TechnologyMarch 22, 2024

Replacing outdated controls with IIoT edge solution

Point Energy Partners has replaced outdated controls with an IIoT Edge Solution that is preventing spills and improving efficiency using Opto 22’s groov RIO. Automating water level monitoring and pump operation has not only made the jobs of field operators easier, but has also resulted in significant cost savings.

In an industry where every spill carries a hefty price tag, Point Energy Partners (PEP) found that the manual and low-tech systems at their saltwater disposal (SWD) sites were a significant problem.

SWD sites are where the byproduct water from oil and gas production is managed and disposed of. These low-tech systems for SWD level management posed several operational challenges—the worst among them being the environmental impacts and financial costs of overflow spills.

Led by industry specialists and U.S. military veterans Bryan Moody and John Sabia, PEP specializes in acquiring and developing onshore U.S. oil and gas properties, with a current focus on the Delaware Basin, situated across West Texas and southeastern New Mexico.

The company has grown its operating production significantly over the past 5 years, mostly focused on midstream assets. PEP is dedicated to the sustainable development of oil and gas resources across the U.S., aiming to create value for its stakeholders and reduce energy costs for Americans.

PEP is unique in its approach, working to assemble small acreage footprints in strategic locations, fostering strong relationships with mineral/royalty owners and service providers, and ensuring high-quality operations.

PEP also operates a substantial water recycling program, showcasing their commitment to sustainable and efficient resource management. This approach not only reflects their dedication to environmental stewardship but also enhances the efficiency and sustainability of their oil and gas production activities in the Delaware Basin.

Point Energy Partners pump equipment at SWD site.

