TechnologyMay 14, 2022

Ethernet for process automation using Ethernet-APL two-wire technology

Ethernet-APL (Advanced Physical Layer) provides a combination of ease of adoption, seamless integration, simplified installation, greater range and valuable data for process industry implementations.

Process plants operate for 20+ years and are required to be safe for people, the product, and the environment. Explosion potential in hazardous areas and harsh conditions require that any deployment of new technology is both thoroughly tested and provides added business benefits. Technology must not be complicated in handling or require extensive training. Ethernet is the de-facto communication standard in enterprises, but it does not meet the requirements in the field of process automation without modification.

Ethernet with an Advanced Physical Layer (Ethernet-APL) will enable long cable lengths and explosion protection via intrinsic safety with communication and power over two wires. Based on IEEE and IEC standards, Ethernet-APL supports any Ethernet-based automation protocol and will develop into a single, long-term stable technology for the entire process automation community. This white paper covers the business environment, technical specifications, implications for different user types, and the development status of Ethernet-APL. For the purpose of this article, fieldbus refers to digital communications technologies to the field within process plants such as HART, FOUNDATION Fieldbus H1 or PROFIBUS PA.

Situation and Business Environment for Process Applications

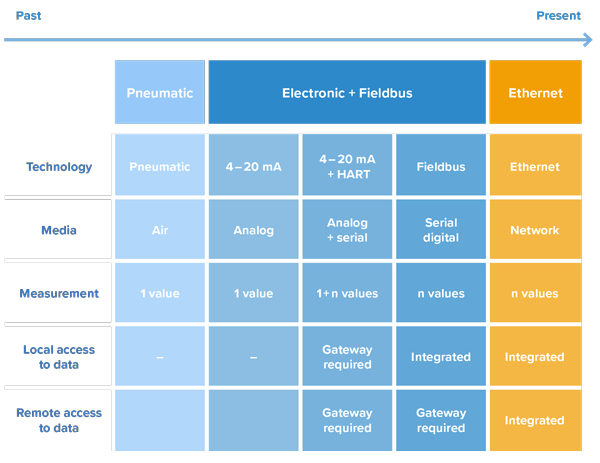

Technologies for the Field of Process Automation.

Process plants today compete to produce more products with less waste, and thin profit margins require increased output yield with increasing quality. Digital transformation has made it increasingly worthwhile for companies to consider making investments to obtain more plant data from process automation systems and instrumentation. However, to do so, new procedures and products are required to gain access to this data from every part of the plant and to extract more value on every production run.

In the manufacturing industries, the Industrial Internet of Things (IIoT) and Industrie 4.0 are already part of everyday operations, and in the near future, these technologies will also enter the field of process automation and instrumentation. In the process industries, domain-specific concepts like the NAMUR Open Architecture (NOA) or the Open Process Automation Standards (O-PAS™) by the Open Process Automation Forum (OPAF) are presently attempting to simplify the efficient construction, commissioning, and operation of process plants. Broader use of wireless solutions, simplified field device integration, and Ethernet to the field represent integral components of these concepts.

Leading suppliers to process automation recognize the need from their customers to add the universality and communication speed of standard Ethernet to existing field device installations. Ethernet has been deployed at the upper levels of the automation pyramid and in the field with 4-wire Ethernet devices, such as drives, flow, analyzers and motor control centers. However, it requires enhancements to support applications in the field of process plants.

A key group of these leading suppliers and standards development organizations have come together with the goal of accelerating development and adopting a new open standard for an Ethernet physical layer for the use in process automation and instrumentation that can be deployed in hazardous areas, allow long-reach connectivity, and include an option for device power over the line. This new Ethernet advanced physical layer, called “Ethernet-APL,” together with the automation protocols that define the structure and meaning of information being transmitted to and from field devices, will be one of the key enabling factors of the IIoT in process automation. It will provide a vital prerequisite to extend the digitized world to process automation and instrumentation.

This article describes the standardization and development of Ethernet-APL: a single, ruggedized and reliable physical layer with attributes that meet the requirements for the field of process plants. Ethernet-APL enables a logical extension of Ethernet-based communications from enterprise systems to the field. This last meter of Ethernet connectivity would allow any enterprise boardroom to obtain data from all regions of its extensive network.

Ethernet-APL group logos

Organization of the Cooperation

The agreement to develop the Ethernet-APL technology under “The APL Project” was established in 2018 and is backed by the leading industry standard development organizations (SDOs) FieldComm Group, ODVA, OPC Foundation, and PROFIBUS & PROFINET International, as well as by major industry suppliers of process automation, including ABB, Emerson, Endress+Hauser, Krohne, Pepperl+Fuchs, Phoenix Contact, R. Stahl, Rockwell Automation, Samson, Siemens, Vega, and Yokogawa.

