TechnologyMay 30, 2021

Intelligent connection: Data and power supply over one cable via PoE

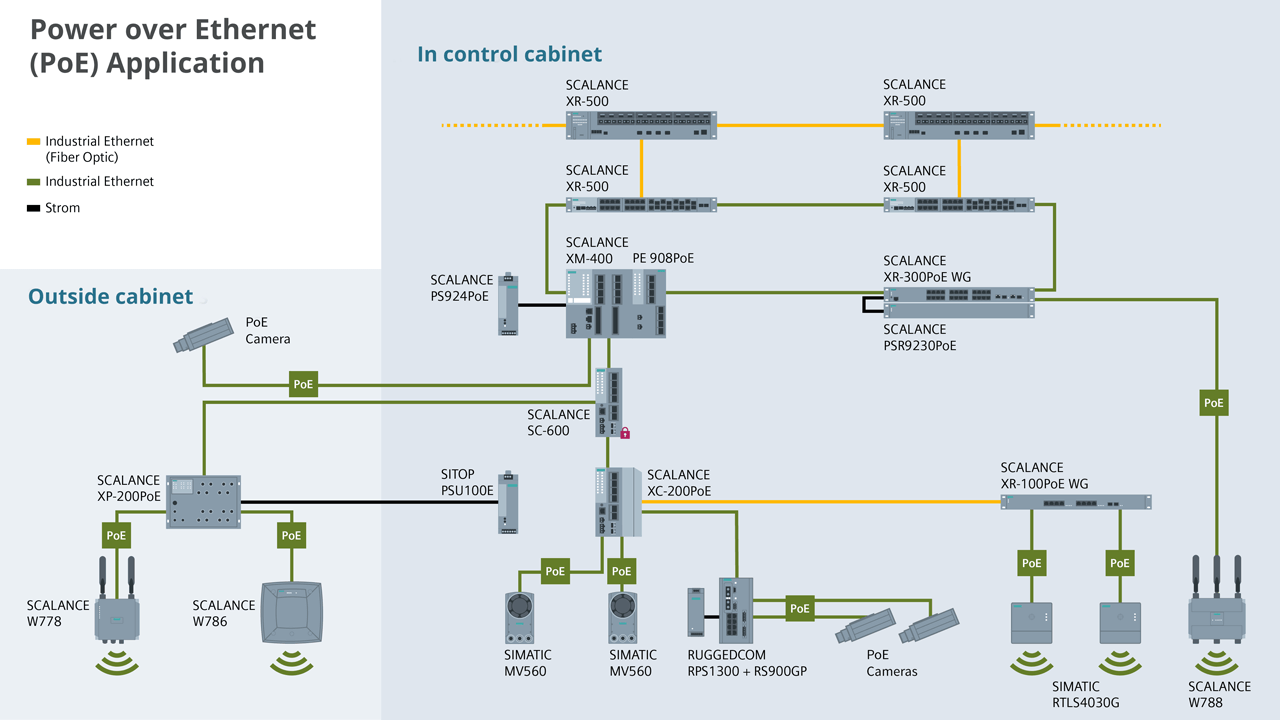

With ever increasing performance and a rising number of supported end devices, Power over Ethernet (PoE) – for the simultaneous supply of industrial end devices with data and power – is becoming a versatile all-rounder in the digital factory. With various components feeding and utilizing PoE, Siemens offers a comprehensive portfolio for even more efficient industrial applications. This saves time, effort, and money – from planning to installation and commissioning to maintenance.

In these times of digitalization, the number of applications in the IIoT, the Industrial Internet of Things, is increasing rapidly. The network components used for this not only have to be long-lastingly and reliably supplied with data, but also with power. The easier that is, the more efficient the solutions, the shorter the time-to-market, and the lower the life-cycle costs.

Data and power over one cable – automated, standardized, flexible

Siemens is expanding its Industrial Ethernet switches portfolio by new PoE variants, including Scalance XR-100PoE WG and Scalance XR-300PoE WG. Should the power provided by the switch not be sufficient, the Scalance XR-300PoE WG, for example, can be augmented with PoE power supplies such as the Scalance PSR9230PoE to deliver up to 570 watts of power.

Power over Ethernet is getting better and better. The technology comes from the home and office area, where WLAN access points, Internet cameras, or IP telephones have been supplied with data and power over a single cable for years. The resultant added values for industrial networks are obvious – starting with the reduced planning effort for new or to be expanded production networks. These can also be set up and commissioned more easily, i.e., assembled much faster thanks to fewer cables. Less cabling also speeds up troubleshooting and component replacement as well as adaptation of networks to changing circumstances.

In the industrial environment, PoE supplies infrastructure end devices such as Industrial Wireless LAN access points for wireless communication, and recently also RTLS (real-time locating system) gateways for real-time locating of objects and/or people. In addition, there are classic end devices, i.e., identification systems for tracking products as well as cameras for quality assurance or for building, area and plant monitoring.

PoE-capable Industrial Ethernet switches function as supply sources (power sourcing equipment, PSE). The specialized switches apply a voltage ranging from 48 to 54 V DC to the wire pairs of the Ethernet cables. End devices thus only need an Ethernet connection. Cabling and communication mechanisms remain practically unaffected, as do established cybersecurity, safety, or redundancy strategies.

The electricity requirements of industrial PoE end devices range from a few watts in the case of simple card readers for access authorization to high double-digit values, for example for heated outdoor cameras. The IEEE 802.3bt standard defines eight power classes and an upper limit of 90 watts per port – practically feasible at the moment are up to 60 watts over distances of up to 100 meters. The power output is usually “negotiated” automatically among the feeding and using devices (hardware-based) according to IEEE standards. The user does not need to configure anything manually in addition. However, they can do this if necessary, as many devices offer the possibility of precisely specifying power output for each port.