The challenge: high tech, low price

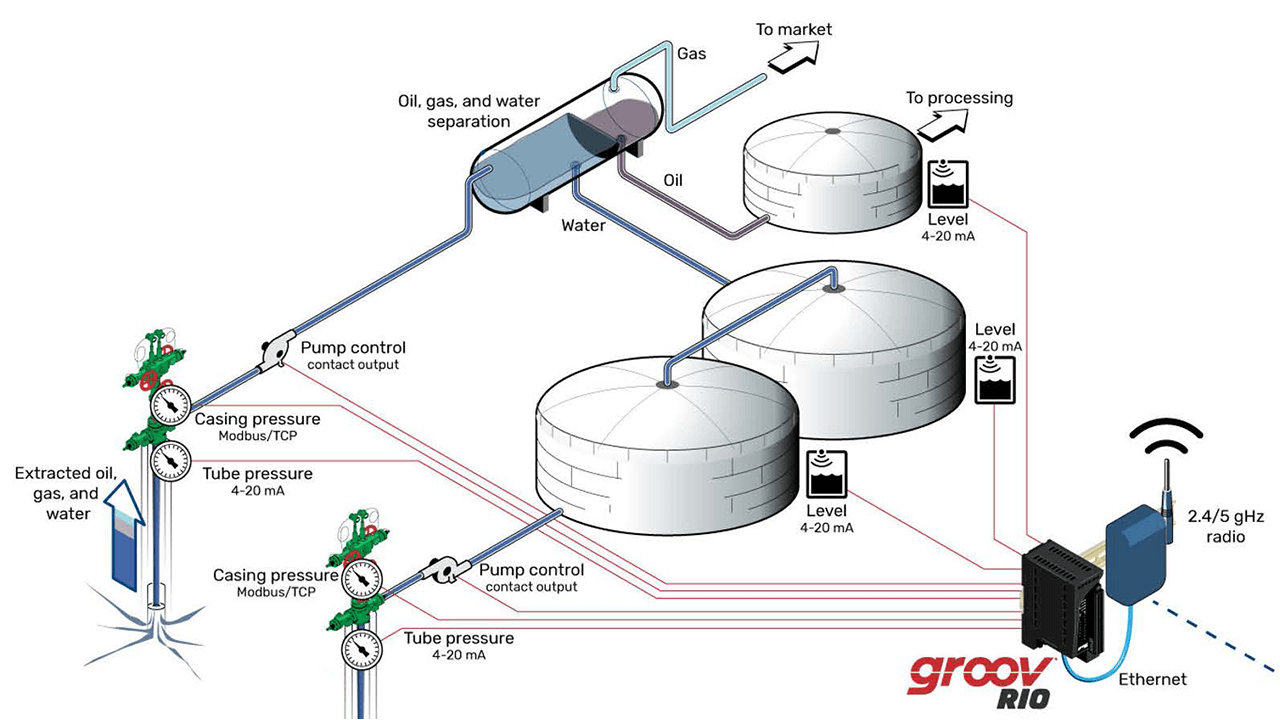

The SWD sites, where water laden with salts, hydrocarbons, and industrial compounds is managed and disposed of, required immediate attention. Manual, onsite checks of their flow measurement systems resulted in inaccurate measurements and unreliable information. In addition, the existing water management system at these sites was heavily dependent on hydrostatic head level switches—technology that had become obsolete and unreliable over time.

Beyond that, the level switches were part of an antiquated system of control that attempted to maintain safe tank levels by toggling transfer pumps based solely on the current switch status (or an onsite manual override). This outdated control methodology left no room for the possibility of remote control or oversight—and absolutely no SCADA overview.

Tanks at Point Energy Partners SWD site.

And these existing operational sites did not have a big budget for upgrades, so most control solutions on the market just wouldn’t fit the bill. But after a recent internal study determined each overflow spill costs the firm roughly $200,000, Automation Engineer Scott Adams knew the status quo would not suffice.

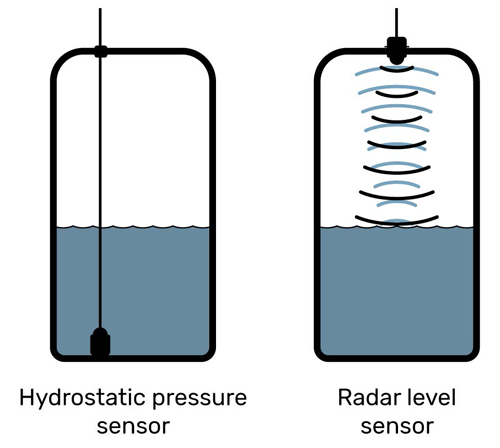

Head level sensing vs. radar level sensing

Illustration of differences between hydrostatic pressure and radar level sensors.

The next generation solution should utilize radar level sensing, a superior solution compared to hydrostatic head level sensing. Unlike hydrostatic sensors, which measure pressure exerted by a liquid column, radar sensors utilize microwave pulses to determine liquid levels. This non-contact method ensures no direct interaction with the liquid, making it ideal for corrosive substances—like the water being stored at SWD sites. Radar sensors, unaffected by changes in liquid density, temperature, or pressure, provide better precision and durability in challenging conditions.

Visibility: to see or not to see? Definitely to see.

The lack of visibility into the operations at the SWD sites, coupled with an over-reliance on manual checks and operations, underscored the urgent need for a modern, automated solution.

