TechnologyJuly 15, 2021

SPE: enhanced cloud access to sensors and peripherals

SPE, short for Single Pair Ethernet, is expected by many to revolutionize the way modern industrial communication networks operate. As technology advances and industrial applications are becoming increasingly digital, requirements for existing Ethernet wiring are shifting.

In this article, industrial communication specialist Hilscher shines a light on the most recent developments and requirements for modern industrial communication and how two drilled cables are set to resolve them.

SPE and why it’s necessary

SPE is expected to drastically change industrial communication due to significant cost and space savings, increased coverage in industrial plants as well as an overall improved performance. The main feature is that only two wires for communication and power over data line within the cables instead of up to eight.

Cable lengths of up to 1 km are possible as stipulated by the IEEE802.3cg, and the increasing number of sensors and actors as well as rising demand for more data has proven that conventional fieldbus systems are insufficient above certain cable lengths.

Industrial IoT requires standardized communication between applications and machines. From sensor up into the cloud, SPE enables data transmission along the entire industrial automation architecture based on an IP network.

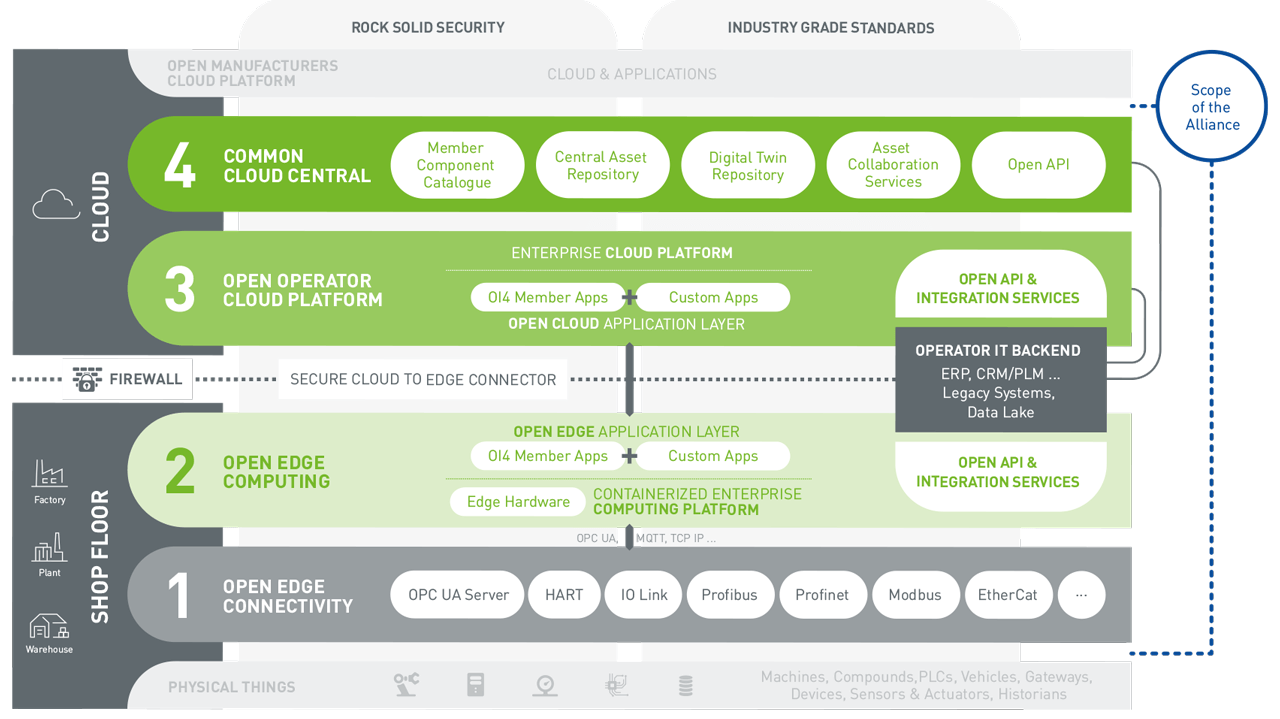

Operating Model of the Open Industry Alliance 4.0 (source: Open Industry 4.0 Alliance 2020)

Introduction

After several years of governmental activities to foster development of new industrial standards as well as rising demands from the market, digitization of modern production lines has picked up the pace recently. Over the course of the last decade, initiatives such as “Plattform Industrie 4.0”, “Industrial Ethernet Consortium” or “Made in China 2025” foreshadowed the need for digital technologies and innovations in order to improve the performance of production facilities all around the world.

Numerous major industrial players as well as renowned consulting groups have since examined the potential that lies in new technologies to streamline industrial processes. A study published by the French consulting company Capgemini in 2015 saw a “new industrial paradigm” come to light with a “need for increased intelligence in embedded systems and value creation through smart services”. Key success factors in this regard were advanced analytics for predictive production actions and process transparency, according to the Capgemini study.

