TechnologyMay 17, 2025

Do you actually know… EtherCAT? Part 2

The first part of this EtherCAT series looked at how the technology works, key features and how EtherCAT and the EtherCAT Technology Group have developed over the last 22 years. In this issue, the critical topics include diagnostics, safety, the solutions EtherCAT offers and the protocol extensions EtherCAT P and EtherCAT G/G10.

This second part of a three-part series, “Do You Actually know … EtherCAT?”, focuses on EtherCAT technology and critical topics including diagnostics, safety and what solutions EtherCAT has to offer here. We also find out more about the protocol extensions for EtherCAT P and EtherCAT G/G10 communications.

Diagnostics with EtherCAT

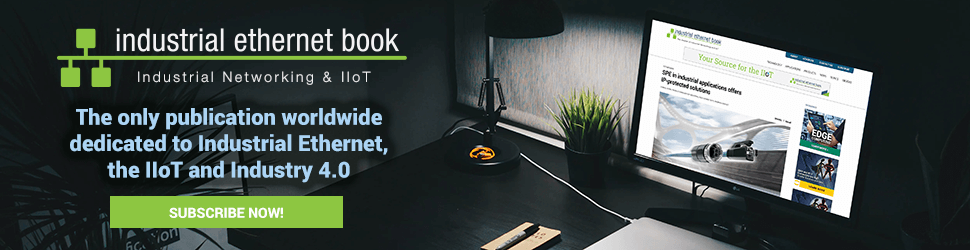

In addition to key features such as high performance and speed, the availability of tools for network diagnostics also plays a key role in communication technologies for industrial environments. However, EtherCAT already has numerous corresponding features inherent in the system and fulfills two basic requirements for diagnostic in a network, namely fast response and precise analysis, “with on-board resources” so to speak.

In an EtherCAT network, incoming telegrams are checked for errors in each node. Only error-free telegrams reach the application, while faulty telegrams increase the error counters and are flagged so that subsequent nodes do not also increase their error counters. Such telegrams are also recognized as faulty in the controller, the EtherCAT MainDevice, and discarded.

