TechnologyJuly 16, 2024

Smart Edge Computing: Optimizing the Entire Value Chain

Edge devices based on PLCnext Technology combine the robustness of proven industrial PCs with an open automation platform and intelligent IoT edge concepts can be built with this approach. By using edge devices to process and analyze the growing volumes of data, the entire value chain can be optimized.

The term edge computing is inextricably linked to the term cloud computing. While cloud computing – i.e., the connection of systems to the Internet – has been gaining in importance for several years as part of the future-oriented Industry 4.0 project, edge computing seems to be a relatively new technology. The possibilities of this approach will be demonstrated using the EPC 1502 edge device.

An Internet connection to link the system to a cloud is often necessary when data volumes need to be evaluated and stored. In many applications, however, the data must be collected, checked, and fed back into the process in very short cycles. Whenever this is the case, a public cloud solution is not suitable – simply because of the latency times on the Internet. Edge computing is therefore increasingly being used for such smart applications.

The edge devices from Phoenix Contact, which are based on the PLCnext Technology ecosystem, combine the robustness of proven industrial PCs with the open automation platform. Intelligent IoT edge concepts can be built with this approach. By using edge devices to process and analyze the growing volumes of data, the entire value chain can be optimized.

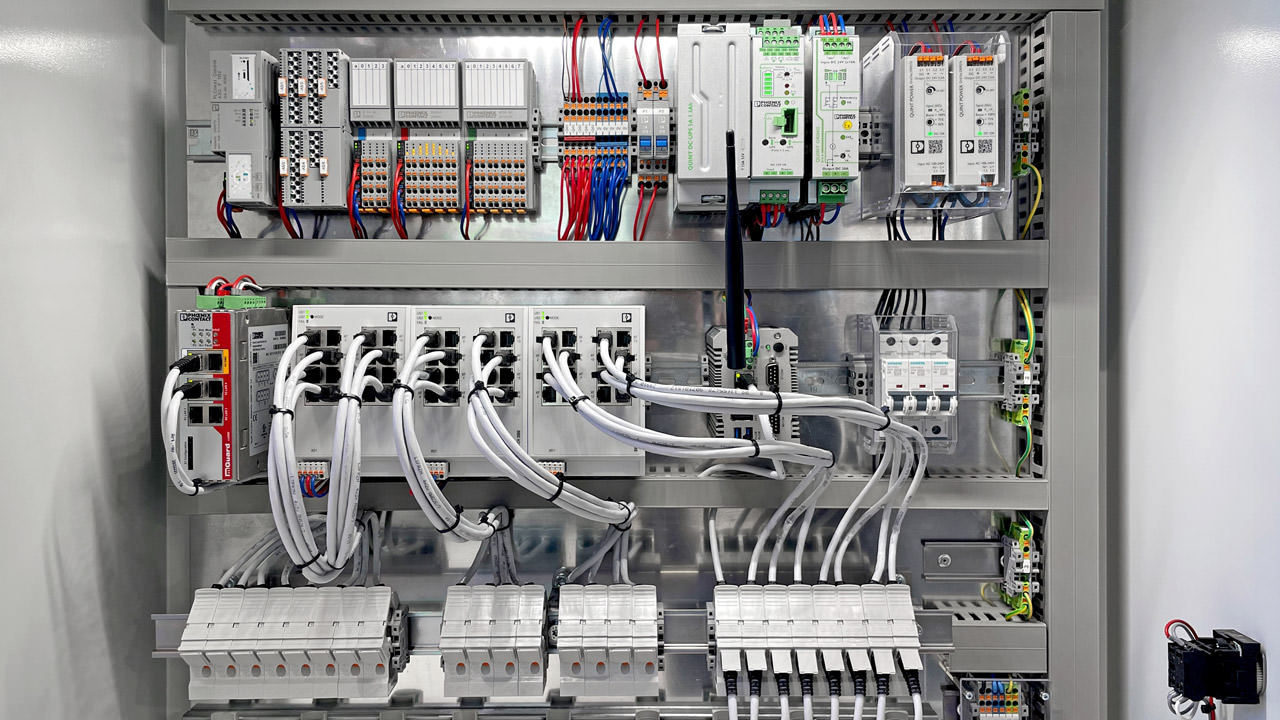

The Data Collection Box from Phoenix Contact for easy data collection in existing systems without jeopardizing the CE marking of the machines.

