TechnologyFebruary 2, 2021

Improving network availability while decreasing maintenance

A fully connected operation will only reach its full potential if network availability is assured. The use of “smart” network devices as part of a back-up power strategy can improve network availability, as companies move to a network model that harnesses standard, unmodified Ethernet and Internet Protocol (IP).

Manufacturers need mitigation systems, such as industrial uninterruptible power supply (UPS) devices, to help protect against power disruptions on industrial networks and resulting downtime.

The limitless potential of the Internet of Things (IoT) is changing the industrial world as we know it, with the collection of vast amounts of new data, seamless communications across the enterprise and more insight into operations than ever before.

But even the most powerful, connected operations are still dependent on one critical, centuries-old element: power.

Designing, deploying and maintaining a network infrastructure must include how to contend with the inevitable power disruptions that every plant experiences from both natural and man-made causes.

These disruptions can stem from extreme environmental conditions, vandalism, equipment failure and service provider issues. The proactive decisions made to address these risks will ultimately determine if operations continue seamlessly or if everything comes to an abrupt halt.

Several approaches exist, but each should be carefully evaluated in terms of its reliability in an industrial setting, how well it can protect network uptime and how it impacts operations including maintenance programs.

This article will discuss the need for back-up power in the context of today’s increasingly connected industrial operations, review the options that are available, and examine the impacts they can have on operations.

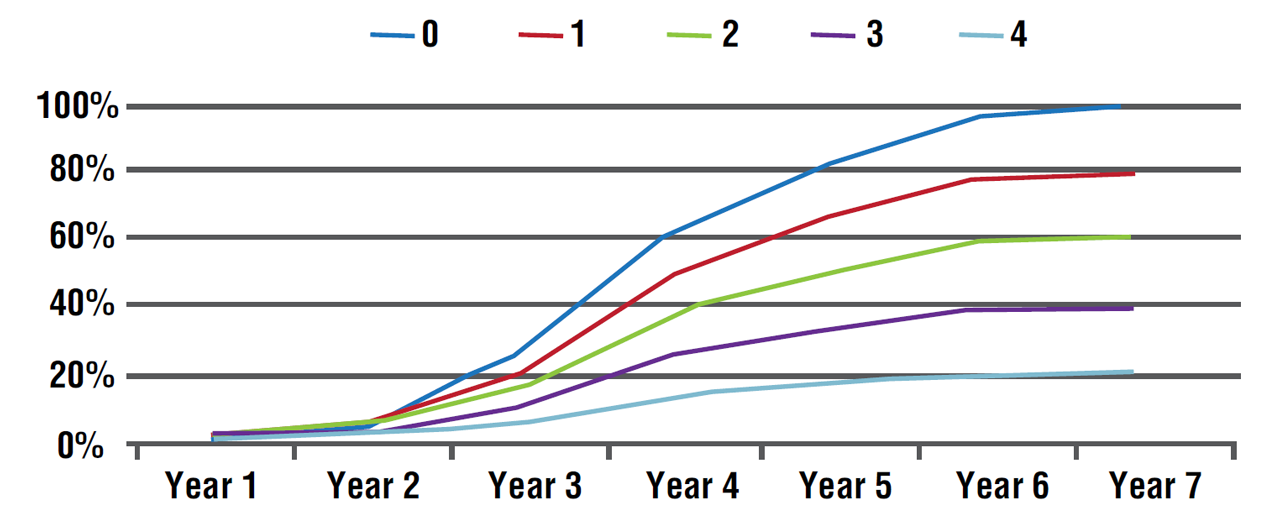

Cumulative failure rates by year based on the number of preventative maintenance intervals per year.

Protect uptime in connected plants

The use of multiple, disparate networks within an industrial enterprise is quickly becoming a primitive practice. Driven by both competitive pressures and opportunities to capture trillions of dollars of value from the IoT, industrial companies are moving toward a network model that harnesses the power of standard, unmodified Ethernet and Internet Protocol (IP).

This movement is driving a new level of connectivity among people, machines, systems, and devices, giving companies the ability to capture, view and report data like never before. It is also enabling greater communication to take place whether between an enterprise and a plant floor or across several plants spread out around the world.

According to I.H.S. Global/IMS Research, this rapid connectivity will continue, as 160,000 new industrial Ethernet nodes are added every day.

For all the benefits that industrial Ethernet offers, it also puts additional demands on manufacturers and industrial operators. Specifically, as a network infrastructure and plant floor operations become more interdependent, network uptime becomes absolutely critical. Whereas machine uptime and productivity went hand-in-hand in the industrial plant of yesterday, the information-enabled industrial plant of the future will be just as dependent on network availability as it is on machine availability.

