ApplicationsJanuary 9, 2020

Enabling IIoT connectivity for virtual power plants

Leveraging IIoT connectivity for virtual power plants requires high data speeds and quick response times. In this ecosystem, a key to the stability of the system is zero network downtime. 4G-LTE and now 5G technologies are helping build stable networks, so that they can connect to remote sites and assets.

Declarations of climate emergencies in many countries around the world have created awareness for the need to switch to clean energy sources, which in turn has prompted the power industry and governments to take action or set definite goals.

Many governments around the world now provide incentives to individuals, industries, and communities who are interested in generating and using power from renewable energy sources such as solar and wind energy. The power grid has seen many changes that have enabled the integration of power from distributed energy sources (DERs).

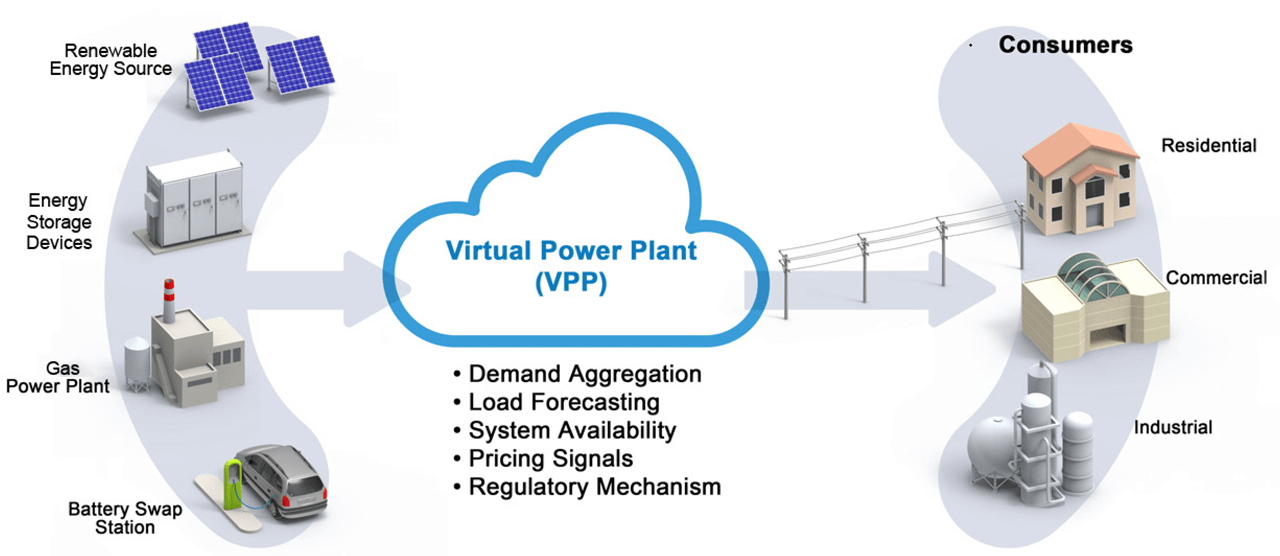

In the new power economy that is emerging, virtual power plants (VPPs) are showing the way by making it possible to aggregate power from different DERs and providing an efficient platform for energy trading.

Catalyzed by these developments, a new “prosumer” class is emerging that consists of consumers who not only consume power from the grid but also produce their own green power and might have excess power to sell. In this article, we discuss the challenges faced by the introduction of virtual power plants and how IIoT connectivity can help them overcome these challenges.

The idea of virtual power plants sounds very encouraging. However, deploying the devices and technologies that are required by a virtual power plant is an uphill task. Even if the technology is in place, a change in the mindset of the stakeholders is required to make virtual power plants work.

Predictable power

A virtual power plant (VPP) works remotely to combine a number of independent energy resources from disparate locations into a network that provides reliable power 24 hours a day. VPPs are a departure from the traditional power plants in that they do not solely rely on a centralized power source. Unlike the traditional ones, they combine a number of distributed renewable energy resources with traditional energy.

Aggregating power from different energy resources can help meet the spike in energy consumption during peaks; the utility company does not need to build additional power plants, which is neither efficient nor economical, to achieve demand-supply balance.

