TechnologyNovember 18, 2021

IIoT solution moves beyond the boundaries of drive technology

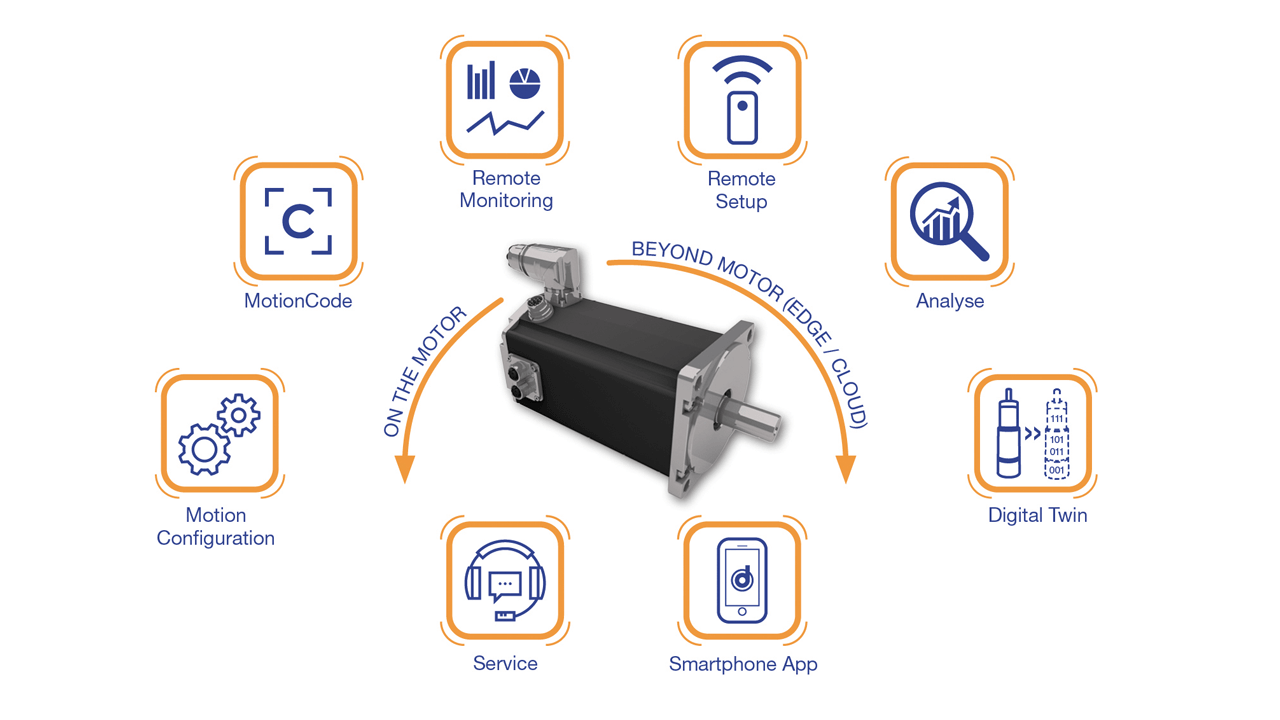

A new holistic technology covers all aspects advancing the use and connectivity of smart motors. Offering a solution from the field level to the cloud, using a single source, it aids the rapid development of decentralized control programming and IIoT solutions.

The Dunkermotoren team has been working on intelligent drive solutions for many years. Even before the boom around Industrial Internet of Things and Industry 4.0, Dunkermotoren provided forward-looking software solutions such as the control functionality integrated in the motor or even condition monitoring.

The Industrial Internet of Things is now creating completely new possibilities in the areas of remote connectivity and decentralized control topologies. In order to fully exploit the opportunities that arise and to create a holistic solution offering for its customers, Dunkermotoren is bundling its expertise in the development of decentralized control programming and IIoT solutions under the new nexofox brand.

For nexofox, holistic means, on the one hand, from the initial consultation and joint concept development to project implementation in partnership. On the other hand, holistic also means from the field level to the cloud from a single source, i.e. from the realization of the control logic with MotionCode to condition monitoring & predictive maintenance using cloud services. In the IIoT area, nexofox naturally also offers solutions for the automation systems of Dunkermotoren subsidiary EGS. The following article is dedicated to the innovative solution approaches, used and further advanced by nexofox technology.

