TechnologyMay 19, 2024

Machines leverage distributed servos and EtherCAT P

New machine concept for the industrial production of brooms and brushes uses distributed servo drive technology and EtherCAT P to facilitate a production process overhaul.

INDUSTRIAL PRODUCTION OF BROOMS AND BRUSHES is not much different from the classic manual approach; the machines just work faster – but still not fast enough for Italian machine builder Borghi S.p.A. This is where the Moon project came in, allowing the company to make a significant leap in terms of productivity.

The project saw the development and implementation of a completely new production sequence using PC-based control and the AMP8000 distributed servo drive system based on EtherCAT P.

At first glance, they are just everyday objects – brooms and brushes in a wide variety of shapes, materials, and colors for both domestic and industrial use.

The distributed connection concept based on EtherCAT P and the compact AMP8000 servo drives save valuable space in the machine.

The range of materials and dimensions is just as broad, spanning from small brushes made of steel, polypropylene, horsehair, or Tampico fiber through to large rollers for street cleaning vehicles. Therefore, state-of-the-art production technology is required to manufacture brooms, brushes, and mops the way Borghi does: economically, in high volumes, and with precision and quality.

Based in the Italian town of Castelfranco Emilia, Modena, Borghi’s roots date back to 1948, giving the company close to 75 years of expertise in this specific segment. Today, Borghi produces in several subsidiaries, including those in Brazil, China, India, Poland, and Spain. It also has sales offices in a number of strategically important regions, such as Asia, Europe, and the USA.

“Borghi is now an international group,” explains Chairman Paolo Roversi, “where more than 250 employees are involved not only in the production of machines, but also in the assembly of control cabinets, mold making, and much more besides. You will often find the work of one of our machines behind the products marketed by a host of major brush and broom brands,” he goes on to point out.

Household items such as brooms are mass-produced goods and therefore often have to adapt to trends – for example, in terms of bristle color.

Broom production with stringent requirements

When it comes to manufacturing a broom, the brush is the most important element. Brushes consist of several rows of fibers that are threaded into what is known as a ‘lath’. Not only can these have completely different geometries, but they can also be made of different materials. “For example, the ability to process synthetic, natural, and metallic fibers all in a single plant calls for extremely high flexibility,” notes Paolo Roversi.

The classic cycle of brush production starts with feeding in the base plates, which are sent to the drilling station once inserted. In the next phase, the tufts are inserted into the drilled plates before being cut to size. The final step is for the finished product to be set aside. This last machining step almost always coincides with the insertion of the next base plate ready for a new cycle to begin. “During the transition between the various processing steps, the motion axes of the work stations constantly have to stop briefly and allow the semi-finished product to pass to the next station,” explains Paolo Roversi, pointing out a major productivity bottleneck. This brief stop typically lasts for 2 to 3 seconds, which might not sound like much, but still represents a productivity loss of around 20 percent for a complete cycle of about 15 seconds. At the same time, these forced breaks hold enormous potential for productivity gains.

Around half of the servo drives are still controlled via the AX8000 multi-axis servo system.

Pause times eliminated via motion control

This is exactly where Borghi’s Moon project came into play to optimize the performance and efficiency of the machines. “With our new generation of machines, we wanted to break with the classic pattern of phase change cycles and develop a machine concept that can operate continuously,” Paolo Roversi notes, pointing out the optimized approach to brush production.

This requires a completely different machine design and an automation supplier who can handle this high level of complexity with a safe, reliable, and deterministic approach. After evaluating various automation concepts, the decision was made in favor of Beckhoff, whose automation solutions, which include the AMP8000 distributed servo drive system and EtherCAT P, made implementation of the concept possible in the first place, recalls Paolo Roversi.