Software-based technologies are being deployed to plan, schedule, monitor, and bid for distributed energy resources to make the power grid more reliable. In many geographies, this has translated to infrastructure and process improvements that have facilitated the integration of distributed energy resources (DER) into the main grid. Another goal of virtual power plants is to make it easy for producers to use clean energy portfolios comprising of grid-scale and behind-the-meter renewable energy resources.

Challenges in virtual power plants

A community of solar energy “prosumers” (consumers and producers of a product) can use the infrastructure provided by the grid to trade excess energy with each other or sell the excess energy back to the grid.

The idea of virtual power plants that are able to solve all power issues of the future sounds very encouraging. However, deploying the devices and technologies that are required by a virtual power plant is an uphill task. Even if the technology is in place, a change in the mindset of the stakeholders is required to make virtual power plants work. Some of the challenges faced by operators are discussed below.

Integrating Distributed Energy Resources (DERs) Into the Grid: Integrating power generated from distributed energy resources into a grid is easier said than done. High penetrations of DERs in the grid can introduce a variety of detrimental conditions, including voltage swings, and reverse power flow, which can cause grid instability.

Most grids have to be retrofitted to be able to integrate power from DERs, increase hosting capacity, and optimize power from DERs. Consumers also need a convenient way to buy power from DER aggregators at an economical price.

Controlling and monitoring devices at the grid edge, especially those associated with DERs, is a major issue. Traditional substation have relied on centralized utility technologies and systems like power supervisory control and data acquisition (PSCADA), energy management systems (EMS) and distribution management systems (DMS). However as DERs have proliferated at the edge of the grid, the requirements for visibility and control of these resources have surpassed the capabilities of traditional centralized systems.

VPPs need the capability to collect and process data from the edge so that the operators know what to expect. Edge devices, such as invertors, need to be monitored for better integration of the system and to prevent grid instability. The ideal percentage of DERs in the total composition of energy sources, including traditional sources, is about 20%.

However, operators are finding it more economical to use power from renewable energy resources because of the increase in demand for green power and a steady supply from producer-consumers.

Virtual power plants require seamless communication solutions to maintain the stability of the grid: northbound communication to acquire data from power devices such as inverters and southbound communication to monitor and control the devices. IIoT gateways, with their computing power and integrated communication interfaces, can help provide the platform for seamless data acquisition and processing. Data acquired from inverters, meters, transformers, and other edge devices can be sent to a DER management system to maintain the grid in a stable state and meet the energy requirements of customers.

Estimating the Power From Renewable Energy Sources: A key factor in the success of the virtual power plant model is the ability to estimate the power from renewable energy resources that is required to meet the requirements of consumers. In addition, some countries have regulations requiring suppliers, such as solar farm operators, to provide power output forecasts for at least three days in advance to ensure demand-response balance and stability of the grid. Most operators do not have a way to gain insight into the power supply. To be able to correctly estimate the power generated, data from aggregators as well as utilities need to be combined together to get the whole demand-supply picture.

