TechnologyJanuary 23, 2023

IIoT Megatrends: 2023 Special Report

Industry experts provide their perspective on the megatrends and technology shaping the Industrial Internet of Things (IIoT). Automation and control system manufacturers are leveraging IT tools and security solutions, and focusing on edge computing to increase the scalability and manageability of IIoT solutions.

IIoT technology is moving ahead with new solutions for smart manufacturing, even if it hasn’t been fulfilling the loftiest predictions of explosive growth.

In this special report, the Industrial Ethernet Book reached out to industry experts to gain their insights into the technology megatrends driving IIoT networking, new applications and the challenges for automation engineers.

IIoT data security

Focus on quality communications utilizing MQTT and OPC UA technologies.

According to Phil Marshall, CEO at Hilscher North America, the Industrial Internet of Things (IIoT) requires quality communications, making both message queuing telemetry support (MQTT) and Open Platform Communications Unified Architecture™ (OPC UA) key technologies.

According to Phil Marshall, CEO at Hilscher North America, the Industrial Internet of Things (IIoT) requires quality communications, making both message queuing telemetry support (MQTT) and Open Platform Communications Unified Architecture™ (OPC UA) key technologies.

“These technologies enable future IIoT developments and allow other technology solutions to work. MQTT is a communications protocol with very low overhead, which makes transferring massive amounts of information into cloud-based systems manageable. OPC UA is a universal way to exchange data between systems, supporting that flexibility on a system-to-system basis,” Marshall told IEB recently.

Marshall said that MQTT and OPC UA must also go hand in hand with security. Cybercriminals will continuously find attack vectors and so to block threats, a collective effort is required. This means that embedded, layered security spanning every link in the communications chain — from the component manufacturer to the end user — is essential. This is where IEC 62443 comes in. With over 30 years of communications experience, Hilscher has long-supported security through products such as its netX 90 communications controller.

netX 90 technology

Hilscher’s netX 90 technology enables security functions to be embedded into automation products, and protects CPU activity with “root of trust” techniques and isolates communications from applications to ensure that neither can be affected by the other. Its successors will be similarly enabled in order to match network security requirements as they evolve. The company recently announced that the netX 90 supports Common Industrial Protocol™ (CIP) Security, an important next step for North American automation vendors.

“IIoT is evolving but it has not seen the quantum leap that many predicted. Instead, it has taken a decade to become mainstream because automation users are conservative about change, particularly concerning security,” Marshall said. “In addition to that hesitation, early IIoT implementations were cumbersome and extremely expensive. These issues led many users, such as small machine builders, to be disinclined with their involvement. Today, powerful IIoT solutions are both far less expensive and far more flexible.”

He added that the reality is that automation users have always pushed for better and more effective ways to operate and manage assets. Today, they recognize that they cannot compete unless they start offering IIoT features with their equipment. The latest products on the market today offer plenty of opportunity to deploy cost-effective solutions in innovative ways.”

Challenges for smart manufacturers

Marshall said that, as of now, IIoT spans the entire manufacturing hierarchy. At the highest levels, global interaction of systems allows companies to manage their enterprises better and more effectively across global markets. And at the lowest levels, processing the data from sensors mounted on machines can help manage equipment more efficiently and send this data to where it can most effectively be used — locally or globally.

“Gathering sensor-level data via smart IO-Link modules delivers continuous access to machine condition and performance. From a performance perspective, this opens up exciting opportunities to improve processes such as enhancing work flows, increasing product quality and boosting manufacturing flexibility,” he said. “Better monitoring can also uncover potential failure mechanisms that may be addressed before the failures cause downtime. Additionally, the “digital twin” version of a machine becomes a reality, enabling off-line diagnosis, process improvement and system design.”

These technologies also allow vendors to monitor their machines from anywhere in the world. This presents new business opportunities because vendors can take greater responsibility for their equipment, wherever it may be. Machine rental, rather than purchase, becomes an option that is paid for on a per-use basis — which is an attractive option as staffing levels decrease and skills and experience are lost. Machine providers can also support continuous quality improvement and online upgrades.

