 technology roadmap and development of a new demo showcasing cohesive 400GbE technology.

It’s a big year for Ethernet as it celebrates its 50th anniversary. The Ethernet Alliance (www.ethernetalliance.org) has released a new 2023 Ethernet Roadmap showcasing Ethernet’s bright future as it continues to expand into new speeds and applications.

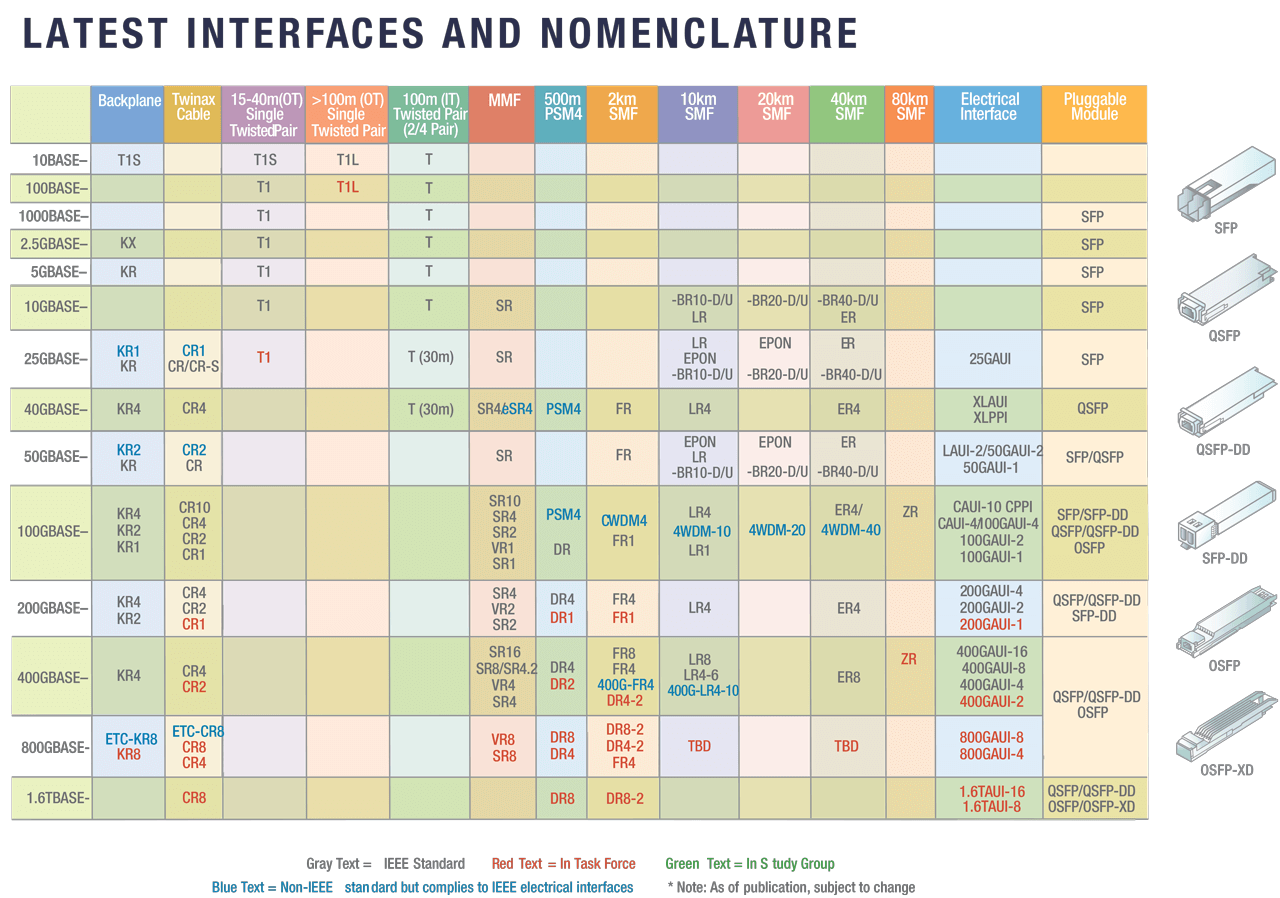

The Ethernet Alliance also announced more details on the multivendor interoperability demo presented at OFC 2023. The demo, featuring 18 member companies with live traffic transiting over Ethernet speeds of 10Gigabit Ethernet through 800GbE and connecting to multiple booths via the OFCnet, showcased cohesive 400GbE technology that is highly representative of real-world deployments.