Because of this, a strong commitment to network uptime is essential. This includes taking steps such as using redundant devices, building in redundant paths to prevent single device network failures, and implementing a cable management and wiring strategy that ensures maximum data speed throughout the network. However, it also must take into consideration the power availability challenges a plant faces.

Availability and power quality

Infographic comparing Uninterruptible Power Supply (UPS) Ultracapacitor vs. Battery.

When planning the deployment of network communications across the manufacturing zone and into the area/cell zones, contingencies will need to be in place for the power outages, “blips” and interruptions that will inevitably occur.

Even the briefest power disruptions can trigger the restarting of microprocessor-based devices, such as network switches, programmable logic controllers (PLCs) and human-machine interfaces (HMIs), which can take as long as three minutes to restart. While these devices are restarting, operations are at a standstill.

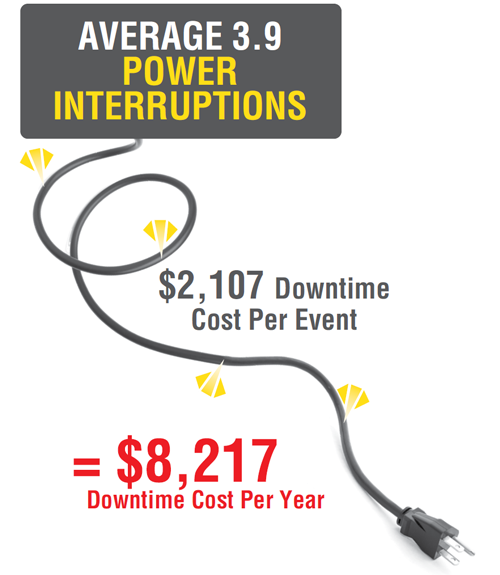

According to the Electric Power Research Institute (EPRI), the average downtime cost for a three-minute power interruption in the manufacturing sector is $2,107. EPRI also estimates that manufacturers experience an average of 3.9 utility-based power interruptions per year, putting the total annual cost at an average of more than $8,200.

In addition, many manufacturers experience other on-site power interruptions that do not originate with the utility provider and, therefore, are not reported. These local interruptions can be due to on-site transformer or distribution panel issues. Some facilities, especially in rural locations, report experiencing dozens of these on-site power disruption events every year.

While power outages that last several hours will be damaging to any company, the EPRI reports that 70 percent of utility-based outages are relatively brief, lasting less than five minutes. Additionally, more than 98 percent of on-site power disruptions are less than two minutes, according to the companies that report them. However, even with brief power outages, it only takes seconds for the disruption to cut off the energy supply to smart devices, forcing them to begin their lengthy restart process.

The only solution to the threat of power disruptions is to ensure there are continuous-power devices in place that will keep network devices and production operations running.

