TechnologyMay 14, 2022

Single Pair Ethernet – when will it have its big breakthrough?

The intensive prototype phase for SPE got underway quite some time ago. PHYs, cables, and connectors are available on the market. Now, the focus is on coordinating the systems and transferring the needs of industrial ambient conditions to Single Pair Ethernet.

When it comes to modern industrial communication technology, there’s no avoiding the trend topic of Single Pair Ethernet – or SPE for short. The first components, including connectors, cables, and PHYs, have been available for a few months. Device manufacturers are now able to design the first prototypes for end-to-end Ethernet-based communication and make the much-quoted slogan “from the sensor to the cloud” a reality.

Available components

The cables for Single Pair Ethernet are described in standards IEC 61156-11/-12/-13 and -14. These four new standards for SPE cables define both their fixed and flexible installation. At this juncture, standards 61156-11 and 61156-12 have already been published. They define the requirements for transmission frequencies up to 600 MHz and a transmission distance of up to 40 m – and are suitable for the 100BASE-T1 and 1000BASE-T1 standards.

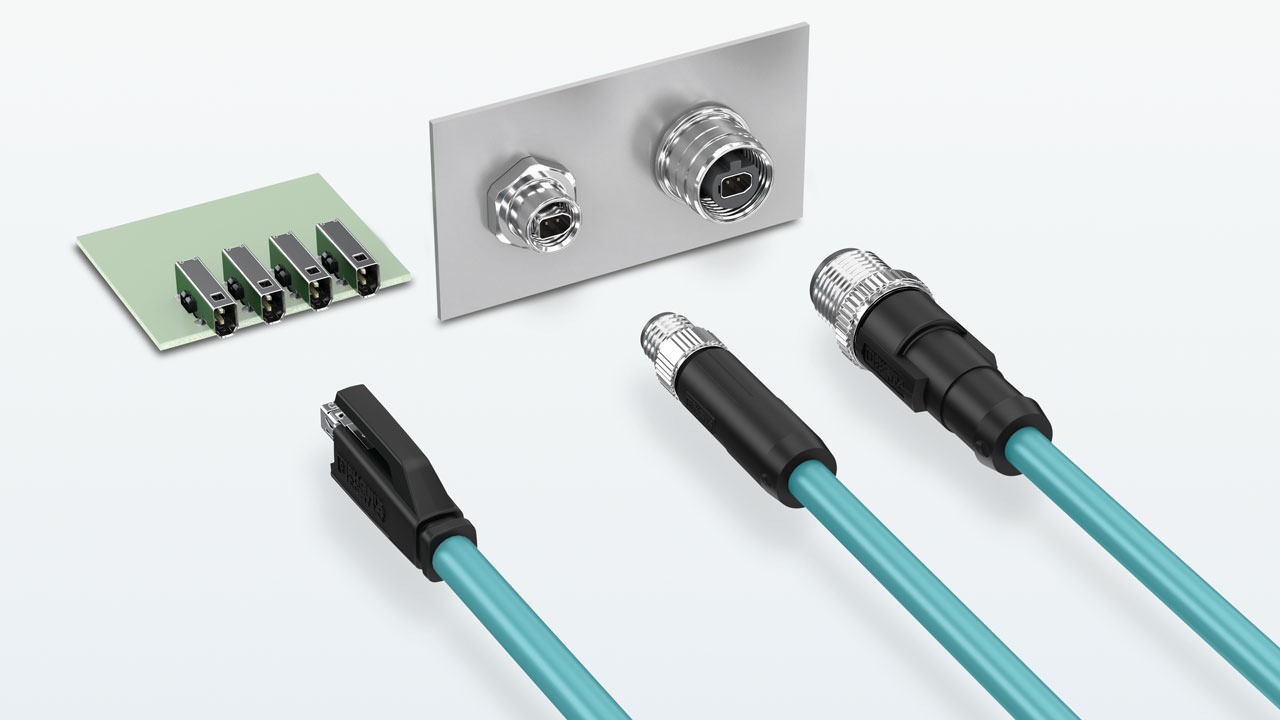

In 2020, Phoenix Contact launched its first connectors for end-to-end connection technology for SPE. The portfolio includes compact IP20 connectors as well as IP-protected M8 connectors for the connection of sensors. To bring these two worlds together, a universal pin connector pattern is used. This eliminates the need for cumbersome adapters, saves additional costs, and thus fully satisfies the key objectives of Single Pair Ethernet: compactness and consistency.

