TechnologySeptember 22, 2019

Business impact of TSN for industrial systems

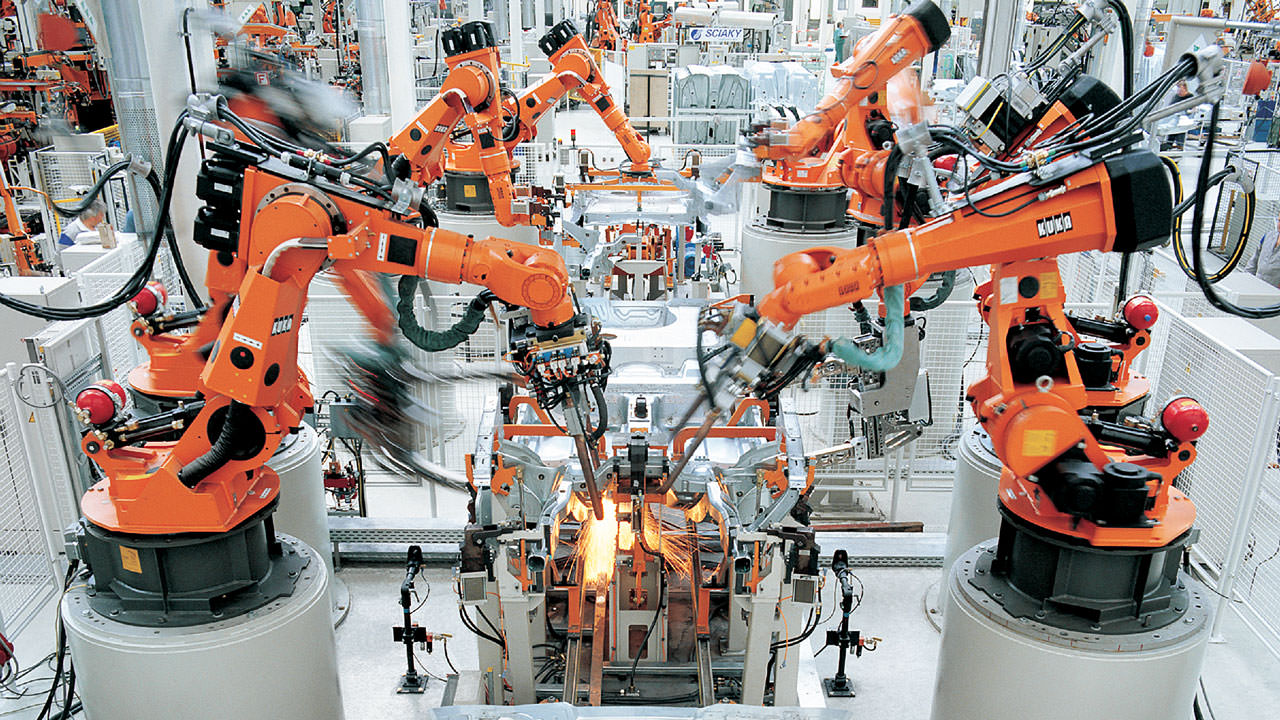

Time Sensitive Networking enables the convergence of networks and systems that were previously separate for reasons of operational integrity, real-time performance, safety or security. Breaking down communication barriers between critical and noncritical systems is a foundational concept of the IIoT and Industry 4.0.

The emergence of the Internet of Things (IoT) is driving the need for networked, time-aware systems in all sectors of the economy. In the industrial market, evolution of the Industrial Internet of Things (IIoT) will increase the amount of data harvested through distributed networks, requiring new standards for managing and transferring critical and non-critical information. There will be a demand for higher levels of reliability and security than what is provided by today’s numerous specialized and segregated industrial communication standards. The latest set of IEEE 802.1 Time Sensitive Networking (TSN) standards represents the next evolution of standard Ethernet technologies, targeted to meet these new market demands.