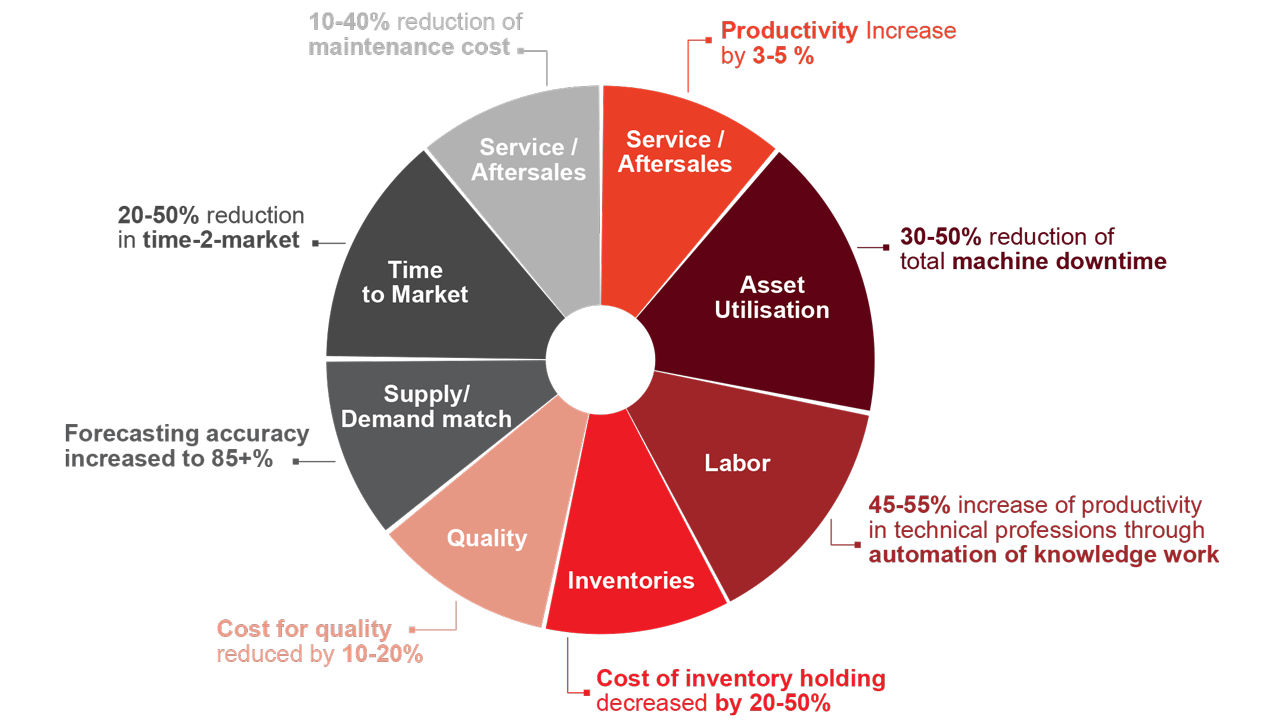

Value drivers and expected benefits of key categories in industrial production (source: McKinsey 2015).

A McKinsey analysis, also published in 2015, similarly concluded that “disruptive technologies will enable the digitization of the manufacturing sector”.

The study, which was based on interviews with about 100 industrial companies, lists cloud technologies, advanced analytics, touch and next-level GUI, virtual and augmented reality, advanced robotics, and additive manufacturing as such groundbreaking innovations. The consulting company Accenture even titled such technologies as game-changing and stated that they could seize a “trillion dollar opportunity” the same year.

Based on the results of the studies conducted by a number of research institutions, they found several value drivers for modern manufacturing as depicted in the following chart:

Interconnecting cloud and sensors

Following several years of research, many players have accumulated extensive knowledge about the needs and requirements of the manufacturing companies in terms of digitization and automation of machines and processes. One of the major problems when it comes to adopting cloud technologies in manufacturing is the vertical integration of sensors from the field level up to the cloud, where current Ethernet technologies are reaching their limits.

However, since the vertical integration from sensors to cloud is a very important pillar for modern digital business models, the benefits to extend IP networks down to the sensor level are becoming more and more evident:

- Enhanced visibility, diagnosis and control

- Access to all automation equipment through one semantic with OPC UA

- One common vendor-independent tooling

- Enhanced robustness and availability

- Enablement of predictive quality and maintenance

Single Pair Ethernet offers added value through thinner cabling, small footprint plugs and connectors and overall less required space for installation, overcoming the limits of current Ethernet technologies. For that reason, it is suitable to replace numerous existing fieldbuses in the sensor and peripheral area. However, a key question is how a deployment into the different areas in automation will happen.

First attempts on standardizing Ethernet based on two single wires were made by the automotive industry. The existing standards for in-car networks such as CAN, MOST or FlexRay were too costly in terms of cabling and software. Hence, a common standard to gradually replace these was found in the Ethernet technology.

