ApplicationsJanuary 20, 2022

AI algorithms simplify complex robot applications

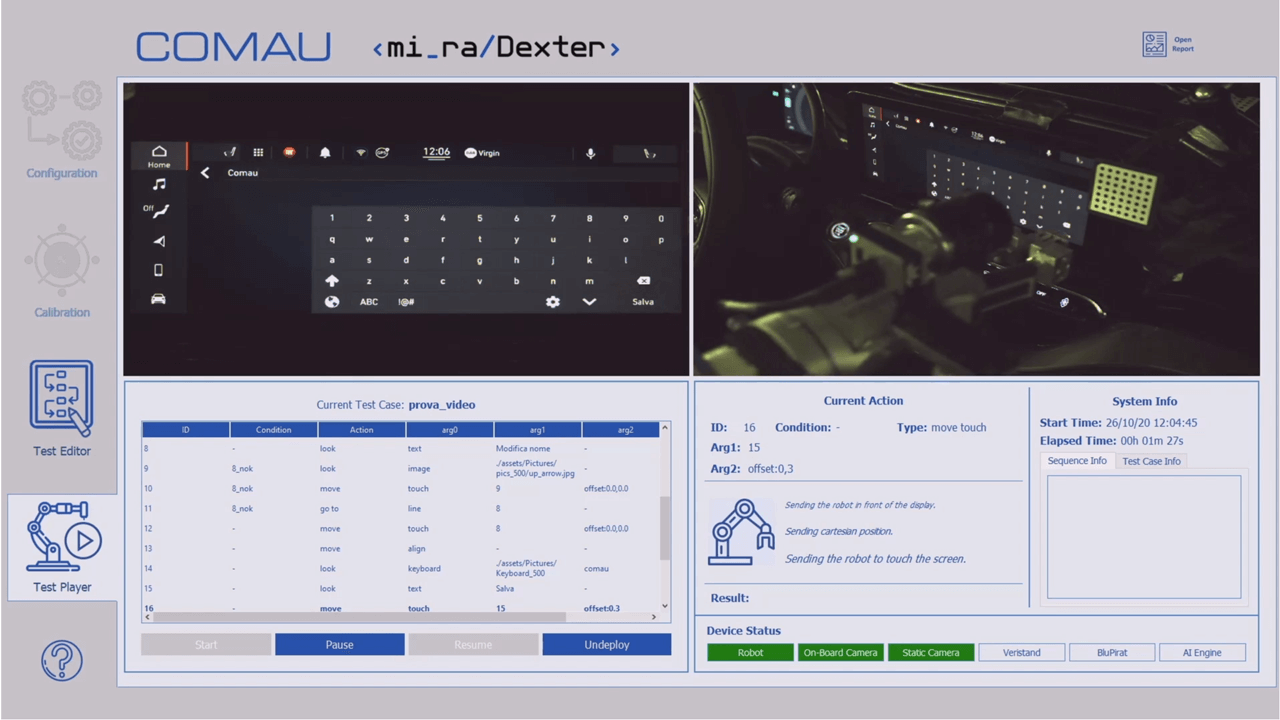

AI-based software facilitates man-machine collaboration using the MI.RA / Dexter software and Racer-5 COBOT to automate and simplify quality control for the infotainment system in the all-electric New Fiat 500. This is usually a lengthy, repetitive and manually executed processes with high costs and error rate.

Thanks to metalanguage-based AI algorithms, MI.RA / Dexter software optimizes the interaction between operators and robot systems. Unlike conventional computer languages, the software can be used without special IT or programming knowledge. By simplifying the programming of robotic applications, it also lowers costs and streamlines deployment.

Software based on AI algorithms

MI.RA / Dexter is a a powerful software program based on AI algorithms that simplifies human-machine interaction and at the same time optimizes industrial processes. In keeping with Comau’s commitment to simplified automation, MI.RA / Dexter is a metalanguage that makes robotics easier for companies of all sizes by translating human language syntax into robot syntax. This allows operators to program a robot system using simple and intuitive controls, such as looking at an object, touch a certain point in space, listen to speech recognition processes and reproduce and carry out complex courses of action. The programming interface enables the operator to optimize workflow efficiency.

Programming interface enables operators to adjust and correct the actions of the robot in real-time.

Since it can be used without any special IT or robotics qualifications, customers can reduce or eliminate dedicated programming costs. It streamlines creation of complex programs required to interact with robotic arms and can be used to program any industrial technology in a smart and straightforward way.

“Thanks to the user-friendly interface and metalinguistic syntax of the software, MI.RA / Dexter makes complex technology more accessible and affordable,” said Giovanni Di Stefano, Comau’s chief innovation officer. “The intuitive system, which is based on AI algorithms and can be used in practically every industrial sector, also allows real-time adjustment of the process parameters for more operational quality and efficiency.”

MI.RA / Dexter was recently used by quality controllers to program a complex robotic cell for the all-electric New Fiat 500. The customer commissioned Comau to automate the testing and control process for the vehicle’s infotainment system. These are usually lengthy, repetitive and manually executed processes with high costs and a significant error rate.

Comau’s solution combined an NJ-220 robot in its safe version with a Racer-5 COBOT, mounted on its wrist, to carry out automated testing processes inside the vehicle, which increases the efficiency, traceability and repeatability of the process. The collaborative system also helps ensure full compliance with the test process by objectively assisting the operator in completing each assigned task. For this purpose, the system has devices that have a “quasi-human” sensitivity, such as a vision system for validating infotainment apps, a microphone and a loudspeaker for recognizing voice commands and a gripper for sensitive contact work. The inherent safety features of the 6-axis articulated arm cobot eliminate the need for protective barriers, reducing both overall floor space and safety costs.

The MI.RA / Dexter programming language enabled the operators to manage the complex robot system autonomously. Activities included the safety management of the activities that the collaborative robot had to perform in close contact with the operator, as well as the automation and subsequent optimization of the required test tasks. It is part of the Comau MI.RA (Machine Inspection Recognition Archetypes) family, which also includes other digital tools and high-tech vision systems developed for the smart factory.