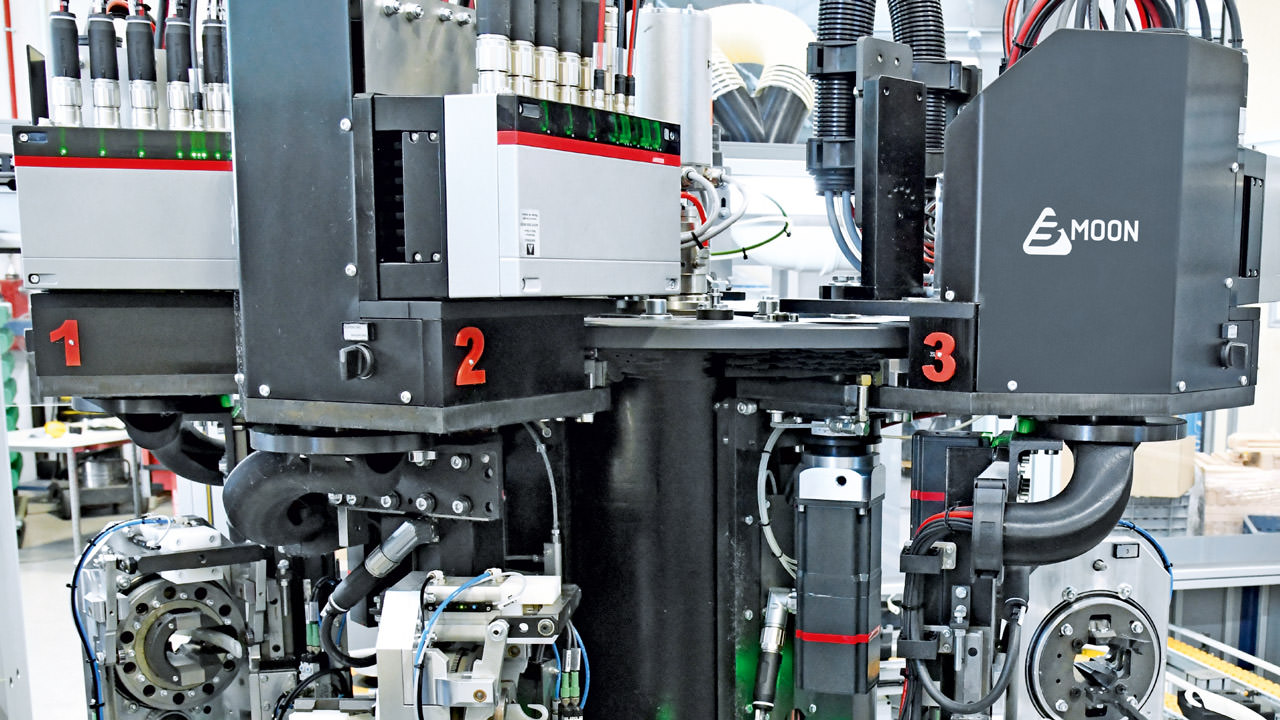

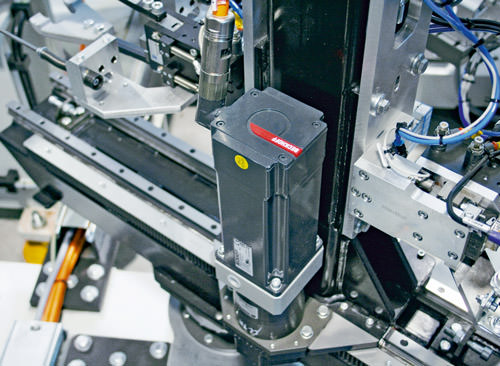

The mechanics had to be extensively redeveloped to enable continuous operation of the machine, with the core element comprising four small, independent machining turrets that transfer the plates seamlessly from one machining phase to the next. Each machining turret can be flexibly positioned via five servo drives to suit the formats of the plates being processed. This concept requires compact and powerful drive technology in the form of AMP8000 distributed servo drives with integrated power electronics. A single EtherCAT P line is used to connect power and communication, including safety, which not only saves space on the turrets, but also cuts down weight.