The main objective of the cooperation is the specification of one single physical layer that meets the requirements of process automation. To achieve this goal, representatives of project members have been working on enhancements of IEEE and IEC standards underlying the technology, have been collaborating on the development of a port profile to fit the specific requirements of the process industries, and are participating in working groups to create or enhance the SDO’s relevant specifications and guideline documents. The finalization of all these standards and specifications makes this technology accessible to all users and vendors.

With the cooperation of large companies and the most important SDOs in process automation, as well as being based on existing and widely used standards, strong market adoption of the single physical layer “Ethernet-APL” is expected.

Technology for Ethernet to the Field of Process Plants

Ethernet is a broadly accepted standard for wired digital communications that is standard- ized in IEEE 802.3. Its wide acceptance in industries and households created an eco-system of standardized tools for installation, troubleshooting, and diagnostics.

This provides efficiencies in practice such as:

- Low network configuration efforts

- Same tool sets for troubleshooting and fault finding in OT and IT

- Low installation efforts

However, Ethernet’s physical layers today do not address and fulfill the specific needs resulting from the harsh environmental conditions in the field of process plants. To be suitable for process plants, an Ethernet physical layer needs to meet the following criteria:

- Two-wire cable

- Long cable runs

- Power and communication on the same cable

- Support of all explosion protection techniques incl. intrinsic safety

- Simple installation technology

- Potential reuse of existing fieldbus cable type ‘A’, which reduces cost and provides easy migration strategies from fieldbus to Ethernet-APL