State-of-the-art intralogistics: Simatic RTLS (real-time locating system) gateways and Scalance IWLAN access points in the electronics production at Siemens in Fuerth are efficiently supplied with data and power via Scalance X PoE switches.

PoE portfolio for various industrial applications

This also applies to the new Power over Ethernet variants of the Scalance X Industrial Ethernet switches from Siemens. Their power budget can be individually split and optimally utilized which may allow a larger number of end devices to be supplied (than with the automated procedure). With the Scalance XR-300PoE WG (WG: workgroup) rack switches – featuring a large number of ports – up to 26 end devices can be supplied with data and power over each data cable.

All of the new PoE switches support the IEEE 802.3bt standard and provide up to 30 watts of power per port. Via their 10 Gbps copper ports, up to 60 watts are possible. Should the power budget offered by the switch be insufficient, additional external power supplies can be used. The Scalance PSR9230PoE power supply in 19” format was specially developed for the rack switches. With up to two of these devices, the power budget can be expanded to a maximum of 570 watts.

The industrial-grade Scalance XP-200PoE devices are designed for an extended temperature range and – with IP65 protection class – suitable for cabinet-free installation in plant environments. The rack/workgroup devices, on the other hand, are designed for use at temperatures higher than encountered in an office environment, the variant with a large number of ports, for example, as a classic star coupler in a control room. PoE variants from the Ruggedcom series – such as the Ruggedcom RST916P or RST2228P – are ideal for the most demanding harsh environments, for example in the transportation, oil and gas, or electric power sectors, as they can supply up to 420 W or 500 W of PoE power reliably at temperatures ranging from -40 to +85 °C. This yields a wide range of potential applications and advantages in industrial environments.

Focus on quality: network components supplied via PoE – such as Scalance W IWLAN access points or HD cameras – greatly simplify complete tracking and continuous quality control. High-performance uplinks of the higher-level PoE switches with data rates of up to 10 Gbps avoid data bottlenecks.

State-of-the-art intralogistics network

A highly complex practical example is the needs-based supply and disposal in the electronics production of the Siemens plant in Fuerth (Germany) using material boxes on Automated Guided Vehicles (AGVs). About 2,000 of these boxes are in circulation on AGVs. The Simatic RTLS real-time locating system provides transparency and, in the future, also collision safety. For position detection, RTLS transponders with a unique identification number are attached to the material boxes.

These transponders are captured by an independent wireless network of RTLS gateways at short time intervals and their positions are determined. The RTLS gateways mounted high up for optimal coverage are connected to the servers via a separate Industrial Ethernet network with Scalance X PoE switches. They are supplied with power over the network cable, as are various IWLAN access points for the wireless communication with the AGVs. This has greatly reduced the installation effort and significantly shortened the commissioning time.

General advantage not only for RTLS projects: the portfolio includes unmanaged and managed PoE switches in Layer 2 or Layer 3 variants. This allows networks to be structured individually and adapted precisely to changing requirements – as has become familiar.

Focus on product and process quality

Unambiguous and complete tracking of components and the monitoring, ideally, of all process steps are essential for a consistently high quality in a highly automated industrial production. Network-capable identification systems such as code readers and RFID (radio frequency identification) readers and cameras, the number of which is constantly growing, play a key role in this. And with it the cabling effort and the amounts of data.

High-performance PoE switches with data rates of up to 10 Gbps provide reserves for the increased use and aggregation of data from increasingly powerful end devices, such as high-resolution HD cameras for quality certification at measuring systems and other locations. With just a single cable, they can be installed and replaced quickly – without specialist thanks to the standardized configuration. Besides the quality, this keeps plant availability and thus productivity high.

The already greatly reduced cabling of industrial PoE components can be simplified even further with the aid of the FastConnect cabling system from Siemens. With it, system-tested solutions from a single source can be conveniently implemented with both RJ45 and M12 connectors.

The comprehensive portfolio of PoE-capable network components and end devices from Siemens supports users in the efficient setup of individually structured network solutions which are adapted to the respective industrial requirements.

More effective access protection – inside and outside

In particularly sensitive areas and in the highly automated production with autonomous AGVs or robots, protection against unauthorized access by means of cameras is important. These often widely spread, increasingly higher resolution cameras are also typically supplied via PoE in order to keep the cabling effort low. Here, the amount of data also quickly exceeds the current, typical transmission rates. The PoE-capable Scalance XC-200 switches support uplink data rates of up to 10 Gbps and resolve any arising bottlenecks. Apart from that, these DIN rail switches can be operated like a classic automation device with 24 V DC, i.e., be powered by a conventional power supply such as Sitop.

The power monitoring in the Industrial Ethernet switch with PoE partially compensates for the lack of management or diagnostics functions in such cameras. And by means of ports which can be switched on/off individually, cameras can be restarted remotely in the event of an error. The use in redundant network structures is also readily possible.

Thanks to increased power, subsections outdoors can also be included via PoE. With up to 60 watts per port, heated cameras can also be supplied – ensuring operation at sub-zero temperatures.

Potential for the future

Power over Ethernet is a cost-effective way of supplying network infrastructure and end devices with data and power using Industrial Ethernet switches. This method is also compatible with upcoming technologies such as time-sensitive networking (TSN) and 5G. With PoE, end devices can be easily integrated into networks and optimally supplied. This makes end-to-end standardized communication solutions also possible for deterministic real-time applications – either wired via TSN or wireless in 5G networks.

Christian Homann, Process Industries, Siemens