However, the cabling effort for standard Ethernet was comparably high, which is why semiconductor company Broadcom made a first pitch with BroadR Reach in order to show that a simple twisted pair cable is sufficient enough to deliver high-speed data over shorter distances.

Following these first attempts, the Institute of Electrical and Electronics Engineers (IEEE) has picked up the standardization initiative under the well-known 802.3 Ethernet Standard and widened the scope to industrial and building area as well in order to address similar challenges there.

More than just two wires

One might ask, why nobody has come up with the idea of simplifying wiring in industrial manufacturing much earlier to utilize the advantages which SPE is now offering.

However, changing existing Ethernet networks to a whole new Standard such as SPE is not quite as simple as an unpretentious exchange of some cables implies. In addition, a number of specifications need to be considered to enable the expected benefits for different industries.

Different Physical Layer: Industrial Ethernet 10Base-T/100Base-TX, the most common standard currently used in industrial manufacturing, utilizes two twisted pairs of cables for a unidirectional transmission and reception data. In contrast, a single-pair Ethernet cable transmits and receives data via one twisted pair and therefore requires a different physical layer as well as different coupling and transducers.

Long distance transmission: Sensors, actuators and other peripheral field devices used in industrial automation often require very long cables in order to transmit and receive data. Hence, a strong demand for longer possible cable length came to light. Currently, SPE is able to cover distances for data transmission of up to 1000m instead of around 100m, which are possible with the current 100Base-TX standard.

Intrinsically safe: Safety is a critical issue for every industrial application, especially in the field of process automation. In addition to the demand for long distance data transmission, process automation companies have to pay particular attention to intrinsically safe transmission for hazardous and explosion-proof areas.

Power transmission: Many sensor communication fieldbuses currently in use also provide power transmission over communication cables. Hence, the single twisted-pair cable used for SPE must be able to supply the necessary power to operate remote sensors and actuators.

Application specific bandwidth demand: Applications in industrial manufacturing are very manifold and require different bandwidths. In addition to field level devices and sensors, which are well covered by a 10Mbit transmission speed, the idea was to also roll-out SPE for applications with a demand for higher bandwidths. Therefore, the IEEE also defined standards suitable for applications such as vision, motion and HMI including the respective physical layers.