- Resilience to electro-magnetic interference Support of surge protection

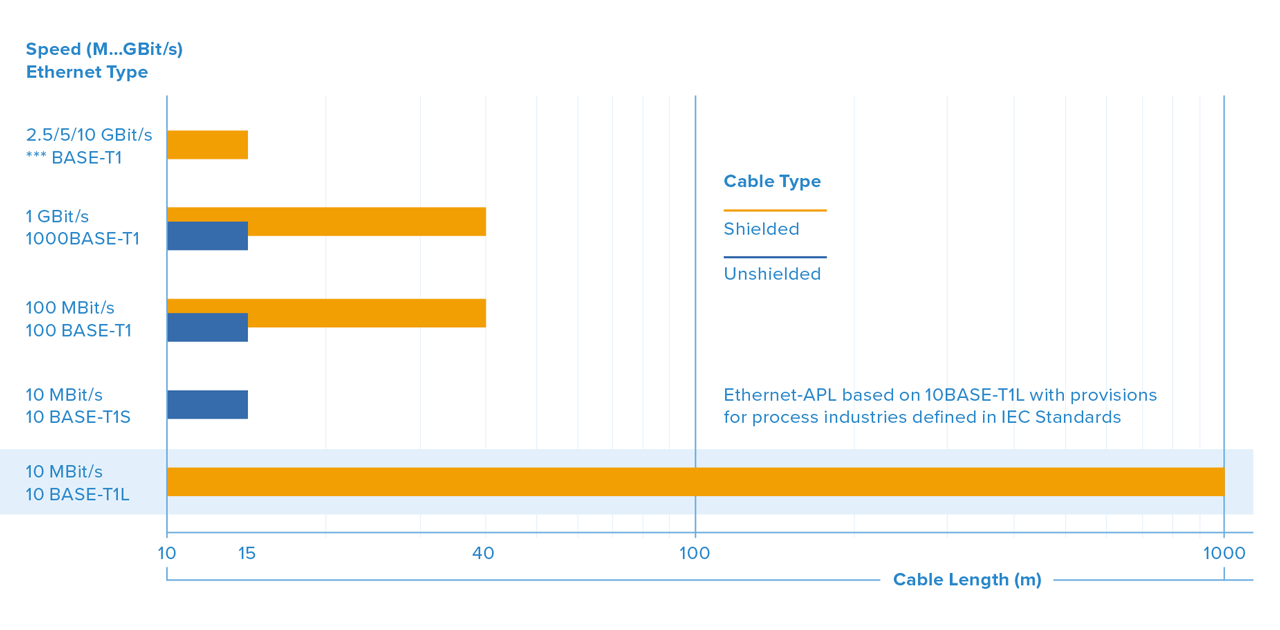

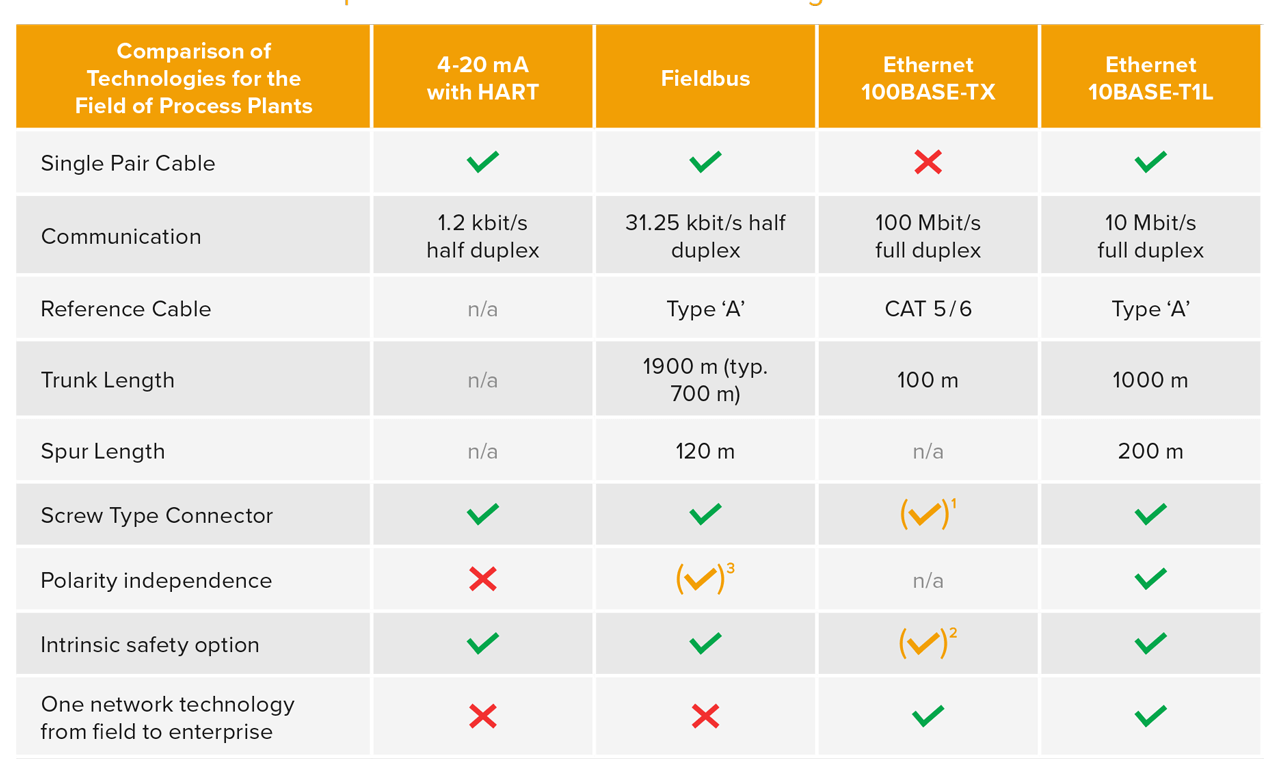

Ethernet-APL is an enhanced physical layer for single-pair Ethernet (SPE) based on 10BASE-T1L. It communicates via a cable length of up to 1000 m at 10 MBit/s, full-duplex, which is more than 300 times faster than current technologies, such as HART or fieldbus. It is the logical extension for Ethernet and provides the attributes required for reliable operation in the field of a process plant. Ethernet-APL is a physical layer that will be able to support EtherNet/IP, HART-IP, OPC-UA, PROFINET, or any other higher-level protocol.

Ethernet-APL and Types of Single-Pair Ethernet defined in IEEE 802.3.

Standardization for Long-Term Stability

Communications are based on 10BASE-T1L as defined in IEEE Std 802.3cg-2019, which is being adopted by suppliers serving many market segments in building and industrial automation. This significant market size enables manufacturers of semiconductors to provide chips in a high volume, contributing to a long-term, stable technology and platform, which can be integrated seamlessly into existing devices or instrumentation.

Ethernet-APL includes additional attributes required by process applications. The requirements result from outdoor installations and explosion hazardous area protection beyond the long cable lengths. The additional electrical features follow respective IEC standards and provide interoperability and simplicity in application.

2-WISE stands for 2-Wire Intrinsically Safe Ethernet. This IEC technical specification, IEC TS 60079-47 (2-WISE) defines intrinsic safety protection for all hazardous Zones and Divisions. For users, this includes simple steps for verification of intrinsic safety without calculations.

“The APL Project” creates the concept of Ethernet-APL by defining port profiles for multiple power levels with and without explosion hazardous area protection. Markings on devices and instrumentation indicate power level and function as sourcing or sinking. This provides a simple framework for interoperability from engineering to operation and maintenance.

Ethernet-APL allows wiring to screw-type or spring-clamp terminals, thus supporting cable entry through glands. Additionally, well-defined connector technology ensures simplicity during installation work.

Components & Topologies

Ethernet-APL is designed to support various installation topologies, with optional redundancy or resiliency concepts and trunk-and-spur. Ethernet-APL explicitly specifies point-to-point connections only with each connection between communications partners constituting a “segment”. Ethernet-APL switches thus isolate communications between segments. This eliminates disturbances such as cross talk and natively protects communications from device faults on a different segment.

Ethernet-APL defines two general types of segments:

- The “Trunk” provides high power and signal levels for long cable lengths of up to 1000 m. The “Spur” carries lower power with optional intrinsic safety for lengths of up to 200 m.

