TechnologyMarch 22, 2024

PROFINET controller for safety controls uses FPGA-based design

As plants completes the digital transition, communication with process control systems is more and more important. HIMA’s digitalization strategy for functional safety has prioritized offering the most popular industry-standard protocols for safety systems, and now includes PROFINET to handle distributed I/O.

In process manufacturing, significant demands are made on safety controls, with many applications requiring a very large number of inputs and outputs, for example. Increasingly, PROFINET is now being used to handle communication with distributed I/O. Given these concerns, HIMA opted to design a PROFINET controller for its safety controls together with industry specialist Softing Industrial.

HIMA Group is an independent global supplier of safety-focused automation solutions to the process manufacturing and rail sectors. Typical safety applications include Emergency Shutdown Systems (ESD), Burners and Boilers (BCS/BMS), Turbomachinery and Compressors (TMC), Pipeline Management Control with Leak Location (PMC), and Fire and Gas (F&G). The number of inputs and outputs can be very high in many of these safety applications, which ensure the safe and uninterrupted operation of plants used in the chemicals, petrochemicals, energy, oil, gas, and rail industries.

The scalable safety platform from safety expert HIMA unifies the hardware and software designed and developed in-house onto a single technology platform that also implements a uniform security model. The discrete safety controls utilize open standards but are both independent and autonomous. This lets the end customer combine the right safety solution for their needs with any leading Basic Process Control System (BPCS).

Future-proof digital communication with PROFINET

As more machinery and plant completes the digital transition, communication between the various parts of the control and automation systems as well as the process control system is becoming more and more important. HIMA’s digitalization strategy for functional safety has prioritized offering the most popular industry-standard protocols for safety systems. PROFINET is a communication protocol that is now increasingly widespread in the industry sectors where HIMA products are typically deployed. Corresponding communication modules have now been designed to facilitate PROFINET communication for safety controls in the HIMax and HIMatrix series. “While deployment of PROFINET and PROFIsafe is still sparse within process manufacturing in particular, we expect to see significant mid-term growth here,” says Stefan Ditting, HIMA’s product manager for safety control systems.