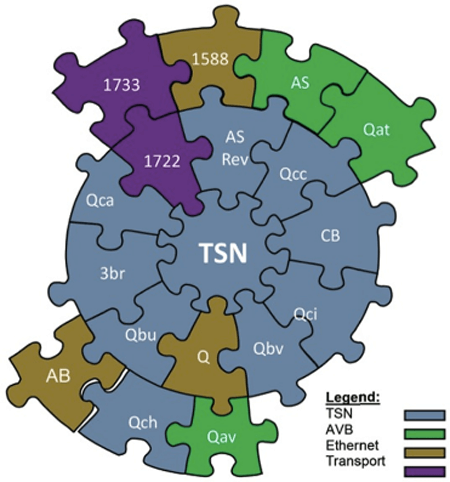

TSN has leverage both AVB (Audio Video Bridging over Ethernet) and Ethernet technologies.

Industrial control applications require consistent and deterministic delivery of data from sensors to controllers and to actuators. The data exchanged between these components is critical in controlling any manufacturing process and it is imperative that interference or hindrance of this exchange is minimized. Historically, this has not been problematic for most automation systems, as control data has been physically segmented from information data over separate networks. However, moving forward, the Industrial Internet of Things (IIoT) proposition changes that paradigm because manufacturers are looking to glean insights and analytical information from the same sensors and devices that are also controlling the process.

Therefore, the total amount of data communicated over the same network increases. Some of that data is critical for control systems, while other data is needed for both the information and analytical systems. TSN is one way to ensure that this control data traffic is delivered in a timely manner by securing bandwidth in the network infrastructure, while simultaneously allowing non-critical forms of data traffic to coexist on the same network. TSN provides the tools to enable the convergence of different data traffic on the same physical network, reducing the infrastructure cost.

What is TSN?

Time Sensitive Networking (TSN) is a collection of Ethernet standards introduced by IEEE, which defines a new set of mechanisms for managing traffic. TSN standards define new functions for Ethernet networking such as traffic shaping, frame pre-emption, traffic scheduling, ingress policing, and seamless redundancy. When all parts of a network are running with the same sense of time, traffic can be coordinated based on a schedule, one method that allows for better control of critical traffic. These new features provide a whole new layer of control for managing Ethernet traffic; but from a business perspective, is it worth the investment?

The legacy of Ethernet

Since its inception in the 1970s, Ethernet has morphed from a CSMA/CD technology where hubs were used for connecting multiple segments together. Over the years, hubs and collision detection methods have given way to switches and switching technologies. Prioritization mechanisms were introduced to give preference to critical traffic over non-critical traffic, and traffic shapers provided further control to help ensure reliability for data delivery.

As new technologies and features have been introduced to “standard Ethernet,” the number of mechanisms added to the control plane has expanded, and today’s switches carry all these functions in order to be backwards-compatible for any application. The majority of today’s switches carry nearly 50 years of technology, most of which is not used in any single application.

A drawback to this phenomenon of “feature accumulation” is the multitude of control functions that has left the switch and the network itself fundamentally unpredictable and incapable of being modeled. As various prioritization mechanisms are enabled and weighting mechanisms are applied, and as traffic shapers are employed and more switches are arranged into increasingly complex topologies, the ability to know when data will arrive or if it will arrive has become murky at best.

Most networks today are designed with an empirical sense: If a certain design worked on a previous system with ‘X’ amount of data over ‘N’ nodes, then this design should work with a few extra nodes and a few more bytes of data. But the difference between should work and will work can be an installation that goes in smoothly, or one that requires additional hardware or extra conduit – at a point in the commissioning cycle when such additions can be extremely expensive.

Historical network configuration

Traditionally, network configuration has been managed on a component-by-component, switch-by-switch, and node-by-node basis. The software used for such configuration has been similar to DOS in its presentation, utilizing such interfaces as CLI (command line interface) where hierarchical precepts are often inferred and knowing where one is in the command hierarchy is often not intuitive or clear.