Phoenix Contact offers a consistent, compact, and robust range of SPE connectors standardized in accordance with IEC 63171-2 (IP20) and IEC 63171-5 (M8 connectors).

The IP20 connectors are standardized in accordance with IEC 63171-2 and feature the most compact pin connector pattern in the entire series of standards for SPE connectors. The IP20 portfolio includes pre-assembled patch cables in various lengths as well as compact device connections for the reflow soldering process available in different designs. The newest member of the family is a new insulation displacement connector for field assembly. The IDC connector featuring die-cast zinc housing promises to satisfy the requirement for robustness in all types of industrial applications. Phoenix Contact is thus providing its customers with even greater convenience when it comes to field cabling and greater flexibility when selecting cables.

The IP-protected portfolio in the M8 design is standardized in accordance with IEC 63171-5 and also includes pre-assembled patch cables with different cable types for different applications and device connections in the standard M8 design. For device manufacturers, the advantage of using standard M8 components is that they can benefit from easy design-in and maximum flexibility for the cabling. Existing housing geometries and panel feed-throughs can be incorporated and assembled with the new SPE inserts. The inserts are available as straight and angled versions, and are also available for different soldering processes (THR and SMD). With the launch of this M8 portfolio in the fall of 2020, series items for connecting compact SPE sensors are now available on the market for the first time.

The SPE System Alliance

The M8 device connectors enable compact and standardized connection for SPE switches or sensors in the field, for example.

Right at the very early development stage of the new pin connector pattern for SPE, it was clear that the topic of Single Pair Ethernet would not just be confined to connectors. Indeed, it concerns all the infrastructure components involved: from PHYs through cables to sensors. The SPE System Alliance, which Phoenix Contact cofounded, has been in existence for over a year. Leading technology companies from various industries and fields of application have come together to form a registered association in order to bundle their expertise and ensure the target-oriented exchange of this knowledge. Through this orientation toward a cross-industry and cross-application exchange platform, companies from all areas of the SPE ecosystem are coming together.

Together, all SPE System Alliance partners are pursuing the goal of driving the development of SPE further forward for the Industrial Internet of Things (IIoT).

The SPE System Alliance does not champion a specific connector system or product. Whatever the individual positions of its members, the System Alliance generally maintains a neutral and manufacturer-independent stance with regard to products. The objective behind the System Alliance’s activities is to promote SPE technology.

The System Alliance focuses on the entire future SPE ecosystem and any open issues in this context. This encompasses far more than just physical components like cables, PHYs, connectors, sensors, or switches. For example, it deals with questions regarding topologies, standardization proposals, and application scenarios for different areas of application. This broad approach is also reflected in various working groups within the System Alliance, which focus on different issues.

