TechnologyMarch 30, 2021

Signal meets power meets data in miniaturized connectors

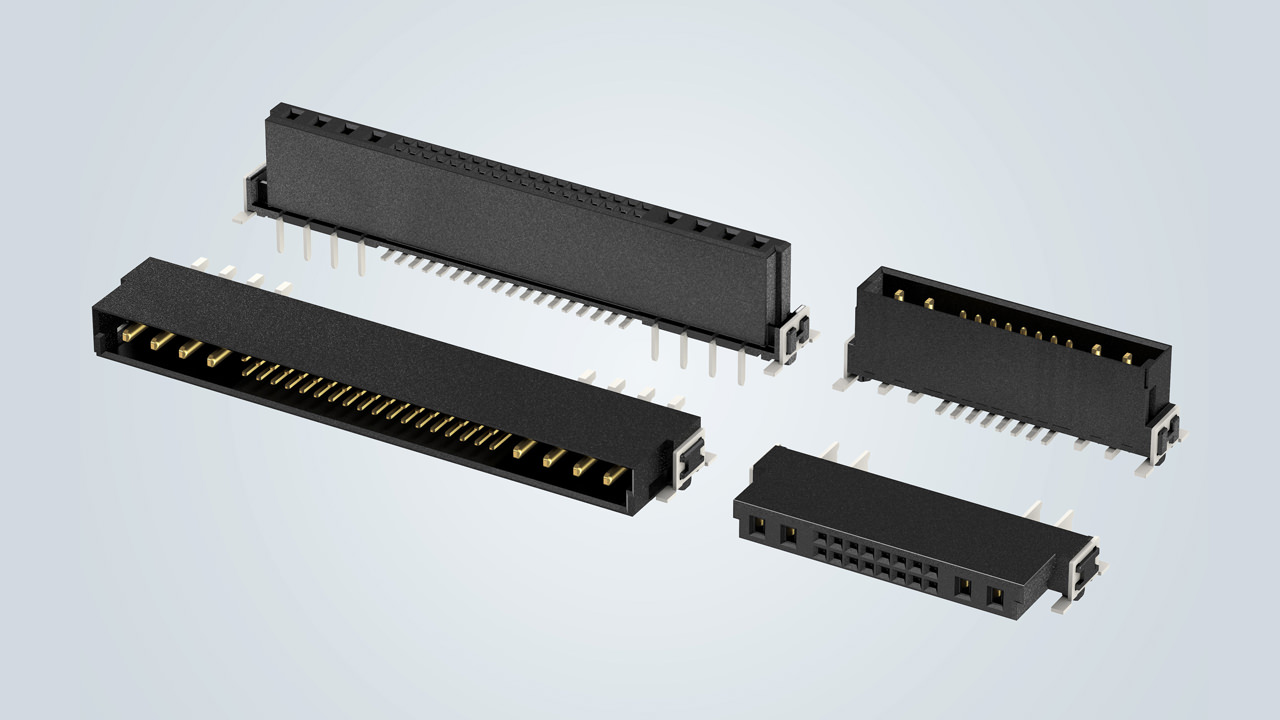

The miniaturization of devices has led to a drive toward more compact connector solutions for both power and data transfer applications. New technology is adding building blocks to produce more compact designs, including hybrid and power applications and new HD card edge options for transferring at high data rates.

Miniaturization is a megatrend driving development of miniaturized and flexible PCB connections technology, and often leads to clever solutions. One challenge is that there is no place where the miniaturization takes greater effect than inside the device itself.

In this regard, har-flex® technology from HARTING has already been providing flexible and compact connection solutions but now it is being equipped with two important building blocks for wide-ranging possibilities in device development: har-flex hybrid and power for compact applications with power, and the har-flex HD card edge with an 0.8 mm pitch for transferring at high data rates.

Miniaturization of devices

The miniaturization of devices is a steady process in industry but components such as connectors need to shrink even more. To address needs, HARTING has expanded its har-flex technology. Flexibility in pin count from 6 – 100, and stacking height from 8 – 20 mm, lets developers enjoy all freedoms in the development of their devices.

This factor is increasingly gaining in importance because every case is unique in the construction of industrial devices. Every connector housing needs to be able to cater to the needs for different sizes, shapes and requirements. The PCBs inside devices also are constantly required to make up for other spatial conditions. Every board needs to be at a firmly defined position for interfaces with the housing wall or other electronic components. These vary depending on the device and use. To achieve the required miniaturization here, the har-flex interface makes for a particularly space-saving option with its 1.27 mm pitch.

The miniaturization of devices has led to the need for compact connectors for power and data transfer.

