ApplicationsJuly 25, 2022

Secure and smart: Edge computing with SCALANCE LPE

Data is a treasure for every company; the question is how to lift this treasure safely and efficiently? For ROBUR Automation, an industry and application-suitable data preprocessing is key. For this task, ROBUR relies on a local processing engine to provide a new parking experience in the German city of Miltenberg.

Andreas Kuhn, Head of Process Automation at ROBUR Automation, got the idea of evaluating data with a Scalance LPE platform while he was having a conversation with a user from the industry: “We chatted about a storage solution for process data and detected that in this case we record around five terabyte of data per year and facility.” Recording data is only the first step, said Kuhn. Much more important is to use and process the data to gain information that leads to decisions.

“From my point of view, there is no way around this kind of OT/IT integration, which makes it necessary to capture data close to the process, prepare, and condense it. But the big question is how to implement this in the process. There are often concerns with regard to a direct link to a cloud solution – especially because many of our users operate in the critical infrastructure. Therefore, we searched for an industry conform platform, with which we can safely implement the OT/IT integration,” he added.

Compact, integrated, and secure

ROBUR Automation was one of the first users of the Scalance LPE local processing platform. Since then, they are convinced of the possibilities this component offers. The abbreviation in Scalance LPE stands for “Local Processing Engine”, and that is exactly the task of this component in the industry-proven design of Simatic S7-1500. It collects data directly at the process, prepares it, and makes it available to other systems, e.g., for predictive maintenance or to detect anomalies in communication networks. The operating system of the platform is based on Linux.

Therefore, users can develop new applications or use Docker© applications. “From my perspective, this device fits in nicely with the idea of Edge computing – as part of the network, Scalance LPE acts as mediator for OT/IT applications within OT, meaning it is right at the edge of networks. For us, the Scalance LPE platform is perfect: not too big, not too small”, Kuhn said.

As of late, there are no more barriers at entrances to parking areas and garages.

From the idea to the application

One of the first users for data processing with Scalance LPE was EMB-Energieversorgung Miltenberg-Bürgstadt GmbH & Co. KG, a German power supplier, for whom ROBUR Automation just recently implemented a solution for parking space management. “The project was triggered by the desire to replace the maintenance intensive access control with barriers at our parking areas and garages with a system that detects parking occupancy and duration by capturing the license plates of the vehicles”, as Michael Frank, working for EMB in the Electrical Engineering Department, explained.

Additionally, EMB teamed up with a start-up, which uses camera data to identify the license plates of incoming and outgoing vehicles via an artificial intelligence algorithm. The driver simply parks the car and as soon as they want to leave, they can pay the parking fee via app or as usual at the payment machine just by referring to the license plate. “This solution already worked quite well. But we asked ourselves pretty fast, if there is a possibility to connect this cloud application to our parking guidance system – and, if possible, without any complex modifications”, as Frank goes on.

Instead, an algorithm captures the license plates of incoming vehicles via artificial intelligence and camera.