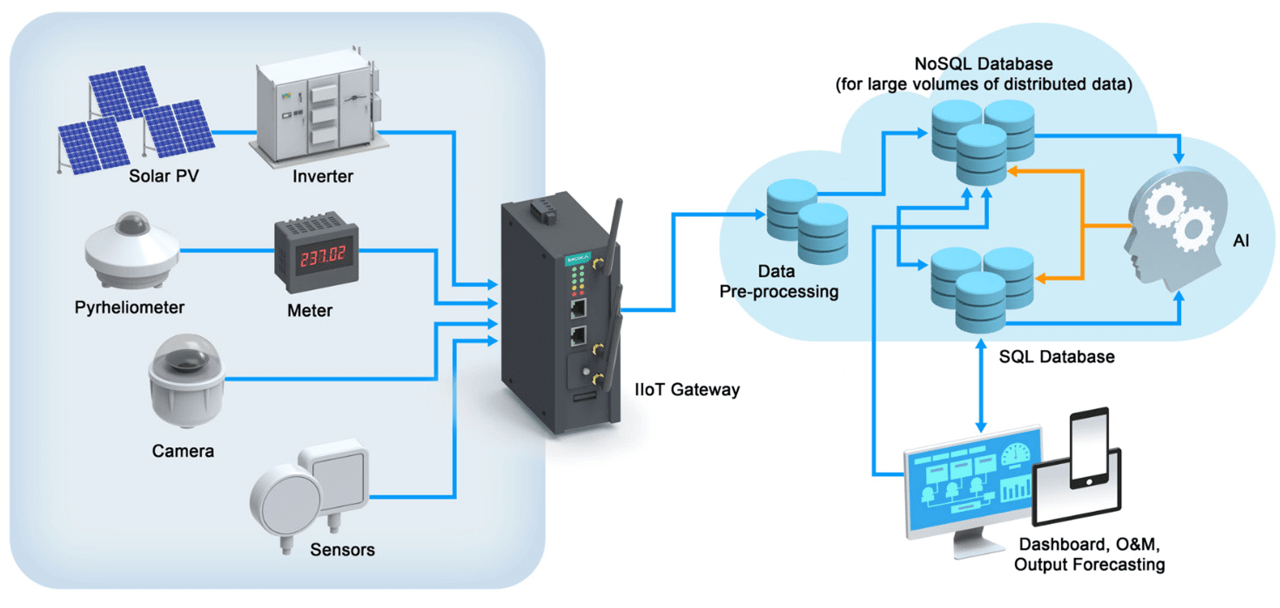

Being able to provide power output forecasts is dependent on the ability to acquire multiple weather parameter values (e.g., ambient temperature, relative humidity, and wind speed), data on the wear and tear of equipment in the field, and conversion efficiency of inverters, among other things. But, solar farms are usually spread over a large area and distributed over different locations. Each farm could return around 20 KB to 50 KB of data per minute. Existing systems may not be able to deal with the large amount of real-time data that needs to be processed and hence the response time may be slow. Other problems that the operators have to deal with include data integrity, data loss, and data security.

A solution consisting for an IIoT gateway and remote I/Os can be used to securely acquire data from various edge devices, such as PVs, located in remote and harsh environments. Solar farm operators can instantly access huge volumes of data from inverters and weather monitoring devices, and use AI technology to accurately forecast the amount of power that is required from renewable energy resources to be able to sufficiently meet the energy requirements of consumers.

Being able to provide power output forecasts is dependent on the ability to acquire multiple weather parameter values (e.g., ambient temperature, relative humidity, and wind speed), data on the wear and tear of equipment in the field, and conversion efficiency of inverters, among other things.

Demand-response programs

Energy aggregation is a good way to connect energy producers to the grid so that the excess energy produced can be sold back to the grid. This model helps maintain the demand-supply balance. To prevent wastage, the excess energy produce can be stored in batteries and only released to the grid when required, for example, during peak consumption.

Another way of conserving energy is to shift or eliminate the peaks in energy consumption through demand-response programs, especially in heavy-load applications. For example, significant peak shifts can be achieved if there is a way to bundle industrial consumers together so that they can shift or optimize their power usage periods during the day to avoid peaks in energy consumption.

Demand response (DR) can be defined as the incentive payment received by consumers (or demand aggregators) to reduce their electricity consumption during high energy rates and increasing the electricity consumption at times of low energy rates. However, one needs to be cautious and avoid disrupting critical industrial processes.

Monitoring power consumption is key to maintaining the demand-supply balance. In order to provide an efficient platform for energy trading, virtual power plants require advanced metering solutions. IIoT gateways, with their built-in communication and computing capabilities and multiple interfaces, can enable advanced metering solutions in virtual power plants, thereby maintaining demand-supply equilibrium.

Self-sufficient energy communities

Although the idea of creating a virtual network of power resources that is equivalent to the capacity of a power plant is still in the works, there are several examples of communities that have adopted the virtual power plant model to become self-sufficient in energy. For example, a community of solar energy “prosumers” (consumers and producers of a product) can use the infrastructure provided by the grid to trade excess energy with each other or sell the excess energy back to the grid.

A solar panel manufacturer could be part of this arrangement such that the manufacturer installs solar panels free of cost in each household and in return the householders agree to buy the solar energy generated for a nominal price.