Looking ahead

Given that the IIoT is already more than ten years in the making, his assessment of the progress and overall impact of the IIoT on industrial automation and smart manufacturing is that it is a work in progress.

“So far, IIoT has moved forward at a pace that I would expect. But now, I see it accelerating as the possible added value of new solutions become clearer,” Marshall said. “For a product vendor like ourselves it offers exciting new opportunities too. Our netX family, especially the netX 90 system on a chip (SoC), has become the foundation of a new range of Hilscher IIoT solutions called netFIELD.”

He added that 30 years of communications experience plus the security offered by netX allows Hilscher to broaden its product range to include a variety of processing solutions that deliver fast results at the point of greatest need. These can be edge or cloud-based solutions and they are suitable for virtually any class of user. Furthermore, all of this can be delivered at a far lower cost than before.

In effect, products like netX and netFIELD are typical of a new generation of IIoT solutions that are less costly, more versatile and easier to deploy.

And, these solutions operate without compromising performance or security. Huge IT infrastructure is no longer needed to implement IIoT since solutions can now be tailored to exact needs and budgets. Fewer IT skills are required, existing software can often be reused, and users can focus on what they know best – their own processes – by utilizing solutions that are user-friendly and less expensive than any previous offering.

Development of IIoT applications

Marshall said that semiconductor developments will continue to drive IIoT forward as always.

“Solutions will become better and more secure while added value will continue to grow as users become more and more familiar with the options. It is certain that with the type of scalable and cost-effective IIoT solutions on the market now, users will become smarter in the ways they utilize the features. Innovation will play its usual role and the manufacturing world is likely to find plenty of new opportunities to exploit,” he concluded.

“Edge computing in combination with machine connectivity enables applications to work with relevant (and possibly a huge amount of) machine data, and with low latency. This is a precondition for many innovative algorithms and applications, such machine learning and predictive maintenance.” — Dr. Christopher Anhalt, VP Product Marketing, Softing Industrial Automation.

Edge computing

Adoption of standard IT tools and edge computing increases scalability and manageability of IIoT solutions.