Celebrating a half century

“We’re now at the half-century mark, and Ethernet’s star continues to rise. As a profoundly resilient technology that’s getting progressively faster, it is an innovation engine that drives market diversification and fuels business growth,” said Peter Jones, chairman, Ethernet Alliance. “As the volume and variety of applications expands, bridging between legacy systems and emerging technologies is increasingly critical. The Ethernet Alliance OFC 2023 demo underscores the importance of interoperability and perfectly frames Ethernet’s ability to operate seamlessly across disparate industries and environments.”

According to Ethernet Alliance OFC 2023 technical leads Jean-Marie Vilain of EXFO, Bob Wagner of Panduit, and David Estes of Spirent, “Our 2023 interoperability demo is formidable, given the manifold technologies, interconnects, and speeds on display, and mirrors the challenges facing the industry. Highly representative of real-world deployments, it interweaves the newest generation of switches, servers and test equipment at speeds of up to 800G, proving the Ethernet ecosystem is ready for 800G’s broad adoption.”

50th anniversary

Industry leaders respond to questions around the 50th anniversary of Ethernet technology.

Ethernet has made it 50 years, is it the perfect technology? Why do you think it is so resilient?

“Ethernet has succeeded by building a comprehensive, open community that provides the technology that underpins the Internet. It doesn’t attempt to be perfect. It specifies just enough to satisfy the customer need, maintains an intense focus on interoperability, and adapts to changing needs and technologies as they arise.” – Peter Jones, Chair, Ethernet Alliance

“Ethernet is so resilient because it has the flexibility to operate over multiple speeds and media supporting a wide range of industries and network types, while maintaining a strict standards creation process to ensure that technologies will interoperate, perform as expected in the real-world, and deliver high-quality user experiences.” – Dave Estes, Board Member, Ethernet Alliance

“The key to Ethernet’s success has been its commitment to openness and interoperability, as well as its adaptability. Ethernet constantly evolves to address new use cases – moving data from the cloud to the edge to serve an increasingly smart and connected world.” – Sam Johnson, HSN Subcommittee Co-Chair, Ethernet Alliance

“Ethernet is updatable to support higher bandwidth needs. Specifications for higher rates leverage the architectural understanding gained from the previously defined Ethernet rates. Commonality over Ethernet rates provide for it to be resilient. Expectations are met generation to generation. Innovation is employed when needed such as for providing feasible physical interconnects at the higher rates.” – Jeffery Maki, Treasurer, Ethernet Alliance

“Ethernet’s resilience is a testament to its adaptability across multiple interconnect and options and applications. Ethernet is not constrained by cable nor connection, hence its use over a myriad of copper or fibre cables, in homes and offices, across factory floors, in automobiles, and as the backbone of cellular phone networks. This adaptability is not by accident, rather it’s a product of the combined efforts of engineers across the world who come together to maintain and innovate the underlying standards. Due to its adaptability and engineering community oversight, Ethernet is and continues to be the backbone of our connected world.” – David J. Rodgers, Events & Conferences Chair, Ethernet Alliance

“Ethernet has never been perfect, but it has been good-enough, and perfection is always a narrow point, not broad-based enough to really succeed. What’s kept Ethernet alive is interoperability at the packet, frame, and behavioral levels while changing radically – from half-duplex to full-duplex, across varied media and speeds.” – George Zimmerman, Technical Chair, Ethernet Alliance

Why is the 50th anniversary of Ethernet worth celebrating?

“With this being the 50th year of Ethernet we have much to celebrate. Many technologies have come and gone over the past 50 years while others have “peaked” and are now on the downward slope. Ethernet keeps rising to greater heights. With Ethernet, the best is yet to come!” – Chris Lyon, President, Ethernet Alliance

“The world runs on Ethernet. It’s an innovation engine for growth and market diversification, with the ability to seamlessly operate between disparate environments to benefit a growing variety of applications and users. Ethernet has established itself as the foundation of networking globally and is likely to remain so for the foreseeable future. This year as we mark Ethernet’s 50th Anniversary, it is the perfect opportunity to celebrate all those who contributed to Ethernet’s success and to appreciate the immense value this resilient technology brings to the world.” – Orshi Abraham, Marketing Chair, Ethernet Alliance