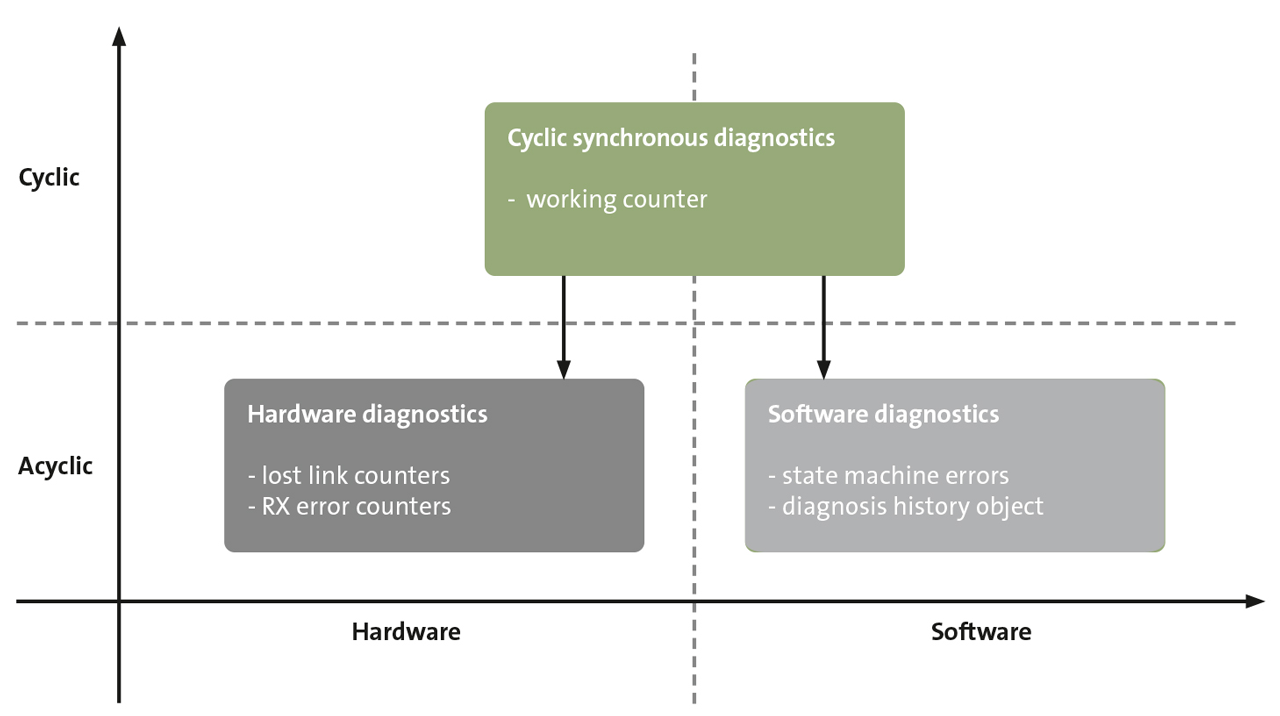

Figure 2: Principle of the controller-independent diagnostic interface.

The MainDevice can precisely localize errors by evaluating the counters. EtherCAT also detects rare faults at an early stage, minimizes their effects and thus facilitates error handling.

Each datagram contains a working counter for monitoring data consistency. Addressed devices increment this counter so that the MainDevice can check whether all devices have processed the data.

For developers, less for users, it is important that EtherCAT uses standard Ethernet telegrams, which can be evaluated with free analysis tools. The tool Wireshark, for example, can display information for EtherCAT in plain text.

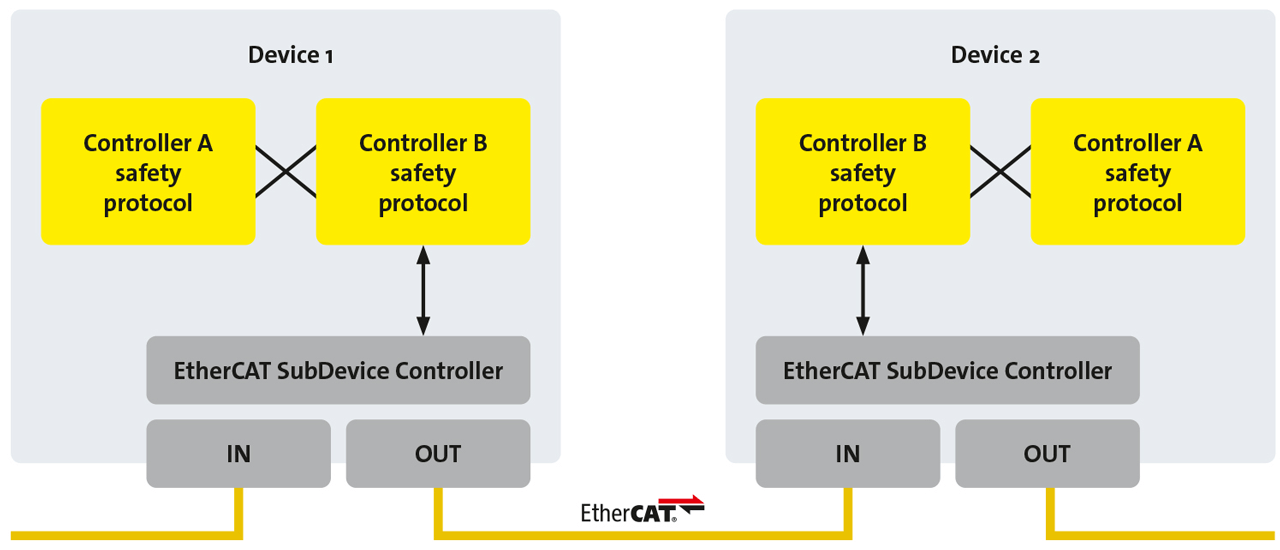

Figure 3: Easy and flexible safety architectures thanks to Safety over EtherCAT.

