ApplicationsSeptember 19, 2024

Heat treatment OEM chooses flexibility and scalability

Heat treatment machinery OEM Mercer Technologies continues to innovate, adding energy cost per part. Using energy monitoring, the company is able to calculate in real time how much it costs to heat treat parts, and can accurately and effectively assign the cost of energy to the production of a particular component.

Industries like aerospace and power generation, where the margin for error is virtually nonexistent, utilize heat treatment to enhance the performance, durability, and reliability of critical components. Heat treating can improve strength, wear resistance, and lifespan of commonly used parts like camshafts, crankshafts, and turbines.

Mercer Technologies, a veteran owned and operated company in Terre Haute, Indiana, is an expert on heat treatment processes. At Mercer, they not only perform heat treatments on parts, they build full heat treatment systems that they provide to their customers, and they refurbish existing heat treatment systems, breathing new life into existing machinery to extend service life and enhance performance.

“All projects are different. Every furnace is different,” explains Cody Young, Mercer Technologies’ Controls and Automation Engineer. “There’s annealing, brazing, pre-welding, post-welding, and so on. For that reason, we wanted a platform that was flexible and scalable. Customization is a must.”

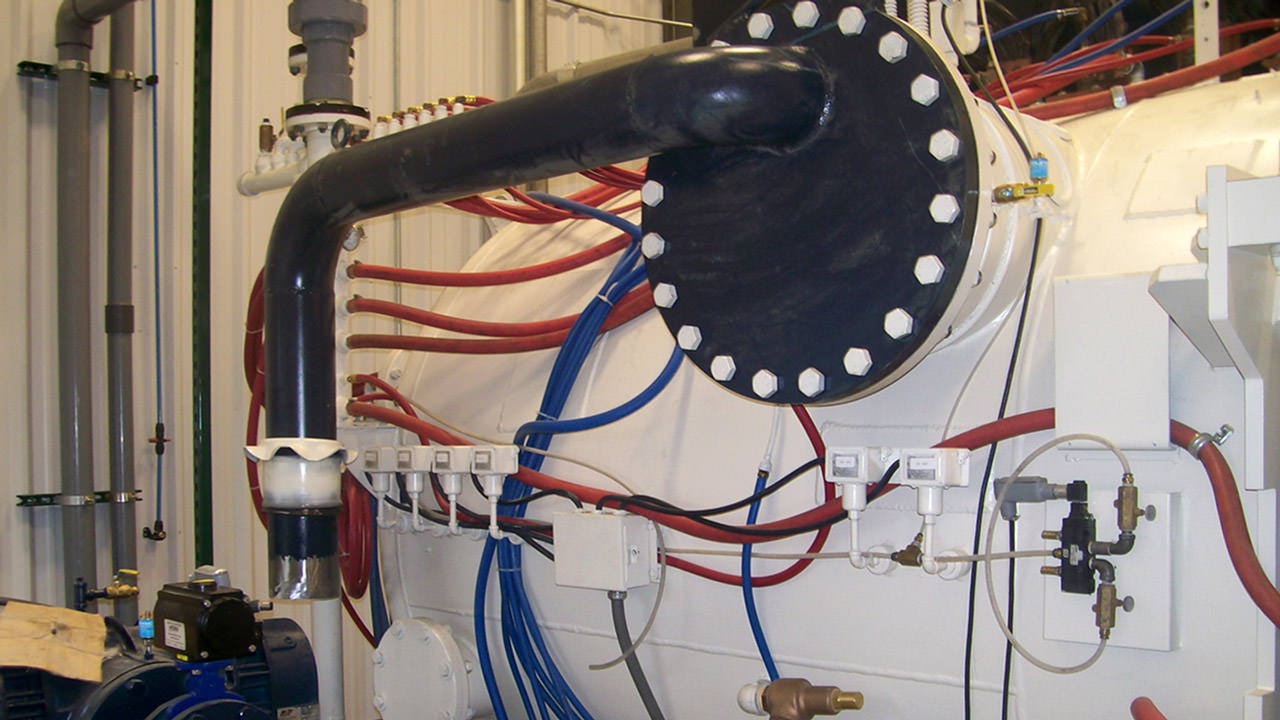

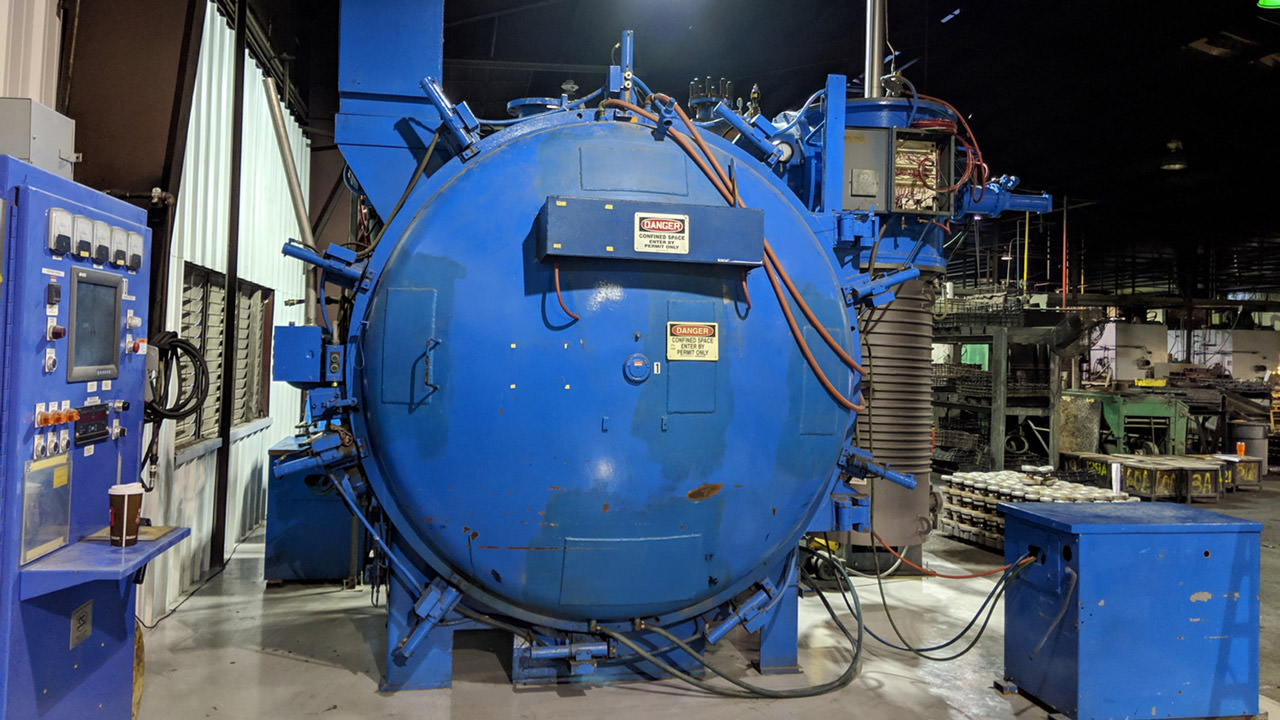

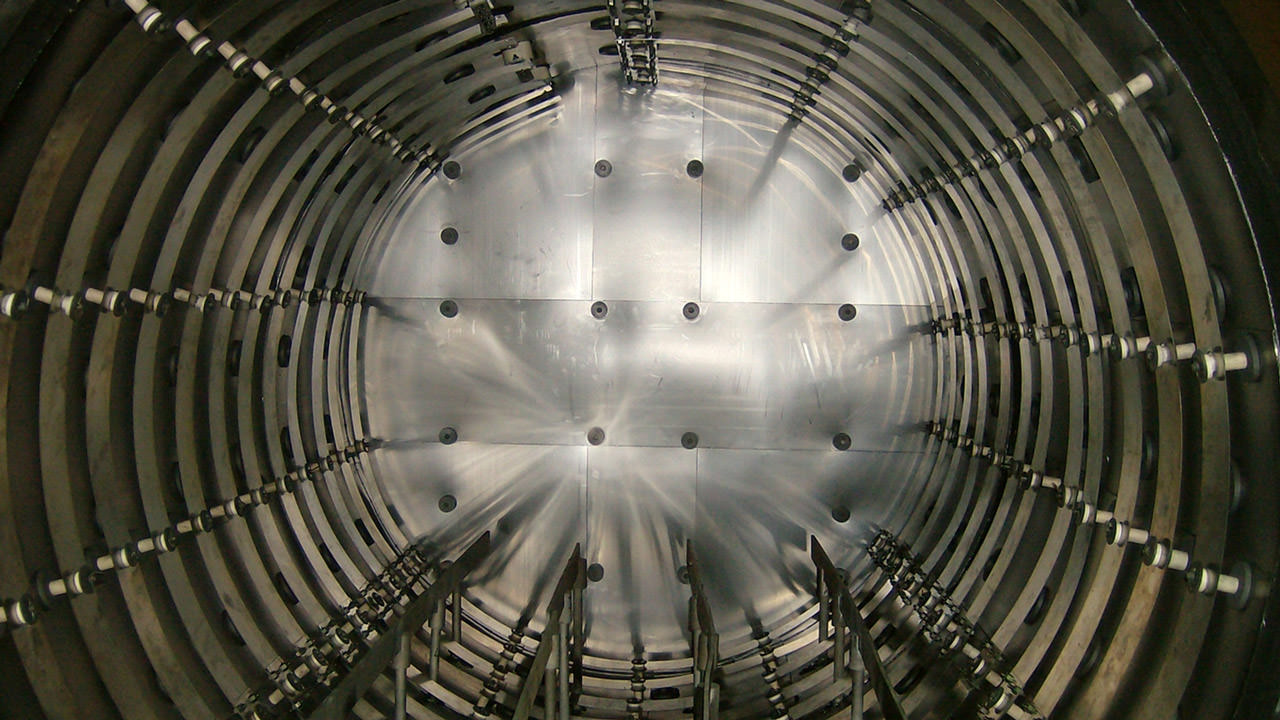

Vacuum furnace (exterior)

Heat treatment challenges

The heat treatment process involves heating and cooling materials, typically metals, in a controlled manner to alter their physical and mechanical properties without changing their shapes. Heating to temperatures in excess of 1000° C requires a high degree of care and precision.

Ridding the chamber of contaminants before the treatment begins is a key part of the process, and it can be accomplished in various ways. The atmospheric method, which is done by purging the furnace with an inert gas like nitrogen, is generally safer but takes longer and increases the overall cost of the process. Vacuum furnaces, on the other hand, which use vacuum pumps to decontaminate the chamber, can reach their deepest vacuum level in just a few minutes, but the operation is a bit more perilous.

Ridding the chamber of contaminants before the treatment begins is a key part of the process, and it can be accomplished in various ways. The atmospheric method, which is done by purging the furnace with an inert gas like nitrogen, is generally safer but takes longer and increases the overall cost of the process. Vacuum furnaces, on the other hand, which use vacuum pumps to decontaminate the chamber, can reach their deepest vacuum level in just a few minutes, but the operation is a bit more perilous.

“Improper valve sequencing during vacuum furnace operation can cause oxygen in the air to go where it’s not supposed to. Oxygen in the wrong place can lead to potential explosions or implosions, which is obviously a very bad situation,” explains Young.