“Ethernet and IEEE 802.3 in general constitutes some of the world’s best engineers and international organizational principals in work collaboration and development. Its contributions in bringing the world together a little bit tighter than it was 50 years back with efficient and scalable networking technology has brought about change at a global level. The transformative nature of networking technology now impacts us and our communities for the better in countless ways.” – John Calvin, Board Member, Ethernet Alliance

“Ethernet and IEEE 802.3 in general constitutes some of the world’s best engineers and international organizational principals in work collaboration and development. Its contributions in bringing the world together a little bit tighter than it was 50 years back with efficient and scalable networking technology has brought about change at a global level. The transformative nature of networking technology now impacts us and our communities for the better in countless ways.” – John Calvin, Board Member, Ethernet Alliance

“As we mark Ethernet’s 50-year anniversary, it has become the foundational technology used ubiquitously across the whole networking industry. Ethernet’s efficiency and resiliency lends itself to a broad set of applications and while non-Ethernet optimizations might exist, the universality of Ethernet across and between these applications results in its ever-broadening adoption.” – Mark Nowell, Advisory Board Chair, Ethernet Alliance

“It is truly remarkable to see how Ethernet, born 50 years ago, is still going strong. With its ability to scale and evolve with new standards, Ethernet continues to keep up with every changing need of the marketplace and meet the challenges of today’s applications, such as enterprise, datacenter, service provider, industrial and automotive. As the data being generated in our digital life continues to grow, Ethernet technology will be the networking technology of choice for a seamless digital experience powered by AI/ML.” – Kishore Racherla, Board Member, Ethernet Alliance

“The versatility of Ethernet and growth of applications is continuously on the rise. I’m amazed that Ethernet deployments have evolved from office environments to common day use in the home, automobiles, and portable handheld devices providing seamless data connectivity anywhere. I look forward to seeing Ethernet’s evolution over the next 50 years!” – David Tremblay, POE Certification Chair, Ethernet Alliance

What are the greatest innovations that Ethernet has enabled?

“The Ethernet innovation that I am most excited about is Time Sensitive Networking. It is my opinion that this emerging use case will fundamentally change transportation and industrial manufacturing by enabling unprecedented component synchronization and coordination. This could not be possible without the recent enhancements built upon Ethernet over the last few years.” – Carl Wilson, Secretary, Ethernet Alliance

“Today, we can solve large problems and get answers to questions through the virtue of being connected one to another – you to me, both of us to others, and all of us to computers and storage. Ethernet is a key part to our interconnectedness. We are much more powerful and capable due to our interconnectedness, as well as more inclusive than ever before. Thank you, Ethernet, for being the fabric of the connectedness between humans. Let us use the power of this fabric for good; for better and more prosperous lives, creating larger knowledge for all by connecting all.” – Pavel Zivny, HSN Subcommittee Co-Chair, Ethernet Alliance

What do you think the next decade holds for Ethernet?

“The next 10 years with Ethernet hold great promise as we are poised to fully utilize its capabilities. Ethernet will not only monitor/communicate/control connected assets but also will provide power delivery, augmenting applications like Smart Buildings and Smart Factories. As we approach a complete Ethernet footprint from cloud to edge, enabled by technologies like Single Pair Ethernet, we’ll further leverage the transparency and availability of information from all facets of the enterprise.” – Bob Voss, SPE Subcommittee Chair, Ethernet Alliance

Future of Industrial Ethernet

Industrial Ethernet technology is celebrating its own milestone and looking forward to a bright future.

Along with celebrating Ethernet’s fiftieth year, Industrial Ethernet is surpassing its own 25-year milestone (IEB started as a publication in 1999). So we asked Ethernet Alliance members Peter Jones, Chair, Ethernet Alliance (Cisco); Bob Voss, SPE Subcommittee Chair, Ethernet Alliance (Panduit) and Razvan Petre, Principal Member, Ethernet Alliance (Spirent) to provide their insights into the current state and future prospects for Industrial Ethernet technology.

What is the current state and outlook of Industrial Ethernet Solutions for factory automation?

Industrial Ethernet solutions for factory automation have seen significant growth and adoption in recent years. This trend is expected to continue in the future, with an increasing number of factories embracing digitalization and Industry 4.0 concepts. Adoption is accelerated by technologies like Single Pair Ethernet (SPE) that bring power and data to the network edge, both simplifying and augmenting edge device functionality.

Ethernet communications protocols like EtherNet/IP and Profinet have become popular choices for industrial automation applications due to their high-speed communication, real-time control capabilities, and ability to handle large volumes of data. These protocols are widely adopted by leading automation vendors and are supported by a vast ecosystem of products.