Furthermore, if the configuration of one switch or router requires a complementing configuration in an adjacent router or switch, any configuration error in either of the adjoining components would cause problems in the network. Essentially, there is no system-level knowledge at the component level for configuration. Both the CLI interface as well as the PuTTY (terminal emulator) interface are cryptic and difficult to navigate. Closer inspection of the command lines themselves begs the following questions: “What set of skills must I hire to manage my networks?” and “Is this really necessary in the year 2019?”

TSN network configuration

If TSN represents yet another layer of new standards added to an already complex system, how can TSN create a simpler system for the end user?

TSN standards were specifically designed to facilitate system-level configuration and were created with a system view in mind, rather than from a component perspective. TSN enables end-stations to publish their requirements on the network and allows bridges and switches in the system to announce their capabilities to the wider network. As an example, the “P802.1Qcc Stream Reservation Protocol (SRP) Enhancements and Performance Improvements” specification is one of the mechanisms designed to allow the network infrastructure to be more intelligent at a system level and to convey the information necessary to transition the control plane from a manual configuration workflow to an automated process.

In the future architecture pictured above, the user is provided a view of the system that allows for the configuration of the I/O and control devices as well as for the layout of the topology and the infrastructure devices. A core principle of the TSN value proposition is that all network communications are managed so that performance and data delivery are guaranteed. To accomplish this, all devices need to participate in traffic planning by publishing to or notifying the system of its traffic requirements and of its capabilities for managing traffic.

In this example, a Centralized Network Configuration engine, or CNC, is used to configure the system. In this future reality, the CNC is an intelligent tool, enabled by the information collected and conveyed from TSN standards; it will calculate the best possible solution to accommodate all the traffic flows between all connections in the network. The system sees the available bandwidth and configures the infrastructure components in the network (i.e., the bridges) to accommodate the traffic flows. If the system is not able to solve for a configuration that meets the performance requirements and loads of the traffic streams in the subnet, it will notify the user so that topology, performance requirements, or loading can be modified.

TSN makes it possible to run the calculations that can help the implementor predict if a network design will be successful for a given application. This wasn’t possible in previous generations.

With TSN’s intelligence in the network, the system can become more automated and less dependent on human intervention and subsequent error.

Meaning for businesses?

The industrial market currently requires two types of networking professionals: informational technology (IT) and operational technology (OT). The current industrial control and associated enterprise-wide systems require many IT and OT personnel to manage and configure network infrastructure and control system parameters. Now, with TSN and its potential for smart software, there is an ability for the smart system to configure the network infrastructure. With TSN’s intelligence in the network, it becomes more automated and less dependent on human intervention and subsequent error.

The costs for highly-trained personnel could be mitigated using intelligent systems and devices capable of participating in a wider, self-configuring ecosystem. Software Defined Networking (SDN) type tools can enable system-level configuration software, as well as diagnostic and monitoring tools. These new mechanisms would allow the end user to finally manage the network from the manufacturing floor to the business systems.