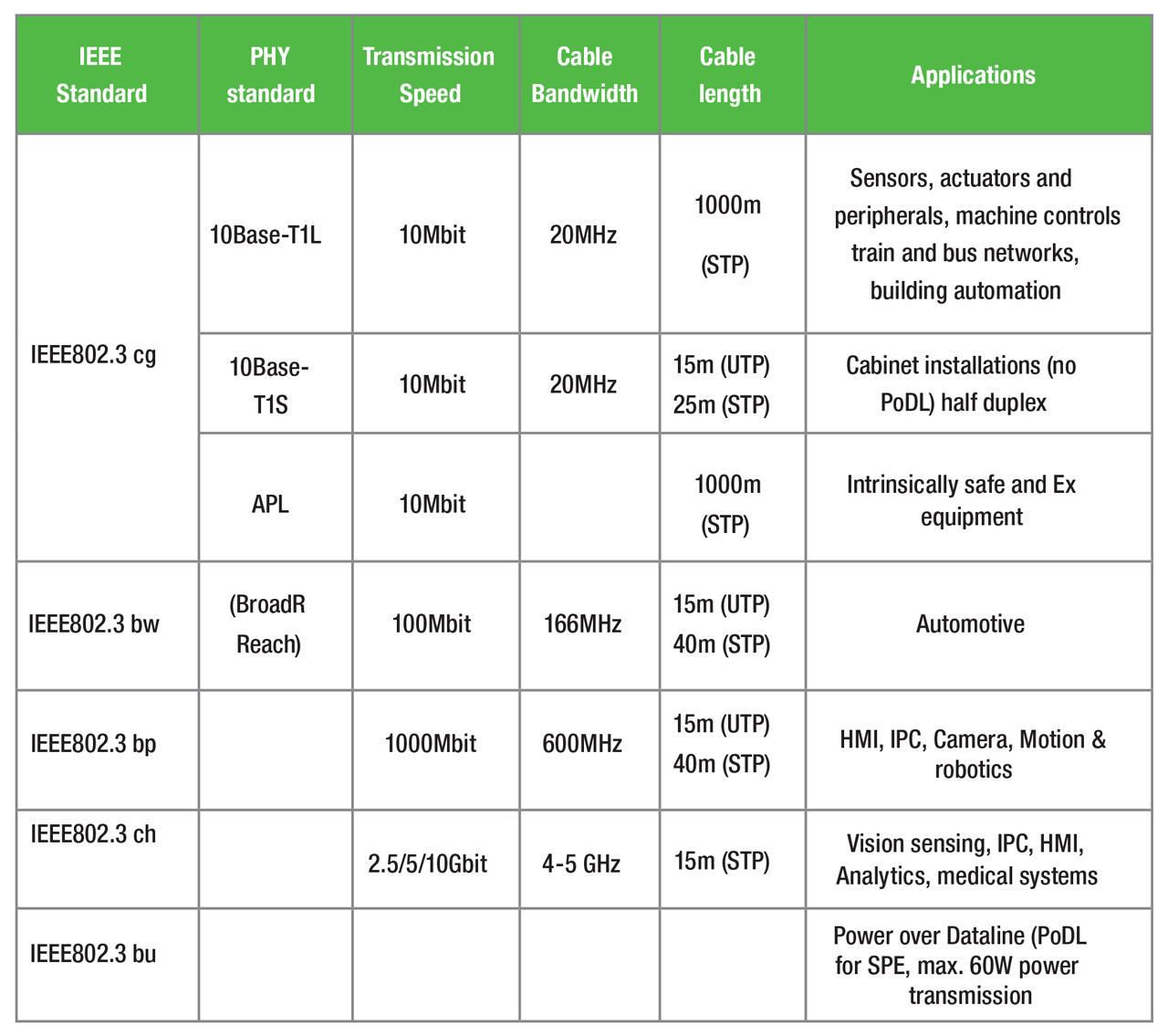

IEEE Standardization & applications

All these requirements and demands from the industry towards SPE are being adopted by the IEEE and incorporated into global standards. In the table below you can see different SPE related standards defined by the IEEE and their specific transmission speed and application.

Overview of different SPE-related standards.