- Port profiles specify levels for power and communication signals, ensuring interoperability.

Ports can be classified as:

- P = Powered, power source

- L = Load, power drain

- C = Cascade, for daisy chain configurations

- U = Unpowered

Shows all technical attributes applicable to Ethernet-APL.

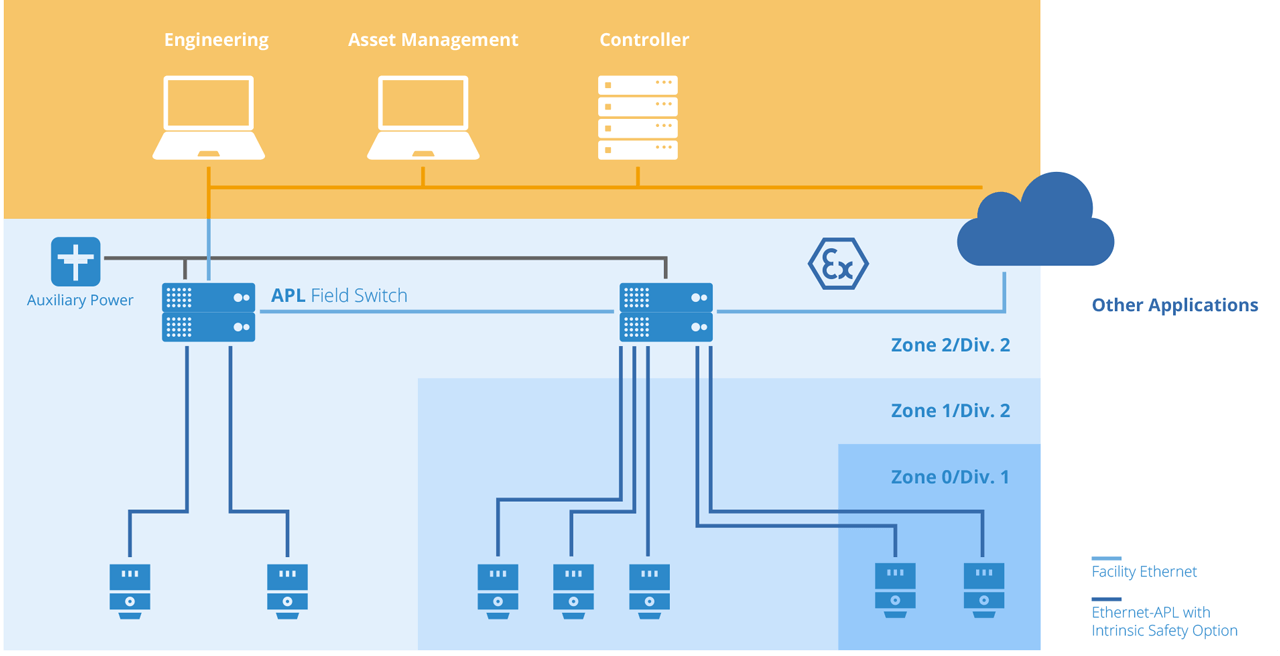

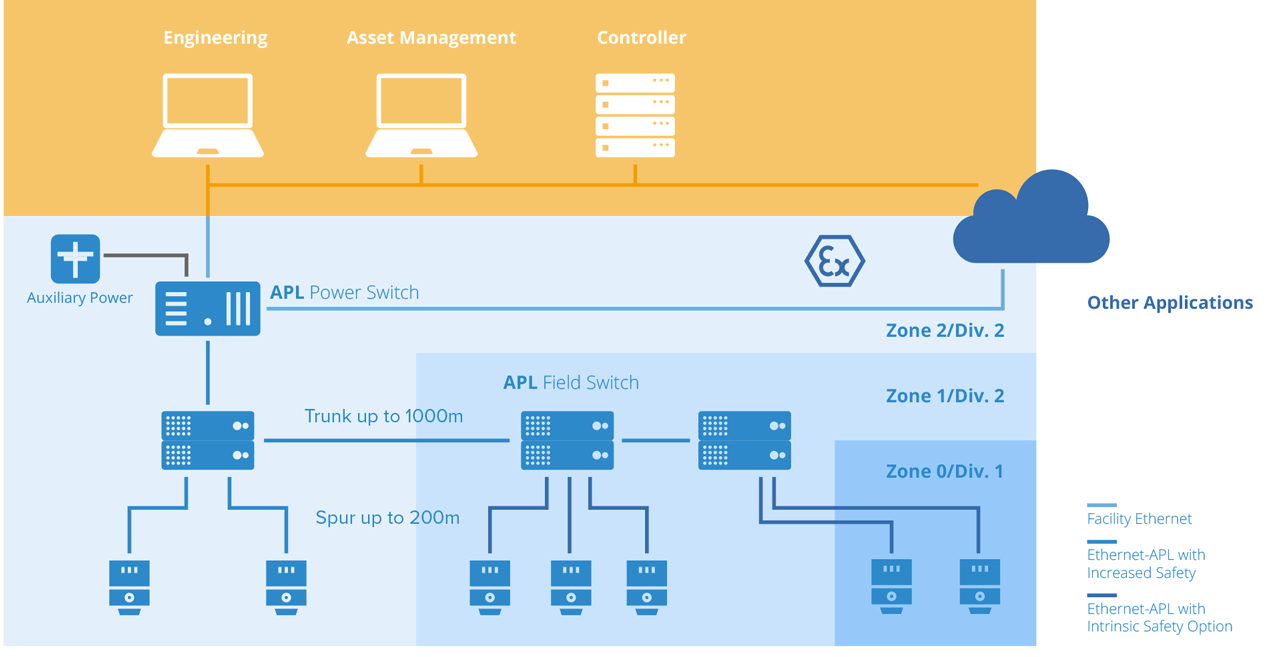

Figure 4 and Figure 5 illustrate the flexibility of topology choices for compact layouts and for plants requiring long cable runs.

Two typical types of switches enable full flexibility of topologies:

- The power switch feeds power and communication into one or more trunk ports. It is typically externally powered.

- The field switch provides at least one port to which a spur can be connected. It can be powered via the Ethernet-APL trunk or externally.

Example topology for a compact star installation.

Example topology for long cable reach with up to 1000 m between switches on the trunk.

Scalability & Redundancy

A managed switched network architecture, a power budget of up to 60 W, and data traffic at 10 Mbit/s provide for excellent scalability with regards to the number of Ethernet-APL switches and instruments that can be connected. Additionally, Ethernet-APL transports and enables the functions from higher levels of the ISO-OSI model. These higher-level functions fulfill the general requirements for simplicity, convenience, and automation of the network itself, which users generally expect from Ethernet-based communication. These include:

- Automatic neighborhood detection at the switch that provides the means for simple device exchange.

- Multiple communications paths that can run in parallel. Users gain complete access to field instruments for asset management and dashboards in parallel and without interfering with process automation communications.

Ring redundancy or resiliency concepts at the network layer re-route communications in the case that an Ethernet-APL trunk segment fails for superior plant availability.

Ethernet-APL provides a single and highly ruggedized version for Ethernet that is fit for process plants. It provides the best possible simplicity in handling of all aspects with digital communications in the field.

Handling & Installation

All connection choices standardized for Ethernet-APL are proven in use and well-known:

- Spring-clamp terminals

- Screw-type terminals

- M8 and M12 connectors

