ApplicationsMay 27, 2019

Mobile configuration of field devices in process industry

Digital, mobile, networked and standardized solutions are providing new connectivity for process control users to communicate via HART, FOUNDATION Fieldbus and Profibus PA. The result is that machine and field device data is more available to improve and rationalize processes for configuration and troubleshooting.

Intelligent field devices in modern process industry plants including temperature sensors, pressure, level and flow meters can provide plant operators with well-founded findings on the plant status. The information gathered by management systems, such as diagnostic data, general information relating to the device status and specific device parameters, help when planning predictive maintenance.

In this way, they contribute to avoiding unplanned downtime, reducing failure times and lowering maintenance costs. In order for plant operators to be able to use this potential for process optimization and cost savings, all installed field devices must be configured and implemented properly and monitored during continuous operations.

Intelligent field devices

Intelligent field devices offer innumerable configurable parameters. A radar level sensor, for instance, normally has more than 500 parameters which can be configured. Added to this, field devices with different protocols are used in typical process industry installations and explosion-proof areas.

The most common protocols are HART, FOUNDATION Fieldbus and Profibus PA. It is not unheard of for process plants to use several hundred or even more than a thousand field devices by different manufacturers, which have different protocols. The different device manufacturers normally also provide different interfaces to device configuration. This increases investment costs and makes data collection and analysis unnecessarily complicated and inefficient.

Initially, it seemed impossible to maintain an overview of the many different technologies and handle the many tasks required. Different organizations and institutions identified the need for standardization early on and developed integration technologies and data provision technologies which are based on open, protocol- and manufacturer-independent architectures and offer seamless interoperability and flexibility during integration. But a generally applicable solution could not be agreed upon. Currently, end users have a choice of the following integration technologies which use different approaches:

- EDD (Electronical Device Descriptions): text device description file

- FDT/DTM (Field Device Tool, Device Type Manager): device driver with integrated user interface

