ApplicationsJune 2, 2021

High data rates for effective vision-based sorting

Optical sorting machines for the seed industry rely on EtherCAT plug-in modules for fast real-time communication technology that optimally supports the high data rates of the vision-based sorters. Compact I/O modules reduce hardware requirements, as well as costs, and cut equipment assembly times in half.

For its solutions for automatic seed sorting, VMek relies on EtherCAT from the very beginning. The fast real-time communication technology optimally supports the high data rates of the vision-based sorters. With a switch in the I/O level to EtherCAT plug-in modules, the company succeeded in further reducing costs, device footprint and commissioning times.

In 2012, Kent Lovvorn, general manager of VMek™ Sorting Technology in Midlothian, Virginia, left his previous job with a clear vision: “I wanted to specialize in some segment of high-speed machine vision.” The company he founded in 2014 offers numerous software and hardware solutions for optical sorting. The machines, including the Metrix Analytic Lab Color Sorter and Element Analytic Production Color Sorter™, leverage new technologies to meet the needs of customers in the agriculture industry, including the top three seed producers in the U.S.

The Metrix Analytic Lab Color Sorter, one of VMek Sorting Technology’s top hardware solutions, uses two full-color GigE cameras to separate and gather data on seeds.

The Metrix machine uses two full-color GigE cameras and offers a throughput of 600 seeds per second, while the Element sorter with four such cameras even achieves a throughput of 12,000 seeds per second. Unlike other color sorters, which only separate products into good and bad parts, the VMek systems are able to provide valuable data on every seed in real-time, as Kent Lovvorn explains: “Our software performs composite analysis using the front and back images of each item. The software isolates each part and mates them together to complete a 360-degree full-part analysis.”

This data allows seed producers to analyze why individual parts were rejected and compare lab results with plant floor realities. They can also use insights to plan for the future, Kent Lovvorn explains: “The seed companies can plan accordingly for the next grow cycle to either enhance or eliminate specific traits.”