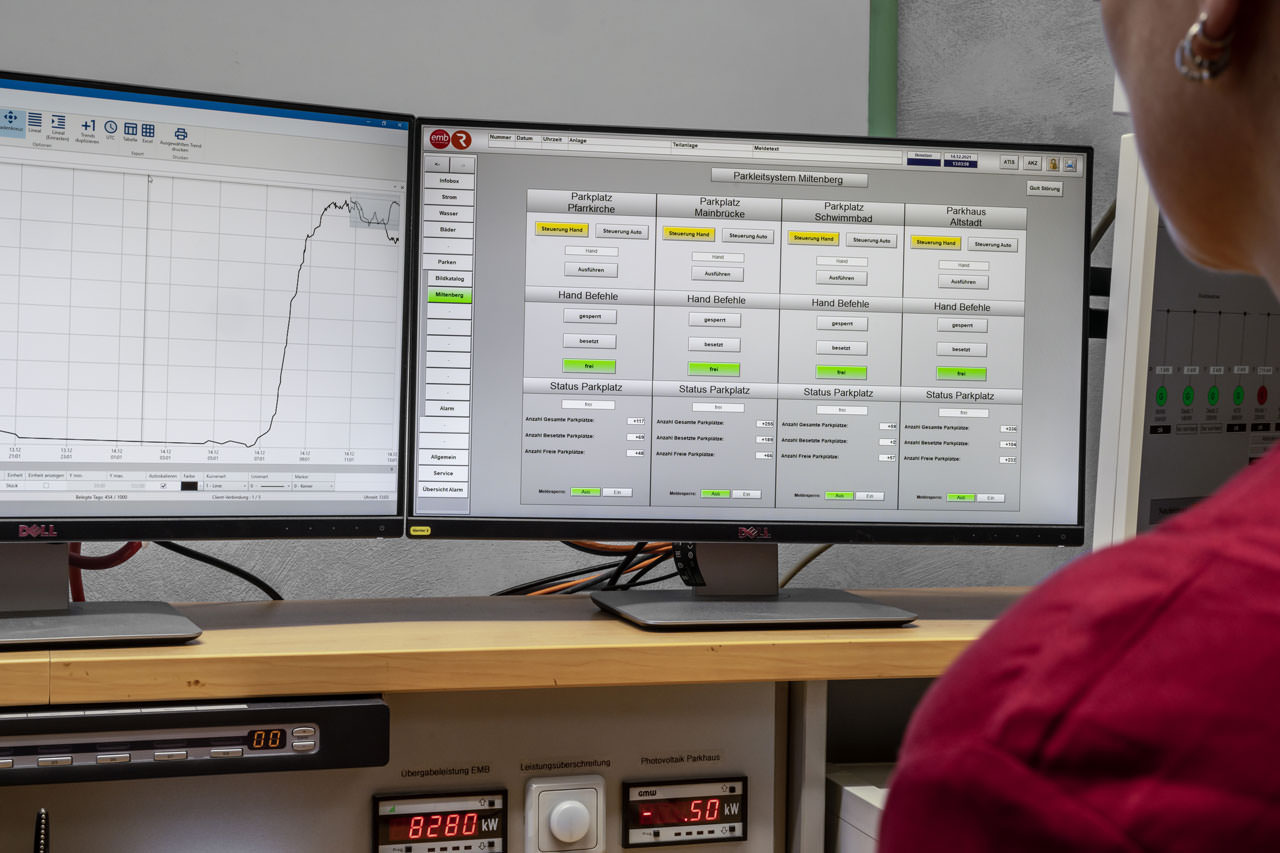

Together with the developers from the start-up, the software and automation specialists from ROBUR Automation found a suitable solution: a REST interface is used to transmit occupancy data from the cloud application to Scalance LPE. The latter then forwards the data to Simatic S7-1500, functioning as parking management computer. Depending on the situation, the control unit then switches the signs of the parking guidance system and transmits all information towards the guidance system of EMB.

“At the beginning, we had some trouble in terms of how to implement the OT/IT integration”, Kuhn said. “The developers of the license plate detection were working in high level languages. When it comes to automation, you work more with switches and assemblies. It was important to get the right teams to work together – another kind of OT/IT integration.”

Parking fees can be paid via app or at the usual payment machine.

Sustainable and cost-efficient

The easy integration into the existing infrastructure is one of the main advantages EMB sees in the realization with Siemens components. “First and foremost, we benefit quite a lot from using secure and certified products. In terms of IT security, we can fulfill all requirements.

Due to coupling our guidance system with the Simatic S7 controller, we have the possibility to control all signs manually in case of network failure. The new parking guidance computer integrates easily and seamlessly into the Simatic WinCC environment and can therefore also be integrated into our reporting concept. Last, but not least, we are able to keep all existing signs in use. All in all, a completely sustainable solution,” Frank concluded.

ROBUR Automation is also very happy with the results of the project: “The main part of the development was to enable connectivity towards the cloud application via REST interface, which we implemented as C# application in a Docker© container. To communicate towards automation and Simatic S7-1500, we decided to use OPC UA. That only took about two days”, explained Kuhn. Since the processing platform as well as the controller were configurable via TIA portal, ROBUR Automation was able to use its existing automation know-how in this project, Kuhn added. “Any other solution would have been significantly more complex to implement, especially regarding the high security requirements. Summed up, we saved approximately one week of engineering work just because we use one consistent system for SCADA, parking guidance, and network components.”

Scalance LPE safely transmits the data of the license plate detection via REST interface and forwards it to the automation level via OPC UA.

Future-proof solution with options

Following the successful launch, Michael Frank is already thinking about extensions: “Now, we can connect data from parking space usage with further information from automation. Maybe we can add a traffic light to the ”free“/“occupied” signs for certain situations. Further parking areas and signs are also in discussion, which would each be integrated with an individual Scalance LPE.” Thanks to the consistent engineering, it will be easy to integrate these new components into the existing system.

ROBUR Automation also sees a huge potential in edge applications, explained Tina Hain, Product Manager at ROBUR Automation: “With the Scalance LPE platform and our own Data Collector, we can offer our users a bundle of simple, robust, and secure solutions for data processing and edge application in a close-to-process environment. Areas, which may benefit from this, are isolated stations common for many suppliers, e.g., small water plants without their own guidance system.

The SCADA system Simatic WinCC provides all relevant data from the parking guidance system to the control center.

In these cases, Scalance LPE from Siemens may be a good possibility to safely integrate those plants into a guiding system.“ The advantage for the users is that this solution is reliable, and calculated costs won’t be exceeded. “You buy an industry-capable hardware device as secure component between internet or cloud and PLC. It is equipped with a suitable and protected power supply for buffering data in case of network failure. At the same time, we can develop our own applications for this platform in a high-level language and have more possibilities regarding storage capacity and interfaces. This creates new options for many use cases.”

Scalance LPE: Highlights

- Data collection, preprocessing, and transmission close to the process for applications like predictive maintenance or anomaly detection in communication networks

- Secure component for OT/IT integrations with high standards regarding IT security

- Easy integration in existing infrastructure

- Efficient engineering and industry-capable quality support cost-efficient and sustainable solutions