New holistic technology covers all aspects advancing the use and connectivity of smart motors.

Technology Solutions

Nexofox starts where the pure Dunkermotoren or EGS automation system leaves off. On the one hand, nexofox enables free MotionCode programming of the BG series of Dunkermotoren in order to map PLC logic directly to the motor. This offers several interesting use cases, which are realized for customers or for which customers are supported. For smaller systems such as AGVs or AGVs, for example, the entire logic of the vehicle can be implemented on the motors without the additional installation of a PLC.

The necessary sensors are then connected directly via the digital and analog IOs of the motors. The motor can receive the position commands from the navigation control system via the integrated CANopen or Industrial Ethernet interfaces and can be addressed by the safety via the integrated Safe Torque Off interface. The advantages of this solution are obvious: space and cost savings due to the elimination of a separate PLC.

This approach is not only interesting for small plants. More complex machines can also be built up modularly by coupling all axes belonging to one function to one module. The sensors are again connected directly to the motor. The associated control logic can be implemented directly on the motors, as in the above example. This not only creates mechatronic modules that are addressed from a central PLC, but they also act fully autonomously and contain all the information they need.

The advantages of a decentralized approach are obvious. For one thing, wiring is much simpler and faster because it is done much more locally. On the other hand, this approach also offers further advantages in terms of scalability. All information and tasks are encapsulated in functional modules and can be combined as if from a Lego construction kit. This eliminates the need for central adaptation of the software. Data is exchanged between the modules and other system components, such as an HMI, via standardized interfaces programmed on the motor.

But as already indicated at the beginning, nexofox does not stop there. The entire integration of the smart BG series of Dunkermotoren as well as EGS automation systems into the IIoT and the development and provision of digital services also falls within the range of solutions offered by nexofox.

The basis of the technology are software solutions via which drives and systems that can be connected to the EDGE and provide their data there. Alternatively, the data can also be transferred directly to the cloud and thus be viewed and evaluated from the desktop worldwide. This solution is implemented at nexofox via specially developed Docker containers, which can read out the motors and systems via the fieldbus and thus provide the acquired data, such as the electronic nameplate via MQTT or OPC UA. nexofox has already demonstrated in a demonstrator that the data can be received and evaluated in the cloud.

Looking to the Future

But what are the benefits for the customers of Dunkermotoren and EGS? In the future, Dunkermotoren sees itself even more strongly as a service provider for customers with nexofox. As a service, the data supplied by the intelligent motor or automation system will be analyzed and transferred directly to the customer’s application via plug-in apps or web services. This means that users no longer have to worry about interpreting the device data and can concentrate fully on their application.

The roadmap for IIoT is already clearly defined. Remote monitoring to display and provide device data is at the top of the list. Various tools, such as the remote oscilloscope for real-time analysis, can be used to analyze device data in detail. Alarm and status messages can also be called up at any time.

In the area of remote control nexofox sees the firmware and software distribution to single motors and plants or whole fleets as well as the motor tuning by remote. This is also the basis for the machine analysis of device data and the prediction of failure probabilities. This enables just-in-time spare parts deliveries. Ad-hoc maintenance calls will then be a thing of the past and can be replaced by planned, prepared maintenance. Conclusions can be drawn about defects or malfunctions in the mechanics connected to motors by means of sudden deviations in the data. This makes it possible to avoid consequential damage to motors.

The service technician is also not forgotten with nexofox. A smartphone app enables him to retrieve the electronic nameplate and accompanying information via 2D code. Live data such as temperature, messages or operating hours can also be displayed via the app. In this way, service technicians can access the device data at any time – smart factory – smart working. When data transmission/data monitoring is mentioned, the topic of IT security naturally comes into play. Here, too, Dunkermotoren has the best possible integration in mind with nexofox.

To fully exploit the potential of IIoT, Dunkermotoren believes that open and generally recognized standards must be relied upon. This goes hand in hand with the need to think in terms of ecosystems rather than individual solutions. For this reason, since 2019 the company has been a member of the Open Industry 4.0 Alliance and MindSphere World e. V. There, the drive technology manufacturer is working together with other market leaders on joint solutions.