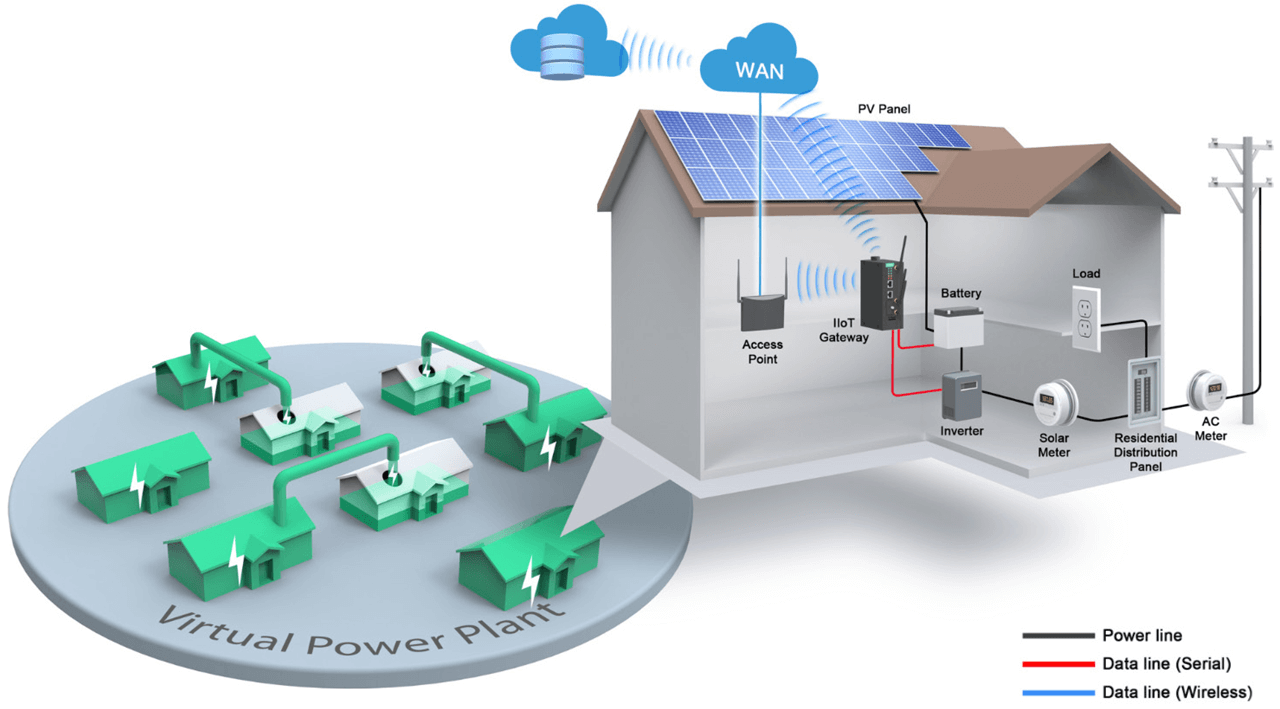

For this business model to work, a reliable network is important to ensure that the solar energy company can monitor the end users energy consumption in real time to ensure accurate data billing.

Furthermore, the solar energy company needs a way to monitor and balance demand against supply through flexible pricing and other options. IIoT gateways installed in the solar energy system can play an important role in acquiring energy production and consumption data from batteries and inverters via Modbus communication, and then transmit the data to a Cloud with a ready-to-run data acquisition platform via wireless networks. IIoT gateways enable the solar energy company to retrieve data related to solar energy storage and consumption, in real time, from sites spread over a large geographical area.

In order to prevent loss of data, the IIoT gateways need to have a failover mechanism whereby the network communication will switch automatically to the secondary transmission method (cellular) if the primary transmission method (Wi-Fi) fails.