Application solutions focus

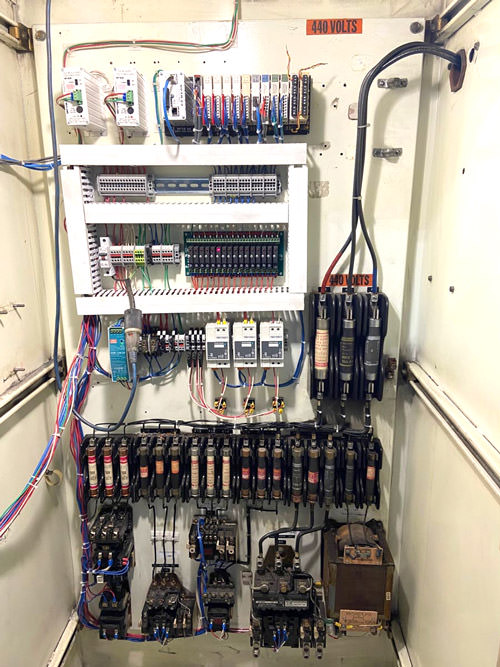

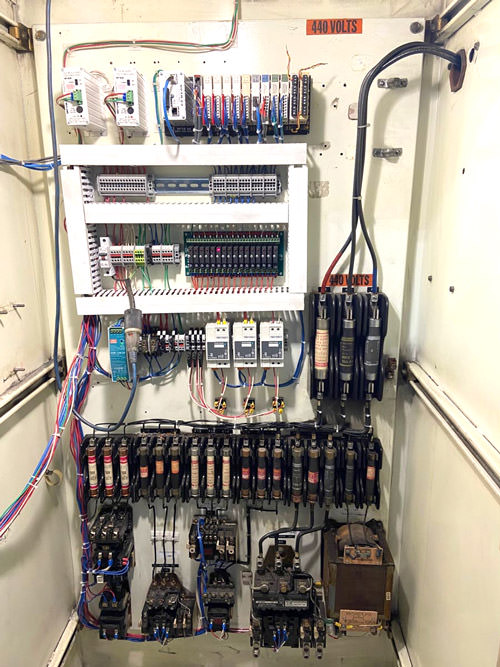

Mercer’s most recent hardware design uses a groov EPIC System for control.

Back in 1994, when Mercer Technologies was starting out, they needed a control solution that could do two things: flexibly adapt to a variety of applications and safely ensure proper sequencing of valves to prevent dangerous accidents.

Young found that the modular design of Opto 22 products offered the hardware scalability that Mercer needed. And OptoScript, a scripting language found within Opto 22’s PAC Control flowchart-based programming software, offered the flexibility Mercer was looking for. “Back in my college days at Ivy Tech, we learned C++, so I was familiar with a similar scripting language. I can customize it however I want to,” Young recalls.

Beyond capable products, Mercer needed a platform that offered local support. Based in the USA with free product support, Opto 22 fit the bill. Young explains, “Opto 22 has competitors, but they are unmatched in support, and using products made in the USA is important to our mission. Every issue I’ve ever had with Opto 22 products was resolved quickly, usually with help from the OptoForums [Opto 22’s factory-supported online community forum for exchanging ideas and application support].”

30 years later …

Mercer’s most recent hardware design uses a groov EPIC System for control.

Opto 22 has been providing solutions for Mercer since the firm’s inception in 1994, and today, Mercer has over 100 heat treatment systems operating in the field at various customer sites and 8 systems running in their Terre Haute facility.

Young explains, “Vacuum chambers in heat treatment systems used to be manually controlled with pushbuttons and switches. Automating with Opto 22 products has enabled us to build a less error-prone system, but most importantly, a safer environment for our operators and customers.”

New products enhance heat treatment process

While the heat treatment process itself hasn’t changed much since 1994, better instrumentation and technology have opened the door to further enhancements in safety, reliability, and intelligence.