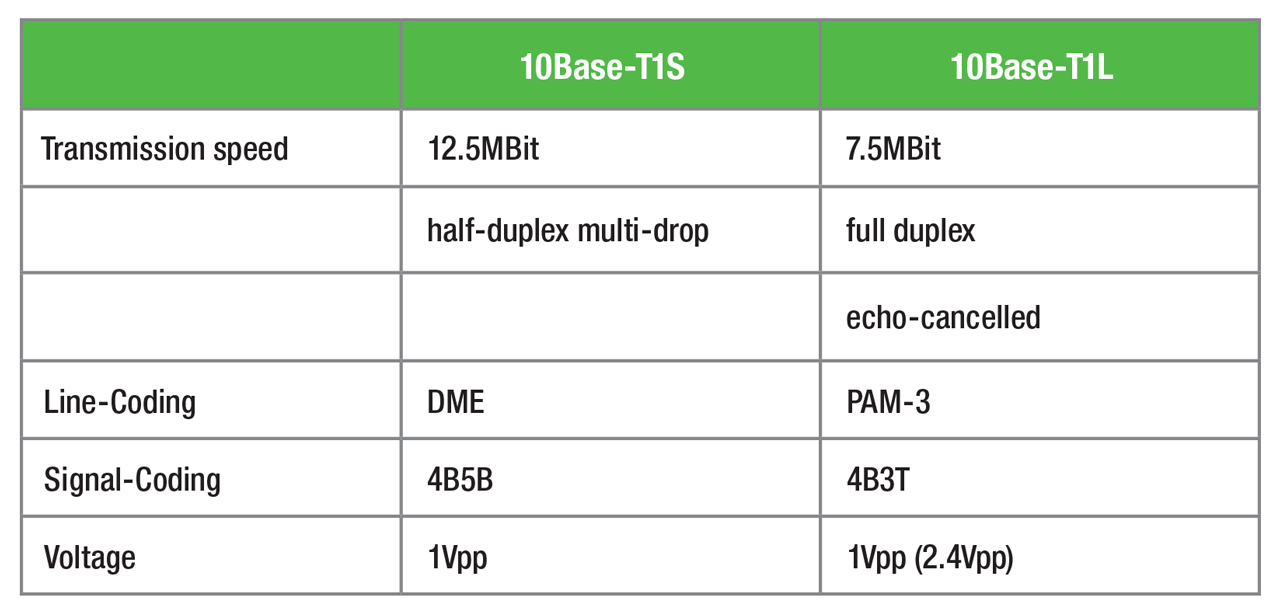

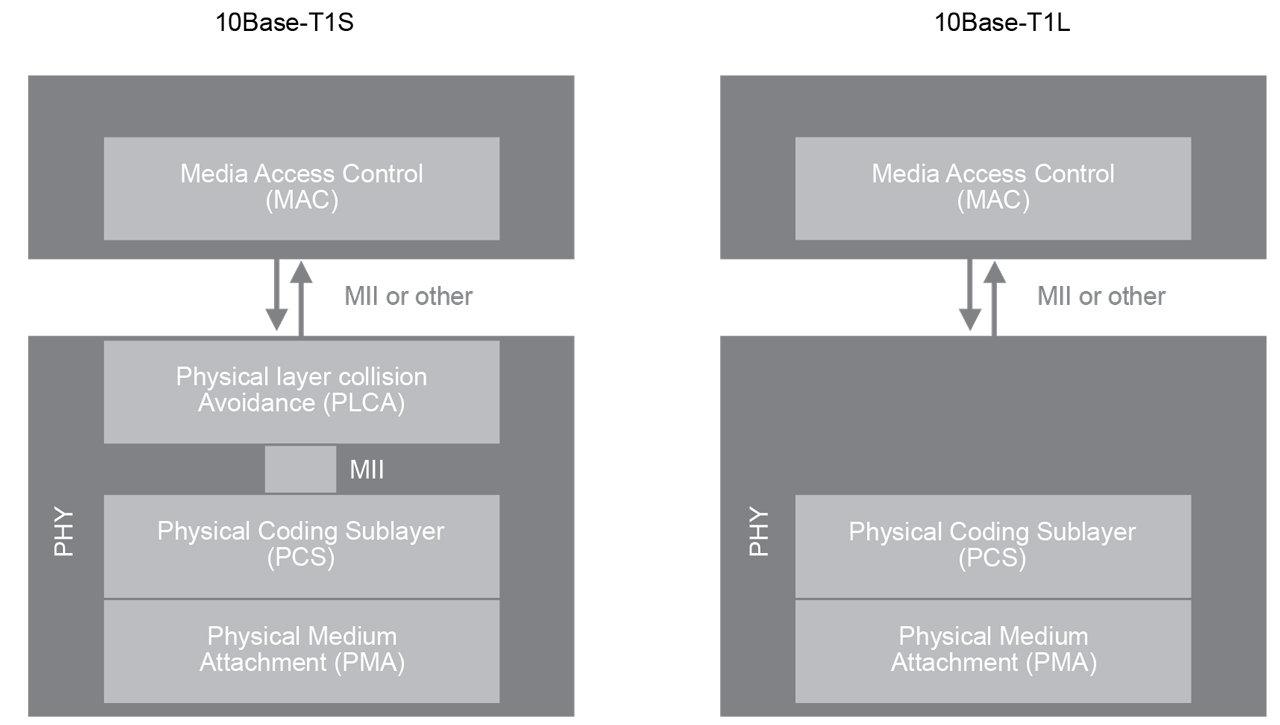

Comparison between the two specified physical layer specifications of SPE.

The table above shows that the 10Mbit Single Pair Ethernet Standard IEEE 802.3cg is split into three different iterations to reflect the different needs from various sensor, actuator and peripheral applications.

The 10Base-T1L is mostly applicable for sensors as it allows up to 1000m cable length in a point-to-point connection and fits very well into current installations.

In terms of defining the physical layers, which are addressed in the scope of the IEEE’s SPE standards, the Advanced Physical Layer (APL) is exactly the same as T1L, but it is adding the necessary components for intrinsically safe data transmission for critical use cases such as hazardous and explosion proof areas.

In contrast, the 10Base-T1S allows for a multi-drop setup with much shorter cable lengths and a different PHY layer called PLCA (physical layer collision avoidance). Multi-drop is especially suitable for, among other things, cabinet installations or other short-range applications. Both systems require a different physical layer as shown in the table above.

Although the physical layer differs in some details between T1S and T1L, the connection to the upper layers remains the same. The IEEE has gone to great lengths in order to make sure that any system with a MAC and an MII connection can interface with the new PHY. That means that major changes only affect one OSI layer.

