ApplicationsDecember 4, 2020

Connectivity in the changing robot industry

Changes in the robotic industry, especially trends toward connectivity, miniaturization and Industry 4.0, led to a partnership between HARTING and Kuka. Responding to these megatrends put the focus on detailed application knowledge, a common view of holistic customer benefits and concrete new product solutions.

Quality, competence and trust form the foundations and guarantee for a good partnership. With this in place, convincing performance and high standards can be achieved. With the willingness and know-how to innovate, companies can always master new challenges, weather competition and shape the future.

Digital transformation

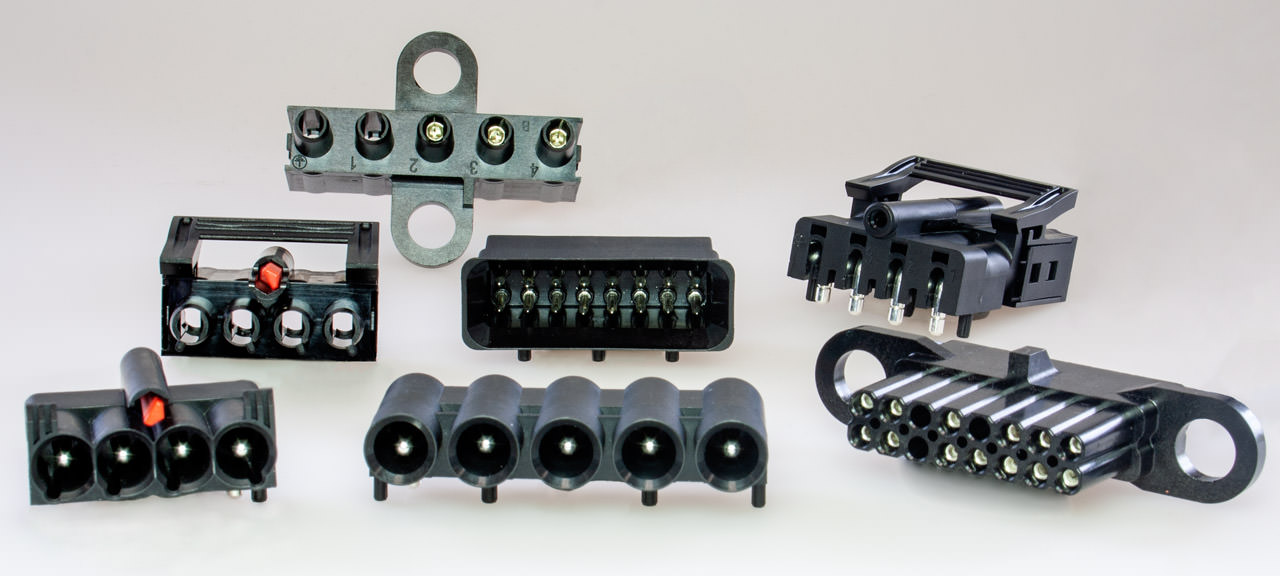

Han Board connector system.

More than ever before, today’s world is characterised by digitalisation both in the consumer and industrial sectors. With a look to industry, it is clear that this cannot happen without cooperation and partnerships.

Specialists with a wide range of competencies and skills are needed everywhere to offer suitable holistic solutions. This is already clearly demonstrated by the large number of platforms and exchange formats that exist for IoT and IIoT systems today.

HARTING har-motion connector

This understanding of the bundling of competencies and requirements has shaped the cooperation between KUKA and HARTING from a very early stage. Some examples from this partnership show the path from the jointly developed specific solution through to the resulting standard.

Since embarking on cooperation more than 20 years ago, HARTING and KUKA have always created new solutions with a view to market requirements. One example is the constantly increasing EMC requirements which led to special EMC housing designs for connectors, and which have meanwhile become a standard today.

