TechnologyJuly 27, 2019

Parameterization & monitoring of Ethernet Hart devices

In the same way that personal smart devices receive new features from firmware upgrade, industrial facilities are driven to get more out of the equipment. With the Ethernet Hart Multiplexer GW PL…Bus, the various measurement and diagnostic data of the Hart devices can now be used to increase system efficiency.

The process industry is confronted with the challenges of all industrial sectors; operating costs must be reduced and system availability increased. This can be achieved, for example, by providing additional diagnostic data. Monitoring equipment health can improve overall equipment effectiveness (OEE) and can be part of a predictive maintenance strategy that reduces operating costs.

If calibration and configuration activities can also be carried out remotely, this saves the time for the responsible employee to travel to the site and also increases his or her safety. However, the economic efficiency that can be optimized in this way should not be accompanied by an interruption of the running system. That would be counterproductive.

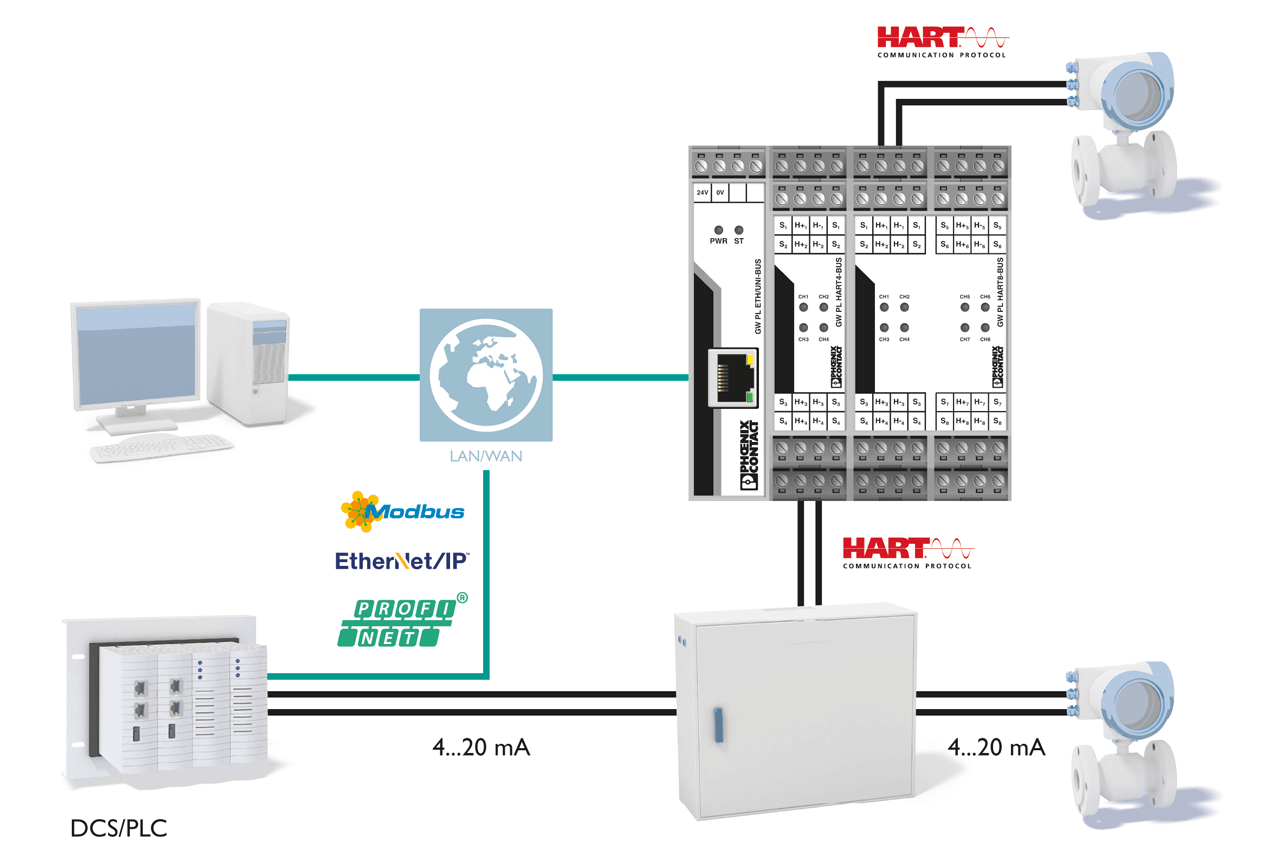

The Ethernet Hart Multiplexer allows both direct connection of the sensors in new installations and non-reactive parallel connection to existing analog measuring lines in retrofit installations.