Hardware design

Mercer’s most recent hardware design utilizes Opto 22’s groov EPIC system with a variety of I/O modules that serve the following functions:

- The GRV-CSERI-4 module (and in some cases, a USB-to-serial converter from Gearmo®) provides RS-232 communication to a EuroTherm® temperature controller, which includes PID loops for control, and a Televac® vacuum measurement instrument, which ensures proper vacuum levels.

- The GRV-OVMALC-8 module outputs a 4–20 mA signal to provide fine-tuned control of heating elements.

- The GRV-OMRIS-8 module’s relay outputs, with a 5 amp capacity, control higher current valves on the vacuum chamber.

- The GRV-OACS-12 similarly controls lower current rated valves on the chamber.

- The GRV-IDCS-24 provides input from pushbuttons and on/off feedback from valves.

- The GRV-ITM-8 provides valuable temperature data through thermocouple inputs.

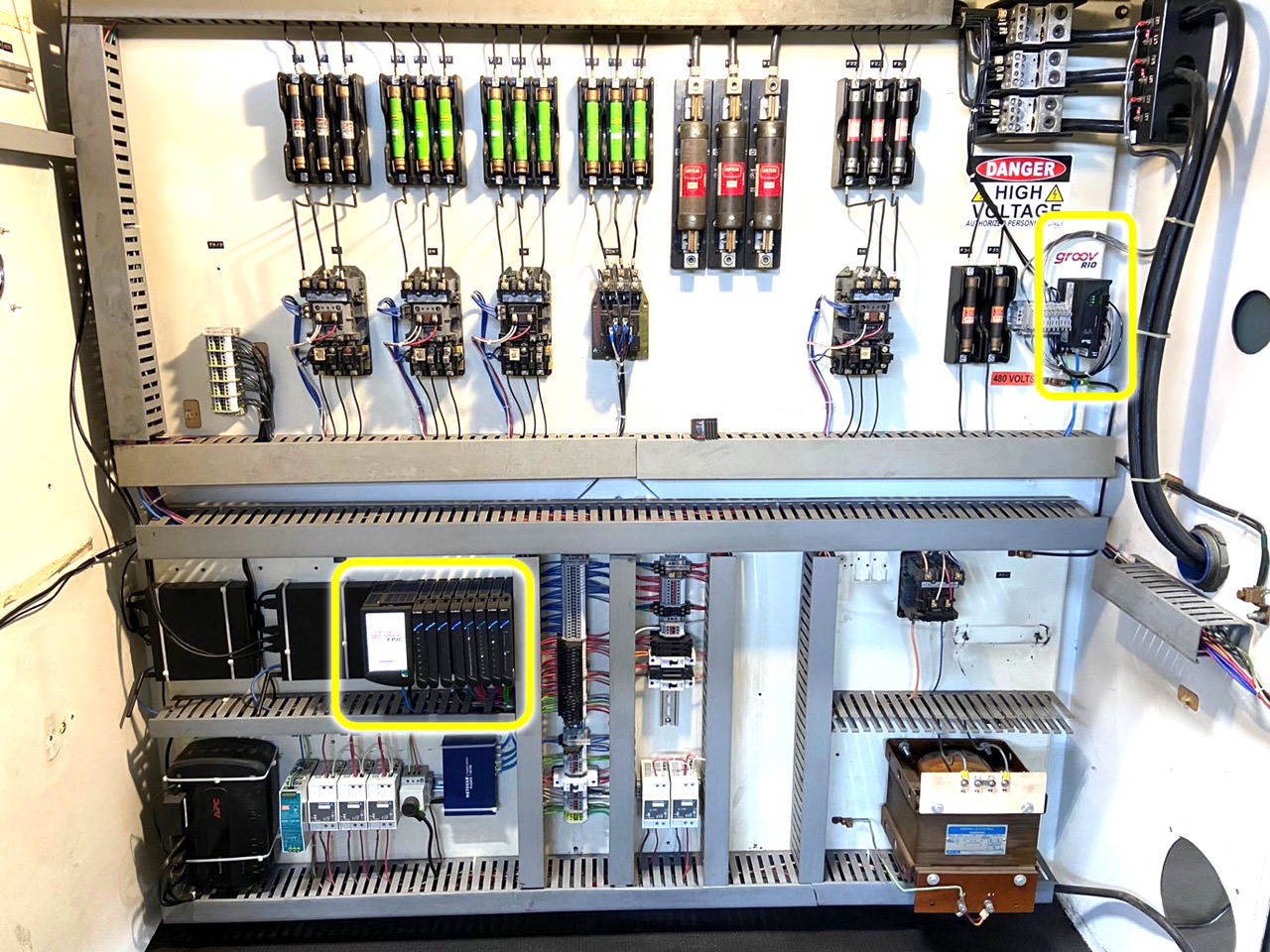

Mercer’s latest design incorporates a groov RIO EMU and a groov EPIC system.

Software design

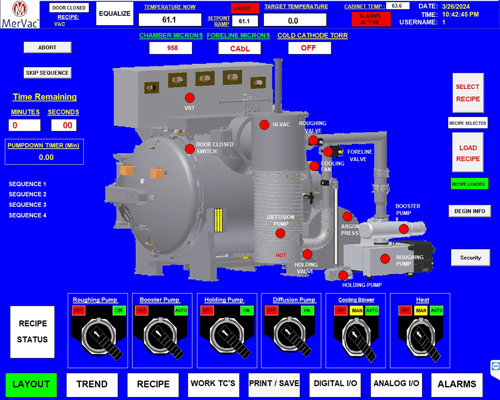

Mercer HMI screenshot.

Most of Mercer’s systems utilize Microsoft® Windows® 11 PCs running AVEVA® software [formerly WonderWare®] for visualization. AVEVA’s OPC drivers provide seamless communication to Opto 22’s groov systems and also to legacy Opto 22 SNAP systems.

Onboard the groov system, Node-RED, an open-source flow-based programming tool for IIoT applications, handles the RS-232 serial communication between the groov EPIC and third-party instrumentation.

At the heart of the application is still Opto 22’s PAC Control. The flowchart programming environment is designed for safely controlling a sequential operation like heat treatment.

PAC Control handles all of the critical valve sequencing, and runs independently of the PC.

