ApplicationsMarch 20, 2022

Prepared for the future with seamless data transparency

TwinCAT 3 IoT Data Agent feeds the data lake at Wienerberger AG. In the digitalization initiative, the Group started sending several million measured values to the cloud every day for analysis, to derive actionable insights in all areas of the company as a basis for targeted optimization measures.

In globally competitive manufacturing, every minute of time, every gram of raw material and every kilowatt-hour of energy counts. The Wienerberger Group has faced this challenge for decades. But recently, this leading international supplier of innovative building materials and infrastructure solutions and, according to the corporation, the world’s top brick producer, has leveraged TwinCAT and “Data Agent support” to achieve these goals.

Comprehensive digitalization

In the course of a comprehensive digitalization initiative, the Group has started sending several million measured values to the cloud every day for analysis to derive actionable insights in all areas of the company as a basis for targeted optimization measures.

In energy-efficient buildings, safe sewer systems, and attractive public spaces, evidence of the Wienerberger Group’s expertise can be found in all areas of life. The Vienna-based producer of bricks, pipe systems and surface pavers, whose roots go back to 1819, has been successfully driving the future of building for 200 years.

With 197 production sites in 29 countries, the group is one of the leading international suppliers of building materials and infrastructure solutions. In order to be able to defend this pioneering position even in times of increasingly tougher global competition, the Group launched a comprehensive digitalization initiative. On the one hand, it promotes the production of smart products – for example, plastic pipes that collect data on water levels or rainfall – and the development of new digital business models.

On the other hand, the company is doing everything in its power to increase transparency in its own production sites.

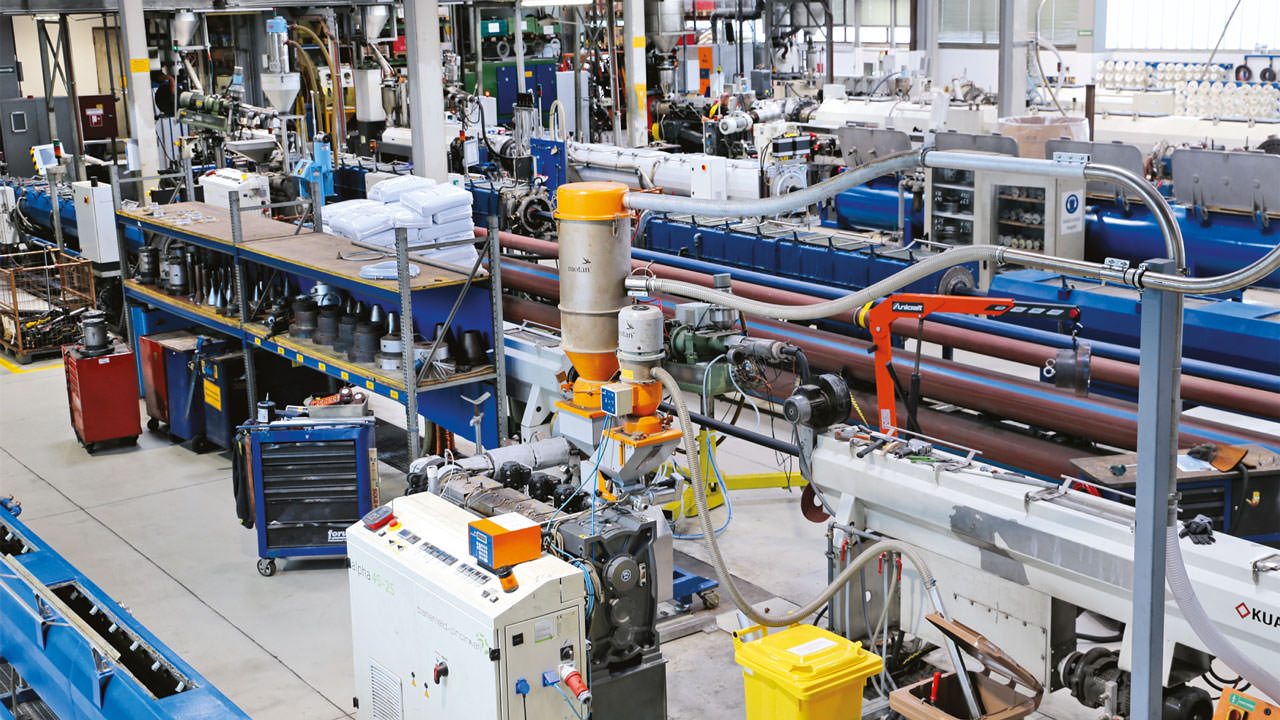

Wienerberger subsidiary Pipelife specializes in a wide variety of pipe systems. © Pipelife, Uwe Strasser