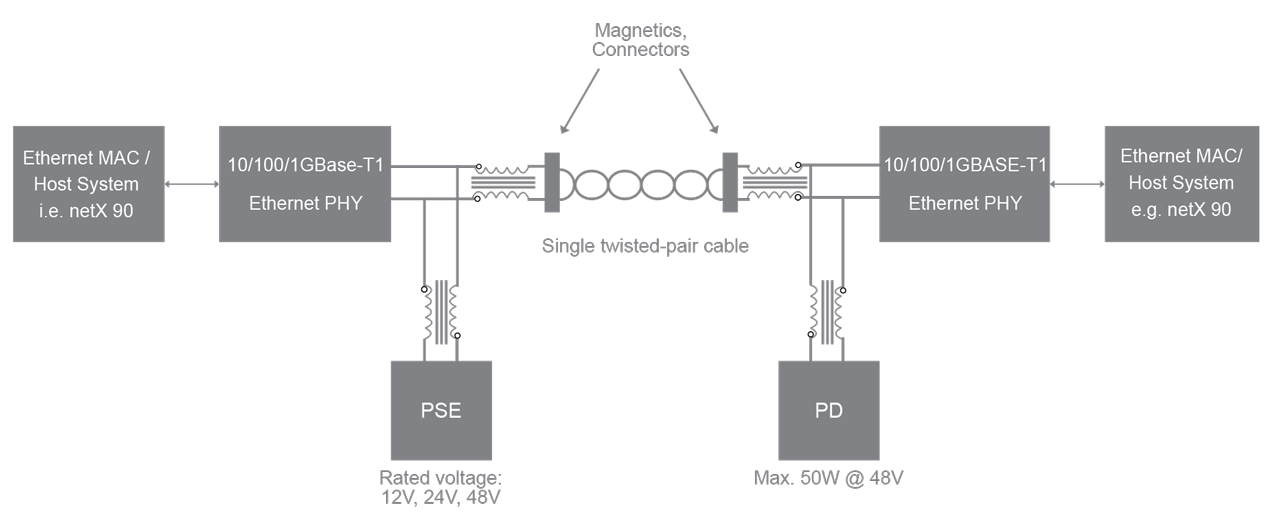

In addition, the IEEE 802.3bu standard is also defining a standardized power supply over the data line for applications up to 50W to a single endpoint. This feature allows backward compatibility to several existing sensor network standards that also power the connected sensor from a central power controller. Such a setup with contemporary power distribution is shown in the following figure.

The system requires a Power Sourcing Equipment (PSE) in order to deliver energy over the wires. Three different voltages are defined by the IEEE which are linked to specific power outputs. On the receiver side, the Powered Device (PD) in the above case requires a maximum of 50W at 48V, which can be delivered in a point-to-point T1L connection. At 24V the PD can still put out a max. of 10W with a regulated PSE. Such a system is largely compatible with the trunk and spur topology in process automation networks.

PHY connection to upper layer host system.

The standardization of Single Pair Ethernet, as stipulated by the IEEE to date, is well suited to support the demand of the industrial automation companies. Since the physical layer technology is already in use in some different variations in the automotive industry, industrial users can rely on an already field-proven technology when they start to implement it into their plants.

The challenge is now to bring these advantages into existing IP-based networks that already enable many of the current data-driven business models. And challenges are plentiful.

For example, some of the industrial Ethernet standards do not have a 10Mbit transmission speed in their specs or have just started to include it. Therefore, a key question for existing fieldbus standards in factory automation, driven by groups like PI, ODVA and others, are the possible use cases in context of the current automation architecture. Currently several scenarios and potential integration scenarios into the field are in discussion.

System setup of a point-to-point connection with power distribution.

For factory automation, there is already a standard that supports data access into each sensor in the system: IO-Link. Several sensor manufacturers are actively aligning their needs within the IO-Link standard.

IO-Link already supports parameterization, diagnosis, and full integration into Industry 4.0 eco-systems. However, transporting IO-Link Frames up to 1000m based on SPE physical layer would transfer the former point-to-point sensor network into an alteration of a fieldbus system.

A discussion about the positioning of IO-Link in regard to SPE physical layer is on-going to resolve and avoid confusion. The current discussion reviews the potential use cases that could be enabled with an SPE physical layer, but by keeping the IO-Link ecosystem as is in order to maintain existing investments.