Easy to integrate box for collecting local data

The range of applications for edge devices is broad, as potential applications can be found wherever data needs to be analyzed or is already being analyzed in the cloud. At the beginning of the development of every edge application, the user always asks the same question: how can the data be accumulated centrally?

Developing autonomous vehicles, a traffic light system, or intelligent thermostats that would benefit from the power and responsiveness of an edge computer can be a complex undertaking. Above all, the edge device used must be flexible. In addition, a large amount of system data, which is usually provided by numerous different sensors from various manufacturers, must be collected. Furthermore, the field devices communicate via a wide range of industry protocols. And what is more, the data is often analog, which cannot be accumulated easily.

The tailor-made Edge Collection Box from Phoenix Contact is therefore ideal for collecting local data. The switchgear and controlgear assembly collects digital, analog, and temperature signals via the connected sensors. The box can be easily integrated into an existing production environment. The data is captured in parallel so that, for example, the CE marking of the machines is not invalidated. The main component of the Data Collection Box is the EPC 1502 PLCnext Control with an IIoT framework. Energy and process data can be collected easily via the framework based on the familiar industry-standard communication protocols.

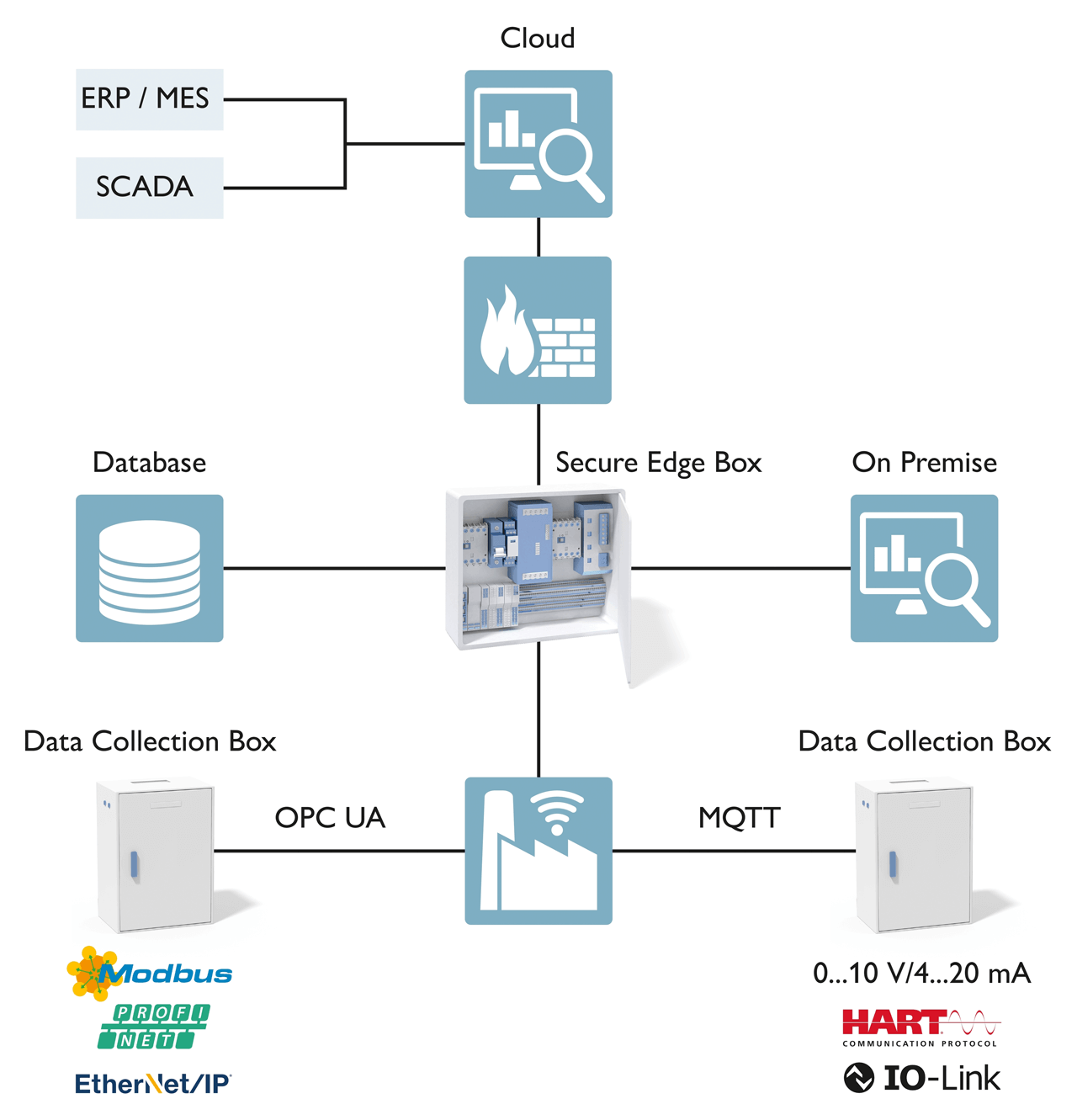

Interaction between the Data Collection Box and Secure Edge Box for securely visualizing data locally and sending it to the cloud via a VPN tunnel.

Secure Data Box as a secure interface to higher-level IT systems

Once the data has been collected and analyzed locally via the edge device, the device then often serves as an intermediate layer to the cloud. While collecting data in existing systems may already be difficult, potentially there is an even greater task to be solved: how can the summarized data, evaluated alarms, and edge device analyses be transferred securely to the cloud?

This is where another integration-capable solution from Phoenix Contact comes in: the Secure Data Box is designed for use in combination with the Data Collection Box switchgear and controlgear assembly. It establishes the secure interface between the production network and higher-level IT networks, external service providers, and cloud systems. Unauthorized access is blocked by the firewall of the integrated FL mGuard security router.

The firewall only allows the necessary data traffic, ensuring optimum protection of the segmented network. Optionally, the EPC 1502 edge device can also be accessed directly via the mGuard Secure Cloud app. With this approach, the user receives all information regarding remote maintenance.

Reliable operation of automated guided vehicle systems