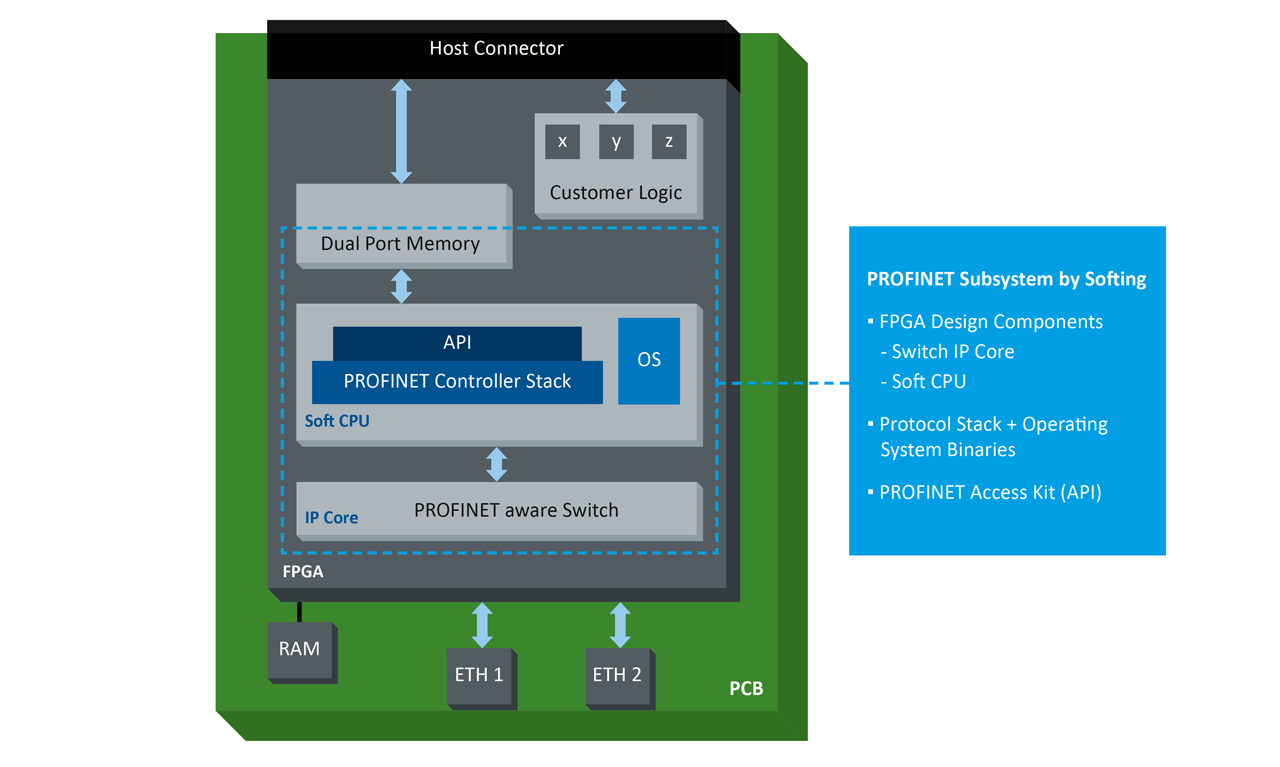

Integrating the PROFINET controller into the HIMA device architecture.

A reliable partner for development and long-term project management

HIMA was looking for a highly capable partner to design its communication modules for PROFINET communication. “In fact, it took us some time to find the right design partner for our controller,” Ditting recalls. Ultimately, the HIMA project team brought Softing Industrial Automation GmbH on board – an experienced partner able to offer wide-ranging know-how in the field of industrial communication design and development.

HIMA also gains a decisive advantage from this partnership, because the industrial communication experts at Softing not only handle the original design engineering work but also ensure that the communication module is kept up-to-date going forward. These maintenance tasks make up a large workload that Softing handles for HIMA. “Specifically, we would have found the steady stream of protocol updates from the PROFIBUS User Organization (PNO) especially challenging,” Ditting explains. These updates then have to be integrated and tested in each of the communication modules – a job HIMA is happy to delegate to the experts at Softing.

