ApplicationsSeptember 10, 2018

IP router simplifies installation of gas-fired turbine systems

FlexEnergy used IP router technology that simplified both the machine installation and commissioning, along with the Ethernet network configuration within the control system for its gas turbine systems. The solution enabled technicians to have dependable external access to the devices without IP address conflicts.

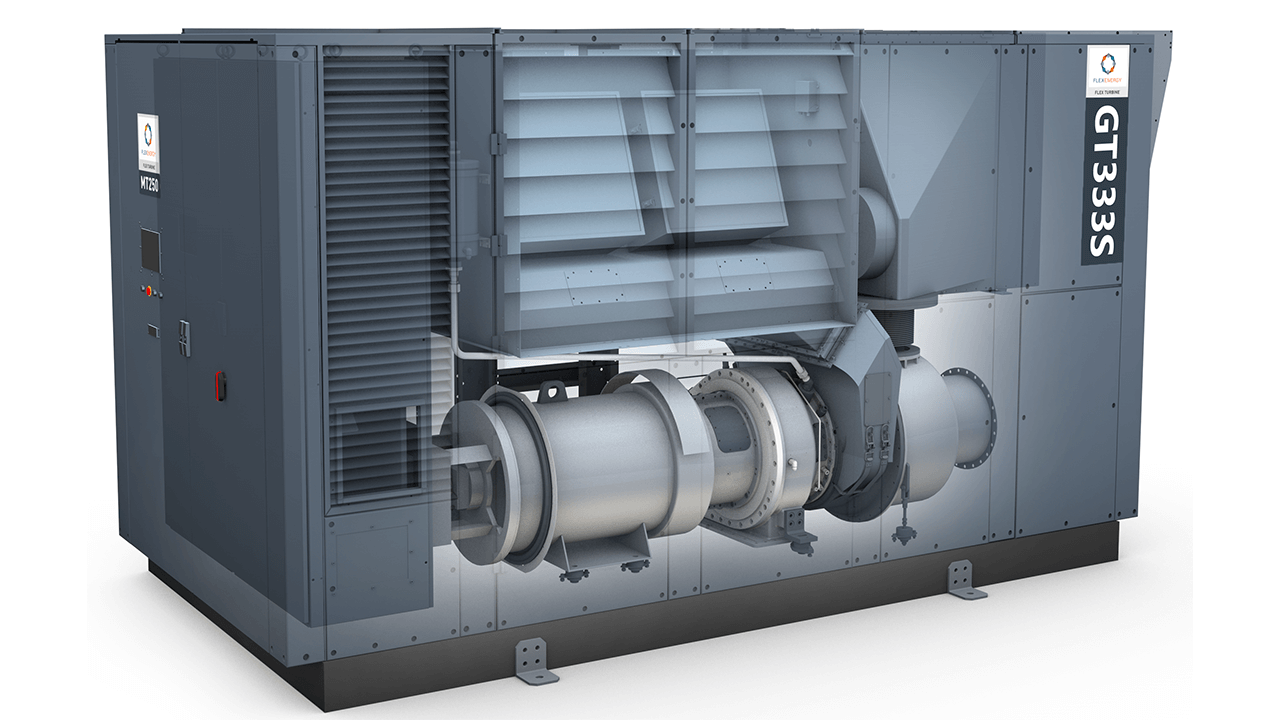

IP routers were used by FlexEnergy to simplify the machine installation and network configuration of their GT333 gas turbine system. The project required a method that would simplify the Ethernet network within the control system allowing technicians to have dependable external access to the devices without IP address conflicts.

Small gas turbine

FlexEnergy engineers and builds robust small gas turbine products. The GT333 consists of a 480V AC high-voltage panel where the generator is located and a 120V AC and 24V DC low-voltage panel for the controls.

“During development of the GT333, we were looking for a method to simplify the Ethernet network within our control system. We had two goals in mind, one goal was to create a ‘cookie-cutter’ setup of all the devices within the machine to make the configuration of all machines the same, thus simplifying configuration management and service training,” said Adam Mitchneck, controls engineer at FlexEnergy.

“The other goal was to have only one IP address for external access to all devices within the machine, thus simplifying network configuration on customer sites. While searching for a method to achieve our goals we happened upon Contemporary Controls and their Skorpion IP routers.”