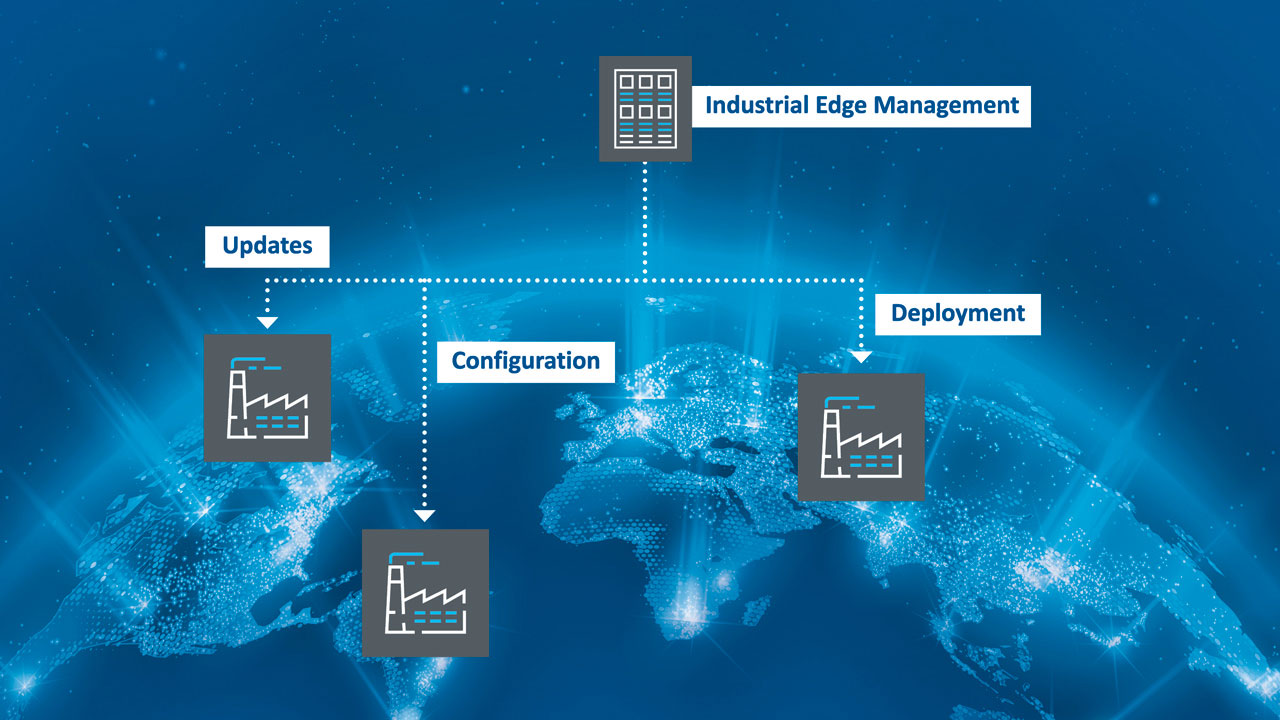

Dr. Christopher Anhalt, VP Product Marketing for Softing Industrial Automation, said that one of the technology megatrends that will be shaping and enabling development of the IIoT in 2023 is edge computing, i.e. a system of computing nodes which reside near machines and devices on the shopfloor, and which can be managed centrally.

“Edge computing in an industrial context is increasingly based on standard IT technologies and tools. Customers use edge computing in combination with cloud, but limit or eliminate cloud-vendor lock-in,” Dr. Anhalt said. “Key technologies are Docker container, Kubernetes based management platforms, and the communication protocols MQTT and Kafka. Machine- and device connectivity can be implemented based on these technologies, and fully integrated into edge computing.”

Technology benefits

Edge computing provides specific technical benefits that will enable new IIoT application successes, versus what is possible with typical applications today.

Anhalt said that edge computing in combination with machine connectivity enables applications to work with relevant (and possibly a huge amount of) machine data, and with low latency. This is a precondition for many innovative algorithms and applications, such machine learning and predictive maintenance.

“The integration with cloud platforms means that relevant data can also be made available to surrounding business processes, for example improving energy efficiency of production sites,” he said. “And the increasing adoption of standard IT and central platforms for operation means that these systems can managed efficiently by personnel with standard IT skills, and that the solution scales more easily.”

Looking to the future

Anhalt added that the adoption of IIoT at scale has probably been slower than most people in the industry expected ten years ago. Reasons include organizational challenges, the different speed of innovation cycles in IT- and traditional automation industries, and sometimes difficult ROI estimates which imply a “start-small-and-grow-as-you-learn-more” approach. On the other hand, the pressure to operate production sites more flexibly, more efficiently and in sustainable way is only increasing, and the IIoT can obviously help to address these challenges.

“On a technology level, the adoption of standard IT and edge computing will increase scalability and manageability of IIoT solutions. Top level management attention is required to overcome organizational challenges, and to change business processes as needed to take full advantage of the IIoT,” he concluded.

ISA100 WCI, NAMUR, ODVA, PI, VDMA, and ZVEI are planning to partner with FieldComm Group and the OPC Foundation to collaboratively develop the process automation device information model standard.

Effective network management

Harmonizing data semantics and secure communication between IT and OT networks.

According to a joint statement by Dr. Frank Possel-Dölken, Chief Digital Officer and Member of the Group Executive Board and Dr. Christoph Kelzenberg, Director Digital Innovations, for Phoenix Contact, cyber crime currently poses the greatest threat to manufacturing companies in terms of IIoT.

“The barriers to entry for cyber criminals are low because factories contain a variety of network-enabled devices from different manufacturers. There is little holistic overview in terms of asset management; furthermore, there is no assurance that all security vulnerabilities have been addressed through software updates. Besides the lack of knowledge regarding assets, the common process of update and patch management does not master the threat not in the least,” Possel-Dölken stated.

“It goes like this: go to web page of device manufacturer, search device via article number, check notification for bug fixes and software updates, download software and patch the device, make sure the device works properly – that needs to be executed for each and every device at least once a day! This is neither practical nor manageable. The options for hackers to access factory networks are numerous – at every industrial enterprise,” Kelzenberg added.