A hardware-based FPGA solution

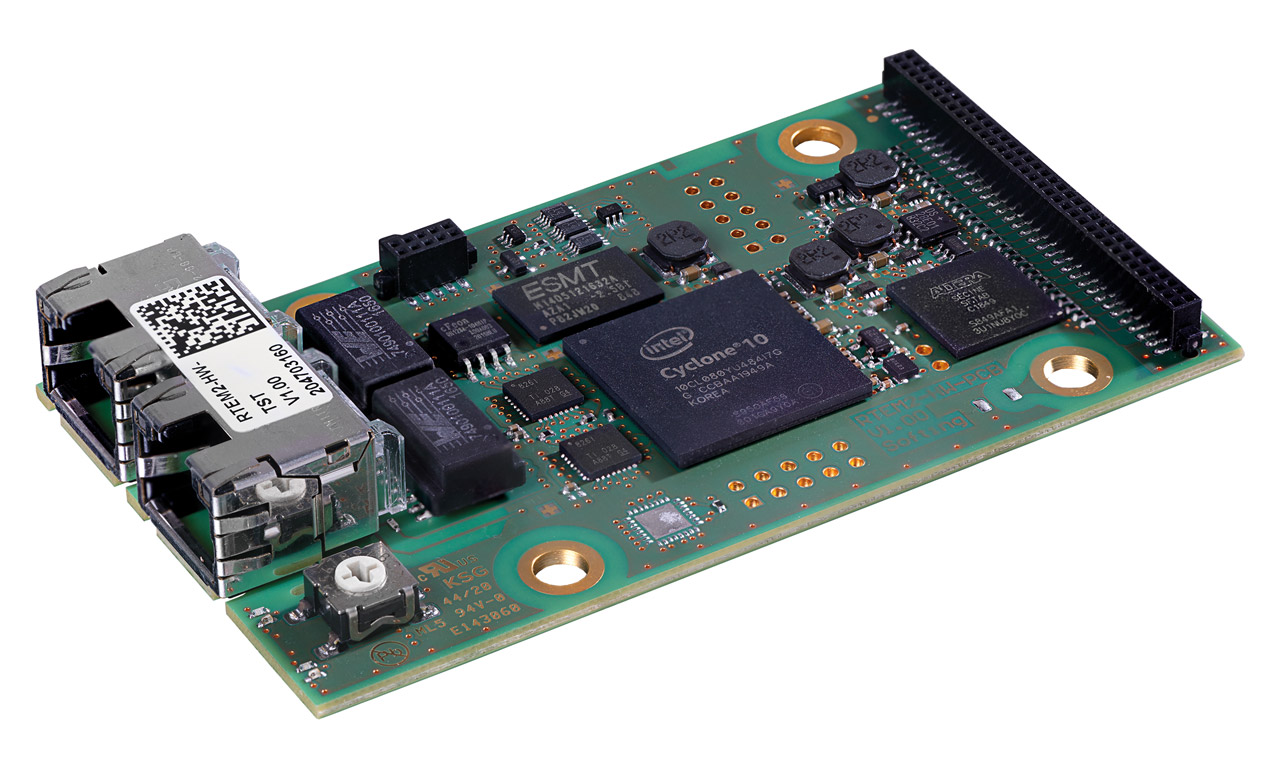

Softing has spent many years implementing, improving, and maintaining its proprietary software stack for PROFINET communication. And this is also the reason why the PROFINET controller design project for the HIMA controls could be completed so quickly. The solution is based on an FPGA hardware module designed for integration into the HIMA devices.

Ditting: “This provides us with a very sharply defined interface between control system and controller.” The interface uses shared memory to ensure a highly streamlined design, with another benefit here being the configuration options offered by the Intel FPGA hardware used. Thanks to loadable processors and logic components like the Ethernet switch developed and optimized by Softing, this makes the hardware simple to scale, highly flexible, and easy to update. The controller’s entire communication subsystem consists of a single binary block, containing the logic, processor, operating system, and associated communication software, which can be integrated easily without any modifications being necessary.

“A Profinet controller is always an advanced design project,” Ditting explains, “because you have to account for not just the communication but also the configuration.” Added to that, PROFINET also defines a great many features. All of the functions required have to be both implemented and then also configurable. Thanks to Softing’s experience with PROFINET and its reference implementation of a real-time Ethernet module (RTEM II), which was used as the reference design, the controller design project was completed successfully over a very short timeframe.

Integrating the PROFINET controller into the HIMA device architecture.

Key strengths

To implement connectivity with the existing HIMA host system and its expansion slots, only a few adjustments needed to be made to the RTEM II hardware design. The Industrial Ethernet switch plus two external ports included in the communication subsystem ensures a very short cycle time while maximizing determinism in process data processing.

Thanks to filtering capabilities offered by the built-in firewall, the integrated protocol software is also protected from harmful flooding while achieving Netload Class III robustness – the highest level of PROFINET conformance testing. “That the controller is regularly updated to match the current specification from the PROFIBUS User Organization is a priority issue for us,” Ditting explains. Every year, the PNO publishes two to three updated versions of the communication standard. Softing updates the controller to reflect the changes, allowing HIMA to focus on application development work.

Collaborative spirit

During the controller design and test project, regular meetings and workshops were organized to promote close coordination between the two partners. The experts at Softing also completed several other work packages alongside controller design, including support for carrying out firmware updates in the field as well as unit testing software for use in module production. Ditting: “The level of cooperation that was achieved throughout – from planning to testing – really made life easy for us. The teams complemented each other perfectly and inquiries from our side were always answered very quickly.”

The PROFINET controllers from Softing can now be supplied for the latest versions of the HIMax- and HIMatrix-series safety controls, and offer uncompromising reliability during operation. As Ditting explains, improvements to controller functionality are already part of the planning pipeline.

“One example is the Media Redundancy Protocol, which we would like to implement as this offers higher availability in combination with a ring topology.” Whatever new features are needed, HIMA is certain to be working with the specialists at Softing to implement them.

Dr. Jörg Lantzsch (Agency Dr. Lantzsch) and Christian Bräutigam, Product Manager, Softing Industrial Automation