TechnologySeptember 22, 2025

Process-X: moonshot thinking in the process industry?

NOA, AAS, and Process-X not only allow for secure data exchange between OT and IT but also lay the foundation for digital collaboration between companies. Looking at specific use cases and security architectures, it becomes clear how "moonshot thinking" can also become a reality in the process industry.

The process industry is at a turning point; digitalization, sustainability, and regulatory requirements demand new ways of thinking and innovative technologies. This article shows how concepts such as NOA, AAS, and Process-X not only allow for secure data exchange between OT and IT but also lay the foundation for digital collaboration between companies.

Looking at specific use cases and security architectures, it becomes clear how “moonshot thinking” can also become a reality in the process industry—and why now is the right time to get started.

What does the “X” in GAIA-X, Manufacturing-X, and Process-X stand for? Originally, the focus was probably on “eXchange,” i.e., the idea of sharing information. In view of a 20% decline in production the German chemical industry has been facing since 2021, something else would make sense: the “X” of the tech industry in Silicon Valley, i.e., the idea of “moonshot thinking” of radical innovation and scaling by “10X”.

These are big words that seem to completely ignore technical and financial realities. However, there is a good reason for optimism: decades of intensive collaboration between a number of important user, manufacturer, and standardization organizations have made the increasingly automated integration of devices, systems, processes, and applications possible within and outside of core industrial processes, providing a solid foundation for a real digital revolution in the process industry.