Managing network-enabled devices

Thus, one major topic of IIoT in 2023 and beyond will be finding solutions for a scalable, automated and fast update and patch management of network-enabled devices. The basis for this solution is seamless and barrier-free data logistics between different industrial companies and their software systems. The Asset Administration Shell (AAS) as a standardized technology for developing digital twins plays an essential role.

Additional areas of focus are specific technical benefits that new technologies can provide that will enable new IIoT application successes, versus what is possible with typical applications today.

The goal is that through seamless and barrier-free data logistics, the current process of data transmission – which requires high amounts of time and money, and a lot of resources – will be revolutionized! Now, establishing new data connections requires more than generation costs of almost zero! (In business administration and economics, “generation costs” refers to the costs generated by the production of one additional unit.) For data transmission from one system to another, the data needs to be unpacked, checked, reorganized, and packed again – in fact, before it is even sent and also after it has been received. This process includes many activities and thus is extremely prone to errors. Consequently, comprehensive testing is necessary to ensure operability.

“The big advantage of the Asset Administration Shell: it is standardized! The AAS operates as a standardized data container and enables the standardized data transmission via common sub models, structure and security requirements.” Possel-Dölken and Kelzenberg said.

“The chances that AAS is becoming at least one or even the standard for digital twins is high as a big consortium of international key players – under the umbrella of the Industrial Digital Twin Association (IDTA) – are continuously working on the development of the AAS and its implementation with their internal processes.”

Challenges for automation and control engineers

The topics/technologies mentioned before address the currently missing interoperability of software systems within one company as well as between different companies. The consistency of data is not only required from customers (e.g. digital twin of products with regards of traceability), it is furthermore required by law (e.g. burden of proof for raw materials and components alongside the entire supply chain – supply chain act in Germany).

One exemplary benefit for customers of automation and equipment industry: the end customer receives an “As-Is” bill of material. Currently, the end customer receives an “As-Built” bill of material – but this is not the exact (digital) representation of the physical good! Why is that? Alongside the different value creation steps – for example of a cabinet – different entities add, configure and adjust components.

They do parameter adjustments, apply software updates and execute other customizations that the customer does not know about – because he receives the “As-Built” bill of material. While consistently using the Asset Administration Shell among other technologies – for example saving the configuration of a power supply within a cabinet – the “real” digital twin of the physical good is developed along the different value creation steps and displayed within the “As-Is” bill of material.

Overall IIoT impact

“With regards to IIoT, we often hear statements like ‘data is the modern oil’. However, the ‘new oil boom’ has so far failed to materialize – looking through economic statistics for evidence of the predicted efficiency or productivity potentials seems to be in vain,” Possel-Dölken and Kelzenberg said. “All in all, the progress and the impact of IIoT is way lower than expected. The reasons behind have been illustrated in the questions before – it is because the current processes for data transmission within one and between several companies are very time-consuming and costly.”

They added that developments in freight logistics – especially the introduction and establishment of the standardized ISO container that led to tectonic changes within the global economy – are an excellent analogy for the current situation in data logistics. They should serve as an inspiration to us when it comes to Industry 4.0 – because they have allowed the costs of global freight transportation to either decrease significantly or even become negligibly small. This holds true equally for the standardization of goods transport itself (in the form of containers, load carriers) and for the many year’s process of developing the standards through the participation of various entities (such as ports, shipping companies, freight forwarders, etc.).

Key next steps and/or technologies are important to enable rapid development of IIoT applications. Possel-Dölken and Kelzenberg said that, as stated before, industrial enterprises are well advised to participate in the development and usage of the Asset Administration Shell for efficient data logistics and digital twins. A close collaboration between the Industrial Digital Twin Association and its members is highly recommended. Development and use of this standardized technology especially facilitates projects and activities with other industrial enterprises (that use the Asset Administration Shell).