Analog 4…20 mA signal

Most users only use this type of signal so, in many cases, any additional data required can already be supplied by existing devices. Around 40 million Hart devices are installed worldwide, with 90 percent of users using only the analog 4…20 mA signal.

The functions for configuration, calibration or plant management are therefore not used. If access to unused data were retrofitted, an estimated 20 percent of devices could provide valuable information. The Hart protocol (Highway Addressable Remote Transducer) was standardized almost 30 years ago and is now the most frequently used communication standard in the process industry worldwide.

Hart originally aimed to make analog process measuring devices smarter by superimposing digital data on a 4…20 mA signal loop. Due to the introduction of additional transmission methods – such as the forwarding of data via Ethernet or wireless – the standard has evolved over the years. The backward compatibility of the technology and the interoperability of devices from different manufacturers ensure that users are not restricted to vendor-specific or regional solutions.

The Hart data is recorded independently by the process control and is available without security risks.

Knowledge not lost

The Hart protocol offers numerous possibilities which only few users know. Many times, the DCS or PLC was in place or specified without Hart capabilities. As a result, the control system does not use the additional measurement and diagnostic data provided by the Hart devices. Only the maintenance personnel use the Hart interface for local troubleshooting or calibration using a handheld device. Therefore, knowledge about the capabilities of the Hart devices is lost. Against this background, their advantages are to be made clear once again.

Configuration: In the simplest case, the devices can be configured via the Hart protocol. Preconfigured setups allow the selection of operating parameters including measurement range, engineering units and sensor type.

Calibration: After initial installation and configuration, the user can calibrate the device by setting the zero and span, trimming the 4…20 mA signal or taking external sources of measurement errors into account.

Diagnostics

Hart devices are rich in diagnostic data. Many of them can monitor the condition of a sensor or probe, indicating inaccurate measurements at an early stage. In addition, a configuration error or an operating mode can be detected that may lead to problems in the future. Most importantly, however, diagnostic data is used to determine the health of a large piece of equipment or the quality and efficiency of processes. This helps to avoid unplanned maintenance.

Multivariable Devices: Most Hart devices are multivariable, meaning that they can provide multiple measurement values. Only the primary value is represented by the 4…20 mA signal, while other variables are only available as digital data. Pressure transmitters can, for example, provide absolute or gauge process pressure as well as the ambient temperature.

Temperature transmitters may also provide the user with the process and ambient temperature as well as cold junction compensation values. Differential pressure transmitters provide not only differential pressure, but also static pressure and ambient temperature. Coriolis meters deliver information such as mass flow, density and temperature. Not to forget the valve positioners, which report data such as the target and actual position of the valve stem as well as the actuator pressure and the output signal to the actuator.

Missing serial interfaces

If in the past the plant operator decided to upgrade the control system and wanted to access the Hart data, an RS485 Hart multiplexer was usually installed and connected to a PC. However, most of the PCs do not have an RS485 interface, so an RS232 converter was used. Currently, not even an RS232 interface is often integrated in the PCs any more. Users must therefore purchase a device server for conversion from RS485 to Ethernet protocol. This proves to be a complicated solution with several devices to configure and maintain.

The Hart Foundation recently published a standard for Hart IP, essentially the Hart protocol over Ethernet. This provides a user-friendly and generally available interface for communication with the Hart protocol. It enables the integration of tools that most plant operators already use: Pactware (or other FDT containers), Hart Server, Hart OPC Server, Simatic PDM and Honeywell FDM. Hart IP thus takes into account the megatrends Industry 4.0 and Industrial Internet of Things (IIoT), which require Ethernet-based data exchange and high network connectivity.

Hart data converted to Hart IP

Modular Ethernet Hart Multiplexer GW PL…. Bus technology offers the option of parameterizing and monitoring Hart devices via Ethernet. They can be easily integrated into almost any host system via industrial Ethernet systems such as Profinet, Modbus TCP or Hart IP, whereby the analog control system remains fully operational and does not even have to be shut down for installation.

The Ethernet Hart Multiplexer consists of a head station and a series of four- or eight-channel Hart expansion modules, which is why any user requirement can be implemented. Up to five expansion modules can thus be connected to the head station for a maximum of 40 Hart devices and supplied with power from it. The modular design therefore provides a scalable solution for modern distributed control systems as well as phased roll-outs. The multiplexer converts the Hart data to Hart IP so that the corresponding devices can communicate with many host applications, such as those already mentioned above. Via Simatic PDM, which provides Hart access via Hart Server, the GW PL system also supports asset management via EDD (Electronic Device Description).

In addition, the Ethernet Hart Multiplexer was tested for compatibility and approved by Emerson for use with its AMS package. If several Ethernet protocols are used, users with Hart IP can use the diagnostic data via AMS or a technology station while the process data is simultaneously transmitted via Modbus TCP or Profinet to a process control system. For example, I/O points on the controller become free or the secondary variables of a Hart device can be accessed easily.