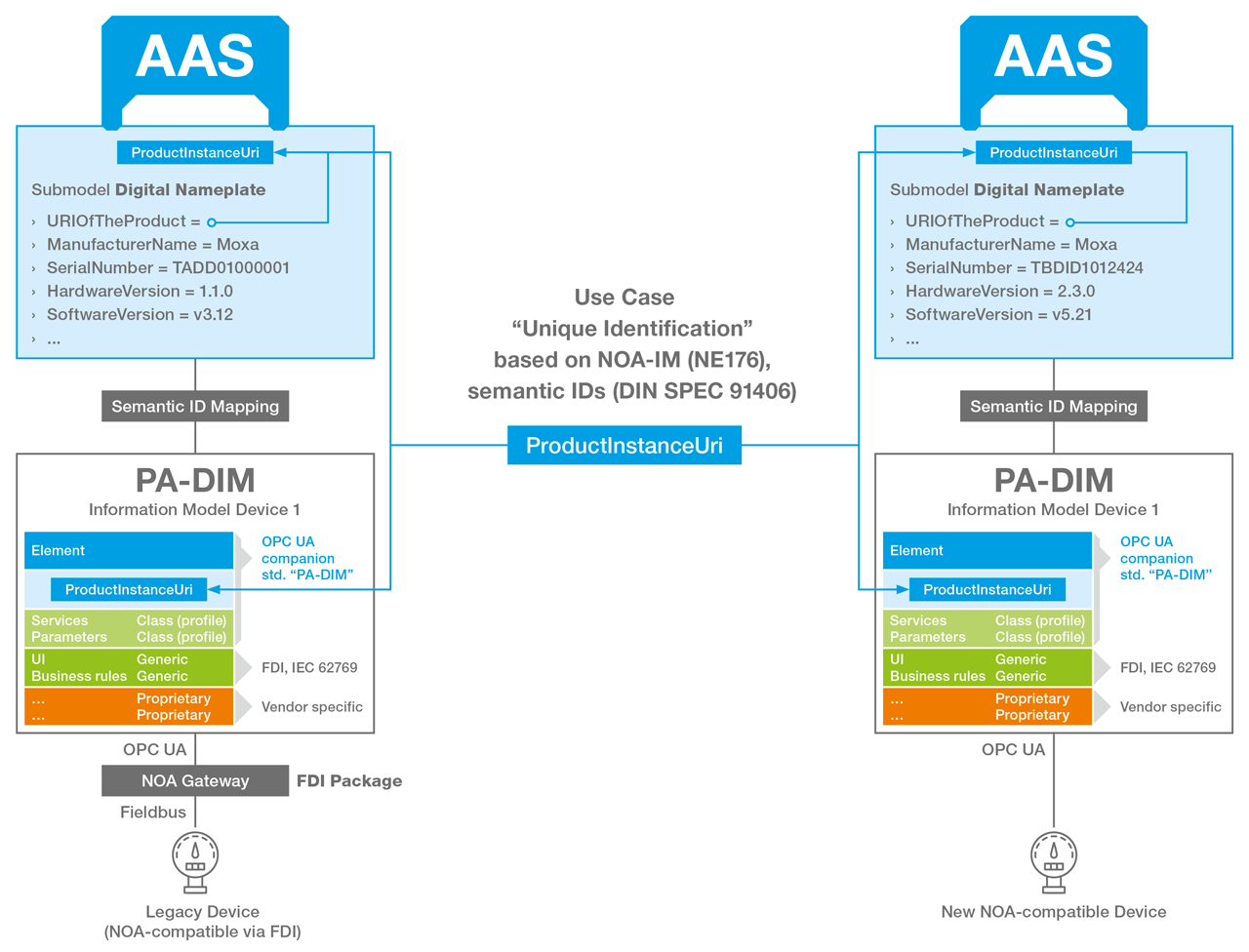

NOA connects field devices to their Asset Administration Shell via Semantic IDs.

NOA as the basis for secure OT/IT data exchange

NAMUR Open Architecture (NOA) is a concept that was introduced in 2016 and has been continuously developed since then. It allows IT applications to securely access data from process control systems, i.e., the heart of chemical, petrochemical, and pharmaceutical production, without compromising the integrity of the control systems. NOA separates the classic automation domain from a new monitoring and optimization domain (M+O), which is more closely associated with the IT and Io world.

A central element is the use of PA-DIM (Process Automation Device Information Model) as an implementation of the NOA information model. It permits a semantically standardized description of the most important field device data based on OPC UA—a game changer for interoperability and the result of collaboration between the FDT Group, FieldComm Group, ISA 100 WCI, NAMUR, ODVA, OPC Foundation, PROFIBUS and PROFINET International, VDMA, and ZVEI.

NOA for greenfield and brownfield

NOA makes two things possible: in new installations (greenfield), which increasingly rely on modern technologies such as the modular approach (Module Type Package, MTP) and field devices based on Ethernet APL, the significantly faster exchange of larger amounts of data can extend to the M+O domain. In existing plants (brownfield), process data can be easily and securely extracted from the core process automation and thus used for monitoring and optimization applications outside the process control systems. In a pilot project at the Höchst Industrial Park, an existing plant is currently being made “NOA-capable” thanks to 4-to-20mA-based field devices that can transmit data externally via the NOA channel with minimal effort using HART, PROFIBUS, and a NOA gateway. This is part of the ongoing NOA implementation project, a collaboration between NAMUR and ZVEI. The results will be presented at NAMUR’s general meeting in November 2025.

Process-X: automated digital collaboration between companies

If NOA is now accelerating the digital transformation within a manufacturing company, what could be achieved if companies in the entire supply chain could collaborate digitally in an automated way?

ZVEI presented a groundbreaking example at this year’s Hannover Messe: the “Predictive Steam Production” use case from NAMUR’s Process-X initiative. By intelligently networking energy companies, the operator of the industrial park, and the various users of process heat on site, the available energy on the one hand and the required process heat on the other can be reconciled in advance. This saves CO2 emissions and costs.

Data spaces provide a trustworthy environment and form the basis for this cross-company digital collaboration. Here, companies can share information confidently, securely, and in a standardized way while retaining full control over their data. This means that data is not stored centrally in a cloud, but exchanged directly between companies—without the firms involved having to develop the necessary infrastructure themselves. The first data room providers have become established, e.g., Cofinity-X for the Catena-X initiative in the automotive industry. But even without an established data room provider, companies in the process industry can and should create the conditions for automated cross-company data sharing internally. In addition to NOA, this can be achieved by an administration shell infrastructure with semantic anchoring of the parameters.

