TechnologyNovember 16, 2025

Virtual testing, real results: digital twin adoption expanding

With digital transformation, demand has emerged to speed up the process from product planning to commercialization. But the labor time required for rework, on-site adjustment due to problems during equipment development and delays in decision-making make it difficult to visualize the effects of investment.

Imagine being able to test a complete production line 100 times, identify every potential bottleneck, and optimise all workflows without installing a single piece of physical equipment.

This isn’t science fiction; it’s a reality that’s transforming manufacturing across Europe. Forward-thinking enterprises are already eliminating costly trial-and-error cycles and dramatically reducing time-to-market for new production systems. How? Through the power of digital twin technology – a virtual revolution that’s quietly reshaping industrial processes.

The Manufacturing IT/OT Trend Report 2025 confirms this growing interest, indicating significant investment in digital twins across European manufacturing enterprises. Currently, 41 percent of organisations are in the pilot phase of implementation, while 20 percent report full integration and 15 percent use the technology in selected areas.

To understand what’s driving this trend and how manufacturers can benefit from digital twins, Simone Faruggio at Mitsubishi Electric Europe, provides his viewpoint on the future of virtual manufacturing.

What’s driving the shift to digital twins in manufacturing?

Simone Faruggio: Digital twins transform how we approach production planning. Traditionally, testing new setups meant physical trials and significant expense. With digital twins, manufacturers experiment virtually before committing resources.

The digital transformation trend has created demand to speed up processes from planning to commercialisation. Digital simulation tools allow verification before actual implementation, helping identify issues early when changes are less costly.

