TechnologyJuly 20, 2023

Standardization promotes user safety and opens new markets

Beckhoff hybrid connectors and One Cable Automation has been proven in thousands of field installations. Florian Vogel from I/O Product Management discusses the technical advantages associated with these connectors and the significance of their definition within an IEC standard for decentralized automation.

The Beckhoff portfolio of hybrid connectors, and thus One Cable Automation (OCA), has already been proven in thousands of field installations. In this interview, Florian Vogel from I/O Product Management at Beckhoff Automation discusses the technical advantages associated with these connectors and the significance of their definition within an IEC standard for decentralized automation.

What sets the hybrid connectors from Beckhoff apart?

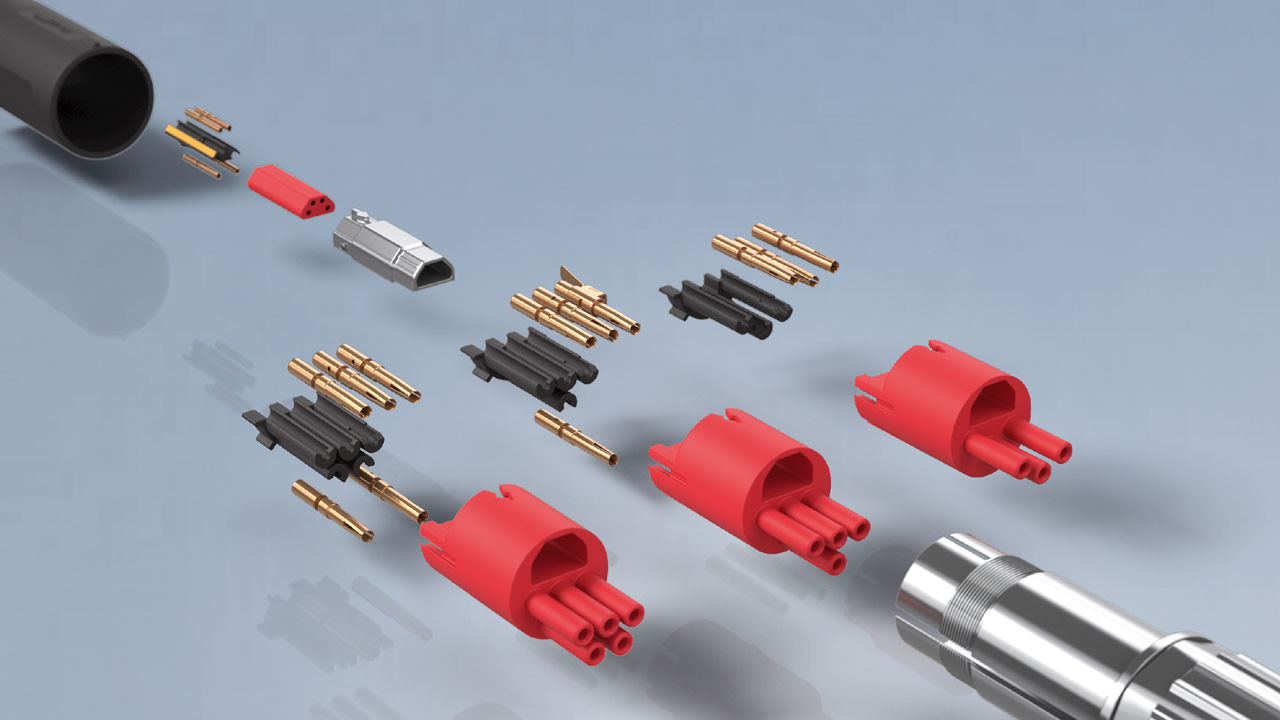

Florian Vogel: Hybrid connectors are essentially used to transmit power and data via a single line to save on cables and connectors. But the solution developed by Beckhoff together with a partner offers the additional advantage of a high degree of modularity, which allows a wide range of variants for a host of different applications, while also providing connection security through mechanical coding. It also features a uniform data core in all four connector sizes – B12, B17, B23, and B40.