They added one last remark to the development of industry-wide use of IIoT applications and solutions: “With regards to completed and current (research) activities in the field of IIoT, we often see that highly complex use cases are addressed. These use cases will always be use cases and not real cases – because they usually do not solve day-to-day problems in industrial enterprises!”

“Our advice is to focus on solving those day-to-day problems – as “easy” as they seem. If you take a closer look and speak to other companies, you will immediately see that (standardized) solutions for the majority of these so-called ‘low hanging fruits’ do not exist…so please start with simple cases that could run within a year and directly raises the efficiency within your own processes. This approach will furthermore contribute to scalable solutions and industry-wide roll-outs.”

“The most important new tools are cybersecurity features that resemble those of a Linux computer, server, or IT system. Built-in cybersecurity features are vital for IIoT applications to scale in 2023.” — Arun Sinha, engineer, Opto 22.

Leverage IT tools & security

Automation and control system manufacturers leverage IT tools and security solutions.

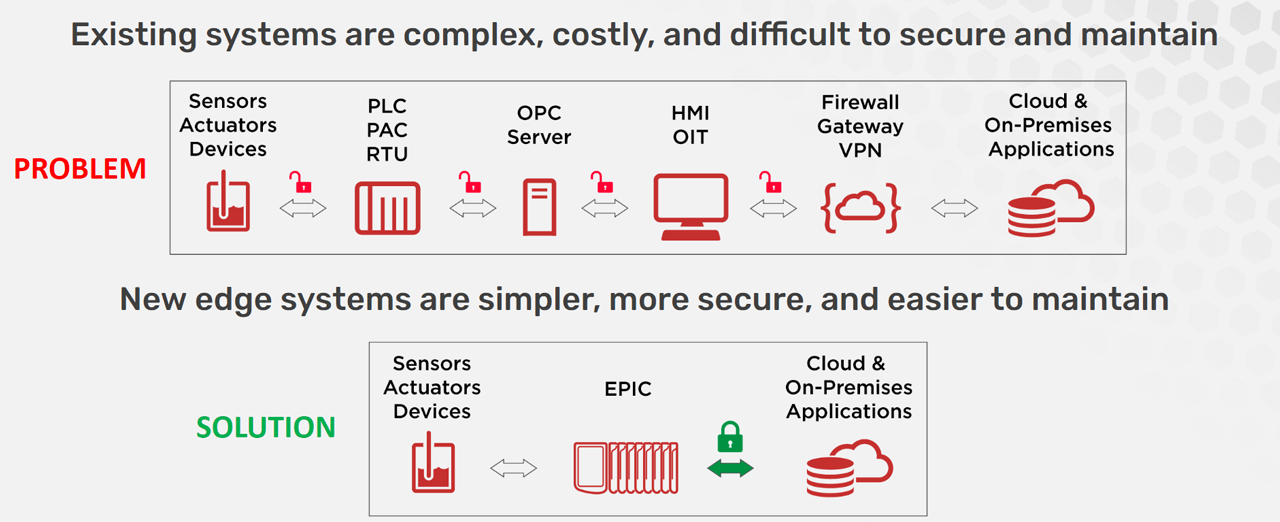

Arun Sinha, an engineer at Opto 22, told IEB that a key technology trend that will enable IIoT development is the new IT functionality that automation and control system manufacturers are adding into their products, including new tools and applications onboard the controller itself.

“The most important new tools are cybersecurity features that resemble those of a Linux computer, server, or IT system. Built-in cybersecurity features are vital for IIoT applications to scale in 2023,” Sinha said.

“Onboard applications beyond PLC programming that facilitate edge computing will shape the future of IIoT, too. Examples include higher-level programming languages, secure access to the operating system to run custom or third-party applications, and even open-source tools geared towards IIoT, like Node-RED.”

In addition, automation platforms will support next-generation communication methods. A fundamental premise of IIoT is for OT data to be shared with IT systems easily and securely. Forward-thinking automation vendors will directly support APIs, MQTT, SparkplugB, JSON, and OPC. This trend will continue as additional PLC manufacturers come on board with these IIoT-enabling technologies.