Signal meets power

To enable the simultaneous transfer of signals and power from one PCB to the other, the har-flex family offers a new Hybrid variant that needs to be small, flexible and robust. The har-flex Hybrid enables signal and power contacts to be combined in one insulator. A current carrying capacity of 18 A permits power to be provided while providing space-savings transferred by way of few contacts.

In the past, several signal contacts needed to be combined in this for power transmission, which was linked with greater space requirements, as well as the use of a separate connector just for the power supply. The throughput times in production are also improved, so the placement of an additional power connector can be avoided.

To prevent the power from inductively interfering with transferable data, adjoining pins can be earthed. Whoever has the room and still wants to transfer power in a small space can bank on the separate har-flex Power connector. This is of the same type as the already familiar har-flex Signal connectors and thus offers the ideal complement.

Besides the pin counts, users can choose between SMT fixing or with additional hold downs in the Hybrid or Power variant, depending on the application. The power pins are all available as THR or SMT contacts.

While the SMT contacts will leave the back of the board virtually untouched, the THR contacts offer a better heat dissipation and higher stability. Hybrid & Power variants have been created in familiar designs and offer solutions for mezzanines, motherboard-to-daughterboard and extender card connections.

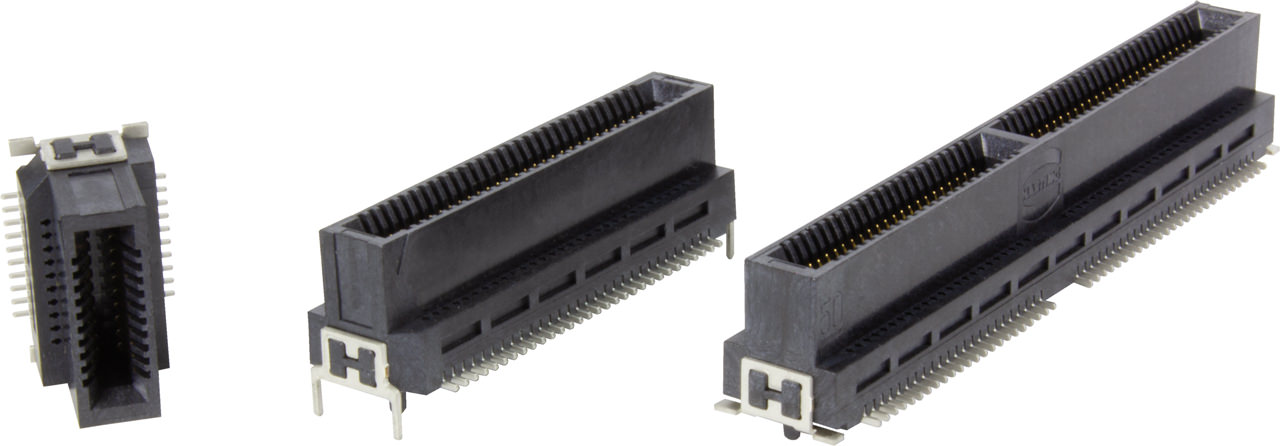

Card edge for high data rates

Advanced Ethernet for IIoT applications is also an important topic on the circuit board. With the introduction of the har-flex HD (high density) card Edge, this is now advancing into even smaller ranges of board connectivity and bringing GBit Ethernet to the PCB from autumn 2020. The start is made with the har-flex HD card series Edge in a 0.8 mm pitch, which transfers up to 25 Gbit/s from board to board.

The series is designed as a one-piece-connector with pin counts from 20 to 140 contacts, meaning that the mating contacts are directly integrated in the board layout and no further connector is required.

Quality and precision

To cater to the increasingly automated production, all har-flex connectors are pick & place capable and contactable in the reflow soldering process. To also support users in their processing, HARTING sets great store by absolute precision with its components.

To be mentioned in this context is coplanarity. This describes how parallel and evenly signal contacts and retaining pins are mutually oriented in a SMD connector, which is decisive for the later quality of the solder connection. If connecting pins deviate too much from one another, the connection can be of a bad to faulty quality.

To ensure good solderability, the coplanarity of all contacts is thus continuously monitored in the production already. This guarantees the high quality and HARTING’s own claim to reliable interfaces.

Besides an optical monitoring in keeping with IPC-A-610 Class 3 standards, which is based on externally visible criteria such as the wetting angle and filling degree, the HARTING labs also use metallographic specimens and radiotechnology to monitor the quality of soldered joints.

For a good connection besides the correct position of the contact pins is the coating used, so contacts are equipped with a tin coat that forms a reliable bond with the solder pad in the reflow process.