These are all fundamentals to successfully establishing itself as the ideal connector for decentralized automation – also known as One Cable Automation. There’s also the fact that some 95,000 connectors have already proven themselves in the field, so this is by no means a completely new product that has yet to demonstrate its worth. In fact, our development has benefited from the fact that Beckhoff has always maintained close contact with its end customers and has therefore been able to implement their requirements more consistently than a straightforward connector manufacturer.

Florian Vogel, Product Management I/O, Beckhoff Automation.

How does the modular design impact the fabrication or installation effort?

Florian Vogel: The modularity of this design actually represents a considerable simplification rather than additional work. As the individual parts can only be assembled in one direction, the whole process is essentially intuitive and prevents any possibility of incorrect assembly from the outset. What’s more, there are clear colored markings on the contact carrier that correspond to the wire color of the cable, which does away with the need for a complex assignment plan detailing each individual pin assignment. Our hybrid connectors also comprise just ten individual components – significantly fewer than comparable third-party products. In combination with the additional data module, this usually results in a reduction of the assembly time by two thirds.

The hybrid connectors from Beckhoff will form part of an IEC standard in the future. What exactly does this mean?

Florian Vogel: Beckhoff hybrid connectors are among the first products to comply with the upcoming IEC 61076-2-118 standard, which is expected to be published at the end of 2024. The aim of establishing a global standard like this, first and foremost, is to ensure security for the customer or user; not only with regard to supply chains and second-source strategies, but also in terms of the level of product reliability defined by established and widely adopted standards. Key focal points here are always technology and being fit for the future, and our hybrid connectors already tick these boxes with their modularity, uniform data core, and optimal design for OCA.

All things considered, standardization within the framework of an IEC standard is certain to also lead to an expansion of the market for a circular connector like this. Initial estimates see an immense market potential of 800 million to 1 billion euros. In addition to the advantages of standardization already discussed, connector manufacturers have also recognized that the market addressed by these highly functional and universally applicable hybrid connectors has largely not yet been tapped, and can be reached much more easily through IEC standardization.

Who will find this standardization particularly important?

Florian Vogel: In our experience, all users see a clear need for this development, from machine builders and end users across a range of sectors, including automotive, through to device manufacturers. After all, compliance with an IEC standard does not mean that development will come to a standstill for the next few years or decades. On the contrary, our modular hybrid connectors are the ideal solution not only for retrofitting current systems, but also for use in conjunction with EtherCAT G/G10 to facilitate system developments over the next ten or 20 years. Being fit for the future to this extent is generally quite unusual for a normed standard, but in this case it is a given.

To what extent do device manufacturers and technology user groups such as the EtherCAT Technology Group (ETG) benefit in particular?

Florian Vogel: Device manufacturers have a keen interest in an IEC standard because it promotes and ensures worldwide availability of the components. Furthermore, the openness of standardization and a corresponding variety of suppliers usually lead to a much lower procurement price. For technology groups such as the ETG, there is another fundamental aspect in that these organizations want to concentrate as fully as possible on the development of their technology and not deal with all of the peripheral considerations. As for connector manufacturers, they also have a vested interest in following standards, since it is not common to find a complete portfolio of circular connectors, and standardization can facilitate rapid market entry here.

With One Cable Automation, Beckhoff is one of the pioneers in the field of decentralized automation.

To what extent will hybrid connectors further advance the concept of decentralization?

Florian Vogel: With CP-Link, OCT, and later EtherCAT P, Beckhoff advanced and implemented the concept of the one-cable solution very early in the game. So across our entire portfolio, from IPC, Motion, and I/O through to the new MX-System and Vision product categories, there are already opportunities for decentralized automation with PC-based control from Beckhoff. With the modular hybrid connectors, it will be possible to implement this One Cable Automation even more consistently and universally going forward.