“For fail-safe reasons, the HMI is only used to view operations and to transfer recipes into the PAC Control strategy. Once the values are transferred and the process begins, the PC could be unplugged, but the groov EPIC system will remain running to keep the furnace in a safe state,” explains Young.

Powering through: the energy dynamics of heat treating

“In our most recent design, we’ve utilized a groov RIO EMU [Opto 22’s IIoT-ready power and energy monitoring module] to monitor energy consumption of a particular furnace,” says Young. “At max output, this furnace consumes nearly 350 kVA per hour, roughly 420 amps at 480 volts—enough to power an entire residential subdivision!”

Young goes on to explain, “With energy monitoring, we can calculate in real time how much it costs to heat treat parts, and we can now accurately assign the cost of energy to the production of a particular component.”

With this new energy data, Mercer Technologies can make informed decisions on how to optimize energy consumption and ensure pricing strategies are accurate and competitive.

New opportunities

Mercer Technologies isn’t done. Their recent foray into groov products has opened the door to new opportunities to enhance their product offering and better serve the industry.

One of Mercer’s customers, an Inductive Automation® Ignition® user, recently expressed interest in adding their Mercer Technologies equipment into their Ignition application. “I haven’t crossed that bridge yet,” Young says, “but my experience with Opto 22’s support has been phenomenal. I’m sure when the time comes, I’ll be able to find most of what I need on the OptoForums.”

Reflecting on the 30-year history using Opto 22 products, Young declares, “We’ve done a lot of refurbishing of older systems where we replaced older, outdated controls with SNAP and groov systems. We know they’ve been a success because of all the repeat business. I almost never deal with failed systems. We have systems that have been in the field for over 20 years that are still running.”