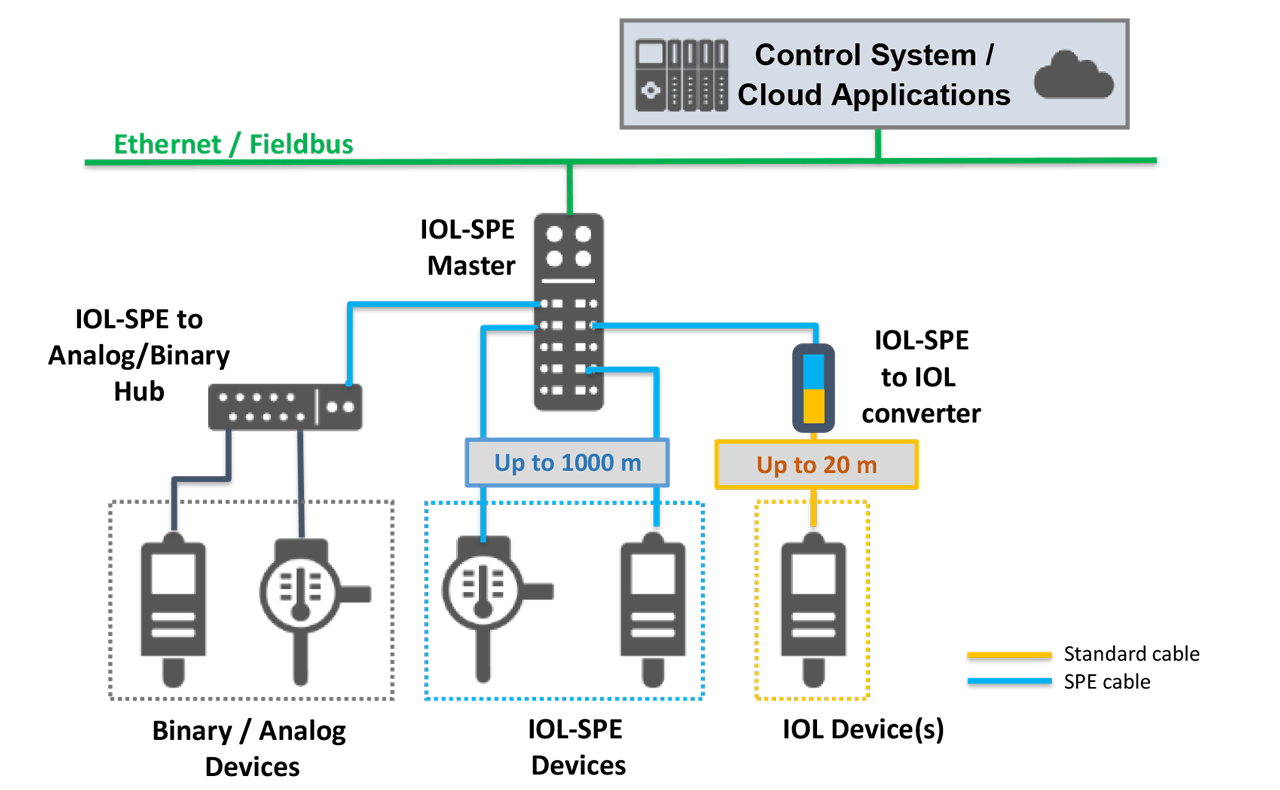

SPE installation in an IO-Link ecosystem (source: IO-Link Consortium, 2020).

In order to show a possible deployment, the IO-Link Consortium has released a whitepaper containing several precedents of deployment scenarios (IO-Link Consortium, 2020) based on brownfield installations:

The example above allows for an integration of an IP67 SPE master into an existing installation of IO-Link as well as binary sensors and devices. The proposal in the whitepaper sets SPE mainly as a transport medium for IO-Link Frames to keep the IO-Link Eco-system largely as is.

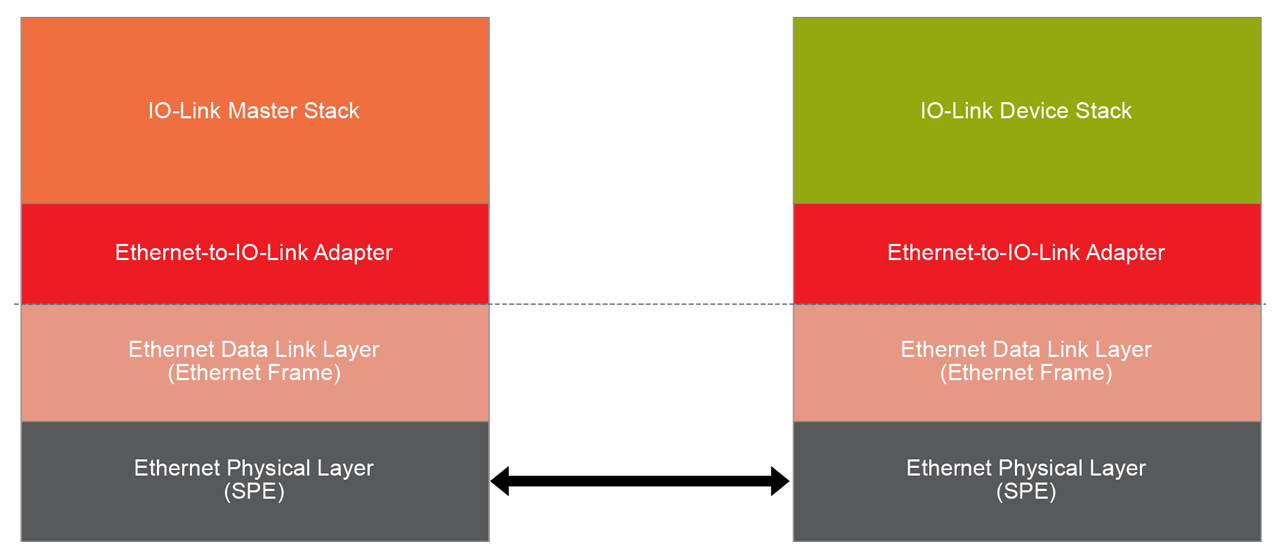

A software-based Ethernet-to-IO-Link adapter makes it possible to maintain the data format and benefit from the extended range and other advantages of SPE, while simultaneously maintaining the existing infrastructure and installations.

Hilscher participates in several projects of the PI group to contribute to the discussions on SPE for PROFINET. We also contribute to the IO-Link working group evaluating the benefits and challenges for a complementary integration of both standards into the field.

IO-Link data integration into Ethernet hardware and datagrams (source: IO-Link Consortium, 2020).