In addition to the aforementioned diagnostic functions, the EtherCAT Technology Group offers a manufacturer-independent diagnostic interface by means of a corresponding specification (ETG.1510 Profile for Master Diagnosis Interface), which can be added as a software extension to any standard control implementation.

Safety over EtherCAT — safety included

In communication systems, safety is of course of the utmost importance. Here, the transmission not only of control information but also of safety-relevant data on one and the same medium is generally used. EtherCAT relies on the safe protocol Safety over EtherCAT (FSoE), which has numerous other advantages.

For example, it offers flexible expansion options for the safety-relevant system structure as well as ready-made, certified safety solutions. FSoE also has many diagnostic options for safety functions and allows the safety concept to be seamlessly integrated into the machine concept. Development tools can support the programming of both standard and safety applications.

Figure 4: The Black Channel principle enables the use of the standard communication interface.

FSoE was developed in accordance with IEC 61508, is internationally standardized in IEC 61784-3 and can be used for applications up to a Safety Integrity Level SIL 3.

With FSoE, the transport medium is regarded as a black channel and is therefore not included in the safety assessment. Basic EtherCAT remains single-channel and transmits safe and standard information in parallel.

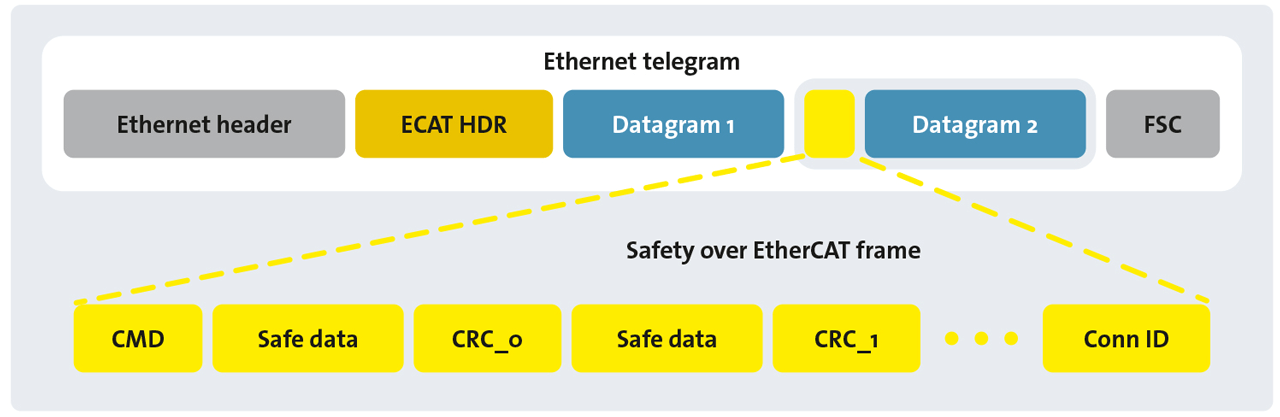

The FSoE frames contain the safe process data as well as additional information on data security and are sent as a container with the process data of the communication. The transmission path is arbitrary and not limited to EtherCAT: the safety container can be transmitted via any fieldbus, Ethernet or similar communication technologies – regardless of the physical medium, even wirelessly.

Figure 5: EtherCAT safety container embedded in the process data of cyclic communication.

This independence also simplifies the safety-related networking of system components. The safety container is routed via the control systems and evaluated in the other part of the system. Comprehensive emergency stop functions and targeted shutdown of machine modules can therefore be carried out without any problems, even if they are linked to each other via other communication systems such as Ethernet. The implementation of the protocol requires only a few resources and can achieve high performance and therefore short reaction times.

Figure 5: EtherCAT safety container embedded in the process data of cyclic communication.

EtherCAT for all cases

Since its introduction in 2003, there has only been one single version of EtherCAT. New features have always been added in a fully backward-compatible manner without changing the basic technology. Requirements that did not fulfill the original features of EtherCAT are managed via the protocol extensions that have been added over the years. This has many advantages and is also very attractive for cost reasons, not least when maintaining older systems.

