TechnologyMay 30, 2021

SPE Changing the Face of Industrial Communication

Single Pair Ethernet is more than just new connectors. SPE has become the connector standard for the network infrastructure of digital transformation.

Single Pair Ethernet – or SPE for short – is the trend topic when it comes to industrial communication technology. Usually, the focus is on components. But there is so much more to it than that – it is actually the Ethernet-based communication structure of the future. The SPE connectors from Phoenix Contact provide a glimpse of this.

There is currently a lot of discussion about components, cables, and connectors, but which PHYs (physical layers) are available? Which cables can be used? How far is the range and what sort of data can be transmitted? And last but not least, has a standard already emerged among connectors? The driving force behind all of these questions is a fundamental paradigm shift in industrial communication – for the entire infrastructure including devices and sensors for numerous application scenarios.

What is already available?

BroadR-Reach technology – an Ethernet physical layer standard for connectivity applications in the automotive industry – can be considered the starting point for the development of SPE. Modern mid-range vehicles have over 100 sensors – a trend that is on the increase. The number of control devices, sensors, actuators, and items of communication equipment keeps growing from one vehicle generation to the next – as does the amount of cabling. Innovative sensor technology with a uniform communication standard is required in the automobile.

Seeking a successor for the CAN bus, it was therefore the automotive industry that identified the TCP/IP-based transmission method and spurred on the first SPE standards. Through the IEEE 802.3 working group, the first SPE standards were published in the relevant task forces as 100BASE-T1 and 1000BASE-T1. Rosenberger Hochfrequenztechnik GmbH & Co. KG is already producing the connectors for these applications on a series scale.

With the cg standard from IEEE 802.3 finally being adopted in 2019, a standard for longer ranges has now been defined for the first time, which will be of interest for many industrial applications. This cleared the way for SPE to enter new fields of application such as factory and building automation. In order to create the first device generations for this purpose, corresponding individual components such as chips, cables, and connectors are required.

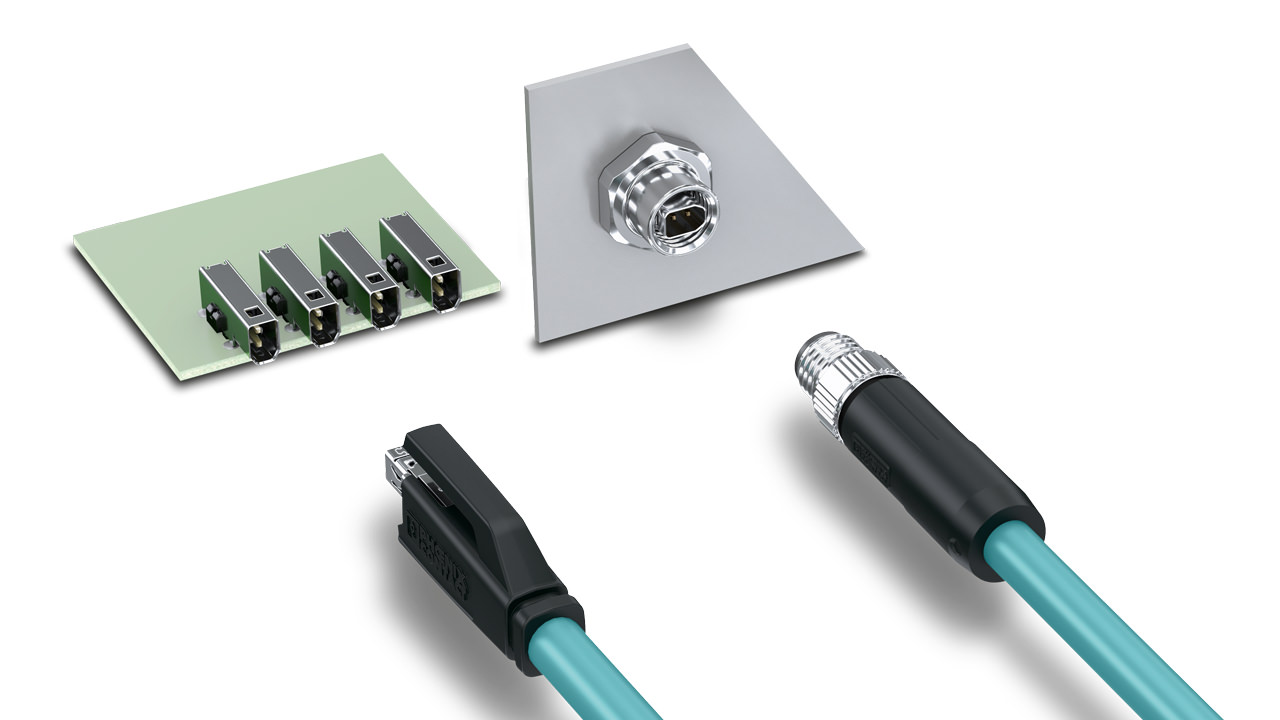

Universal use: the SPE connectors from Phoenix Contact are based on standards IEC 63171-2 (for IP20) and IEC 63171-5 (for IP65/IP67).