At the IEEE, we take part in the open topic discussions regarding the 802.3cg, in addition to the efforts by the ODVA on SPE topics. Our goal is to help build a migration path for low-effort integration of SPE into existing systems and to support this with our communication competence and solutions.

netX: New Technology

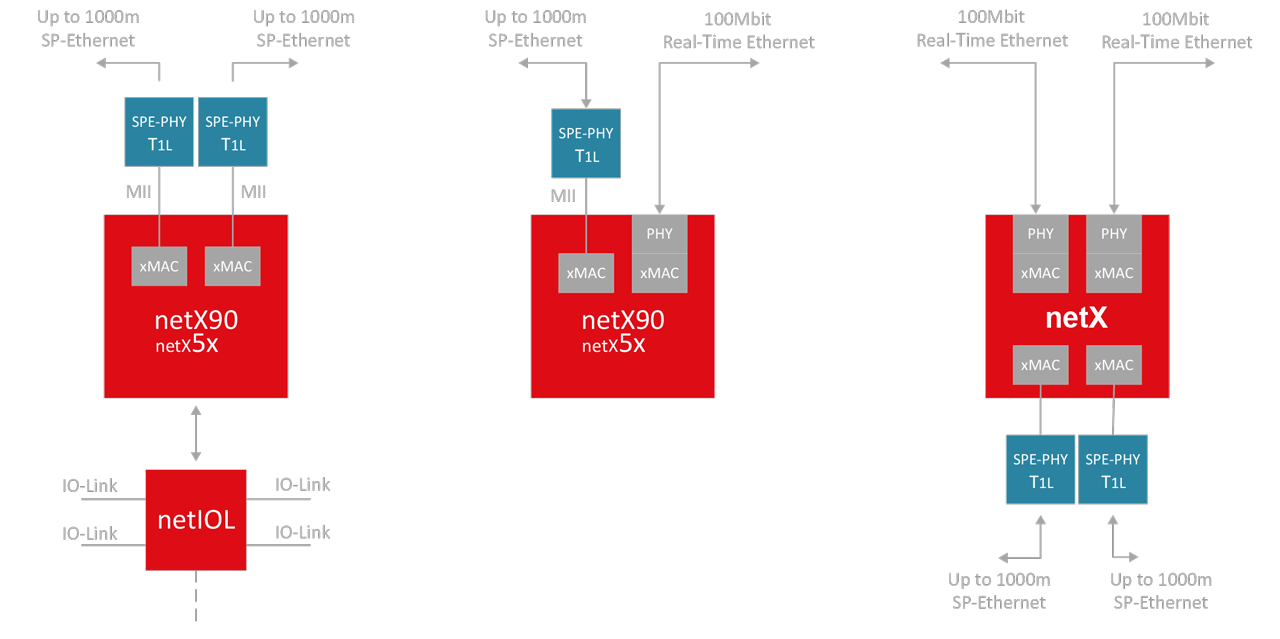

netX-based configurations in SPE networks.

Hilscher’s sophisticated multiprotocol chip solutions, the netX SoC product family, are at the forefront of SPE deployment worldwide. The netX 90 chip, as well as modules and PC Cards based on it, allows connection to external PHY products via MII interface. The internal xMAC processors enable the protocol specific switching between the two channels. On the left side of the following figure, the use-case shows two 10Mbit channels SPE port up to 1000m line length, connected to an IO-Link sensor network through our 4-channel netIOL Master chip for legacy implementations.

The middle use case shows an existing 100Mbit Real-Time Ethernet (RTE) system connected to a 10Mbit SPE network. In this case, one internal PHY and xMAC serves the 100Mbit side, the second xMAC with the external SPE PHY connects to the up to 1000m long two-wired cable of an SPE network. In the right side use case, the netX acts as a switched device between a 100Mbit based RTE and a 10Mbit SPE network.

Hilscher has developed a first evaluation board with the netX 90 and SPE 10Mbit T1L PHYs for engineering and testing purposes. The board offers a simple extension of a 100Mbit network towards 2ch SPE to evaluate SPE in context of the different Industrial Ethernet Standards. Hilscher expects a starter kit during the fourth quarter of 2021. As the standardization bodies are still in progress to finalize SPE in their respective releases, the diagrams above and the board are showing some of the possibilities and options to support brownfield installations based on netX. With the progress in SPE definitions, we will release more options and solutions; stay tuned.

Conclusion

Single Pair Ethernet has reached a level of standardization that allows companies and whole industries to start adopting it into their systems, mainly focusing on a seamless connection from sensors up to the cloud based on Ethernet technology.

SPE benefits differ tremendously depending on the degree of digitization integration measures. The robust and smaller cables and connectors, the comparably high transmission speed, the distance of up to 1000m, a possible multi-drop set-up, and the opportunity for one vendor-independent tooling makes SPE an excellent solution for such a vertical integration of sensors and peripherals in various applications.

Subsequently, this leads to a different demand and pace when it comes to implementing SPE into advanced manufacturing systems.

Hilscher is expecting an early adoption and deployment of SPE in the process automation sector starting in late 2021 to enable digital business models. Hybrid and discrete Industries to follow with reference implementations based on the enhancement of relevant standards.