From digital twins to operational excellence

“Our vision is to create a digital twin of every production line in which not only process, planning and quality data are stored, but also, for example, detailed training course information for system operators,” explained Roy Sibbald, manufacturing excellence officer at Wienerberger subsidiary Pipelife. Ultimately, he wants to know about every single minute of production, and whether this period of time was used productively or not.

“If not, it wasn’t a good minute. The same goes for every gram of raw material we use. Was this turned into something that we could sell or what happened to it? The value of reliable answers to all these questions is enormous,” explains the expert, who, according to Manfred Heger, head of IT strategy, innovation & projects at Wienerberger, made a significant contribution to advancing digitization in the production environment.

Extrusion lines 21 and 26 at the Pipelife location in Wiener Neudorf were selected for a solution’s proof of concept developed jointly with the solution providers TietoEVRY and HEAP Engineering GmbH as well as with Beckhoff. Plastic pipes with special quality requirements are manufactured on these lines. “Here data on wall thickness, ovality, eccentricity, kilograms per meter, sawing pulses and much more must be captured,” said Andreas Roither-Voigt, senior business consultant at TietoEVRY, describing a production process in which, among other things, it is necessary to find out which pipes were cut to measure and in what time, and whether this really was done to an accuracy of one millimeter.

The measuring tasks are supported by the EL1512 and EL5151 EtherCAT Terminals from Beckhoff. “One I/O terminal enables the direct connection of encoders, while the other transmits the current counter readings in real time for calculating the pipe lengths in TwinCAT software – all on the edge gateway,” explains the control engineer.

Ultra-compact C6030 Industrial PCs (left) – supplied via Beckhoff PS series power supplies (right) – play a central role as edge gateways.