The simple two-wire cable, with shielding, requires just a screwdriver to ensure connectivity, and the related wire preparation tools to physically connect to the rest of the automation installation. Ethernet-APL specifies fieldbus cable type A (100 ohms resistance, +/- 20 ohms tolerance), IEC 61158-2 as reference cable of AWG classes 26 – 14, wiring cross section of 0,324 … 2,5 mm2. This provides easy migration strategies for existing fieldbus installations, including support for intrinsic safety. Ethernet-APL prescribes polarity independence, reducing wiring errors during installation.

Inherent diagnostics of an Ethernet-based system can be easily utilized to determine network robustness, detect signal strength, and identify possible installation issues. Working in tandem with operational staff in the control room, the maintenance and engineering team can easily and quickly install, replace, re-connect and commission any device. Installation guidelines from the standard development organizations provide details and guidance for technicians and electricians. The installation guides cover the planning and selection of cable types, cable lengths and parameters to be considered. Like all Ethernet-based technologies, numerous software and hardware tools exist to monitor, verify, and test system behavior throughout the lifespan of the installation.

Adoption of Ethernet-APL

Ethernet has proven itself as a reliable communications technology in an environment with strong requirements for interoperability. This is true for industrial industries, office buildings, and many private homes. High standardization of Ethernet technology causes a largely accepted environment with tools that range from product development and protocol stacks to network planning, commissioning, and troubleshooting. The seamless implementation will ensure fast adoption, high involvement, and thus a long-term business environment for all parties in the life cycle of the process automation system: vendors, engineering companies, installers and operators. Increased flexibility and reduced risk are provided by the re-use of the already installed fieldbus cabling, which provides a path for clear migration strategies. This significantly reduces cabling cost as firewalls remain untouched.

Ethernet-APL supports all current and future higher-level communication protocols and services and flattens the network infrastructure. Ethernet-APL removes the need for protocol conversions and gateways, providing barrier-free and parallel accessibility and providing the extra speed required in a data-driven economy. Table 2 compares major attributes of communication technologies in use today.

