TechnologySeptember 19, 2024

Maximizing automation efficiency with Industrial PoE switches

This article explores how industrial PoE switches can maximize efficiency and flexibility in automation by simplifying cabling, reducing installation time and centralizing management.

Industrial automation is a complex and rapidly evolving field that requires robust and versatile networking solutions. One technology that has emerged as a key enabler of automation is Power over Ethernet (PoE), which combines power and data transmission over a single Ethernet cable.

PoE in industrial automation

The PoE standard was first approved by the Institute of Electrical and Electronics Engineers (IEEE) more than 20 years ago. This standard, known as IEEE 802.3af, allows for up to 15.4W of DC power per port. Since then, IEEE has released updated standards. The most recent is IEEE 802.3bt Type 4, also known as 4-pair PoE (4PPoE) or PoE++. IEEE 802.3bt can supply up to 90W of power per port to a range of devices such as IP PTZ cameras, gas analyzers, video monitors and embedded computers that require higher wattage.

PoE has rapidly gained traction in the industrial sector for a variety of reasons, just as it has in enterprise and commercial networks. For one, it significantly lowers infrastructure complexity, especially in remote locations or areas of the plant without available power outlets. An electrician is not needed to install or maintain a PoE cable due to the low voltages involved, nor does the installation require long runs of steel conduit or earthing enclosures, reducing initial deployment costs. Another advantage of PoE is that it gives network managers the ability to centrally monitor a device’s PoE power consumption and other power-related data.

Nonessential devices being monitored by a managed PoE switch can have their power automatically decreased or turned off entirely when not in use. Flexibility is yet another benefit. Network devices can be mounted in previously inaccessible locations since power outlets no longer restrain their placement. Swapping existing devices on the network entails a little more than plugging in the device’s Ethernet cable into a PoE network switch port. Also, PoE is standards-based, for vendor interoperability.

An area of automation where PoE is paying dividends is Supervisory Control and Data Acquisition (SCADA) networking. SCADA is a means of remotely monitoring and controlling equipment in automation processes in industries such as manufacturing, oil and gas distribution, utility power, and wastewater management.

One of the largest shifts in SCADA has been its evolution from serial networking protocols to the Internet protocol (IP). Adopting IP has meant equipment costs are less expensive, and bandwidth can scale up to 10 Gbps for end stations and up to 100G bps for backbone networks.

It also means a SCADA network that deploys Ethernet as an access network can benefit from PoE. A SCADA’s array of PLCs, RTUs, sensors and other end devices can all be supplied with power simply by connecting the device’s cable to an open switch port.

Industrial safety

While PoE is frequently touted for its flexibility and infrastructure savings, this technology also contributes to industrial safety.

It is not unusual for the electrical systems powering industrial facilities to be 480V or 600V, more than enough to injure an employee from electrical shock, arc flash, explosions or other hazards.

Low-voltage PoE reduces or eliminates the risks of short circuits, exposed wiring, or accidental contact with live voltage. Overload protection, which guards against high power consumption and consequent damage to devices or cables, is also built into PoE devices. If an overload is detected, power distribution is reduced or turned off to safeguard or repair the connected equipment and lower the possibility of overheating or a fire.

Is electrical safety important in automation projects? Overwhelming, the answer is yes. According to the National Fire Protection Association (NFPA), electrical accidents in the workplace cause thousands of injuries annually and nearly one fatality per day.

Selecting a PoE managed network switch

Network architecture, capacity, and scalability must all be carefully considered when designing an industrial automation network that can accommodate PoE devices. This will require configuring several PoE managed switches in order to guarantee dependable and effective network operation. So, what should you be looking for in a managed PoE switch?

Ruggedized equipment

Antaira PoE managed Ethernet switches featuring 16 Gigabit PoE+ ports integrating robust M12 connectors and capable of supplying 30 watts per port (IEEE 802.3 af/at) with two 10G SFP slots.

Numerous risks confront switch operation such as electrical noise, humidity, corrosive chemicals, vibrations, and extreme temperatures. To mitigate or reduce these factors, confirm that you are purchasing industrial-grade PoE managed switches featuring ruggedized, environmentally hardened packaging with the appropriate ingress protection (IP) rating. Although less common, another threat is the presence of classified areas within a plant where volatile flammable liquids or gases are handled, processed or used. In these environments an explosion-proof switch will be required by Class 1 Div 2 and ATEX codes.

Bandwidth requirements

Switch bandwidth determines the data-carrying capacity of a network, influencing the speed and reliability of data transmission. Inadequate switch bandwidth can lead to network congestion, latency, and compromised device functionality. Whether a 10/100, 2.5G, Gigabit, or 10G switch is necessary will depend on your application. It is also a good strategy to plan for extra bandwidth in case needs increase.

Power requirements

Ensure the industrial PoE switch’s overall power budget can simultaneously support all of the devices by factoring in each device’s power consumption. Industrial network devices, including optical sensors, APs, networked lighting, and IP cameras, have significant variation in wattage requirements, typically swinging between 15 watts to 100 watts.

Confirm that the industrial PoE switches have enough PoE power and power budget to support your devices. You’ll also need to factor in that the maximum distance for PoE is 100 meters (328 feet) and that energy loss can occur over longer distances. If that’s the case, you’ll need to install additional network infrastructure, such as intermediate switches, PoE extenders or power injectors.

Port configuration and types

A switch’s required PoE port count depends on the number of PDs you plan to power, although it is good practice to have more to allow for expansion. Port count and the PoE standard will significantly impact the quality, scalability and flexibility of your network. Having a mix of Gigabit and Fast Ethernet ports allows you to cater to devices with varying bandwidth requirements.