With the modular Ethernet Hart Multiplexer GW PL… Bus, users save time and money by controlling configuration and calibration, such as partial stroke testing, process monitoring or current loop tests via Ethernet – and all this with the existing Hart devices in operation.

New technology opportunities

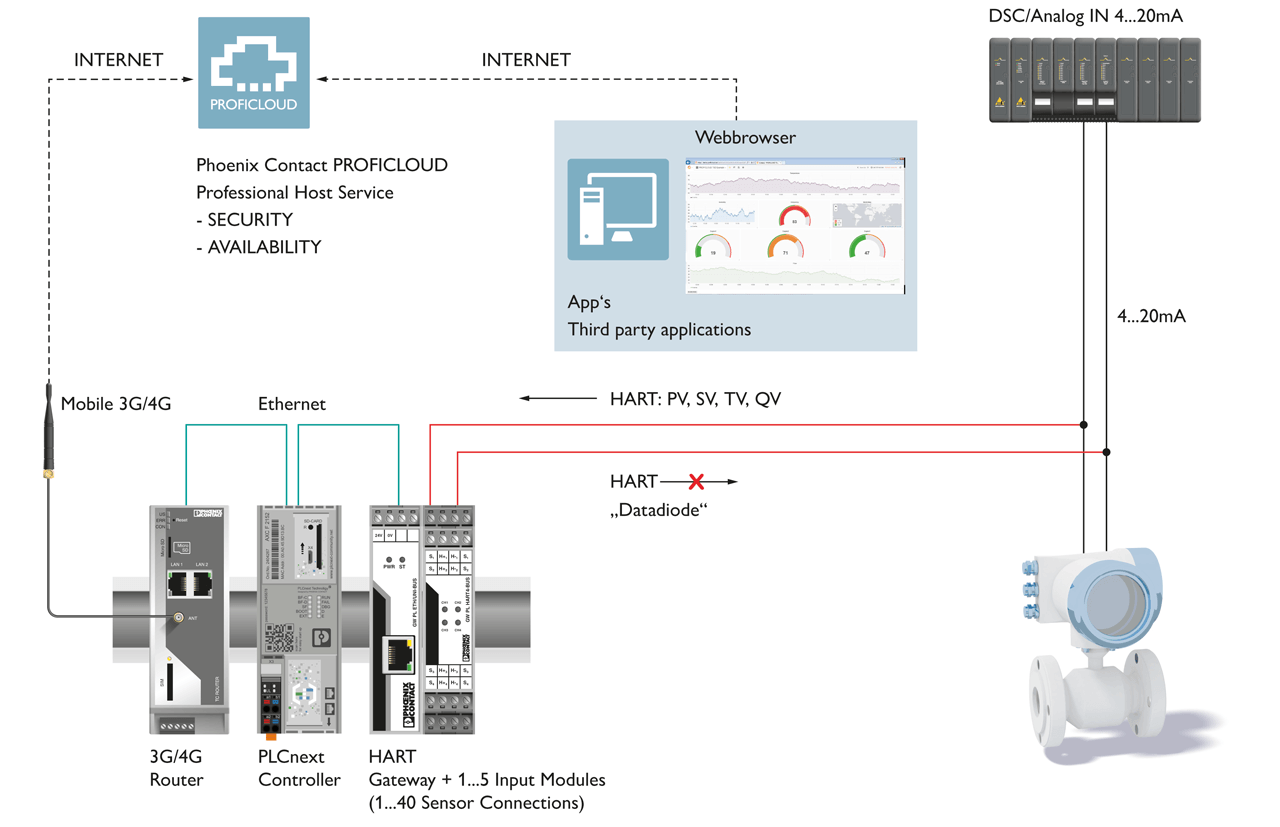

Cloud-based solutions will be an important part of future automation solutions and IIoT. However, users here have many different requirements, which result, among other things, from the desire for a high level of security and the adaptation of the solution to their individual conditions. Perhaps they may want to develop their own application on a cloud service such as Microsoft Azure or Amazon Web Services. Or they prefer an “off the shelf” solution such as Proficloud. In addition, there will be users who want to operate the cloud on a private server on the company premises.

Then how does the data get to the cloud? Protocols such as MQTT, AMQP or OPC UA are often mentioned in connection with IIoT and Industry 4.0. And how can users access the cloud? Some devices called “data diodes” grant read-only rights. This increases security, as no outputs can be actuated and changes can be made in the parameterization. The new technologies offer exciting possibilities for remote access, predictive maintenance or asset management. It remains to be seen how things will develop. In any case, new technology will continue to provide innovative, profitable solutions in this environment.