Ethernet-APL combines the best attributes of Ethernet communication with two-wire installation techniques. This makes Ethernet-APL easy to deploy as a standard for field applications, from process plants with hazardous areas up to Zone 0 / Division 1 to hybrid plants, employing technologies from discrete and process automation. Since Ethernet-APL is the physical layer only, any current and future concepts for functional safety and security applications can be applied that reflects the needs of end users. New developments can be applied independent of the physical layer, providing long-term stability of the technology and protecting the investment in the installation. Like any other physical layer, Ethernet-APL transports application-layer safety and security services from the leading industrial automation standards bodies, which utilize standards such as IEC 61508 and ISA/IEC 62443.

Device Development and Implementation

Field devices oftentimes contain a lot of smart data about themselves, such as self-diagnostic functionalities.

Ethernet-APL provides the optimal method to access this data in parallel to process control. This technology provides access to the instrument separately, and thus combines the potential of smart instrumentation with IIoT applications. This enables product managers to design additional services, business models, and unique selling propositions for differentiation of the field device supplier. Ethernet-APL significantly reduces the costs to access this beneficial data in comparison to traditional technologies. Ethernet-APL reduces the need for protocol converters, additional system components or retrofit solutions, which would otherwise be required.

The case for considering Ethernet-APL in field device implementation is strongly bolstered by the expected market volume:

- Ethernet-APL fulfills the requirements of process automation (e.g., hazardous areas, long cable reach, simple maintenance, etc.)

- The availability of a single network technology opens new business potential for both device manufacturers and plant managers based on access to data from smart instrumentation.

- Large companies and SDOs focused on process automation are involved in the APL Project and collaborate in the working groups, thus a high market acceptance for the technology can be expected.

- In order to strive for technological leadership in the market, Ethernet-APL must be considered in the product portfolio in the near future.

Implementing Ethernet-APL in smart instruments requires limited effort only concerning the PHY and the protocol stack. What must be considered during device implementation specifically for Ethernet-APL? The answer is simple:

- Ethernet-APL enhances the Ethernet physical layer. By implementing the corresponding 10BASE-T1L PHY in the field device hardware, the necessary connection is ensured. Standard PHY chips are available from reputable chip manufacturers.

- Due to the independence of the individual layers according to the ISO OSI model, there are no restrictions for the implementation of any Ethernet protocol. Therefore, no adaption is necessary for the implementation of Layer 3-7 protocols regarding Ethernet-APL. Application layer protocols, which have been in use for many years, especially in discrete automation, can easily be implemented according to their existing specifications, guidelines, and certifications.

- As part of the extension of the specifications on the Ethernet-APL physical layer, the corresponding test specifications and certifications can also be adapted. This ensures that the implementations comply with the standards.

Operation

Plant efficiency is becoming an increasingly important topic in process automation. For this purpose, it must be ensured that a process plant operates reliably, provides information on future maintenance intervals for the instrumentation, is easy to diagnose in case of failures, and works with devices from different device manufacturers. The basis for these aspects is the continuous collection and analysis of data from the installed base.

Ethernet-APL supports all of the following requirements of a highly efficient process plant.

- Reliability: Based on well-proven Ethernet standards, the reliable operation of the plant is ensured. Ethernet has been the standard in the IT world for decades and has also been used successfully in discrete, process and hybrid automation for many years.

- High availability: Ethernet protocol features ensure the high availability of the process by availability concepts, e.g., system redundancy for controller failures or media redundancy for cable breaks.

- Predictive Maintenance: Smart field devices have the data for predictive maintenance inside. With Ethernet technology, the data can be made accessible and used for central monitoring of the device status.

- Diagnostic: For Ethernet technology, easy network diagnostic tools are available to identify the root cause and reasons for failures.

- Interoperability: For Ethernet-APL, test specifications and certifications will be available to ensure the interoperability of components from various device vendors and will also support device exchanges.