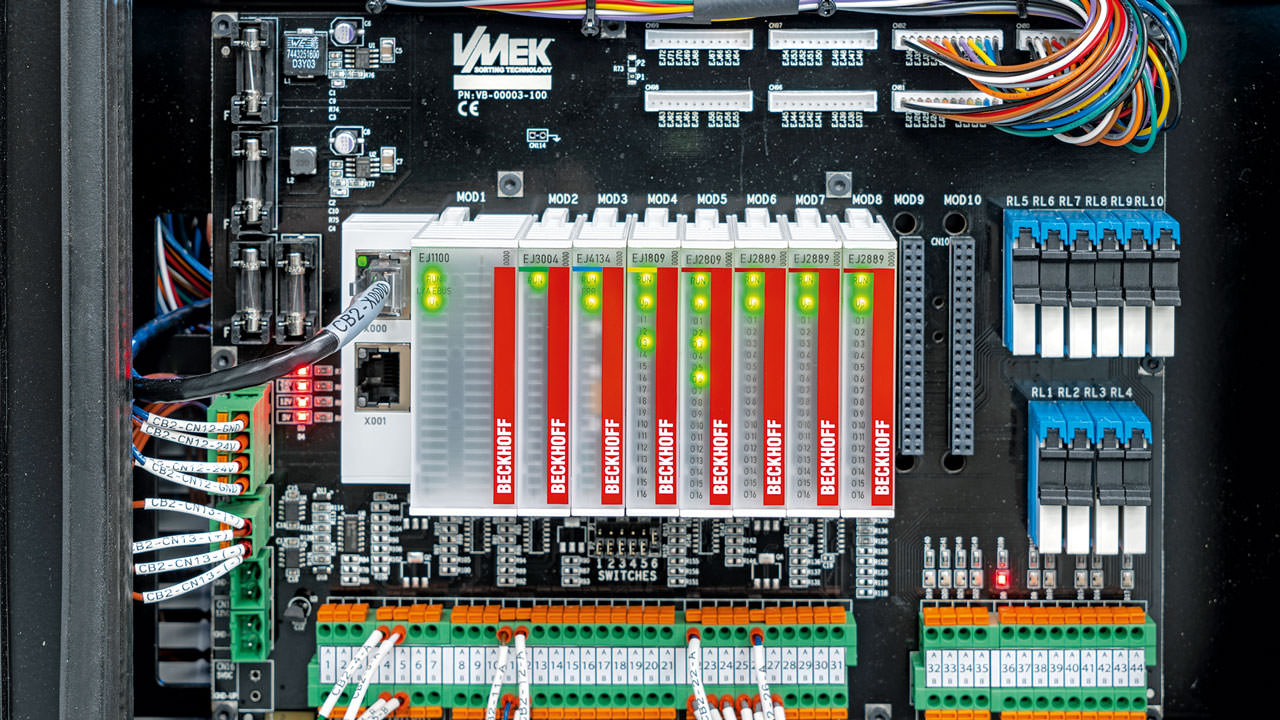

The compact EJ boards reduce footprint on VMek hardware solutions. The LED lights of the EtherCAT plug-in modules can be seen through a window on the machines and provide important EtherCAT diagnostic information at first glance.

Improvement in I/O solutions

From the beginning, company founder Kent Lovvorn believed that continuous improvement of these high-tech systems would only be possible by partnering with top-tier vendors: “When I started to lay the foundations for VMek, I searched for hardware and software partners that developed quality components the right way. That’s when I found Beckhoff.”

During a presentation on the EtherCAT industrial Ethernet protocol, Kent Lovvorn learned about the network’s ability to use PCs as real-time machine controllers. He decided then that in his opinion EtherCAT was the best technology to use in his high-speed vision machines, and this led to the decision to standardize on EtherCAT I/O terminals from Beckhoff.

During a 2017 redesign of several systems, VMek set out to further reduce costs and space requirements but wanted to continue using EtherCAT hardware. This effort did not need to increase reliability, as the first machine that shipped in 2015 has operated continuously and reliably. The aim was rather to enhance the offerings and decrease time to market by reducing the amount of hardware modules and the requirements for point-to-point wiring.

VMek General Manager Kent Lovvorn (right) and Beckhoff Regional Sales Engineer Chuck Padvorac, P.E., collaborated closely on selection of EtherCAT solutions.

Footprint, costs and assembly time

Through discussions with Beckhoff Regional Sales Engineer Chuck Padvorac, Lovvorn found a fitting solution: pluggable EJ series EtherCAT modules.

These I/O modules are roughly half the size of standard EtherCAT Terminals, but they provide the same functionality. Together with the JST connectors selected by VMek for this application, they mount directly to custom-designed PCB boards, and the entire signal distribution board connects to the larger PC-based system via prefabricated cables or coded plug connectors. Because the boards come essentially prebuilt, this makes series production more efficient and cost effective compared to traditionally wired terminals.

“The core benefits were logical and came down to the ease of use that enables us to build distribution boards with the exact functionality, size, connectors and labeling we need,” explained Lovvorn. “Because the signal distribution board for each machine is customized for our designs and processes, we can build machines prior to buying the EJ components, which delivers benefits in terms of equipment costs and just-in-time assembly.”

Sorting technology advances

By implementing EJ series EtherCAT I/O modules with standardized signal distribution boards for each sorting machine, VMek was able to cut time to market significantly. “We estimate that we reduced our equipment assembly time by 50%,” Kent Lovvorn said. “We have also minimized service time, if it’s ever needed.” Small adjustments at the hardware level helped VMek cut costs by roughly 700 U.S. dollars per I/O segment, and the company reinvested these savings in R&D to continue to enhance its optical sorting machines and software.

“As leaders in agribusiness, our customers see our complex sorting algorithms and ability to gather data on every part as indispensable,” said Lovvorn. Therefore, VMek will continue to focus on the continuous development of its solutions in collaboration with partners that work to lead in their fields.