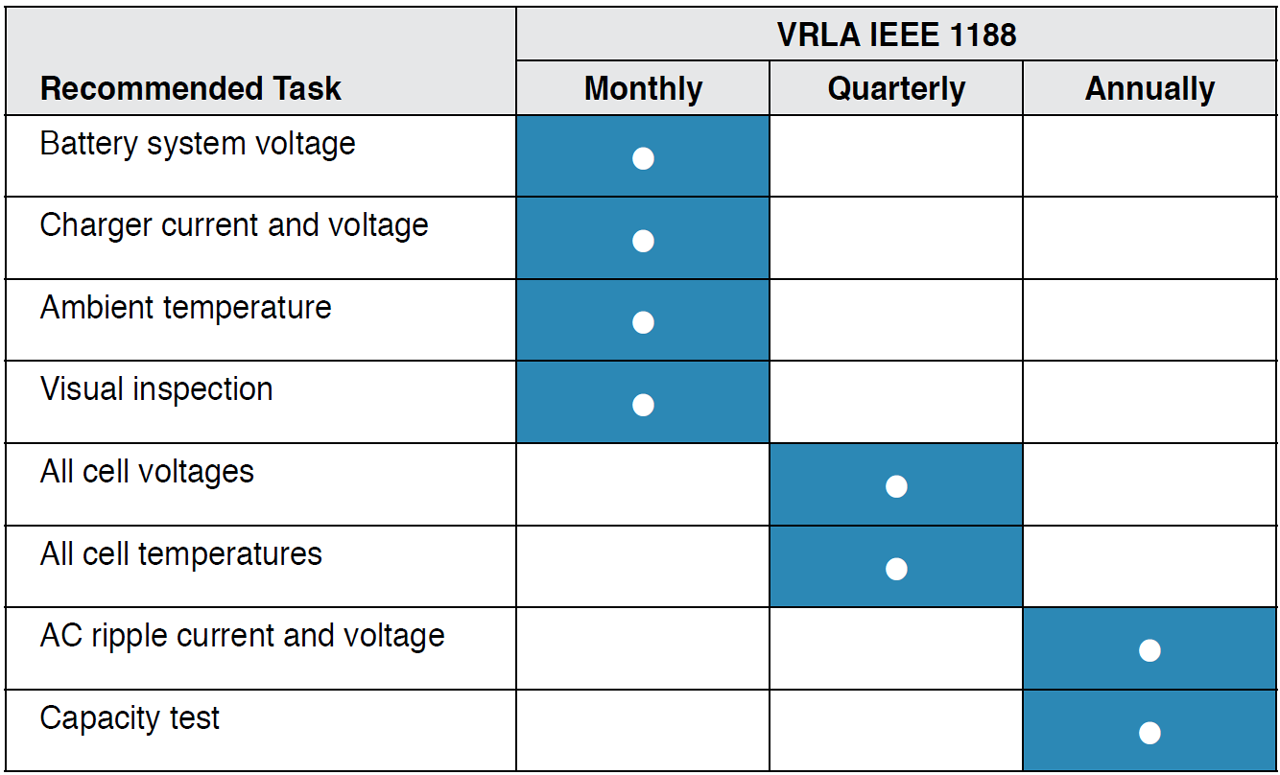

IEEE Standard 1188-2005 – IEEE Recommended Practice for Maintenance, Testing, and Replacement of Valve-Regulated Lead-Acid (VRLA) Batteries for Stationary Applications.

Consider the network infrastructure

A network architecture for industrial automation may recommend the use of a zoned network topology to create unique zones at every level of the organization, from an enterprise zone and a manufacturing zone, down to individual cell/area zones on the plant floor. Unlike a centralized topology with cabling originating from a central control room, this zoned approach allows for the selection of the network component types that are best suited to each environment or application. Additionally, implementing small virtual local area networks (VLANs) with managed industrial switches for each cell/area zone can segment and isolate low- and high-priority traffic for improved manageability. These cell/area zones require back-up power to ensure the dedicated switches and other network devices will continue running in the event of a power disruption.

Back-Up power options

Network switches and devices can be supported using either a centralized or localized back-up power approach.

A centralized approach could use an on-site generator, which is popular for data centers and increasingly being adopted in new factory construction. The biggest drawback with generators is a lack of continuous power support, meaning there is a need for an additional power solution to bridge the gap from when the outage occurs to when the generator begins providing power.

An alternative to the generator is a centralized uninterruptible power supply (UPS). Unlike a generator, a UPS device provides instantaneous power and does not require a bridge. Retrofitting a centralized UPS into an industrial environment, however, is an arduous task. It can require extensive new wiring and cabling distribution, which can be costly and time consuming.

A localized UPS – placed at each industrial switch, rather than stored in a central location – is a more practical solution for industrial environments. However, battery-based UPS solutions present challenges for use on the plant floor. Just as Ethernet technology must be resilient and adapted for use on the plant floor, a UPS also must be carefully selected to ensure it fits in with overall operations. Key considerations to evaluate before making an investment in a battery-based UPS device include:

Battery Life: An industrial environment’s harsh conditions can significantly reduce the battery life of a UPS. Batteries are prone to losing capacity in colder temperatures, and battery life can weaken significantly in warmer temperatures. Battery life is reduced 50 percent for every 15 degree increase above 77 degrees Fahrenheit. In short, a UPS battery’s service life will likely fall short of its design life if a plant experiences hot and/or cold temperatures.

Maintenance Demands: Batteries used in indoor and outdoor manufacturing environments can be a burden on maintenance personnel.

Table 1 shows the multitude of recommended maintenance tasks for batteries. There are also the additional employee demands to order, stock and properly dispose of UPS batteries. Given the challenges operations and maintenance personnel face on a daily basis and the lack of personnel at most plants, battery maintenance is unlikely to get the full attention and support it requires.

Device Management: Battery-based UPS devices typically only provide relay outputs or minimal indicators, such as single-color LED lights to show a battery’s input power, charge status or fault condition.

More advanced battery UPS devices can deliver detailed information and control options, but these devices often require the use of proprietary software and a USB or serial port connection to a dedicated computer for continuous monitoring.

This lack of automation or interoperability with a networked operation is enough to discourage most manufacturers or industrial operators from making an investment to address these issues.