IIoT successes versus typical applications today

Sinha said that traditional PLCs have been the workhorses for industrial automation applications since the early 1980s, playing an essential role in what we now call Industry 3.0. The technology advanced incrementally with modular I/O replacing fixed I/O, increased processor memory and speed, and serial communications. A paradigm shift occurred (albeit gradually at first) with the implementation of Ethernet and TCP/IP as a control network on board PLCs in the late 1990s, which paved the way for where the industry is today—poised for Industry 4.0, digital transformation, and IIoT.

Typical PLCs today are still purpose-built for traditional plant-level and machine control. Edge computing, data cleansing, and interfacing with higher-level software and IT systems often require protocol translation, middleware, or custom code. Next-generation automation platforms and communication methods will enable IIoT success by being more like a smartphone, with apps installed to do the required tasks.

“You pick the app or software you need based on the task you want to perform, and that choice is based on how familiar you are with a given app or the app’s suitability for the given task,” Sinha said.

He added that, as automation and control engineers set out to address their applications and projects in IIoT, they typically end up with a mixed bag of technologies stitched together to achieve the desired result. With this patchwork of components, engineers have to deal with multiple vendors, software licensing, Windows updates, IT integration, cloud connectivity, and much more. Over time, these systems become brittle, complex, expensive, and difficult to maintain. This approach not only presents scalability problems, but also the often overlooked side-effect of cybersecurity issues. There are too many security vulnerabilities and so-called “attack vectors” between these components.

New automation products like Opto 22’s groov EPIC (Edge Programmable Industrial Controller) combine the functionality of a PLC, cyber-secure edge computer, communications gateway, and HMI into one platform. This technology helps reduce or eliminate extraneous pieces, parts, and components while adding security to build maintainable IIoT applications over the long term.

IIoT progress report

According to Sinha, significant progress has been made in IIoT for industrial automation and smart manufacturing. Perhaps most importantly, OT/IT convergence is an accepted idea. Most stakeholders on both sides in large and small organizations are less resistant to working together than they were a decade ago. Engineers from both disciplines realize that IIoT, smart manufacturing, Industry 4.0, and digital transformation initiatives fundamentally require a confluence of people, strategy, and technology. Regarding technology, a few automation vendors have released new platforms that are more IT and IIoT friendly, and others are sure to follow suit. As a result, OT systems using these platforms are already sharing data with IT systems much more easily.

“Future IIoT progress will depend on how this newly democratized OT data is used effectively for business outcomes such as efficiency improvements, quality, cost reduction, and sustainability,” he said. “The challenge of unlocking siloed process, plant floor, and machine data—and securely sharing it with IT systems and software quickly and inexpensively—has largely been solved. But the tangible examples (in the public domain) of how this data has generated positive business outcomes have just started to emerge. These will be exciting to watch.”

Sinha said that one key technology that will enable IIoT to help reach its full potential is artificial intelligence and its subset, machine learning. The promise of the IIoT is ultimately to use OT data to achieve positive business outcomes. A lot is being written about ML and AI in the automation sector, often in the context of predictive maintenance—yet at this time there aren’t a lot of tangible examples of it in practice. For case studies and tech notes that are publicly available, most present the results but not the mechanics of how they were achieved.

“ML has challenges in the industrial and manufacturing space. Process, plant, and machine data is not homogeneous like data in banking or even healthcare might be. Every process, manufacturing line, and machine is different and more importantly, requires domain expertise from someone with hands-on experience to train the models,” Sinha said.

“I am concerned that we may be approaching a “trough of disillusionment” for IIoT if this is not somehow addressed. The key next step is to find ways to approach these challenges with ML and AI in the manufacturing space, enabling more rapid development of IIoT applications and helping them deliver actual value to the operation or business.”

“We see the convergence of information technology (IT) and operational technology (OT) being a decisive factor: combining the field and automation level of production with the enterprise and management level – as seamless and complete as possible. Harmonizing data semantics and secure communication between IT and OT networks is key.” — Raymond Kok, Senior Vice President, Cloud Application Solutions, Siemens Digital Industries Software.

Focus on IT/OT harmonization

Harmonizing data semantics and secure communication between IT and OT networks.