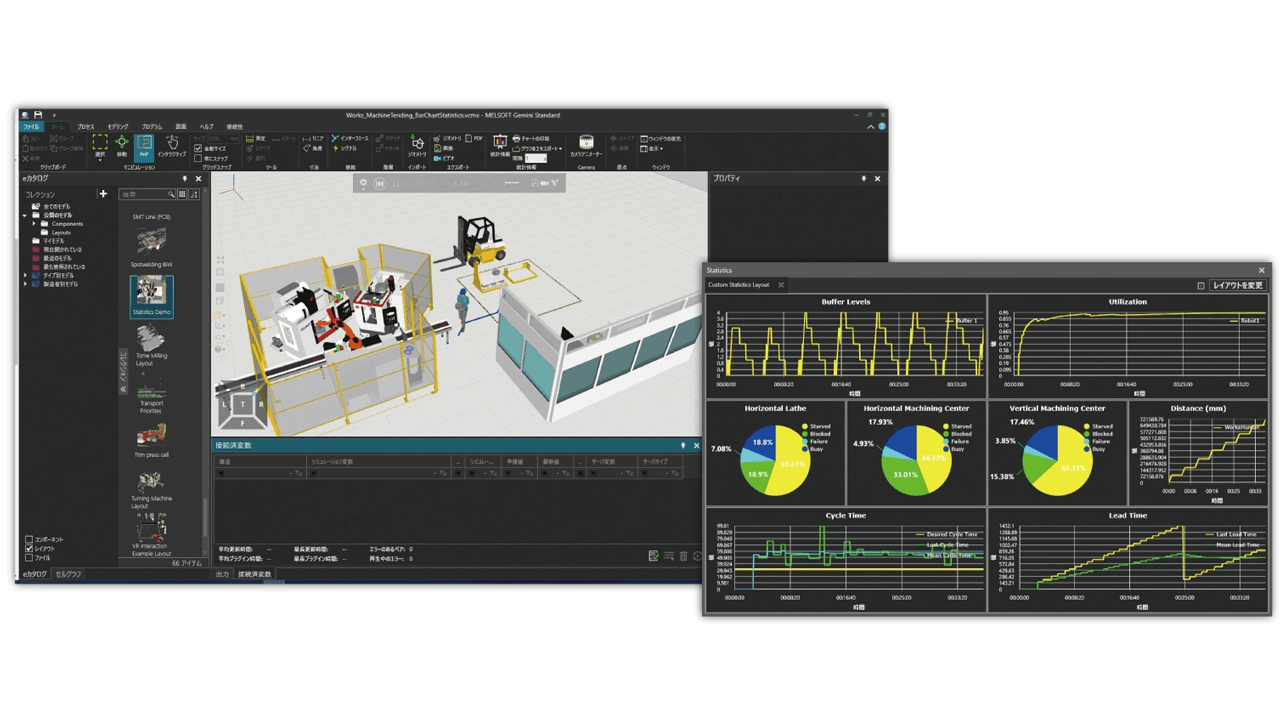

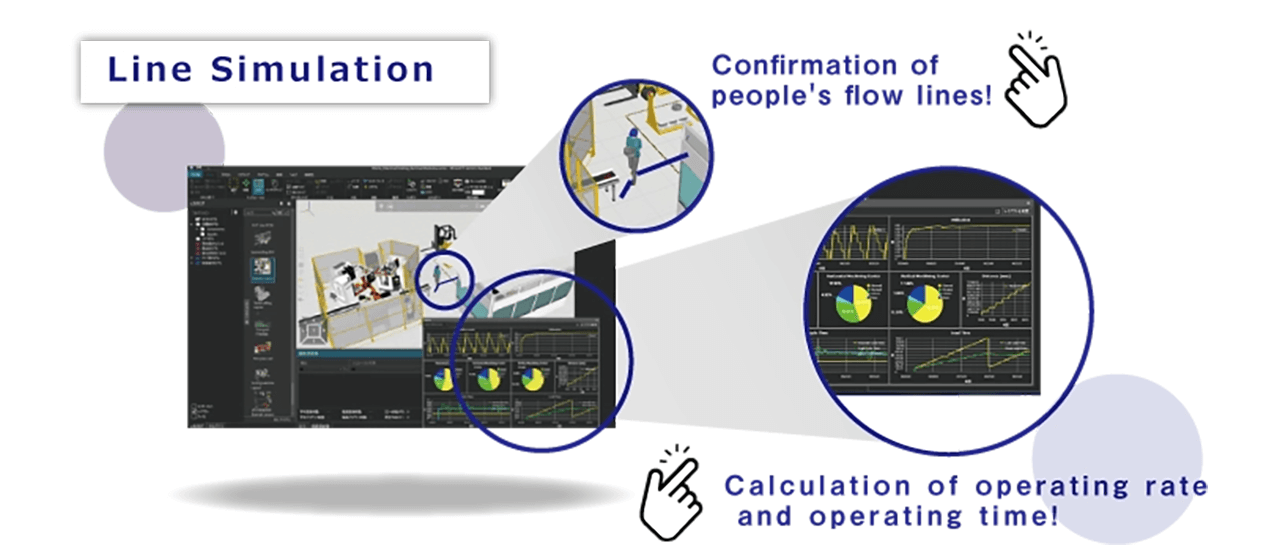

Line Simulation: Line simulation capabilities for people, robots, and Automated Guided Vehicles (AGVs). Innovative technology enables dynamic simulations of complex flow lines and operational scenarios with unparalleled accuracy and efficiency.

How have you seen digital twin technology evolve in recent years?

SF: Digital twins have evolved from simple 3D representations to sophisticated environments that model complex manufacturing processes and integrate with automation systems.

The key advancement has been making these tools accessible to non-specialists. In our work with MELSOFT Gemini 3D, we’ve seen how this democratization empowers more team members to contribute to simulations.

What’s critical is the integration with physical systems. A digital twin is only as good as its ability to accurately reflect the real world.

What specific challenges do European manufacturers face that digital twins can address?

SF: Let’s start with the changing workforce landscape, both rising costs and growing shortages, that requires optimizing automation and human collaboration, which digital twins enable through detailed simulations.

This optimization becomes crucial when dealing with supply chain disruptions. By creating virtual models of entire supply networks, we can help predict problems and develop more resilient systems, particularly important as customer expectations shift toward customization.

The demand for personalized products without increased costs pressures traditional methods. This technology allows efficient testing of customized processes virtually, while simultaneously addressing sustainability concerns through real-time simulation of energy usage and emissions. Ultimately, these capabilities give manufacturers the competitive edge they need through faster time-to-market. By front-loading development work in the virtual environment, this approach reduces commissioning time and helps manufacturers stay ahead in today’s changing markets.

