TechnologyJanuary 20, 2022

The days of the control cabinet are numbered

A completely decentralized automation platform brings devices into the field without control cabinets. Vario-X combined with Digital twin technology saves time and money in all phases of an automation and control project: from planning to installation, operation and service.

Growing digitalization and shorter development cycles, increasing customer requirements and a shortage of skilled workers, the world of automation is changing at breakneck speed.

New technology is implementing a modular, highly flexible automation platform that allows all automation functions to be implemented completely decentrally (i.e. without a control cabinet).

Vario-X brings sensors and actuators directly into the control environment and ensures reliable voltage, signal, data management and the seamless integration of decentralized servo drives.

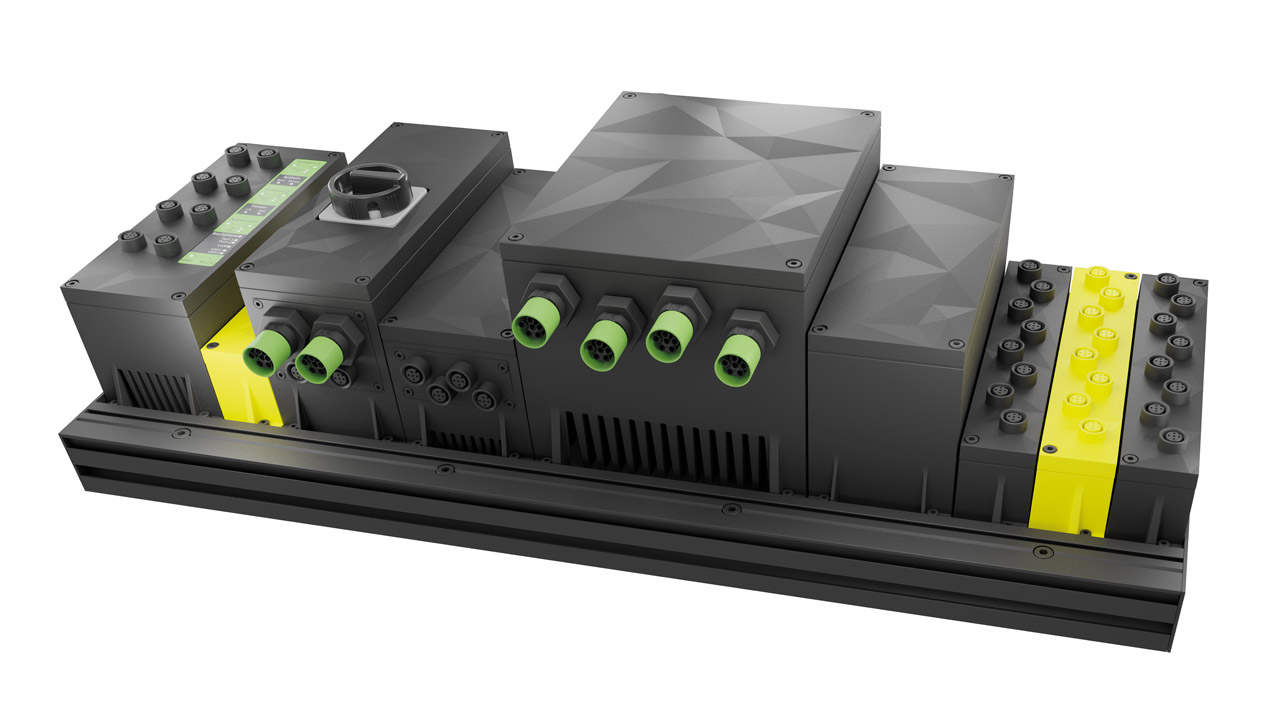

At the heart of Vario-X are robust, IP67 rated waterproof and dustproof modules, which include power supplies, controls, disconnect switches, safety technology and I/O connections. They can be easily assembled side by side on a rugged backplane with integrated mechanical mounting profiles.

Once assembled, the Vario-X solution can be easily attached to all common mounting systems without further protection and, in extreme cases, is rugged enough to be stepped on without damage. Equipped with a multicore CPU, Vario-X can meet all control requirements and be easily integrated into all higher-level Industrial Ethernet networks as an open control platform.

100% cabinet-free automation

The installation and cabling of devices is plug-and-play with standard M12 and MQ15 connectors, eliminating wiring errors and reducing assembly time. This also eliminates expensive and time-consuming installation work in the control cabinet like populating components, stripping and landing wires, labeling and grounding individual components.

To extend the modular concept for your machine control, additional stations can easily be distributed around the machine and connected to each other, like adding an additional power supply to support localized servo motors.

Likewise, remote IO modules can be connected directly to Vario-X to process and control sensors and actuators without a backplane or cabinet I/O. This limits control hardware variants and vastly streamlines the cable architecture.

Turning off the air in production

Vario-X is driving forward the electrification of manufacturing processes and offers a much more efficient alternative to pneumatics. With an efficiency of only ten to twenty percent, far too much energy is wasted by using compressed air as an energy source due to countless leaks in the system and inefficient actuators.

Replacing pneumatics with electrics, swapping an air cylinder with a servo motor, brings advantages to all those involved. This includes the engineer who can reduce the inefficient, low resolution and relatively expensive pneumatics in his machine, the production planner who can focus on one physical energy source – electricity, the employees who can finally operate in a noticeably quieter work environment and by reducing energy use to help our planet.

Digital twin for planning, installation, operation and service

Vario-X is not only a collection of backplanes, modules, cables and I/O. A system automated with Vario-X has a digital twin right from the start: a portable 1:1 image of the virtual system that contains all the functions and parameters of the physical system – even in the design phase, before even the first mechanical component has been ordered or assembled.

For this purpose, Murrelektronik creates a kinematic of machines and systems in unique software, where movements and processes can be simulated. With the digital twin, the same virtual kinematic is then run to control the real machine. The digital system can also be “placed” directly into the manufacturing process with augmented reality (AR) on a mobile phone or tablet, so that all movement sequences and functions can be viewed virtually while assembling the machine or in production.

“All this reduces the assembly and commissioning time many times over, because many problems that are discovered during assembly do not even occur,” Prein summarizes the advantages of the digital twin. In addition, assemblers can use the digital twin as a ‘3D blueprint’, for example via augmented reality app or virtual reality glasses. This often works much faster than understanding a plan drawn in 2D.

“With Vario-X, we are providing the answer to the pressing questions and challenges of production, plant and installation planning in automation technology,” concludes Prein. “Vario-X helps to avoid ‘silo-driven’ planning and to break up static planning processes. In addition to the agile development processes, this consistent focus on customer needs has made a decisive contribution to the development of Vario-X.”

Technology article by Murrelektronik GmbH