Raymond Kok, Senior Vice President, Cloud Application Solutions for Siemens Digital Industries Software said technology and software solutions are poised to continue the pace of IIoT innovation 2023.

“We see the convergence of information technology (IT) and operational technology (OT) being a decisive factor: combining the field and automation level of production with the enterprise and management level – as seamless and complete as possible. Harmonizing data semantics and secure communication between IT and OT networks is key,” Kok told IEB recently.

Kok said that another trend that is increasing is low-coding.

“Rather than using codeful customization, low-code enables model-driven, drag-and-drop UI and application development. All development skill levels — professional developers, novice developers, subject matter experts, business stakeholders, and decision makers — can use low-code to build value-driven IT and OT end user applications. Consequently, application development is more accessible to users without deep software development expertise,” he added.

He also added that, last but not least, AI applications that e.g. enhance quality assurance or predict and optimize scheduling service and maintenance windows, will more and more shift from POC status to productive industrial usage. Development and especially deployment is becoming easier to handle through complementary software-based micro-services / apps.

Emphasis on technology benefits

Kok said that IIoT applications already today simplify operations within a business; data can be accessed anytime and anywhere, and learnings out of it can be re-implemented to improve engineering and production processes. Combining IT with OT now enables industrial enterprises to meaningfully use the data generated across disciplines within and beyond company borders. Breaking up information silos help companies significantly and lead to higher production efficiency due to faster decisions and reduced manual efforts, secure data-supported decisions, maximum transparency, and greater sustainability.

Addressing automation challenges

“Global trends and rapidly changing challenges require quick and confident decisions,” Kok said. “The greater transparency provided by the constantly available analysis of enterprise data creates knowledge, which leads in turn to better decisions and more concrete actions with continuous improvements. The question is how to access and process field data for further evaluation especially thinking about scaling in an industrial context.”

He also added that there are significant challenges in a number of key areas.

- Data security/ cyber security: The growing connection between production networks and office networks as part of IT/OT integration and the utilization of the Internet of Things have many benefits – at the same time know-how and plants need to be protected at all times.

- Sustainability of enterprises needs to be enhanced by identifying energy or cost hogs and optimizing the availability of materials.

- Real-time analysis of workflows and processes enhances transparency in all areas and boosts efficiency throughout the enterprise and throughout the entire value chain: material flows, procurement processes, production, inventory levels, disposition of goods.

Progress and impact of the IIoT

Kok said that “reservations about storing and processing data in the cloud have decreased significantly and we see a growing importance of digital transformation and becoming a digital enterprise.

Purpose-built applications with low-code technologies are accelerating the data-driven insights for manufacturing organizations. With recent global political insecurity and supply chain issues arising, companies need to make their production more flexible and decentralized in order to avoid one-sided dependencies. To maintain efficiency, among other things due to different wage cost levels, IIoT applications are the means of choice to increase productivity and to optimize global networking.”

He concluded by stating that key next steps and/or that will enable more rapid development of IIoT applications involve a series of potential technology solutions.

Low Code

Low-code application development is the fastest and easiest way to build IoT software and applications. Visual model-driven approach enables both pro and less technical developers to consume IoT services from best-in-class IoT platforms to build data driven purpose-built applications.

The low-code approach helps organizations to build rich experiences on top of connected devices to transform their operations, products and business models. With low-code technology the IT – OT convergence and user engagement is realized at an accelerated pace, making edge to cloud and cloud to edge data transparency a reality.

Industrial 5G

Thanks to 5G technologies, IIoT is becoming significantly more flexible, as companies can process large volumes of data many times faster and in real time. The new mobile communications standard is providing an additional boost to edge computing in particular.

AI

Artificial intelligence (AI) and machine learning are technologies that enable engineers and data scientists to structure, analyze and evaluate the vast amounts of data. Use cases span the lifecycle: intelligent recommendations, generative design, anomaly detection, and predictive maintenance optimize the way and speed with which products are designed and produced. To use industrial AI in a trustworthy and value-adding way, they must interact seamlessly with software and automation, as well as the corresponding IT infrastructure.