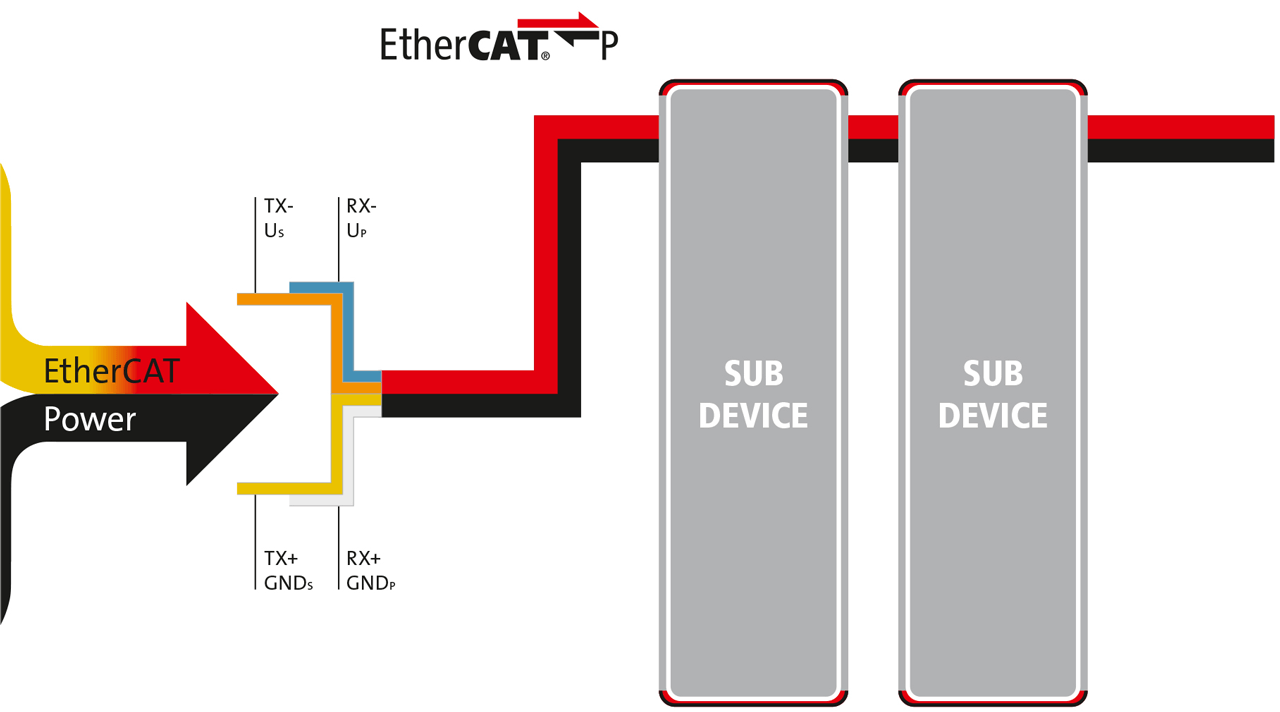

EtherCAT P is used, for example, if power is to be transmitted together with data, and EtherCAT G/G10 is used in the rare case that the 100 Mbit/s bandwidth of EtherCAT is not sufficient.

Data under power

The EtherCAT P protocol extension expands EtherCAT to include power supply via a conventional, four-wire Ethernet cable, but remains identical in terms of protocol, which is why no new EtherCAT SubDevice Controller chips are required. In addition to the advantages of EtherCAT, EtherCAT P enables devices to be powered via the communication cable, which reduces cabling, cuts costs and saves space.

EtherCAT P is particularly suitable for self-contained machine parts or sensors that are integrated into the network via a P-coded M8 connector. The mechanical coding prevents mismating. EtherCAT P can be seamlessly combined with standard EtherCAT in the same network.