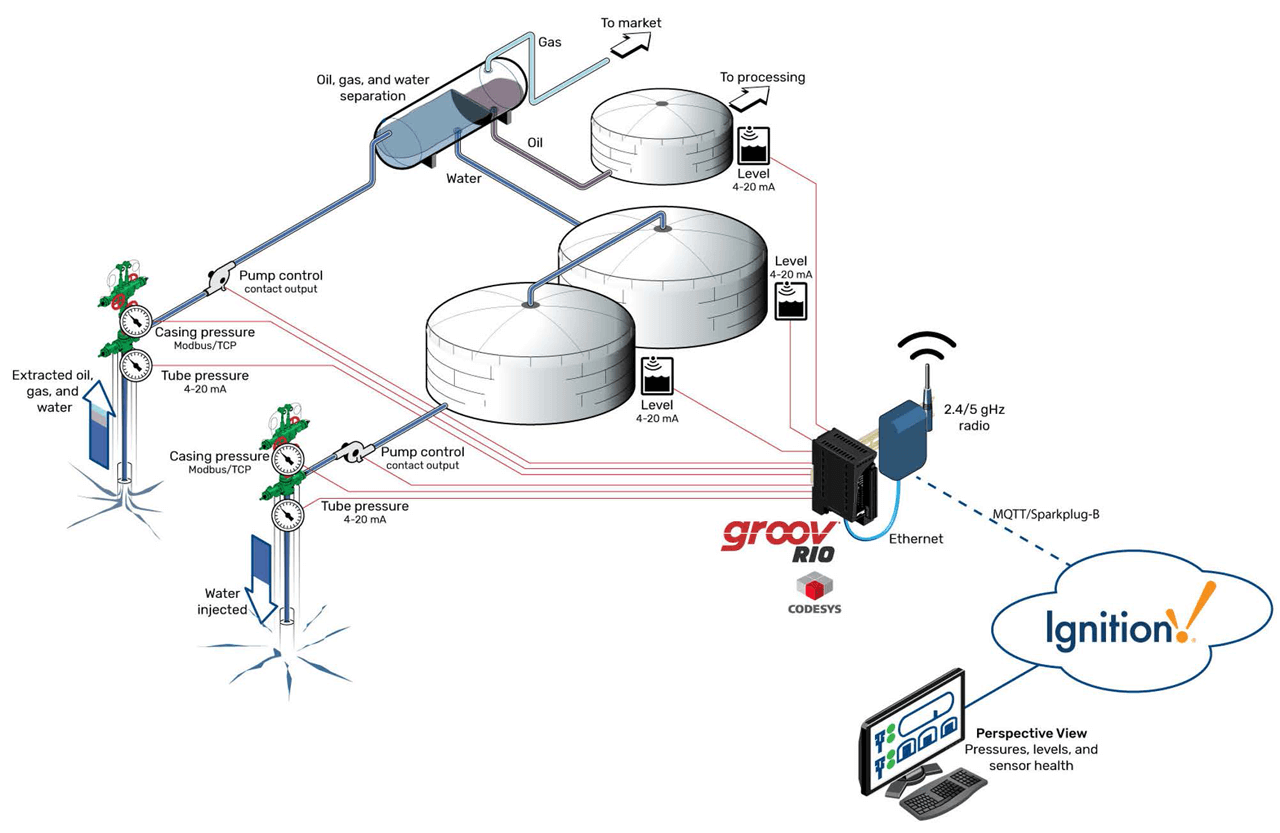

A recent corporate initiative led PEP to use Inductive Automation’s Ignition software as a SCADA platform for their collective sites. Their burgeoning IIoT infrastructure would use MQTT Sparkplug B as a means for getting live, reliable data on their operations into their new SCADA platform. And Ignition’s Perspective® web-based HMI would soon make remote monitoring a reality.

Keeping costs under control

PEP faced significant financial constraints—the budget for improvements on existing sites was tight. The company needed to ensure that any investment made would pay itself back in efficiency, reliability, and spill prevention. They explored various PLC solutions on the market, but price tags were high, and many of the manufacturers required expensive software licenses and support contracts.

As Scott Adams said, “In our industry, these applications are typically done two different ways: low-tech, like our existing solution, or they utilize a $10,000 PLC panel, which is beyond our budgetary constraints for existing sites.”

Blending brownfield with greenfield

When PEP started down their IIoT discovery journey, it was clear that MQTT with Sparkplug B—lightweight, efficient, and reliable—was the way to go. But there were also cases where legacy support was needed, like brownfield installations where Modbus/TCP was highly utilized. Adams also needed an I/O platform that was flexible enough to simply turn on a contactor to run a pump, read an analog signal from modern radar level sensors, or calculate flow from a pulse input generated by a turbine flowmeter.