Industrial PC as an edge device

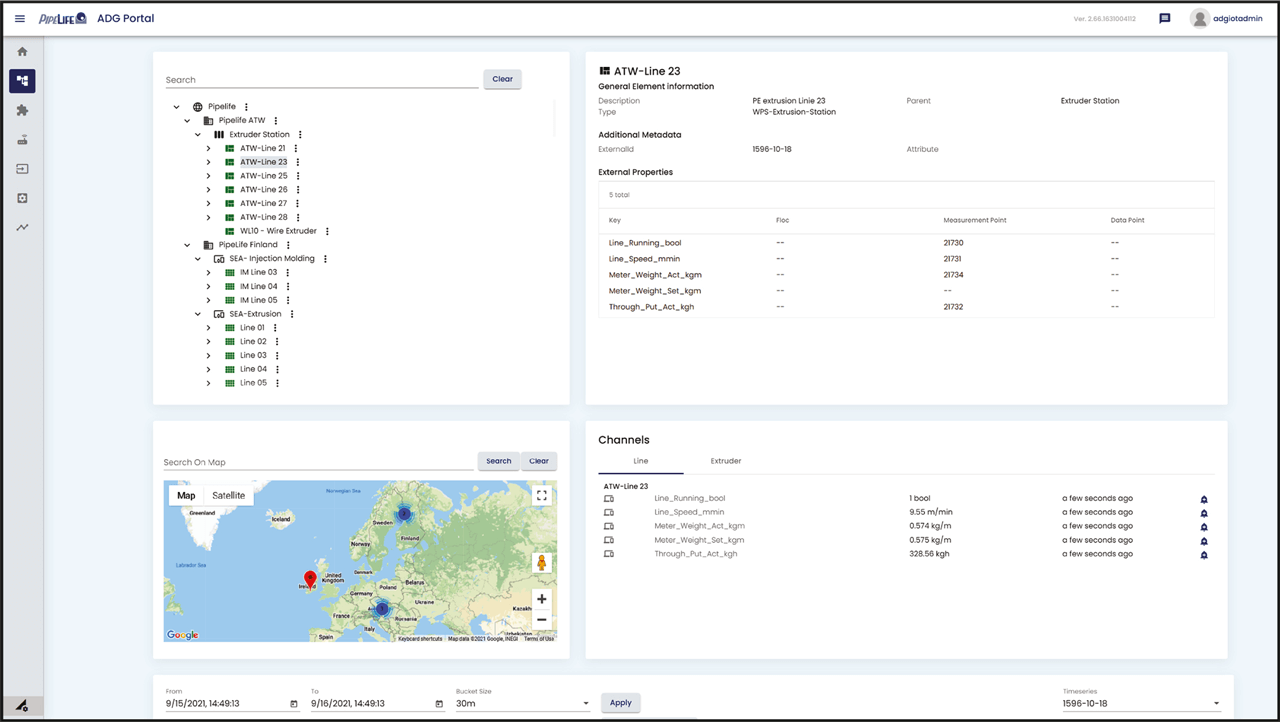

In the meantime, millions of data from different Wienerberger Group plants are stored in the cloud every day for analysis purposes. For a clear assignment of the transmitted signals, they are provided with unmistakable factory, line and machine type codes. “We joined forces to create a ’Single Source of Truth’ to make the company’s vision of ‘all relevant data online – all the time’ a reality. Among other things, it was to ensure that ultimately every user is provided with the information relevant to him or her. “Regardless of whether a data scientist plans to use the raw data as an input for machine learning models or whether these are already consolidated and/or concentrated for incorporation into various reporting tools, they must be complete and correct in any case,” emphasized Manuel Hausjell, IoT and data consultant at TietoEVRY.

The cloud-based information portal provides a clear overview of production data from 197 Wienerberger production sites in 29 countries.

Accordingly, the way in which the individual machines are integrated into the Internet of Things network has also been standardized and specified by the project managers. An ultra-compact C6030 Industrial PC from Beckhoff plays a central role as gatekeeper to the Azure IoT hub in the cloud. Its compact design and a multi-core processor performance of up to 3.6 GHz per core make it the perfect edge device, as Lukas Pechhacker, managing director of HEAP Engineering, explains: “This is the advantage of PC-based control technology – the control devices can be scaled to requirements and offer sufficient performance reserves for data pre-processing on site. In the case of winders, for example, the sampling intervals are in the millisecond range. That’s why edge computing is used here to translate into revolutions per minute in order to keep the flow of information to the cloud in check.”