The IP router keeps multicast and broadcast traffic separated from the LAN or WAN network. The scheme can be easily applied for integrating any IP device network irrespective of the IP traffic or the industry type. Routers are DIN-Rail mounted, have a robust metal enclosure, UL approved, and operate on 24V AC/DC which makes for an easy addition into a control panel.

Control system architecture

The GT333 control panel consists of a PLC, a HMI, an embedded PC and an inverter that form an internal network that is connected to the LAN side of the IP router with a built-in 4-port switch. For sites requiring additional IP equipment on the internal network, a 5-port EISK5-100T switch was used for expansion.

The available Ethernet ports can also be used by the customer to add additional devices to the network if required. Using the Port Forwarding feature of the IP router, the different IP ports from the external WAN IP address were mapped to different internal LAN devices in the control panel.

This setup was then easily uploaded to multiple routers for use in different turbines allowing for the same configuration to be used across all the devices. This helped speed up the testing of the turbine while being built at the factory and the installation at the site by just requiring the WAN IP address to be configured. No other IP settings for the devices or the applications needed to be modified at the install site.

The setup allowed FlexEnergy to have direct access to the PLC through the router, allowing for the programming or monitoring of the PLC. The HMI could also be accessed through the router as well as the inverter. The inverter could be enabled or disabled along with the ability to monitor the battery status. The embedded PC ran some proprietary applications but again, it could be easily accessed from the WAN side by a remote desktop application. All the tools could be run locally on the embedded PC without adding extra traffic to the customer’s network.

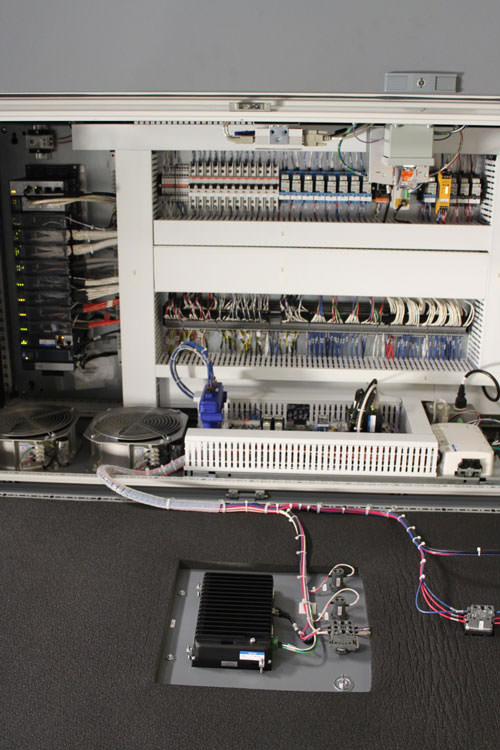

Control panel inside turbine

Skorpion IP routers consist of the EIPR family supporting 10/100 Mbps links while the EIGR-E adds support for Gigabit links and a higher throughput. A built-in firewall prevents direct unauthorized access to the LAN side devices from the WAN side. But the routers provide features such as Port Forwarding, Port Range Forwarding and NAT that allow for WAN to LAN access.

The WAN port can be configured for a static IP address or can be assigned a DHCP address via the built-in DHCP client for greater flexibility in integrating quickly to the customer’s network. The IP router also keeps the multicast and broadcast traffic separated to the LAN or WAN network, keeping the IP devices running smoothly without having to deal with unnecessary traffic filtering. The scheme can be easily applied for integrating any IP device network irrespective of the IP traffic or the industry type. The routers are DIN-Rail mounted, have a robust metal enclosure, UL approved, and operate on 24V AC/DC which makes for an easy addition in a control panel.

“Initially, we were using the EIPR-E router to simplify our machine’s setup,” Mitchneck said. “With fixed IP address for every device, our service technicians can quickly locate the device they wish to communicate with regardless of the customer’s site. We have since upgraded to the new EIGR-E gigabit Ethernet router for its higher throughput and support of 1000T communication.

Transition from the EIPR-E to the EIGR-E was smooth and painless as the two routers have a similar setup and footprint. We have been very pleased with the performance and reliability of the EIGR-E router. It has enabled our customers to collect more data at faster rates for application requiring higher throughput.”