The solution: groov RIO with CODESYS and MQTT Sparkplug B

“We were looking for I/O that would fit with our new SCADA—we just Googled to learn more about MQTT and Ignition, and Opto 22 hardware kept coming up.” Adams said. “We planned to use Ignition’s Historian, Alarming, and Perspective visualization to keep tabs on our SWD sites from anywhere in the world.”

“We were looking for I/O that would fit with our new SCADA—we just Googled to learn more about MQTT and Ignition, and Opto 22 hardware kept coming up.” Adams said. “We planned to use Ignition’s Historian, Alarming, and Perspective visualization to keep tabs on our SWD sites from anywhere in the world.”

So PEP turned to Opto 22’s groov RIO for a transformative solution. The modern communication methodologies onboard, namely MQTT with Sparkplug B payloads, would allow the groov RIOs to reliably transmit real-time tank levels, flow rates/totals, and pump operational states into PEP’s Ignition SCADA.

They could seamlessly and efficiently move data between their field operations and Ignition SCADA software.

Flexible I/O

The multi-signal, multifunction nature of Opto 22’s groov RIO’s I/O gave PEP the flexibility to adapt these edge devices for a number of their applications.

Point Energy Partners’ groov RIO enclosure.

The relay outputs could be used to fire pump contactors on and off based on more accurate level readings, which were now being fed from radar transmitters connected directly into RIO’s analog input channels.

Utilizing groov RIO’s flexible I/O along with the recent addition of a CODESYS® runtime engine allowed them to implement radar level transmitters in the tanks and automatic pump control.

PEP had experimented with groov devices in the past, but the unique aspect of this setup was the utilization of the CODESYS runtime engine, a feature added in groov RIO firmware 3.5. This addition leveled up the capabilities of groov RIO, providing a cost-effective and powerful automation solution.

More than I/O: control at the right price

At right around $1,000, Scott Adams described RIO as the “Goldilocks solution”—not a $10,000 panel with unnecessary extras nor a $100 PLC lacking the I/O and modern communications needed for their IIoT architecture.

Modern yet supportive of our legacy

Support for all of the company’s I/O, control, and communication requirements as future IIoT infrastructure continues to grow was paramount, but the cherry on top was groov RIO’s support for legacy devices. Point Energy Partners had numerous pressure transmitters across their SWD sites around the area that used legacy Modbus/TCP communications.

Using groov RIO as a Modbus master allowed PEP to collect existing data that was once trapped in the field, and add it to the new collection being amassed in their data historian.

Illustration of SWD site technology.

Technical implementation

Implementing groov RIO into PEP’s existing infrastructure was a smooth and straightforward process, highlighting the system’s user-friendly nature.

Technicians, regardless of their programming experience, found the system easy to work with thanks to an intuitive interface and comprehensive training resources available on Opto 22’s website.

As Scott Adams recollected, “We only have one PLC programmer on our staff. He’s the one who programmed CODESYS, but our other five technicians found that commissioning groov RIO was something they could do themselves. Working within groov Manage and Node-RED is something our techs found very accessible.”

The ability to learn and implement the system on the job stands as a testament to groov RIO’s intuitive design and ease of use. “I haven’t even been to Opto 22 for training yet!” Adams exclaimed when describing just how quickly they were able to deploy their solution.