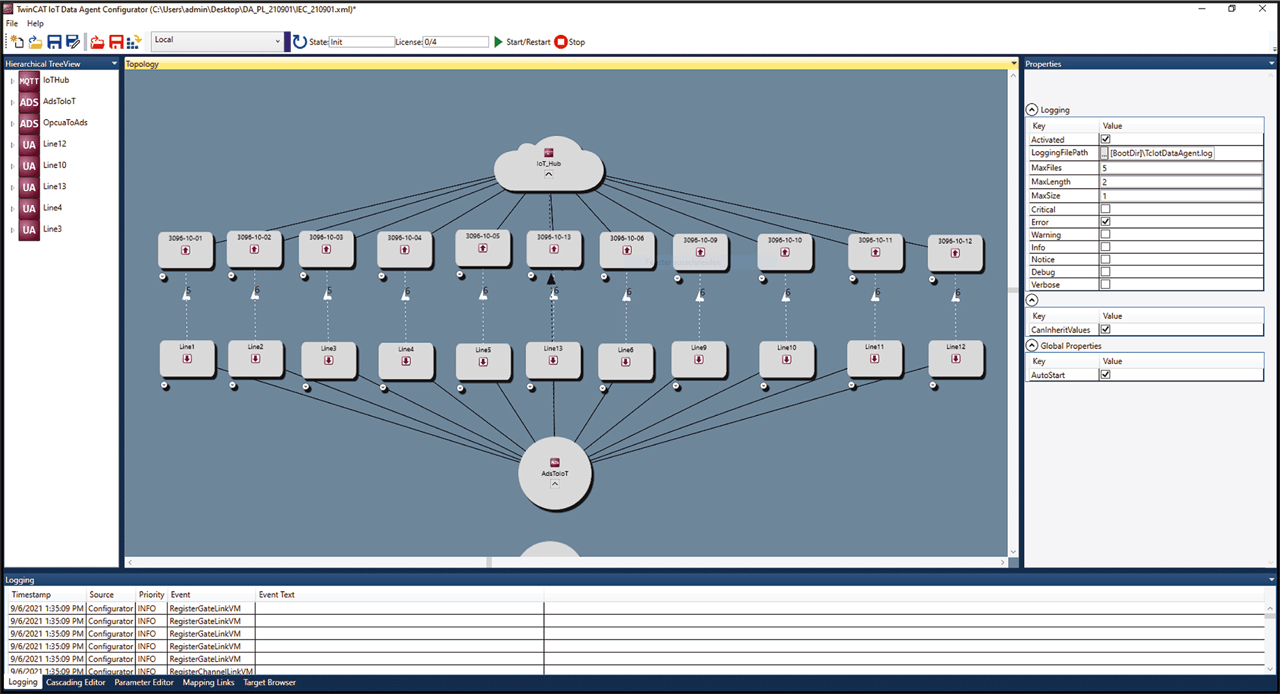

The C6030 with TwinCAT 3 IoT Data Agent generally has to take on many “interpreter” functions: on the one hand, it uses TwinCAT ADS and OPC UA to build communication bridges between machines of different ages and different origins, and on the other hand, it acts as a gateway to the cloud.

“With a total of 197 production sites in 29 countries, we are dealing with an extremely heterogeneous machine landscape and numerous protocols that have to be brought down to a common denominator. In some cases, EL6001 EtherCAT Terminals are required as serial RS232 interfaces to establish the required connections; in others, this works via OPC UA,” explained Pechhacker.

The good cooperation between the team of experts from the end customer, the system providers and from Beckhoff is crucial for success, especially with comprehensive projects such as this one.

Focus on teamwork

As Beckhoff solution providers, both HEAP Engineering and TietoEVRY understand how to fully leverage the possibilities of PC- and EtherCAT-based control technology. “Everyone on our project team can simply trust that the other person knows exactly what they are doing and that they always keep an eye on the big picture in everything they do,” said Manfred Heger. Due to coronavirus-related travel restrictions, two production sites were even remotely connected to the loT network – one in Sweden and the other in the Netherlands. “The local electricians provided the crucial details about the existing infrastructure. Then the required components were ordered from Beckhoff and preconfigured by HEAP Engineering to allow for simple plug-and-play connection on site. Then HEAP Engineering stepped back in to perform the final configuration via a secure remote connection, and we set the appropriate course in the cloud or took care of the data quality checks,” said TietoEVRY employee Manuel Hausjell, describing the collaboration.

Configuration in TwinCAT IoT Data Agent.

“There are always new ideas coming in about what else we could do to improve day-to-day operations in our plants, run benchmarking between the individual sites, achieving quality improvements, supporting predictive maintenance, using fewer resources and much more,” said Sibbald, aware that digitization is an ongoing process. “You can only become lean if valid comparative data is available. And the beauty our system is that it is easily expandable and scalable,” the manufacturing excellence officer sums up. Additionally, current transformers are being placed more and more frequently in the manufacturing facilities right now because, after all, not only every minute and every gram, but also every kilowatt-hour of energy counts. Thus, the project also makes significant contributions with sustainability goals for the reduction of CO2 as well as energy and raw material consumption. And with the subsequent implementation of QR code recognition, the adaptability of the installed solution has already been proven.

“All we had to do was activate the vision software licenses on the IPC, connect a camera via Ethernet and thereby expand the edge gateway with TwinCAT Vision to include image processing in real time. Of course, the QR codes that have been read are transferred to the cloud with the TwinCAT IoT Data Agent. The data is also available for use in the MES and ERP system,” said Bezeczky.

Balazs Bezeczky, head of Vienna sales office, Beckhoff