Figure 5: EtherCAT safety container embedded in the process data of cyclic communication.

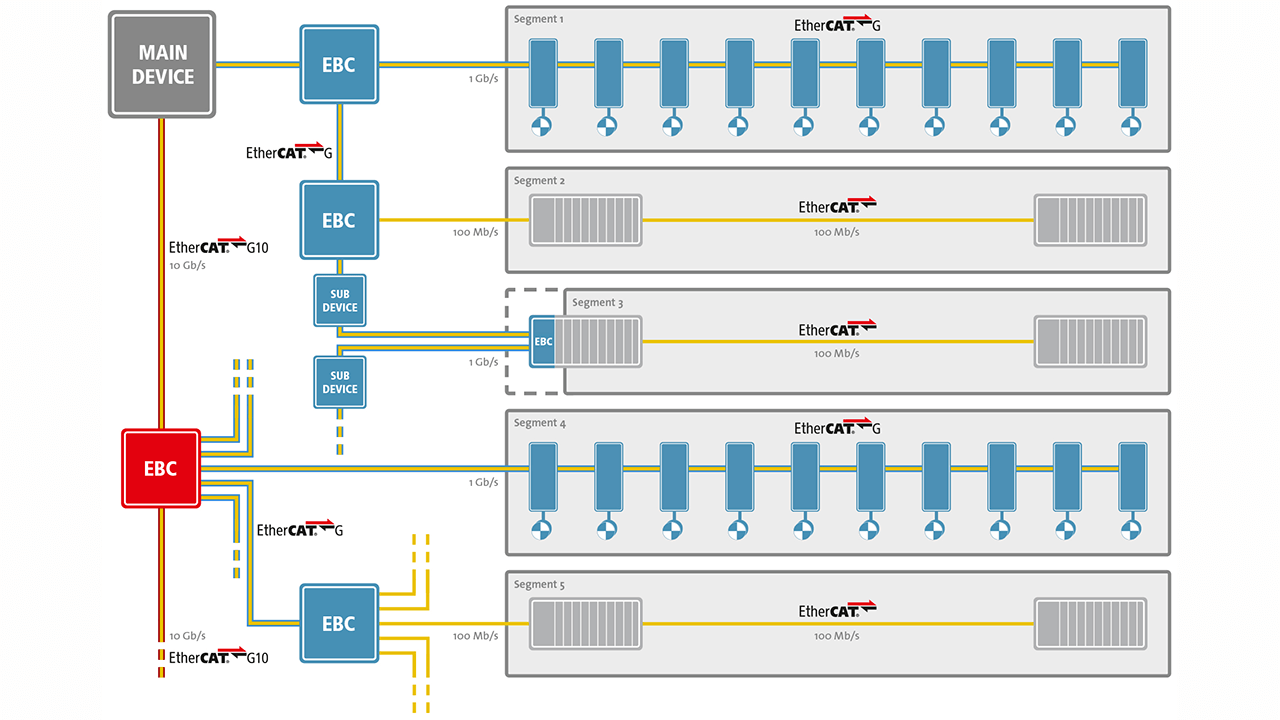

Communication at gigabit level

EtherCAT G extends the EtherCAT protocol to include data communication at gigabit level (1Gbit/s and 10 Gbit/s), which is ideal for applications with particularly high data volumes such as image processing, high-end measurement technology or complex motion applications. The features and benefits of EtherCAT are retained, including IEEE 802.3 compatibility and flexible topology.

EtherCAT Branch Controllers integrate 100 Mbit/s segments and their parallel processing in a gigabit/s network. No additional tools are required and functions such as diagnostics and network synchronization are retained.

EtherCAT G/G10 offers increased bandwidth and reduced throughput times thanks to parallel processing, without the need for all field devices to be gigabit-capable.

Existing 100 Mbit/s devices remain usable and benefit from the technology extension.

In the next issue you can read more about…the EtherCAT Technology Group and the ecosystem around EtherCAT.

Christiane Hammel, EtherCAT Technology Group