- FDI (Field Device Integration): combination of FDT and EDD

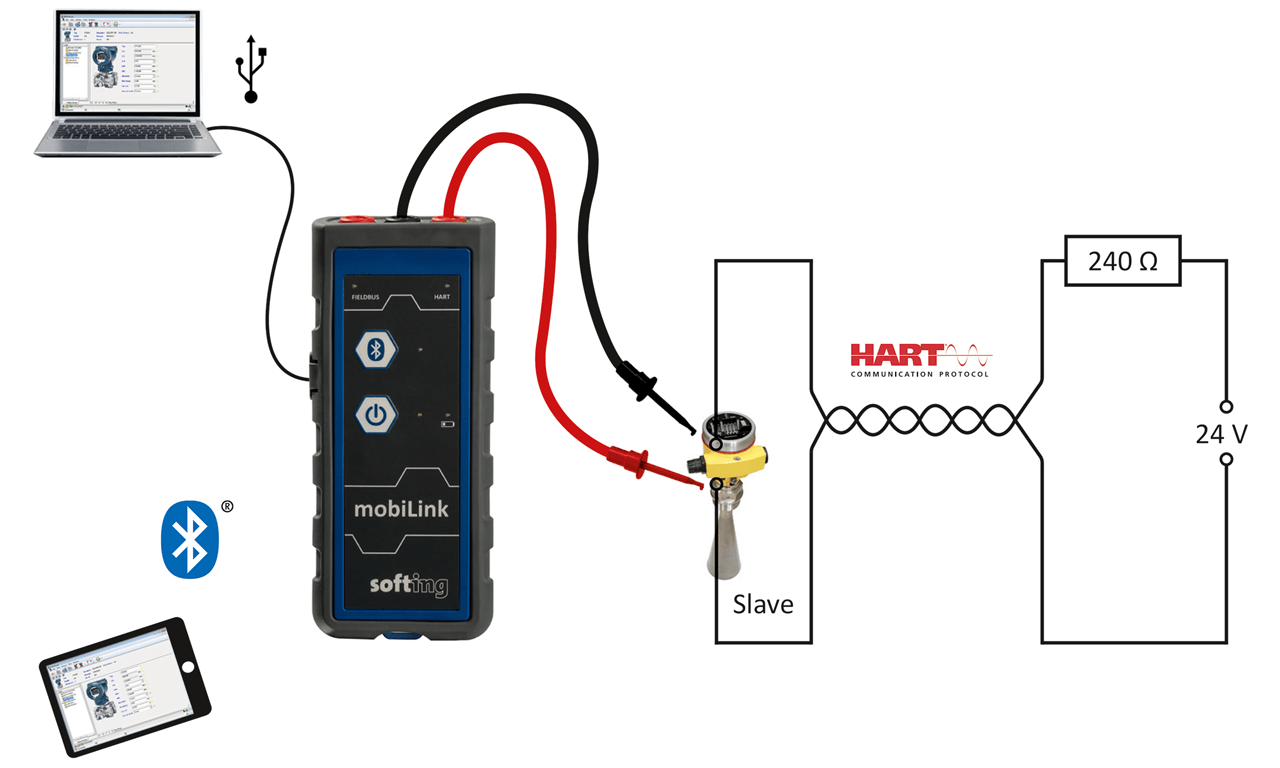

The link to the mobile end device can be accomplished using either USB or Bluetooth communications to aid simplified troubleshooting and maintenance.

Mobile enterprise solutions

Digital, mobile, networked and standardized solutions are needed, which make plant, machine and field device data available easily and which improve and rationalize maintenance processes for device configuration, implementation and troubleshooting.

This is where tablet-based asset management tools are ideal, which enable maintenance personnel to manage the entire field device lifecycle on site and configure devices using standardized integration technologies. By linking up the tablets with the whole system, the data are available anytime, anywhere. Such complete solutions are supplemented by interfaces which enable mobile access to field devices via the corresponding integration technologies and protocols on site.

Field devices are replaced before they break as part of the predictive maintenance strategy. But before maintenance personnel visit the plant, the replacement device is preconfigured on the workbench. The networked tablet is also used here in conjunction with the interface in order to enable a fast, simple device replacement with the lowest possible downtime. The devices can also be configured offline in advance without the need for the device to be physically present. Parameters are saved in the application based on the description files for the integration technologies, and these are loaded when the device is implemented, which saves time and effort.

An interconnected, compatible solution portfolio of tablet, mobile interfaces and professional applications enables technicians on site to monitor and control processes in detail, contributes to more flexibility and helps to increase employee productivity. With mobile solutions, information on assets across the entire process chain is permanently available in real time. People, processes and systems are thus networked as required for Industry 4.0.

Flexible configuration interface

The unit provides access to three important communication protocols in process automation.

Interfaces between mobile end devices such as tablets or smartphones and field devices have highly specific requirements. Depending on the use case and end device used, the interface should be compatible with different technologies. Often, however, the interfaces available only cover a defined requirement and cannot be used flexibly for different use scenarios in often complex plants. Maintenance staff is frequently forced to use several different interfaces in order to perform the varied tasks at the plant.

Softing offers users looking for a multi-protocol solution its mobile interface “mobiLink”. mobiLink provides access to the three most important communication protocols in process automation – HART, FOUNDATION Fieldbus and Profibus PA via a single interface. The link to the mobile end device can be via USB or Bluetooth, with the device being compatible with Windows, Android and iOS operating systems. The scope of delivery includes drivers to connect field devices via FDT/DTM and FDI technology. The additionally included DevComDroid app by ProComSol, a provider of communication solutions for the HART market headquartered in the USA, even makes it possible to easily and intuitively configure field devices via EDD.

The mobiLink technology scans the bus automatically, reports the devices found including device status and underlying device parameters and opens the right device description file. From there, the user can intuitively navigate to the device detail, such as diagnostics, state monitoring, parameterization and configuration.

Users which require interfaces for several protocols save costs when using mobiLink, because they only need one interface. In addition, the use of only one interface results in a significant work reduction when implementing and maintaining field devices. The ATEX-certified mobiLink is suitable for use in potentially explosive atmospheres due to its explosion risk approval for Zone 1, its robust design and the option to connect to intrinsically safe circuits.