Standardization is ongoing

The first PHYs for the cg standard are already available on the market. This standard distinguishes between two variants: the T1L standard for long distances up to 1000 m and data transmission up to 10 Mbps and the T1S standard for shorter distances up to 25 m. This standard also supports multidrop. Therefore, for a bus length of 25 m, at least eight nodes can be connected with 10 cm branch lines. All nodes share the 10 Mbps bandwidth.

The cables for Single Pair Ethernet are described in IEC 61156-11/-12/-13 and -14. These four new standards for SPE cables define both their fixed and flexible installation. To date, the only standard to have been adopted is 61156-11 for fixed installation with transmission characteristics up to 600 MHz and a transmission distance of up to 40 m – suitable for standard IEEE 802.3 bp. The other standards – including those for the cg standard – have not been published yet.

Standardization is also still ongoing for connectors. Connectors for SPE are defined in IEC 63171. With IEC 63171-2, Phoenix Contact – together with partners Reichle & De-Massari and Weidmüller – has developed what is currently the most compact pin connector pattern for this series of standards. It meets two of the requirements for connectors: firstly, miniaturization and cost savings with the introduction of the new technology and, secondly, the industrial-grade latching and automated mounting of device connectors.

The IEC 63171-2 pin connector pattern is also described in IEC 63171-5 – however in that instance it is in industrial IP-protected packaging in an M8 and M12 design. Due to its compact dimensions, this pin connector pattern also fits in a standard M8 connector, and can therefore also be used in standard inductive sensors. Flying leads are also possible for cable-to-cable connection in the field or between field switches. On the device side, the different outlet directions are an advantage: horizontal and vertical to the PCB, a design for THR and SMD soldering processes, and full flexibility when it comes to the mounting direction through front and rear mounting.

What’s next?

From the sensor to the cloud: Single Pair Ethernet is the building block for the consistent use of Ethernet all the way to the field level.

In total, the IEC 63171 series of standards contains six different standards for connectors. The user organizations that are currently working intensively on the topic of SPE will have a large say in deciding which standard will apply to which application. Use cases are presented for the various fields of application that consider not only the individual components but the entire ecosystem. These also demonstrate how and when the popular slogan “From the sensor to the cloud” really takes effect. In order to make SPE technology widely available, it is vitally important that devices, cables, and connectors are compatible with one another.

Device manufacturers still face some challenges when it comes to transferring automotive Ethernet to industrial SPE applications, as the influence of electromagnetic interference is not as predictable as in an automobile and is often far more complex. Industrial Ethernet in its present form was developed over a long period of time. RJ45 connectors have been gradually optimized with regard to shielding concepts, extended temperature ranges, robustness, and integrated transmitters (magnetics) and adapted to the needs of industrial ambient conditions. SPE connectors from Phoenix Contact already offer many of these features. However, the precise requirements of the entire SPE infrastructure will continue to evolve.

SPE as one of many new technologies

There are more exciting things ahead. Further IEEE standards for SPE are expected in the years ahead, which are set to cover longer distances exceeding 100 m as well as data transmission up to 100 Mbps. The portfolio for connectors will also continue to grow over the next few years. As soon as the first innovators develop devices and launch them on the market, connectors for field assembly will also be needed for various cables as will other accessory items for control cabinet and field cabling.

The basic framework for the future of industrial communication technology is currently emerging. SPE is just one element of this, as new communication standards such as the Open Platform Communications Unified Architecture (OPC UA), Time-Sensitive Networking (TSN), and 5G form the basis for integrated networking from the sensor through the machine and higher-level systems to the cloud. As a leading technology company with more than 30 years of experience in industrial communication, Phoenix Contact is therefore actively involved in all of the key standardization committees. The goal: a new, cross-manufacturer communication standard for digital transformation. Together with other communication technologies such as 5G and TSN, SPE also forms the basis for the intelligent networking of the All Electric Society.

Dipl.-Ing. Verena Neuhaus, Product Marketing Data Connectors, Business Unit Field Device Connectors, Phoenix Contact GmbH & Co. KG

The SPE System Alliance – working together for the IIoT network

The initial technology partnership between Phoenix Contact, Weidmüller, Telegärtner, Reichle & De-Massari (R&M), and Fluke Networks for SPE has progressed to create the SPE System Alliance. Leading technology companies from various industries and fields of application have come together in order to bundle their SPE expertise and ensure the target-oriented exchange of this knowledge. Together, all SPE System Alliance partners are pursuing the goal of driving the development of SPE further forward for the Industrial Internet of Things (IIoT).

The network aims to collaborate on the technological challenges faced when implementing SPE in IIoT applications. The goal of the companies is to accelerate their own development of expertise in SPE technology and to allow it to be implemented faster and more reliably in their products.

Through this orientation toward a cross-industry and cross-application exchange platform, companies from all future SPE ecosystems are coming together. The focus is by no means on individual aspects such as connection technology. Instead, the focus is on taking a much more comprehensive approach to the issues and challenges for SPE faced by many market participants. Rule exchange formats and collaborative project activities provide the freedom for close cooperation.