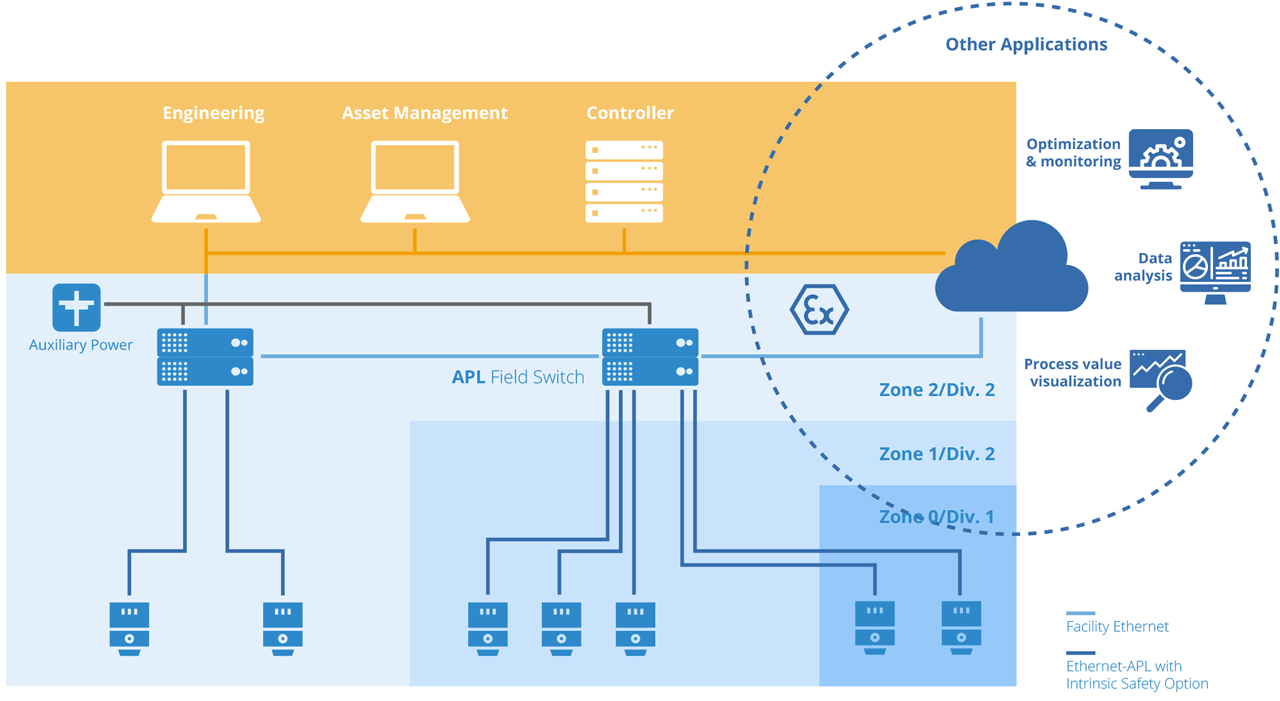

Summarized, Ethernet-APL supports this new paradigm of data by the technology consistency in and across the automation pyramid. With Ethernet technology in the field of process plants, operational technology (OT) is integrated with IT technology, and the vision of the single network technology is achieved.

The access to the data of the field enables new digital services according to the business needs of the process plant. Ethernet technology provides access to this information in real-time. There are hardly any limits to the further processing of the data within the frame- work of IIoT applications, for example those required by NAMUR Open Architecture (NOA). Maintenance dashboards or trend monitoring of process values support the specific process optimization.

Networking the entire automation pyramid.

Prototyping & Engineering

Working habits and procedures based on Ethernet-enabled software and tools provide a high degree of automation to engineering within the field of process plants. Current and coming generations of engineers master these technologies with ease. Ethernet-APL enables the easy integration of these features into the field of the process plant. With this, engineers can meet their project schedules through automation of many tasks.

Software tools simplify or automate:

Network planning

- Creation and design of typical control loops

- Access to all details stored in the instrument such as: device drivers and descriptions, e.g. FDI package manuals, certification

- Instrument parametrization and configuration

- Instrument diagnostics during operation

Engineering and maintenance of protocol converters and gateways will become obsolete. App-supported work procedures running on smart phones or computers satisfy the expectations of the new work force. Developers and experts of the SDOs and suppliers involved in The APL Project are in the process of developing guidelines and best practices for planning and installation. This facilitates an easy transfer of knowledge for early adoption of Ethernet-APL. Standard Ethernet diagnostic tools assist new or seasoned instrument techs and engineers in their daily work, providing a shallow learning curve.

Once all standards and guidelines are available, a broad base of vendors are able to adopt Ethernet-APL in their devices or other product offerings. Companies providing engineering services to vendors and users already show an interest. It can be expected that a robust ecosystem will evolve.

Installation in the Field

The network skills required by a new generation of electricians and instrument technicians are the result of numerous network upgrades, which many plants introduce to access and extract more data across their process automation systems. Wired or wireless, Ethernet has become part of the fabric of everyday life at home, in the office, and on the plant floor. From routers, switches and wireless access points, the only additional feature integrated in Ethernet-APL is the two-wire physical layer, including intrinsically safe ignition protection providing the same installation and protection rules that are familiar to field and instrument technicians. The instruments are not allowed to disturb one another and are only configured in a peer-to-peer manner. With features like polarity protection and the mandatory terminations inside the devices, the technology provides for a smooth and short learning curve.

While today’s technician may require time to calibrate, configure, and prepare an analog field device prior to installation, the time spent preparing a digital field device will be significantly reduced. Supporting techniques include apps and wizards for automatic network setup, device discovery, configuration, and instantiation – as soon as the field device is installed and connected. The 2-wire Ethernet-APL cable allows the use of higher speed data transfer to simplify the installation and allow the technician to complete an assignment with confidence in very little time.

Together with a screwdriver, the handheld data device (such as a smart phone), cable test devices, and an improved user configuration will become additional parts of the technician toolbox in the transition from the analog to the digital field instrument with the related infra- structure devices.