The asset administration shell

The asset administration shell (AAS) was and is being developed as a digital twin or digital administration shell for industrial assets as part of a collaboration between the Industry 4.0 platform and a large number of research institutions, industry partners, and standardization bodies. The Industrial Digital Twin Association (IDTA) coordinates the description of the AAS itself and the creation of so-called submodels for the AAS, which ensure the interoperability of data for specific use cases. A good example is ZVEI’s submodel “Digital Nameplate for Industrial Equipment,” which is also used in the KI-sy Twin project.

The AAS is a digital container for all relevant information about an asset—divided into submodels. It is modular, machine-readable, and based on standardized submodels. Like the NOA information model PA-DIM, it uses semantic IDs such as IEC CDD (Common Data Dictionary) or eCl@ss to uniquely describe data, and can use established formats such as JSON, XML, and OPC UA. This makes it ideal for securely extracting data that previously existed in process control systems but could not be accessed externally without considerable effort as NOA data from the automation pyramid and then exchanging it across companies via the AAS—without translations or manual data mapping.

KI-sy Twin project: end-to-end communication from field to cloud

In the KI-sy Twin project, Fraunhofer IFF and IOSB-INA, together with partners from industry, are creating a new mobile demonstrator for digitalization. Real industrial hardware in a mobile demonstrator (see photo) is brought together with machine learning models, AAS and data space technology in a production-like system. The AAS is the key interface.

The information from the industrial sensors and field devices that are part of the control system and from newly added sensors is transferred to the PA-DIM format and mapped to the AAS via a NOA gateway. For components where this cannot be done automatically, or as an additional comparison, the AASs of the components are created with the help of large language models (LLM). These are also used to map the plant structure as an AAS. All components are integrated in a security-compliant way with an IEC 62443-certified firewall from Moxa. The architecture of the demo plant is based on the NOA security concept.

Based on this digital image, production-related systems such as CAE, ERP, and Datahub are connected. If changes are made to the AAS, e.g., due to the replacement of a device, these systems are notified. The systems then decide for themselves to what extent the user needs to be involved or whether the changes can be applied automatically. Sven Schiffner from the Fraunhofer Institute for Factory Operation and Automation IFF in Magdeburg explains: “Based on the planned implementations in the project, it is easy to use digital tools even in existing plants.

Plant operators can deploy valuable human resources more efficiently and collect additional data easily by integrating new sensors. We are creating a language that all systems speak, the AAS.” At NAMUR’s general meeting in November 2025, the project participants will present challenges and best practices, providing valuable tips for similar projects. The demonstrator will be shown here, and participants will have the opportunity to try it out for themselves.

Security as an enabler

A well-thought-out security concept is an absolute must for the digital transformation of the process industry. Before NOA, opening up the automation pyramid was unheard of. With a solid security concept for NOA and the integration of AASs, cross-company digital cooperation via data spaces can become a reality – without incalculable risks for production.

Conclusion and outlook

The combination of technologies such as NOA, AAS, and standardized information models forms the technical and semantic basis for the scalable digitalization of the process industry. It allows for lower CO2 emissions, reduced energy consumption, and the conservation of resources in addition to the smart compliance with regulatory requirements. It also provides employees with a platform for the automated sharing of data, knowledge, and innovations, which can significantly increase productivity.

This is a historic opportunity for the German process industry—from chemicals and petrochemicals to pharmaceuticals to food production. In Europe, and especially in Germany, there is an ecosystem of associations, research institutions, and companies as well as a network of experts who are making remarkable efforts to develop new standards and technologies together that set global benchmarks.

Standardization and implementation still require a little more moonshot thinking. This means that everyone can look forward with great anticipation to the VCI’s 2030 economic report.

Technology article by Moxa Europe