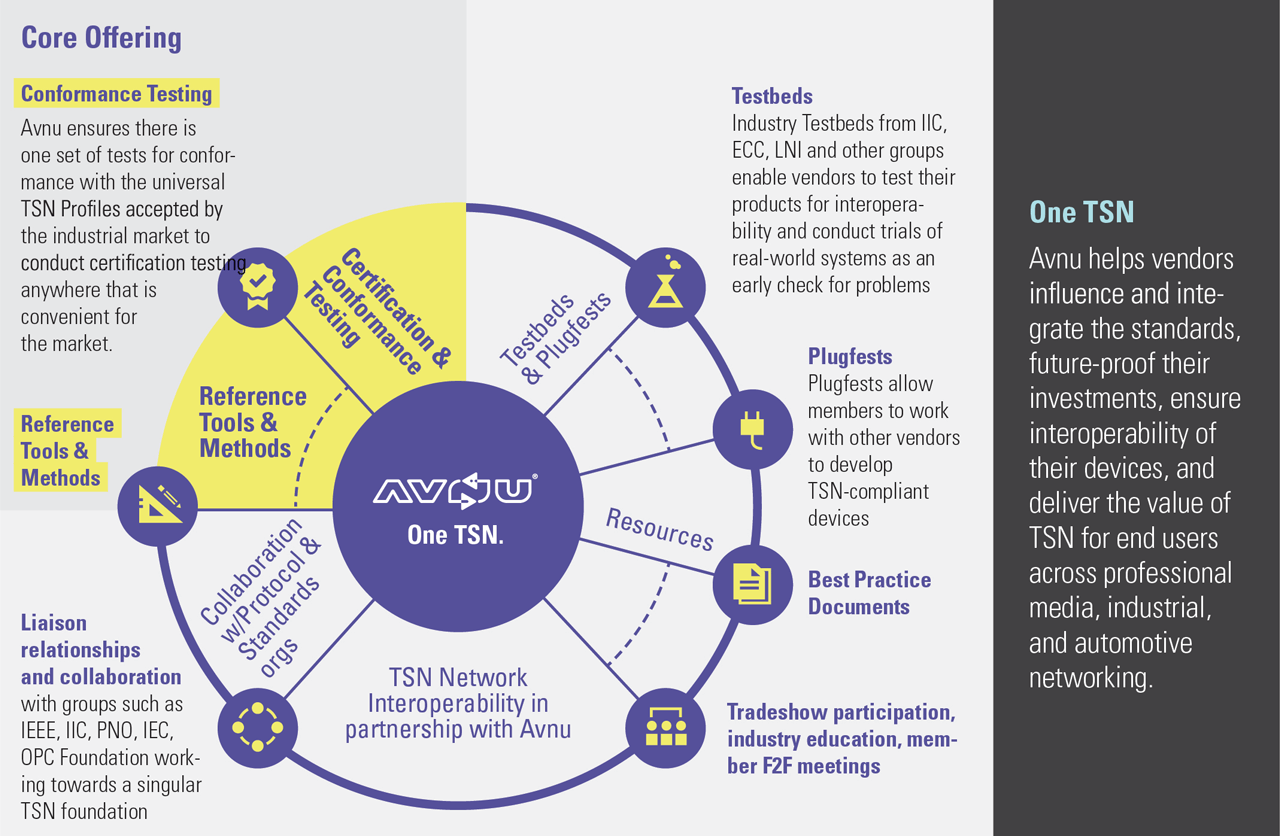

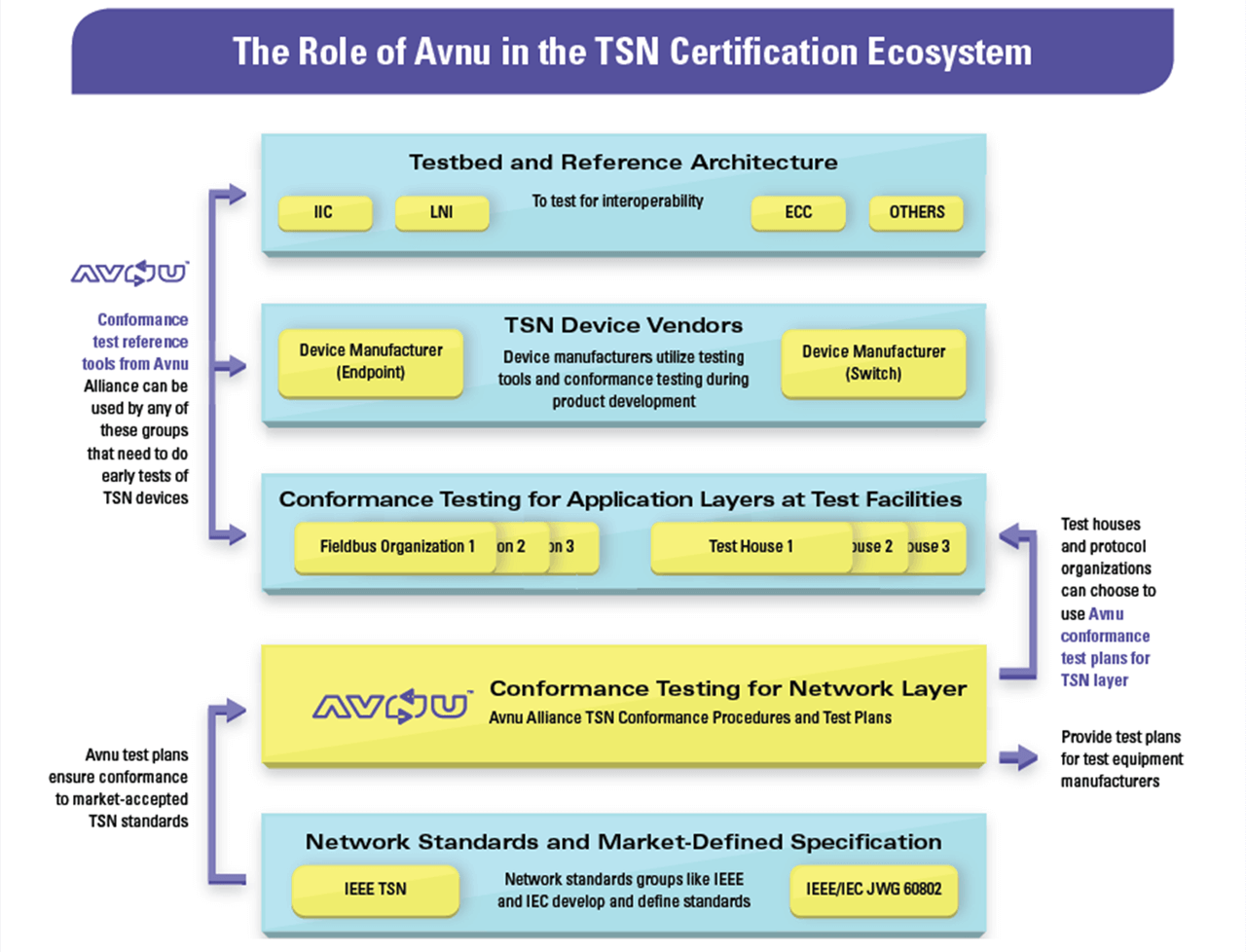

Role of Avnu Testing.

System modeling & network design

TSN is expected to bring a holistic approach to network management, enabling new tools for system-level configuration. In this new paradigm, payload, sampling frequency and maximum latency might be managed from a system-wide view and then used to calculate flows and configure bridges and infrastructure to meet the application demands.

This approach to network management would dramatically change the workflow for designing and planning networks. TSN provides the foundation for network calculus and planning as part of the solution toward managing traffic and guaranteeing performance. If designs prove inadequate or a solution is not achievable given system constraints, then network design could be modified to accommodate the system requirements.

Through TSN’s modeling methods, system designers could proactively answer questions about the network capability before the system is integrated, which allows them to plan for the traffic that needs to be managed.

In addition to understanding the capabilities of the network today, users want to know about possible future capabilities to support business growth. Today, there is no reasonable capability for predicting network success or outcomes; empirical system designs can help managers to baseline their designs, but the system may not work for every application.

SN helps manage the configuration and modeling of these systems, enabling the software-designed environment for predictable system design and advanced planning systems. Offline and online predictive tools that can mathematically simulate network traffic and allow for predictable design could provide more detailed understanding of the system’s success prior to hardware acquisition or commissioning of equipment.

Smart modeling in this way will maximize the life of the system and future-proof the components to facilitate, adding switches to the infrastructure to scale with the system needs. When systems are built with future scalability in mind, huge reductions in cost and time can be made. Fixed cabinet space and previously poured concrete, and existing conduit make changes and additions to the system’s incredibly expensive endeavors. Modeling capabilities made possible with TSN will bring predictability to the success of the future system.