New IEEE standards are waiting in the wings

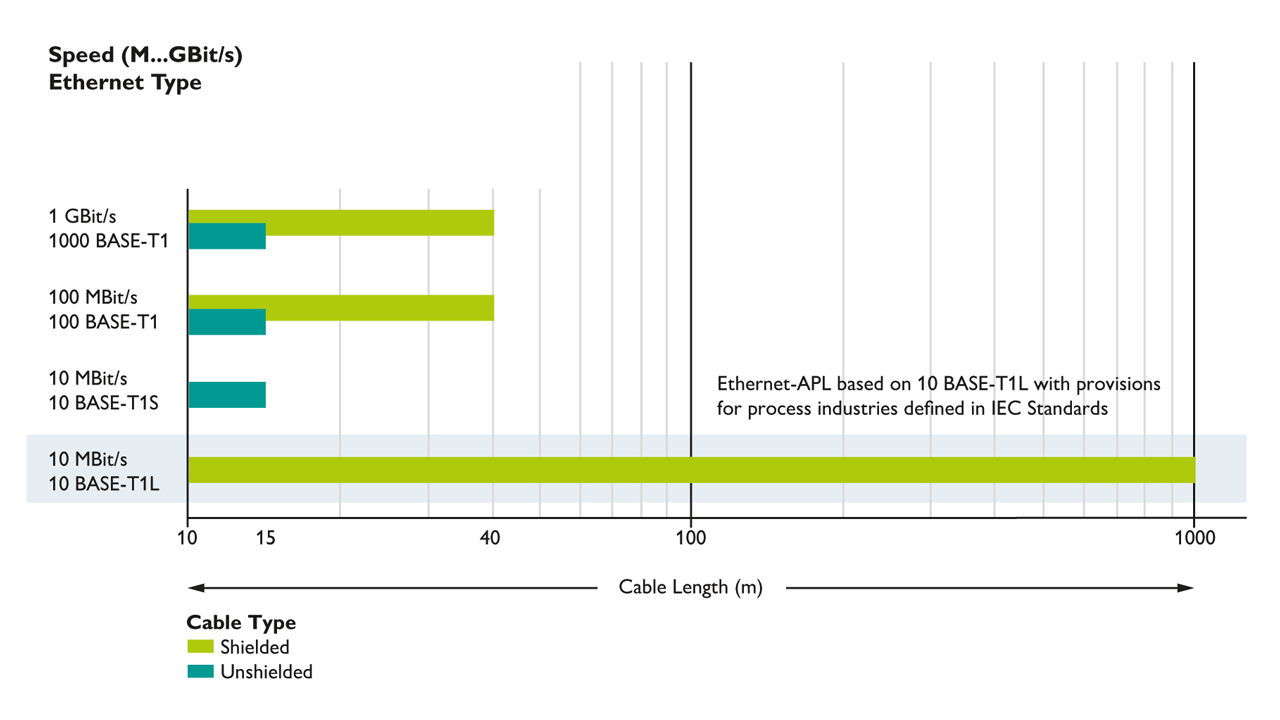

The adopted IEEE 802.3 standards for Single Pair Ethernet cover data rates from 10 Mbps to 10 Gbps and distances up to 1,000 m.

Driven by the automotive industry, the first standards covering shorter distances have been adopted. The 100BASE-T1 and 1000BASE-T1 standards transmit data rates of 100 Mbps and 1 Gbps over distances of up to 40 m (shielded).

Users in the field of factory and building automation are eagerly awaiting the further availability of components for the 10BASE-T1L and 10BASE-T1S standards from the “cg” working group. These standards enable 10 Mbps transmission over a distance of up to 1,000 m for the first time. In addition, multidrop applications are also possible for the first time with the T1S version. All other standards are based on classic point-to-point cabling. The plan is to expand upon these multidrop applications in the newest “da” working group and look at ranges beyond the 25 m mark of the current T1S standard.

The most recently adopted standard from the “ch” working group is MultiGigBASE-T1, which allows a data rate of 10 Gbps with a range of 15 m. There is also the Power over Data Line (PoDL) standard, which enables up to 50 W of additional power over the data line for SPE applications. The multidrop standards are still excluded from this function at present.

Overview of the different SPE standards from IEEE 802.3.

When will the first devices emerge?

The intensive prototype phase for SPE got underway quite some time ago. PHYs, cables, and connectors are available on the market. Now, the focus is on coordinating the systems and transferring the needs of industrial ambient conditions to Single Pair Ethernet. One of the challenges here is the EMC behavior in the overall system, as industrial environments differ greatly from the application area of automotive Ethernet. In contrast to an automobile, the influence of electromagnetic interference is unpredictable and often far more complex depending on the application.

The future is also exciting when it comes to the standardization of connectors. In total, the series of standards for SPE connectors (IEC 63171) currently contains six different standards for connectors – the seventh standard is already in preparation. Will there just be one type of SPE connector in future? Otherwise, which standards are best suited to certain applications? User organizations, such as the PNO and ODVA, that are currently working intensively on the topic of SPE will have a large say in this. Only time will tell how and when the popular slogan “From the sensor to the cloud” will really be true.

Overview of the IEEE standards for SPE:

IEEE 802.3da

10BASE-T1S – ~50 m (tbd) – 10 Mbps (multidrop)

IEEE 802.3cg

10BASE-T1S – 25 m – 10 Mbps (multidrop)

10BASE-T1L – 1,000 m – 10 Mbps (point-to-point)

IEEE 802.3bw

100BASE-T1 – 40 m – 100 Mbps (point-to-point)

IEEE 802.3bw

1000BASE-T1 – 40 m – 1 Gbps (point-to-point)

IEEE 802.3ch

MultiGigBASE-T1 – 15 m – 2.5/5/10 Gbps

IEEE 802.3bu

Power over Data Line (PoDL) includes different performance classes up to 50 W (max. 48 V)