Compatibility

Before power transmission can begin, the industrial PoE switch and the powered device must negotiate to determine the device’s power requirements. The outcome of the negotiation establishes whether the two are compatible and whether the device can safely get the power it needs. If successful, negotiation keeps the powered device from receiving too much or too little power; both conditions can damage the device or cause it to malfunction.

Security features

Having advanced security features in an industrial PoE switch, such as port security and access control lists (ACLs), is essential to protecting a network in light of growing concerns surrounding cybersecurity.

Case history: PoE in car manufacturing

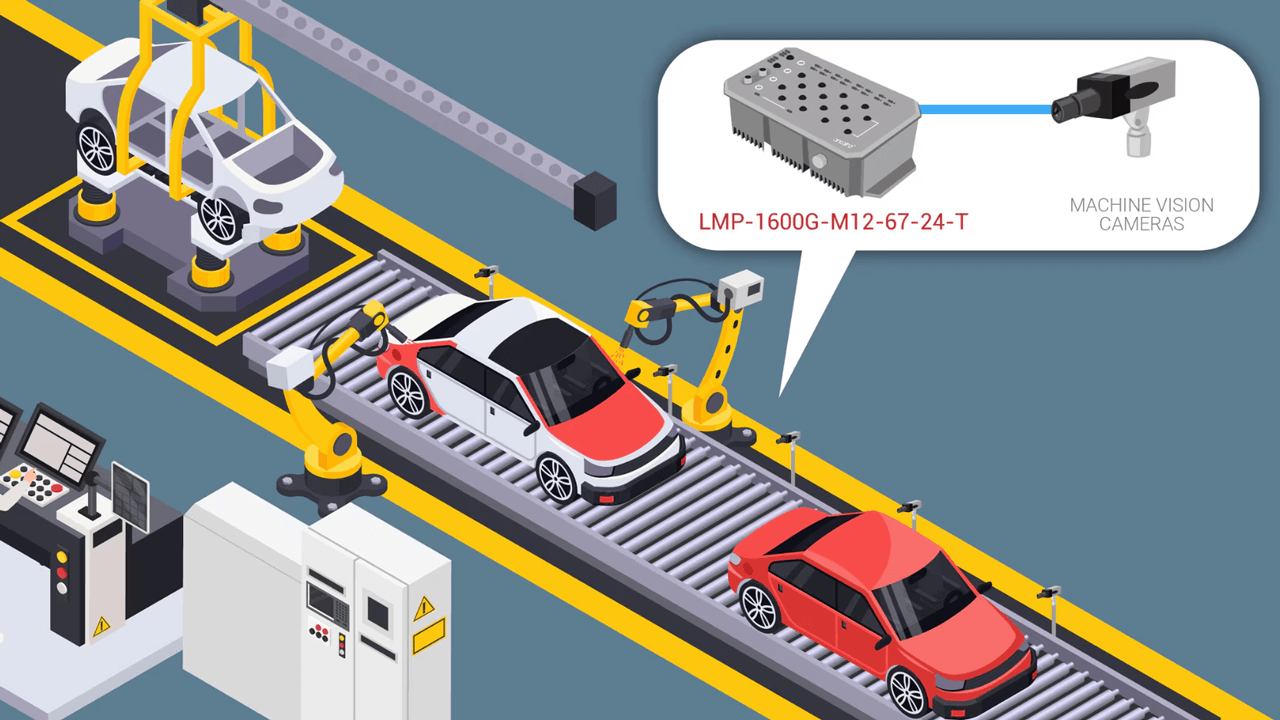

Let’s look at the actual case of an Antaira customer to get a better sense of the importance of PoE in automation. In this instance, the customer was an automaker seeking to add visual guidance to its robotics systems by installing new GigE Vision products and machine vision cameras. In order to simplify wiring, many GigE Vision cameras will use PoE for power so only one cable needs to be run, for instance, on a robotic arm with the camera able to recognize objects or to localize them for welding.

Aggregating multiple GigE Vision cameras into one link into the Industrial PC (IPC) will often require a 10G link from the PoE switch to the IPC running the software.

Among the challenges facing the manufacturer in deploying its machine vision system was ensuring reliable connections from the industrial PoE switches. Harsh conditions prevented use of the standard RJ45 connections found on most network switches since they lack ingress protection and could disconnect due to vibrations from the heavy machinery. The automaker company also needed a powerful switch solution that transmitted image data at high frame rates, along with a special low voltage power (12-24V DC) needed for the GigE Vision cameras to properly operate.

To help make this project a reality, the automaker selected Antaira LMP-1802-M12-10G-SFP-67-24-T PoE managed Ethernet switches featuring sixteen Gigabit PoE+ ports integrating robust M12 connectors and capable of supplying 30 watts per port (IEEE 802.3 af/at) with two 10G SFP slots. M12 designs provide extremely tight connections in areas subject to high vibration, shock, dust, liquid or gases.

Besides the M12 connectors, LMP-1802-M12-10G-SFP-67-24-T industrial switches are IP67 rated as waterproof and dust-tight, plus operate in an extended temperature range from -40°C to 70°C for withstanding extreme conditions. Low voltage power requirements of the GigE Vision cameras were meet by the Ethernet switch’s 24~55VDC power input. In addition, a separate Antaira switch offering two 10G SFP slots for fiber connections was installed as the high-speed link to the IPC.