The use of Industrial Ethernet enables seamless integration between machines, systems, and devices, allowing for enhanced data availability, improved diagnostic, and as a result, increased production efficiency. With the advancements in Ethernet technology, more advanced applications are being developed, including machine learning and AI applications that can improve machine performance, reduce downtime, and enhance product quality.

Ethernet solutions also offer increased security features to protect industrial networks from cyber threats. The adoption of security measures like segmentation, access controls, and encryption, is becoming increasingly important.

How are Industrial Ethernet products solutions evolving and offering new technical benefits that are impacting smart manufacturing operations?

How are Industrial Ethernet products solutions evolving and offering new technical benefits that are impacting smart manufacturing operations?

Industrial Ethernet products and solutions are evolving rapidly, offering new technical benefits that are impacting smart manufacturing operations in several ways:

Increased Bandwidth and Speed: The latest Ethernet solutions offer higher bandwidth and speed, enabling faster and more efficient data exchange between machines, devices, and systems. This allows for real-time monitoring and control of production processes, leading to enhanced productivity and reduced downtime.

Improved Reliability and Resilience: Ethernet products are becoming more reliable and resilient, with advanced features such as redundancy and self-healing capabilities that ensure uninterrupted communication even in the event of network failures. This is critical for smart manufacturing operations that require high levels of uptime and availability.

Enhanced Security: Security is a major concern in industrial environments, and Industrial Ethernet products are incorporating advanced security features such as access control, encryption, and intrusion detection/prevention to protect against cyber threats. This helps to safeguard sensitive data and ensure the integrity of production processes.

Integration with IoT and Cloud Technologies: The integration of Industrial Ethernet solutions with IoT and cloud technologies is enabling new levels of automation and data analytics. This allows for real-time monitoring and predictive maintenance of machines, leading to increased efficiency, reduced costs, and improved product quality.

Compatibility with Legacy Systems: Many factories and industrial facilities still use legacy systems, and Industrial Ethernet products are evolving to ensure compatibility with these systems. This allows for seamless integration between new and existing equipment, reducing the need for costly upgrades and downtime.

Overall, the evolving Industrial Ethernet products and solutions are enabling smart manufacturing operations to become more efficient, reliable, and secure. With the continued advancement of Industrial Ethernet technology, smart manufacturing is expected to become even more advanced, leading to increased productivity, reduced costs, and improved product quality.

What makes new enhancements to Industrial Ethernet technology unique, and how it is being applied to industrial applications?

Industrial Ethernet technology has evolved significantly over the years, and recent enhancements have made it more versatile and efficient than ever before.

Industrial Ethernet technology has evolved significantly over the years, and recent enhancements have made it more versatile and efficient than ever before.

One of the most significant enhancements to Industrial Ethernet technology is the incorporation of TSN (Time-Sensitive Networking). TSN is a set of standards that ensure deterministic data transmission with low and bounded latency, making it ideal for real-time control applications. TSN also provides a mechanism for scheduling network traffic, allowing for greater flexibility and improved resource utilization. It enables multiple critical applications to share the same network infrastructure without affecting each other’s performance.

TSN is being applied in industrial applications such as factory automation, robotics, and process control, where real-time control and synchronization are critical.

Through a collaboration between IEC and IEEE an TSN profile for Industrial Automation is currently being standardized (IEC/IEEE 60802). The profiles select features, options, configurations, defaults, protocols, and procedures of bridges, end stations, and LANs to build industrial automation networks.

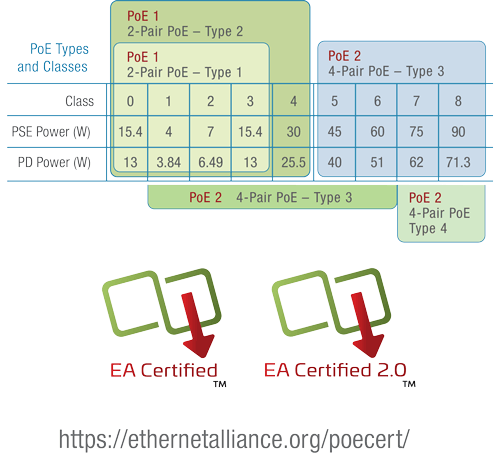

Another enhancement to Industrial Ethernet technology is the integration of PoE. PoE allows power to be transmitted over Ethernet cables, eliminating the need for separate power cables for devices such as cameras, sensors, and access points. This simplifies installation, reduces costs, and improves reliability.