Equipment Simulation: Solution for equipment simulations of mechanical interference in 3D space, seamless integration with control devices for advanced logic validation, and real-time reproduction of error occurrences in immersive 3D environments based on log data.

Could you walk us through the practical steps of implementing a digital twin?

SF: Implementation typically follows four stages: layout planning using 3D models; production flow planning to identify bottlenecks; virtual commissioning to verify programming logic; and ongoing monitoring after deployment This creates “front-loading” – shifting complex work to earlier project stages where changes are less costly. Control debugging can happen simultaneously with mechanical construction, reducing project timelines.

What kind of return on investment can manufacturers expect?

SF: At our Nagoya Works facility, we used digital twin technology to optimise an assembly line with five work stations. By simulating improvement scenarios, we identified that adding one work station and implementing an intermediate work-in-process stand would improve efficiency. After implementation, the cycle time dropped from 128 to 92 minutes per unit – a 30% improvement.

Another example is an equipment manufacturer who used digital twins for front-loading development. They reduced construction time from 40 to 34 weeks, generating an additional 288,000 euros from earlier production with a payback period of just five days.

The ROI typically comes from reduced commissioning time, decreased downtime, and optimised resource utilisation.

How does AI integrate with digital twins in modern manufacturing?

SF: In “cognitive closed-loop manufacturing,” AI agents in digital twins provide predictive support by analyzing equipment data, automatically triggering diagnostics when anomalies emerge.

AI-enhanced digital twins also optimize production workflows dynamically and simulate component-level failures, allowing manufacturers to spot wear patterns at a granular level. This shifts maintenance from reactive to strategic.

Could you explain how the virtual and physical worlds actually connect and work together?

SF: Robotic systems exemplify this connection. In our experience, MELFA robots create powerful synergy with simulation environments.

We first simulate robot placement and movements, determining optimal positioning and verifying range of motion before physical implementation. The teaching and collision checking can be completed virtually.

What’s powerful is the automatic knowledge transfer. After teaching work in the simulation environment, the software generates robot programming with precise coordinates for the physical robot.

In one application, by performing carrier transfer in parallel with robot operation, we reduced cycle time by 30 seconds – from 1 minute and 20 seconds to 50 seconds. This optimization would have been difficult to discover without digital twins

Where are the most successful implementations of digital twins?

SF: It’s difficult to point to specific industries that benefit more than others from digital twin technology. The potential applications and benefits are remarkably universal across all manufacturing sectors.

In food and beverage operations, digital twins help ensure processes are efficient and compliant with safety regulations. In environments where robots, AGVs, and human workers interact, they help optimize workflows by identifying bottlenecks. Another application is real-time simulation of carbon emissions, giving manufacturers visibility into environmental impact.

The fundamental principles of digital twins—virtual testing, simulation, and optimization—translate across completely different manufacturing contexts, with core benefits of reduced downtime, faster commissioning, and optimized performance.

Is this technology accessible to smaller manufacturers?

SF: Historically, digital twins were primarily used by large enterprises with substantial IT budgets, but that’s changing rapidly through modular software options and cloud-based solutions that reduce the need for expensive on-premises hardware.

Digital twins help smaller manufacturers where creating unique products or tailoring processes to specific client needs is a value differentiator, enabling them to run simulations on complex products and opening opportunities for customization.

How will digital twin technology evolve over the next five years?

SF: Digital twins will become more autonomous and predictive, suggesting optimisations based on AI analysis. We’ll see greater integration across entire supply chains, with next-generation digital twins simulating complete supply ecosystems.

Sustainability will become central to digital twin applications, optimising energy usage and minimising environmental impact. This is already expanding beyond manufacturing to other sectors. For example, digital twins are emerging as a powerful tool for Europe’s energy infrastructure, enabling improved monitoring and decision-making across the lifecycle of grid assets.

Finally, user experience will improve through virtual and augmented reality interfaces that allow engineers to walk through virtual factories and interact with equipment using natural gestures.