Back to the application examples cited: what added value would the use of the edge device in an automated guided vehicle system (AGVS) bring, for example? The openness of the edge device bridges the gap between classic control functions and AGVS navigation. A quick connection to existing navigation solutions can be realized with a plug-and-play interface for the Robot Operating System (ROS). With support for high-level language programming, the ROS interface, and Docker software, users can also implement their own approaches directly on the edge device. The PLCnext Technology online store includes a wide range of apps that enable the edge device to send firmware and application updates to all other controllers as well.

The device installed at the “edge” of the network thus provides a simple and secure entry point for remote maintenance of the entire system. The collected data can be displayed locally via dashboards. Artificial intelligence and its algorithms analyze data points to detect anomalies. This creates the basis for predictive maintenance, as the solution warns of failing drive shafts or motors at an early stage.

This enables immediate repair, which in turn minimizes production downtime. With the atypical interfaces, which are not usually provided by a traditional control system, data can be forwarded directly via WLAN, which saves on laying cables. The large internal data storage system means that data can be stored locally over a longer period of time. Edge devices are therefore often essential for the reliable operation of automated guided vehicle systems and the associated efficiency and flexibility.

Wide range of possible uses in large and small applications

Edge computing can be utilized in different ways in different individual applications. The combination of ready-to-install edge boxes can significantly simplify the implementation of large systems with considerable amounts of data that need to be collected using different protocols. Existing systems can be converted to edge computing easily with the integration-capable solutions that are installed outside the machines, meaning that they retain their CE marking. In smaller systems, the edge device must bring benefits with many supported protocols and apps for functional extension so that the user receives added value with simple installation.

Scalable solutions from single source

The EPC 1502 edge computer from Phoenix Contact with a large data storage system, high-performance hardware, and unconventional interfaces compared to a traditional PLC.

In addition to a device with sufficient computing power and connectivity, system manufacturers who do not yet have an in-house solution for realizing an edge application also need the right software environment. With the combination of hardware and software in a ready-to-install product, the EPC 1502 is tailored to the essential requirements of an edge application. The device can also be extended with additional apps.

For existing systems, easy-to-use tailored solutions are required to generate added value from the analysis of the data without losing the CE marking during the necessary conversion.

Phoenix Contact provides scalable solutions, from the high-performance VL3 UPC industrial PC and the EPC 1502 edge computer, through to ready-to-install data boxes for easily collecting data and transferring it securely to cloud systems. By processing the resulting data directly at the point of origin, every application benefits.

Daniel Mantler, Product Management HMI/IPC, Phoenix Contact