Single Pair Ethernet (SPE) is another recent enhancement to Industrial Ethernet technology that provides reliable and efficient communication over a single pair of wires. SPE reduces cabling requirements, simplifies installation, and enables communication over longer distances. For example the new IEEE 802.3cg 2019 standard introduces two new variants of 10 megabit per second Ethernet over a single twisted pair, known as 10BASE-T1S and 10BASE-T1L. Industrial networking experts contributed to the IEEE 802.3cg standard, making it ideal for applications like process control, building and industrial automation, including those requiring intrinsic safety. 10BASE-T1L supports full-duplex communication over a single pair of twisted-pair cable up to 1 km. 10BASE-T1S is intended for short-distance applications and can work in multidrop mode, removing the need for switches and providing a very cost efficient option in terms of installation and operation.

What specific ways are Industrial Ethernet solutions contributing to IIoT and enterprise connectivity?

Industrial Ethernet solutions are playing a critical role in enabling the Industrial Internet of Things (IIoT) and enterprise connectivity by providing the following specific benefits:

Industrial Ethernet solutions are playing a critical role in enabling the Industrial Internet of Things (IIoT) and enterprise connectivity by providing the following specific benefits:

Interoperability: Industrial Ethernet solutions enable different machines and devices to communicate with each other using a standardized communication protocol. This allows for seamless interoperability between different systems and devices, leading to enhanced data exchange and improved decision-making.

Real-time communication: Industrial Ethernet solutions offer real-time communication capabilities, allowing for rapid and accurate data exchange between different devices and systems. This is critical for IIoT applications, where real-time monitoring and control of production processes are required.

Enhanced data analytics: Industrial Ethernet solutions provide high-speed data exchange, which is essential for collecting and analyzing large volumes of data generated by IIoT devices. This allows for better insight into production processes, leading to improved efficiency and reduced costs.

Increased automation: Industrial Ethernet solutions enable greater automation of production processes, leading to increased productivity and reduced labor costs. IIoT devices can be connected to Industrial Ethernet networks, allowing for real-time monitoring and control of production processes, leading to improved efficiency and reduced downtime.

Cloud connectivity: Industrial Ethernet solutions can be connected to cloud-based platforms, enabling remote monitoring and management of production processes. This allows for better insight into production processes and enables remote troubleshooting and maintenance, leading to reduced downtime and increased efficiency.

Overall, Industrial Ethernet solutions are critical for enabling IIoT and enterprise connectivity, providing the necessary communication and connectivity infrastructure to support the connected devices and systems that make up the modern industrial landscape.

What challenges that automation engineers face does Industrial Ethernet address?

Industrial Ethernet enables automation engineers to use “current” protocols and tools to operate their facilities. Adopting Industrial Ethernet opens the door to transformation of the automation landscape. Probably the best discussion of this can be seen in material on Industry 4.0.

Industrial Ethernet technology addresses several challenges that automation engineers face, including but not limited to:

Interoperability: In many industrial applications, different devices and systems from various manufacturers need to work together seamlessly. This can be a challenge when using different communication protocols and technologies. Industrial Ethernet provides a standard communication protocol that is interoperable with a wide range of devices and systems, making it easier to integrate different components into a cohesive system.

Scalability: As industrial systems grow and expand, traditional communication technologies such as serial communication become inadequate due to limited bandwidth and slower data transmission speeds. Industrial Ethernet solutions can easily scale to accommodate changing requirements and growth, making them ideal for automation systems that require flexible and scalable networking solutions.

Deterministic communication: In many industrial applications, real-time control is critical. Traditional communication technologies can suffer from latency and delays, making real-time control difficult. Industrial Ethernet incorporates features such as TSN (Time-Sensitive Networking), which provides deterministic data transmission with low and bounded latency, making it ideal for real-time control applications.

Reliability: Automation systems are expected to operate continuously and without interruption. Any failure or downtime can have significant consequences for production and the bottom line. Industrial Ethernet solutions provide fast and reliable data transmission, ensuring that automation systems operate continuously and without interruption.

Security: As automation systems become more connected, they become more vulnerable to cyber-attacks. Ensuring that these systems are secure and protected against unauthorized access is critical. Industrial Ethernet solutions incorporate advanced security features such as encryption, authentication, and access control.

This ensures that data transmitted over the network is secure and protected from unauthorized access.