Optimized space requirements in the machine and control cabinet

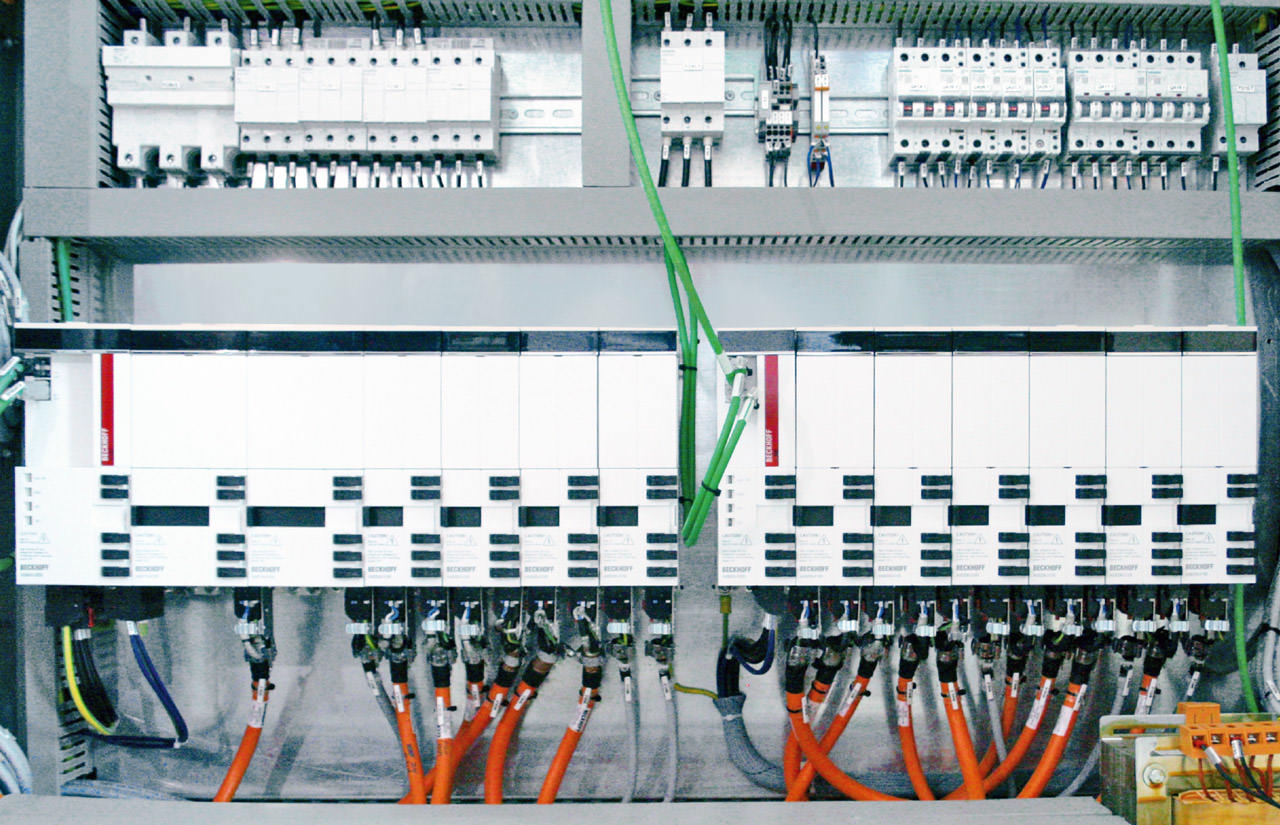

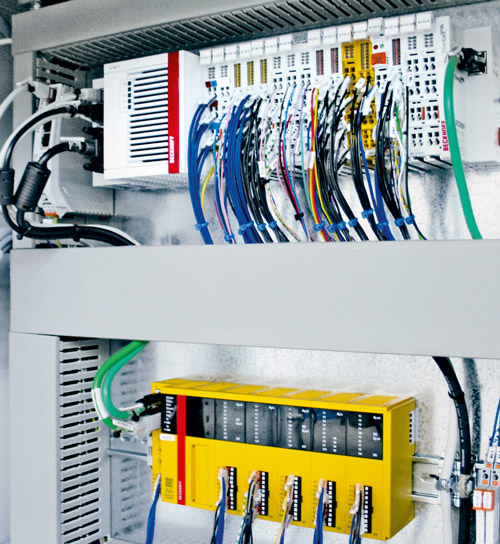

Borghi implements the safety functions with the EK1960 TwinSAFE Compact Controller (below) and additional TwinSAFE terminals, which are integrated into the upper EtherCAT Terminal segment and directly connected to the CX2040 Embedded PC.

The AMP8600 supply module plays a key role in the distributed power supply; one IP65-protected power supply per turret is sufficient to supply its five drives with power and communication via EtherCAT P. The small footprint of the AMP8000 servo drives, the small size and flexibility of the distributed supply module, and the minimal wiring work required for EtherCAT P were essential for meeting the requirements in terms of machine compactness, performance, and reliability.

“We were never on our own when it came to implementing this innovative automation concept,” recalls Paolo Roversi, “The on-site support from the Beckhoff experts made everything easier. What’s more, the fact that we were working with a single project partner to handle all the automation elements from the control panel to the drive meant the compatibility issues that used to occur with multiple suppliers were no longer a problem.”

The consistently distributed approach, with around 50% of the power electronics located directly on the machine, also has a positive effect on the footprint: despite having a total of 45 axes, the machine control cabinet is highly compact and offers sufficient space for the CX2040, the EtherCAT Terminals, and additional servo drives from the AX8000 series. Paolo Roversi enthuses, “This concept has resulted in significant savings in terms of cost, materials, space, and installation effort.”

Ready for Industrie 4.0 and the future

Today’s machines are now all developed with Industrie 4.0 in mind as standard, complete with the corresponding connectivity and sensor technology. According to Paolo Roversi, Beckhoff has also simplified programming in this respect, with TwinCAT 3 using the standardized architecture that is new to Borghi throughout: “At the same time, there is also plenty of space left for future expansions, for developing new models, and for OT/IT integration. PC-based control from Beckhoff offers maximum scalability for this and enables simple integration of multiple controllers and the HMI in a single standard hardware.”