ApplicationsNovember 18, 2021

Cloud-based CNC monitoring for aerospace parts

A CNC monitoring system at Tech Manufacturing collects, analyzes, and enables visualization of necessary performance metrics.

With their 5-axis CNC machines already running 24 hours a day up to 7 days a week, Tech Manufacturing, a Pennsylvania-based supplier of machined metal parts for aerospace clients such as Boeing, Lockheed Martin, and Bombardier, looked to Moxa for smarter operation and real-time machine performance data. The company’s goals were to raise production capacity, reduce lead times for their clients’ largest and most urgent orders, and expand the useful service life of their existing machines.

“We needed a better understanding of how our machines were actually performing for us in real-time. Live and historical machine performance data would also help us identify technical or process issues that were detrimental to productivity,” said Jerry Halley, Chief Engineer of Tech Manufacturing, and one of the company’s 70 employees.

Purchasing additional machines would, of course, be one way to achieve this. But Halley was interested in finding a smarter, more efficient approach that did not require a large capital investment. That “smarter way” was a CNC monitoring system that would collect, analyze, and visualize necessary performance metrics. Before taking the next step, however, Halley carefully weighed the productivity gains of such a system against the cost and effort of deployment, especially if it involved a new and unfamiliar server-based IT infrastructure. The ideal system would be easily deployed without specialized IT equipment, knowledge, or effort, and would not require repeated software installation, updates or configuration.

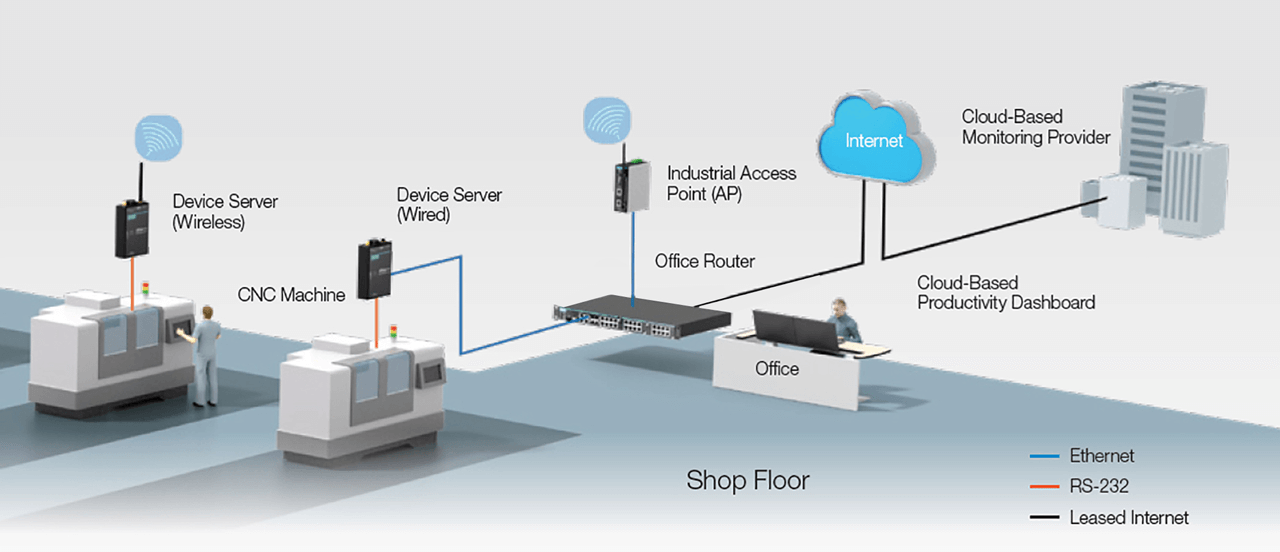

With the local network connected to the Internet, CNC machine performance data can now be easily viewed and analyzed by cloud-based software.

New Life To Older Machines

Tech Manufacturing selected Shop Floor Automations, one of the most prominent systems integrators in North America, to assist with a cloud-based CNC monitoring system. Each of Tech Manufacturing’s CNC machines were connected to the existing local area network, so no additional IT infrastructure was required.

Moxa Device Server permits communications software to access serial and Ethernet devices over the wireless LAN.

For legacy machines that did not have a readily available Ethernet port, Shop Floor Automations provided an easy-to-deploy solution that was developed based on Moxa NPort® W2150A and W2250A wireless device servers that permit communications software to access serial and Ethernet devices over the wireless LAN. Being wireless the device servers required far fewer cables and lets users roam between several access points. As such, the servers offered an excellent solution for devices that are frequently moved from place to place, as is the case in many factory settings.

“Getting our CNC machines connected and monitored has made it much easier for us to deliver on our clients’ build-to-print orders with maximum efficiency and minimum lead time. It is a lot easier to get connected than a lot of people may realize,” said Halley.

With the local network connected to the Internet, CNC machine performance data at Tech Manufacturing can now be easily viewed and analyzed by cloud-based software such as Scytec DataXchange or Predator Machine Data Collection. Key performance metrics are organized on a visual dashboard so the company’s owners and machine operators are able to see exactly how productive each cell is performing, down to the machine level.

Having comprehensive machine performance data on hand also provided an additional benefit: better service from CNC manufacturers.

With a cloud-based monitoring system, Tech Manufacturing was able to minimize their upfront cost and deployment effort, explained a representative from Shop Floor Automations: “Many clients perceive it to be difficult and expensive to set up a CNC monitoring system. However, with today’s cloud-based solutions, you can be set up in less than a day, with almost zero additional IT infrastructure or maintenance effort.”

With the system now up and running, a live dashboard has made it easy for Tech Manufacturing to identify critical productivity issues. For example, one immediate finding was that set-up times on certain machines were unnecessarily long, leading to hours of lost productivity every day. By rearranging setup sequence and on/off times, Halley quickly achieved significant productivity gains with those machines.

Having comprehensive machine performance data on hand also provided an additional benefit: better service from CNC manufacturers. Service calls are now backed by a rich set of historical data, making it easier to identify and troubleshoot potential hardware issues.

“Manufacturers have became more willing and able to provide support when we need it because we have the data to show abnormal operation,” noted Halley.