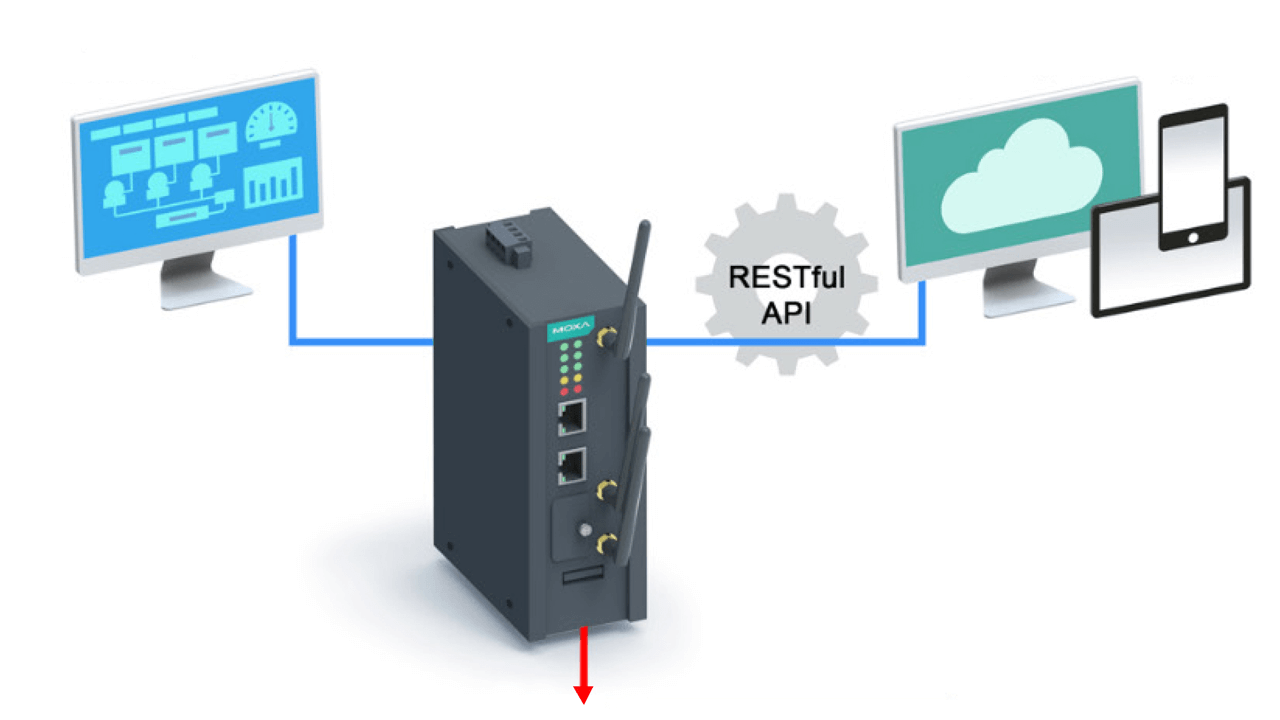

When a failure occurs, the solar energy company can fix and update the Wi-Fi settings remotely via their self-developed maintenance applications that use RESTful APIs, which means operators can do all of the maintenance via their mobile devices. If this model works well, the community can be self-sufficient in energy and reduce their dependency on the power grid for their energy needs.

Leveraging IIoT Connectivity

High data speeds and quick response times are very essential in any modern production facility. This is true for virtual power plants and the ecosystem that consumes and supplies power.

In this complex ecosystem where the roles of producers and consumers are often interchanged, a key to maintaining the stability of the system is zero network downtime. 4G, LTE and now 5G technologies are helping build stable networks for virtual power plants so that they can connect to remote sites and assets. On the other hand, cloud connectivity is enabling the use of cloud-based energy management systems for better management of resources and maintenance of demand-supply balance. In addition to instrumentation, virtual power plants are highly dependent on computing and communication technology to facilitate smooth procurement of power from DERs and integrate it into the main grid without endangering the stability of the grid.

In order to acquire large volumes of data in real time and send this data to the cloud for processing and storage, reliable northbound and southbound communication is critical. IIoT gateways are industrial-grade computers that provide reliable data acquisition and computing capabilities at low power consumption, without maintenance complexities, and with the capability to reliably perform at a temperature range of -40 to 70°C in harsh environment.

Remote I/Os make it easy to acquire data from edge devices, such as sensors, for further analysis.