Modeling and Industry 4.0

Industry 4.0 is underpinned by the idea of digitization and cloud computing for virtual modeling of cyber- physical systems through real-time data. In order to create a digital twin for that kind of cyber-physical modeling, there must be a clear pathway to collect, process and control the data in real-time. TSN ensures guaranteed latency, which means the pathways between the process sensors collecting the data and the analytical computers processing the data are unimpeded – enabling guaranteed data delivery.

The benefits of common time

Digitization and its benefits require a time-stamped data collection to provide a chronology of events, time-based analysis, time-series analytics, and finally, a model for predictable outcomes. The analysis of time-stamped data can allow system managers to see exactly what went wrong, as well as where and when.

TSN provides a common reference of time in which to do this. The same clocks that are required for traffic scheduling on the network can be synchronized with other time domains to provide a wider view of system events or faults. Essentially, “TSN time” can be correlated with time in the enterprise systems so that events and conditions on the plant floor are chronologically comparable to events within the company’s business systems.

Consider a case where more precise understanding of when a product was completed is needed in manufacturing, with respect to the distribution systems that will move such product to the consumer. In the supply chain, there could be a tighter understanding of when products are completed against when the material to produce such products needs to be reordered. What if the cause and effect of faults on the plant floor could be more easily viewed at a system level through a sequence of events capability, where time is common across the entire manufacturing facility? Such capabilities present an opportunity for higher efficiencies that, ultimately, are reflected in a company’s financial success.

The benefits of TSN

Digital technology powered by TSN infrastructure may enable shorter operational lead times, more visibility over systems and more efficient asset utilization. These benefits could be realized in industrial systems soon and can pave the way for improvements by “future-proofing” systems and include:

Ease of Network Configuration: Today, technicians have to configure each network device manually on conventional networks, but TSN can allow for automatic configuration via intelligent configuration tools. The network understands what must happen to achieve the desired performance and will turn specific services on and off as necessary. Standardized methods for network-wide configuration and commissioning required by TSN also create the avenue for offline simulation and modeling of the network and the architecture.

Secure Networks: For industrial automation and control networks, security is critical. Because TSN is standard Ethernet, control networks can take advantage of best-practices for security that have been developed into Ethernet for decades. TSN also adds a layer of security to the data with the precise timing mechanism that facilitates early detection of a network breach.

Reduced System Costs: TSN allows the convergence of different traffic classes on a single network and reduces overall system costs significantly. Hardware and maintenance costs may also be reduced since the system needs fewer devices and cables.

Future Enhancements: As TSN is part of the Ethernet family, it naturally scales with Ethernet, which means that the technology will not be limited in terms of bandwidth and other performance criteria. New nodes can be easily added to the network and discovered via standard networking protocols.

TSN enables the convergence of networks and systems that were previously kept separate for reasons of operational integrity, real-time performance, safety or security. Breaking down communication barriers between critical and noncritical systems is a foundational concept of the IIoT and Industry 4.0.

With TSN and time synchronization, insights from real-time data at the edge arrives on time from anywhere, no matter how demanding the environment. Choosing TSN changes the industrial model and workflow with fewer workers for a more converged and deterministic network built on platforms to protect investments long- term.

Ecosystem approach

Today, many of the underlying systems for Industry 4.0 applications are based on proprietary standards and could present integration challenges. A lack of a broader industrial networks ecosystem perspective in terms of business systems, platforms and standards as well as interoperability could present a significant challenge for the adoption of industry 4.0 into modern workflows. Consortia, industry and government bodies as well as standards associations are working to establish standards, associated profiles and tests. It is incumbent upon everyone involved in the ecosystem to work with partners to stay current on evolving standards, make them interoperable and coexist to maximize the value delivered by Industry 4.0.

Since TSN provides a standards-based foundation, system designers and engineers would be able to architect a network that will stay current with evolving use cases. Avnu’s reference test tools and test plans support vendors with rapid adoption of the TSN standards. As the need for time-synchronized communications continues to grow, Avnu Alliance works to ensure that TSN is successfully implemented to realize the maximum possible benefits of configuration, data use, and cost savings in industrial settings and beyond.