Also in the field of robotics production, it is essential to reduce the installed number of parts so as to keep complexity low and reduce the number of production steps. Here, the two companies worked together and joined forces and took a look at the processes and created a specific component, the so-called multifunctional housing, which optimally combines the connector function and IP67 sealed electronics housing.

This approach is now being offered as a system solutions in various application areas: whether data cabling in the controller, power cabling to the robot itself or solutions which take mechanical requirements into account, such as specific transition elements for a PROFINET infrastructure on axis 3.

Miniaturization trend

Han-Yellock connector system on KR AGILUS robot system from KUKA.

In recent years, a major trend for the robotics industry has been an increasing need trend twoard miniaturization. The KR AGILUS robot system, for example, is a new line of compact robotic systems which are specifically designed for use in increasingly flexible production environments. The requirement for plug-in connections requires fast and intuitive handling, in which the design aspect also plays an important role at the same time.

With Han-Yellock, a new innovative connector system featuring completely new locking technology, a technology solution was found for this new robot series. Finally, the intensification of cooperation was particularly evident in the extension of the technologies and solutions to all the so-called “lifelines” of an application. In addition to the normal connectivity such as plug connections at the robot base or data interfaces at the transfer points, both upward integrations such as system solutions and products such as switches were used.

Here the demand for flexibility and adaptability to the communication systems used by the customer in automation was relevant. Quality switches became the central communication element, as they were able to process various automation systems in a very open manner.

Thanks to this consistency of the power-data-signal infrastructure on the robot, system designers were able to achieve a holistic approach to three infrastructure elements: customer-oriented, application-neutral and flexible.

Industry 4.0 developments

In the field of Industry 4.0 developments, both companies again worked on joint solutions at a very early stage. For example, KUKA equipped the I4.0 demonstrator, the “HAII4YOU Factory”, with new LBR iiwa type sensor-based robots. The system became the stage for an integrated Industry 4.0 approach for individual and cooperative production systems all the way through to quantity.

Flexibility, miniaturisation and also modularity are highly significant trends that are driving joint developments today. While around the middle of 2000 years, the robot control cabinet was as large as a control cabinet, today’s solutions are no larger than a desktop PC. Especially application areas for small robotics call for solutions that are adapted to resources.

In addition to the smaller robot, the controller must also be more compact in the future, as there will hardly be any space envisaged for it. In response to this situation, KUKA launched the KR C5 micro onto the market, which is tailored precisely to these application areas. Connectivity must also adapt in line with these developments.

For this reason, HARTING KUKA is also providing a new solution for this new controller family in the form of the “har-motion connector”, which is particularly suitable for use in compact robotics. Adapted both to the power requirements and to the space available, it can be used flexibly for transferring the lifelines of the robot.

KUKA KRC 5 control cabinet.

Even the larger robots, however, are also subject the miniaturization trend. This is particularly evident in the new KR C5 control system. This system offers customers the option of operating up to three machines on one control cabinet in the same space as a previous control system. A performance adjustment can also be easily and flexibly accommodated by selecting different controllers. This is enabled by a completely new modular and scalable structure of the cabinet system.

A docking solution was developed for this purpose, which makes adaptation to customer requirements very easy: The control systems are inserted into the cabinet like drawers. In order to enable the transfer of the so-called lifelines for such a flexible coupling, a special docking connector solution was developed in close cooperation.

Following the requirements of the protection class applicable in the cabinet and the reduced space conditions, the new Han Board connector proved an optimal solution, allowing for the mechanical plugging necessary for this case. Special mechanical guides, as well as the design structure of the connector solution, ensure the necessary tolerance compensation.

Conclusion

Responding to megatrends, long-term partnerships characterised by mutual understanding, detailed application knowledge and a common view of holistic customer benefits will be capable of developing the necessary technologies and concrete new product solutions. The connectivity and infrastructure solutions incorporated in the new KR C5 generation of control cabinets demonstrate this to a particular degree.

Guido Selhorst, Head of Marketing Services, HARTING Technology Group.