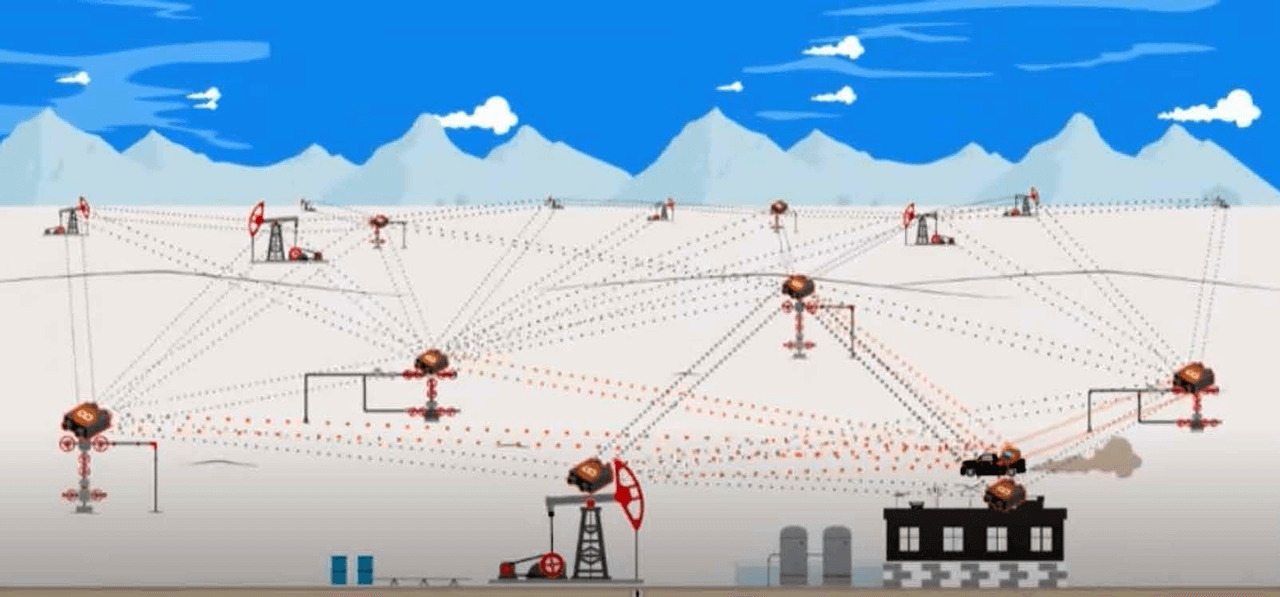

Rajant wireless mesh

Example of a Rajant wireless mesh network.

One of the pivotal components in this implementation was the integration of a wireless mesh radio network provided by Rajant®, a leader in industrial wireless mesh network solutions. Rajant’s technology ensured a robust and reliable communication network, vital for the remote monitoring and control capabilities required at the SWD sites. Combine that with an industrial-grade device like groov RIO with IT-friendly networking tools, and seamless data transmission—even in challenging and remote environments—is a reality.

Netonix PoE switch

The implementation was further simplified and enhanced by the use of a Power over Ethernet (PoE) network switch from Netonix®. Netonix is renowned for their innovative PoE switches, designed specifically for demanding industrial environments. The use of a PoE switch streamlined the installation process as it allowed for the transmission of both power and data over a single cable, reducing complexity and the need for additional wiring when installing groov RIO in the field.

Software stack

Using CODESYS for automated pump control and tank level management was just a part of this solution. PEP is also using Node-RED software running onboard their RIO, which allows them to move data from physical I/O points, CODESYS tags, and various Modbus/TCP sensors into OptoMMP registers, which are then published on change to their Ignition-based MQTT broker.

Results and impact

The implementation of groov RIO at the SWD sites has resulted in a paradigm shift for PEP.

Automating water level monitoring and pump operation has not only made the jobs of field operators easier, but has also resulted in cost savings—most importantly, by preventing potential spills—occurrences that negatively affect both PEP’s bottom line and the environment.

The field operators, who previously had to manually check tank levels and ensure the proper functioning of head switches, now enjoy a more streamlined and efficient workflow. Operators still check on the sites daily, but the systems can be fully monitored remotely, and tank level setpoints can be securely adjusted from anywhere in the world.

The enhanced data reliability and real-time monitoring have also shown PEP the value of further automation across other sites.

PEP management, originally hesitant to make the investment in automation at SWD sites, has shifted their approach to automation and technology, opening doors to new possibilities and applications across their portfolio. The significant improvements in efficiency, reliability, and environmental safety have showcased the transformative power of automation, proving that with the right technology, safe and sustainable energy development is not just a goal, but a reality.