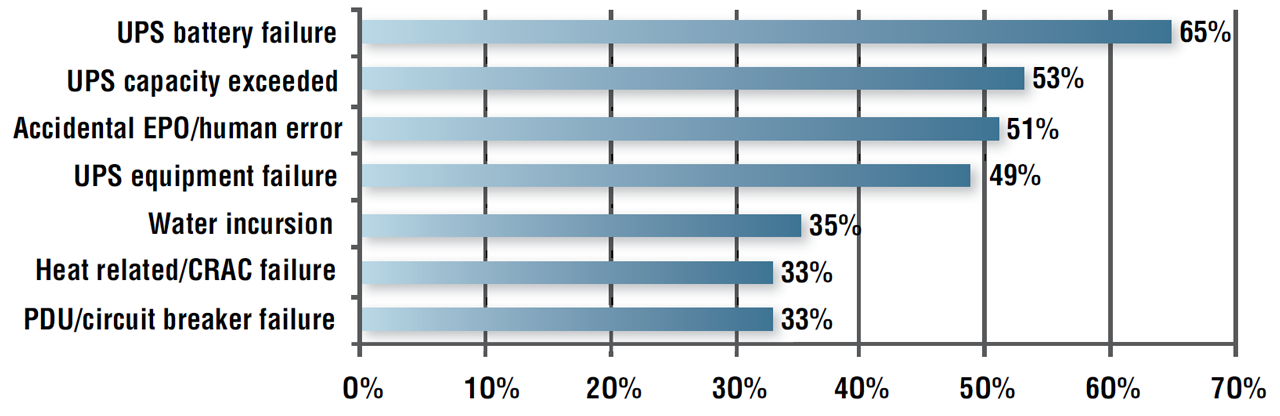

These combined challenges can lead to batteries not performing when they are needed most – during a power disruption event. As a result, batteries are blamed as the No. 1 cause of downtime in data centers.

Additionally, lead-acid batteries are categorized as a hazardous waste material with disposal costs. This additional cost contributes to the annual tonnage of hazardous waste materials, a figure that companies include in their annual corporate social responsibility reports.

A fully connected operation will only reach its full potential if maximum network availability is assured.

Batteries pain in the UPS

An ultracapacitor-based UPS is specifically designed for the industrial network and addresses the challenges that have plagued battery-based UPS devices. Ultracapacitor UPS devices are built to endure harsh environmental conditions, have long lifespans, require no maintenance, and provide remote monitoring capabilities – reducing the total cost of ownership by 50 to 70 percent and significantly lowering the risk of downtime by 39% compared to battery-based UPS devices. This allows for the system back-up of network switches with greater confidence.

When comparing battery and ultracapacitor UPS devices, the first concern is whether they both provide power back up. The answer is yes, but not equally. Industrial managed switches are low power devices, drawing 5 to 15 Watts of power (less than 1 Amp). Both UPS options provide the necessary hold time, but batteries are “overkill” – typically delivering hours of backup time. Ultracapacitors are right sized for industrial network switches and also provide a host of other advantages.

For example, ultracapacitors are designed for a broad range of temperatures, including applications exposed to extreme outside temperatures (-40 to 140 degrees Fahrenheit). Ultracapacitors also do not experience a high level of degradation in hotter temperatures. This contributes to an ultracapacitor’s long lifespan (10+ years) compared to a battery’s one to five year lifespan.

More importantly, ultracapacitors lower the risk of downtime because they eliminate batteries, which have proven to be unpredictable, maintenance-intensive and the leading cause of UPS failure. Manufacturers must conduct numerous preventative maintenance tasks when using batteries or face high failure rates. An ultracapacitor-based UPS, meanwhile, requires no maintenance. These advanced industrial UPS devices also can be remotely managed, minimizing the time and effort needed to monitor them, which reduces operational expenses compared to a battery-based UPS.

Remote device management allows all UPS devices to be monitored from a single location, an office laptop or a mobile device on the plant floor. This is all performed using standard tools instead of proprietary software. Battery-based devices, on the other hand, require an operator or technician to manually walk the floor, open each enclosure and inspect every battery’s status. Remote device management can also be taken a step farther using simple network management protocol (SNMP) software agents or network-based devices. This can enable the monitoring of redundant power supply inputs, view the available load to predict the hold time and measure the ambient temperature in the cabinet.

Emerson Network Power white paper: “Addressing the Leading Root Causes of Downtime” indicates UPS battery failure is the leading cause of downtime.

Optimal network reliability

A fully connected operation will only reach its full potential if maximum network availability is assured. Just as the industry is turning to more integrated, data-driven technology to support better decision making in production operations, the use of “smart” network devices as part of a back-up power strategy should be implemented to improve network availability. This is best accomplished using a localized, Ultracapacitor UPS in each area/cell on the plant floor.

Designed to persist in taxing conditions, an Ultracapacitor UPS eliminates batteries, the No. 1 cause of UPS failure, helping reduce overall plant-floor network downtime. 39% decreased risk of failure, reduced maintenance, and a 50–70% lower total cost of ownership compared to battery-based UPS devices illustrate the quantitative benefits of an industrial UPS device, but the confidence in knowing systems are prepared for the next power disruption can prove both immeasurable and invaluable.