Project Scope, Timeline and Conclusion

The consideration of techniques providing power and data with high bandwidth on two wires inspired developers to develop a common physical layer that serves the needs of process plants. The experts created and published the vision for process plants: “Ethernet to the Field”.

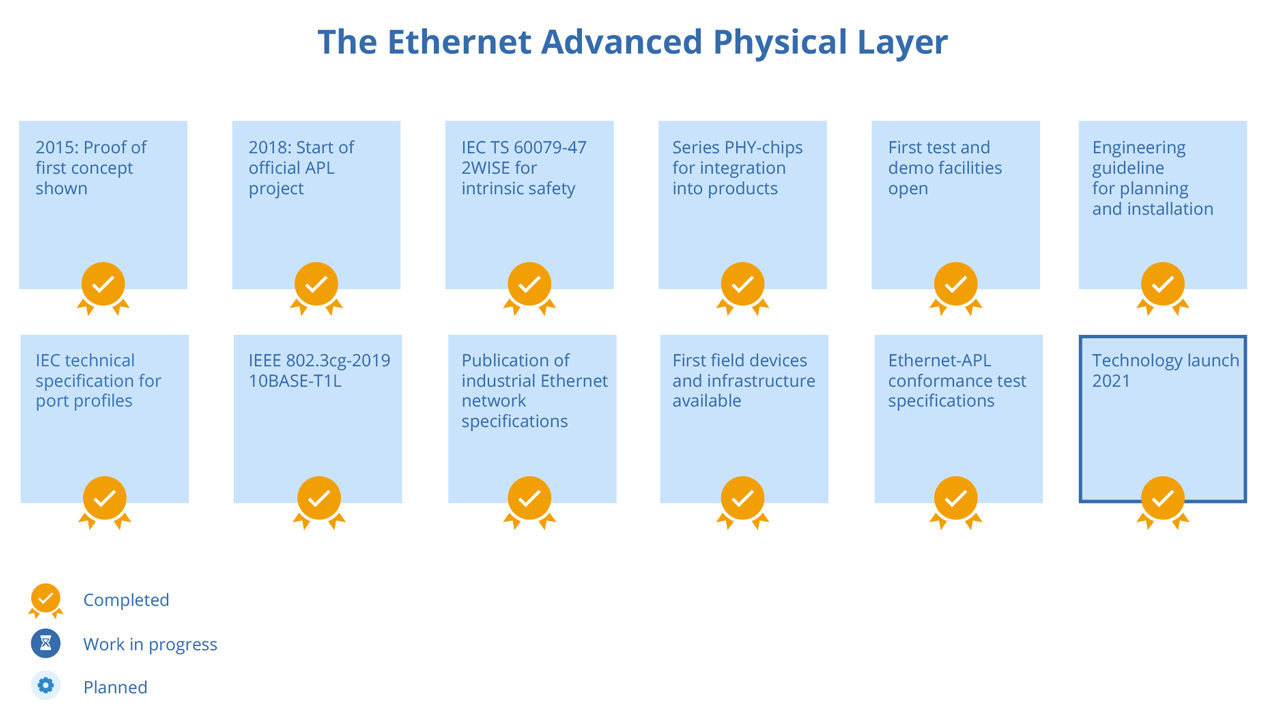

This evaluation project for the Advanced Physical Layer for Ethernet started in 2011 by a group of device suppliers. The objective of the evaluation project was to define a solution that fit the harsh requirements of process automation that didn’t affect the application layer protocols and therefore the established Industrial Ethernet protocols. In 2016, the evaluation project ended successfully with identified enhancements of relevant specifications.

The project to develop Ethernet-APL has already achieved first milestones as visible in the infographic. Together with the release of the 10BASE-T1L specification in IEEE, the progress of IEC specifications for 2-Wire Intrinsically Safe Ethernet (2-WISE) and power port profiles have now officially been published by the APL Project and provided to the key standards development organizations. Final PHY chips are now available, so the first field devices and infrastructure components are expected to be available in 2021 as well. For the installation of an Ethernet-APL system, an Engineering Guideline is now available on www.ethernet-apl.org.

A first pilot project with Ethernet-APL prototypes in Germany proved the working principle and the benefits of the technology. The installation of 2-wire Ethernet field devices, both actuators and sensors for all kinds of measuring types, prove the simplicity of field device installation, integration in the process automation systems, and the parallel access to the data of field devices.

Technologies for the field of process automation comparing attributes of technologies connecting the field of process automation.

Meeting all these requirements will favor acceptance by users:

- extends easily into existing plants,

- enables transparency and open, parallel access to proven-in-use field instrumentation,

- ensures interoperability based on a single network,

- provides standardized and well-accepted procedures for explosion hazardous areas,

- achieves simple, flexible and vendor-independent use of all device functionality.

Enhanced connectivity provides a powerful tool to reduce complexity in daily operation and work. The availability of a single network technology opens new business potential for both device manufacturers and plant managers based on access to data from smart instrumentation.